18/Aug/2023

This project was assigned to me by Dixit sir, and Mr. Harshvardhan Samdani, who wanted to gain new knowledge about sprouts. that is why they come to VA and ask about the thee sporter. after that in a fast conversation, they showed me his workshop where all the materials needed for this project were available.

During our initial conversation, we discussed the quantity of sprouts required and how to utilize the materials in his workshop for our project. Although the conversation was informal, I suggested that he provide us with all the materials related to the project, and we would subsequently hold meetings with my team and other DIC staff members.

Afterwards, we brainstormed on how to build the system. Additionally, I learned more about sprouts through reading a couple of blocks at Vigyan Ashram.

The information provided in the link below should not be worked on in Vigan Ashram.

- https://vadic.vigyanashram.blog/2022/08/02/grocubator-cad/

- https://vadic.vigyanashram.blog/2022/02/11/__trashed-2/

- https://vadic.vigyanashram.blog/2021/09/17/grocubator-v2/

aug-2023

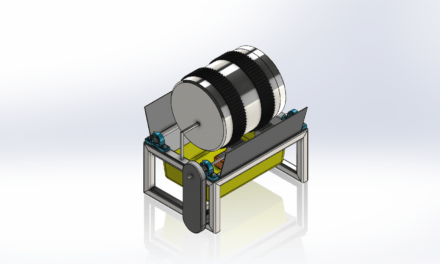

The participants in the meeting were Dixi, Parsad, and Mahesh sir. We discussed how the machine works, specifically how the sprouted machine will rotate and the procedure for sprouting. We also talked about the key terms to pay attention to during the meeting. Several points were covered:

- Structure: We decided to use our old structure, as provided in the Above links information. We wanted to scale it up. Alternatively,

- Drum Rotation: We discussed how to rotate the drum, which contains the sprouting material. There were two

- options: a centre axis rod fixed in the centre of the drum to rotate it, or four wheels beneath the drum that would rotate the drum as they moved.

- Drum Stability: We noticed that the drum was not steady horizontally and tended to move along the X-axis. To address this, we considered using L angles or rods that could be rotated in a circular manner and fixed to the drum. Below, there would be four rollers to drive the drum’s rotation.

- Drum Leakage: We discussed the issue of drum leakage from the cap. To mitigate this, we decided to use a plastic drum with insulation inside the cap to prevent leaks.

- Water Feeding: We discussed how to introduce water into the drum without causing leaks at the joint between the pipe and the drum. We decided to use hydraulic joints.

- Bacteria and Smell: We talked about how to eliminate bacteria that cause Smeal. Additionally, we discussed the spread of smells in the environment, although this is directly related to our project.

In summary, the meeting covered various aspects of the machine’s design and operation, including its structure, drum rotation, stability, leakage prevention, water feeding, and Smeal control.

after that, I did the design of the project.

After I sent the project quotation, the client informed us that they didn’t want any additional GST charges. They also mentioned that they would handle all the material purchases, as they had previously shared the list with us. They wanted us to focus on designing and fabricating the sprouter machine according to our plan.

I discussed this with my team, and they agreed to proceed as per the client’s instructions. Samthani Sir mentioned that we would need to go to Pune to buy the materials at a time that suits them. However, due to some unforeseen issues, they couldn’t make it to Pune as planned. This is the current status of the project so far.