05 July 2022

WHAT IS GROCUBATOR ?

GROCUBATOR is essentially a creative small-medium size incubator for 250 gm of grains or beans to sprout. It may also soak seeds while reusing the water during the entire procedure. The Grocubator will operate using the same conventional processes, therefore all of its output will be organic. The purpose of this is simply to reduce the amount of repetitive work and effort required to produce a given quantity of profit. The hand behind this setup is Mr.NACHIKET ADAMANE (http://vadic.vigyanashram.blog/author/nachiket-adamane/).

Why we need to add sprouts in our diet ?

- Adding sprouts to your diet can give you the necessary protein intake required by your body minus the fat, cholesterol and calories.

- Sprouts help increase bone formation and prevent them from breakdown or osteoporosis. They are also helpful in controlling hot flashes, menopause, PMS and fibrocystic breast tumors.

- According to experts, sprouts contain 100 times more enzymes than uncooked fruits and vegetables. These enzymes act as catalysts for all your body functions and ensure that your body processes work more efficiently.

- Since sprouts are low in calories, they can contribute positively to any weight-loss diet plan. Eating sprouts will make you feel fuller and stave off hunger longer.

- Once sprouted, the quality and fibre in the beans, nuts, seeds and grains improve. Eating sprouted grains helps you maintain a healthy immune system.

- Research shows that certain sprouts are effective for preventing gastritis, ulcers, stomach cancer and even allergy and asthma.

07 July 2022

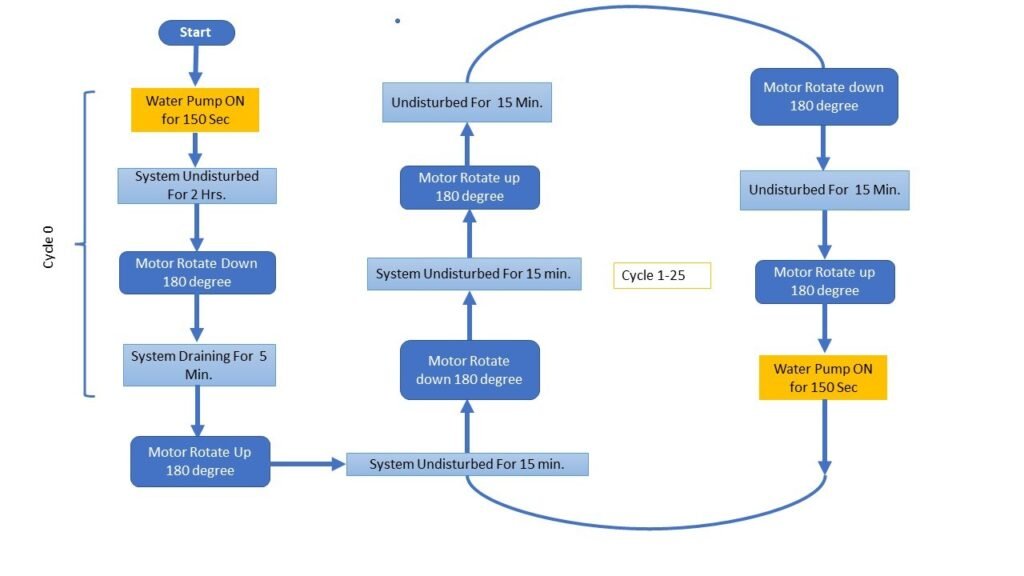

Process Flow :

According to process flow chart we have understand that the working of the grocubator . The water pump turns on for 150 seconds when the system is turned on, then stays off for another 2 hours .The system drains for five minutes after which the motor rotates down at 180 degrees before rotating back up at 180 degrees. System is left unattended for 15 minutes, after which the motor rotates 180 degrees down and 180 degrees up. The system is then left unattended for 15 minutes again, after which the motor rotates 180 degrees up, before the water pump starts for 150 seconds and the cycle is repeated 1 to 25 times.

09 July 2022

Material Flow :

According to above the block diagram , each system is described in detail.

