Introduction

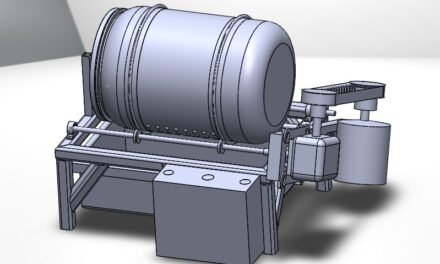

It is basically a smart, medium-sized incubator for sprouting legumes and seeds. It can soak seeds as well and recycle the same water throughout the entire process. The Grocubator will work on the same traditional steps, so its products will be completely organic. The intention of this is just to reduce repetitive tasks and the effort required for producing buck quantity.

More information on the same is available in the blogs provided below :

- https://vadic.vigyanashram.blog/2022/08/02/grocubator-cad/

- https://vadic.vigyanashram.blog/2022/02/11/__trashed-2/

- https://vadic.vigyanashram.blog/2021/09/17/grocubator-v2/

Need

The previous electronic system was complicated, non-modular and prone to water damage.

There was a need to upgrade the system with a better packaging, modular electronics and use of advanced micro-controller like the ESP-32.

How to work system

- The system has a water pump that supplies water to the container in a cyclic process.

- .The system has a metal container with holes on one side for draining the water, which rotates due to the rotation assemble driven by a viper motor.

- The rotation occurred at 180 degree with the help of a IR feedback system that sensed the black lines on the container.

- These black lines act like a switch/trigger for the system to start and stop.

- They were placed in such a way that the holes on the container would be pointed upwards or downwards to flood or drain the system with water, respectively.

- It has an initial soaking step, followed by multiple cycles of rotation and rinsing.

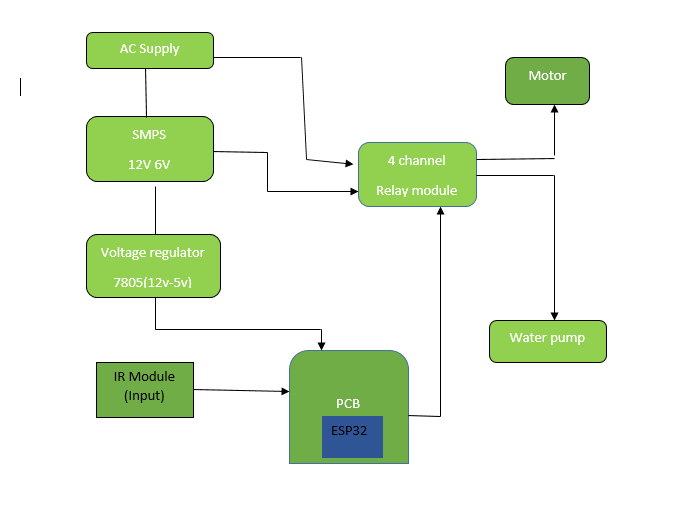

Renew Electronic system

The previous electronic system was complicated, non-modular and prone to water damage.

There was a need to upgrade the system with a better packaging, modular electronics and use of advanced micro-controller like the ESP-32.

In order to do this an PCB for he ESP32 was used along with the input and output sensors.

The ESP32 requires 5, therefore a 7805 voltage regulator was used.

The electronics along with the SPMS was enlosed in an ABS enclosure to protect it from water and make it durable.

Connection diagram

Program of system

Trials conducted on the Sprouter

- The first trial was conducted with 250 g of legume seeds were added to the apparatus and trial was conducted. On completion of trial the legumes sprouted properly with no odor and clean water was left behind. Additionally, the vessel got stuck in the middle of the cycles and needed a slight help in rotation.

- Based on the first trial it was suspected that the low weight of the contents was the reason for the cycle to gave stopped. Therefore, the next trial was conducted with 2kg sand to test the rotation. During this trial it was found that system rotated in the desired way with no problems .

- The third trial was conducted for the agricultural department in order to be used as a feed for the goats. 2 kg of legumes were added to the system. Initially there was some leakage which was fixed by simply adjusting the water tray below. The trial went on for about 1.5 days. In the end the sprouts were obtained as desired. The water in the tray below turned brown and had a mucilage layer on top and the sprouts had a little pungent odor.

- It was decided in the discussion that after working on the problem encountered in the third trial,trials of 10 kg matki should be tried .

| Sr.No | Date | Before Weight (KG) | After Weight(KG) | Problem in system | Result | Solution |

| 1 | 16/5/23 | 1 | 2.25 | System is working properly | There was a smell of matki and water | Changing the time of motor pump |

| 2 | 19/5/23 | 2 | 4.25 | In this trial, system was not working properly problem is rotation of drum is not stoped in particular time IR sensor is no work well | Matki was sticky | Set IR sensor |

| 3 | 22/5/23 | 2 | 4 | The length of sprout is small | Matki had smelled and was sticky | UV light applied in water |

| 4 | 25/5/23 | 2( using UV) | 4.50 | Length of sprout is good | ||

| 5 | 29/5/23 | 1( चवळी) | 2.50 | Growth is well |

NOTE

Capacity of sprouter is 2kg .For 50-60 people,the kitchen needs one and a half kg of pitcher ,lentil and cow .

Handover system 5/6/23

Sprouter handover to Pravin Yadav from food lab.He will sprout matki,cowpeas and mug beans as required by the kitchen.

First Trial

Pravin took the first trial of 1.5 kg matki.He had a problem that the system did not rotate properly due to which the matki did not sprout properly.

Second Trial

In the second trial he planted lentils, he also did not get proper growth because the water in the bucket was running low. Third Trial Ir Sensor's place was moved because the original box was not rotating properly, so the matki did not sprout properly.