A)Driving System

B)Water System

C)Base Frame System

D)Vessel System

11 July 2022

A)Driving System :

1)Wiper Motor

-12V DC

-Speed 45(RPM)

-Power 14watt

-Related Velocity 13.5V

-Current 1.5A

2)Sprocket

-14 no of teeths

3)Chain

as per sprockets distance

4)Shaft

-10mm dia

-580mm length

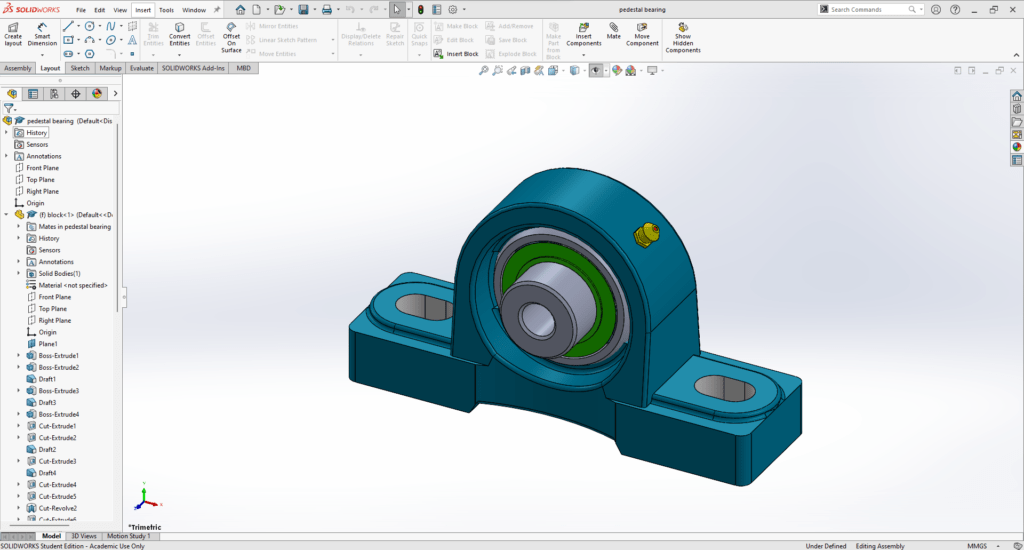

5)Bearing

-pedestral bearing KP002

6)Nylon Roller

-40mm dia

-100mm length

13 July 2022

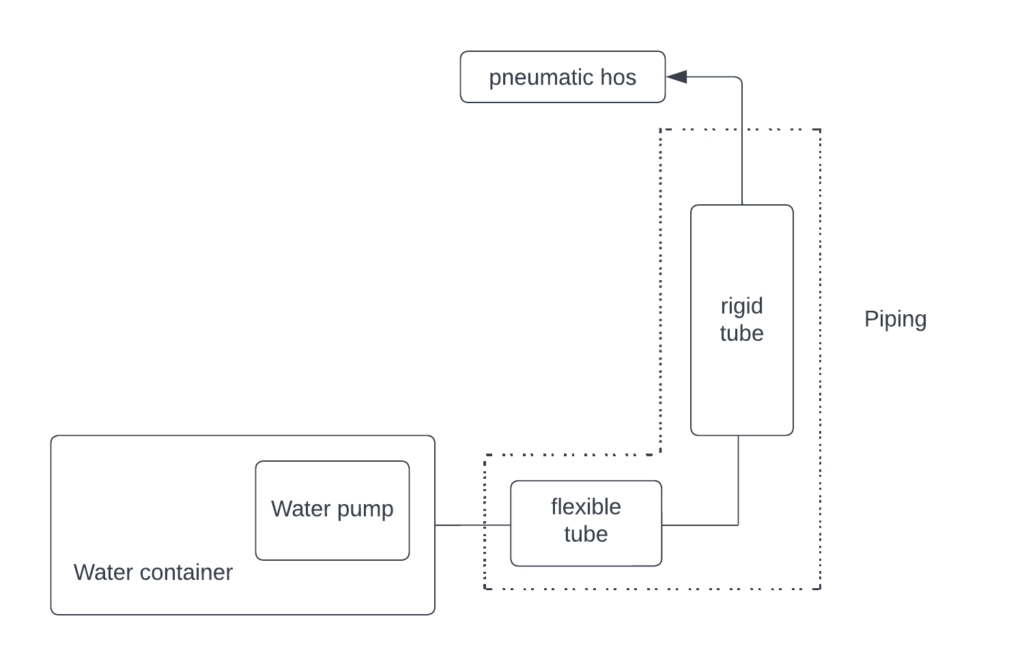

B)Water System:

1)Water container

-Material pp

-volume 15 lit (483414.5)

2)Water Pump

-single phase

-Power Supply 220V

-Power Rating 0.018KW

-Motor Power 0.025HP

3)water tube

as per requriment

4)pneumatic hos

-10mm

15 July 2022

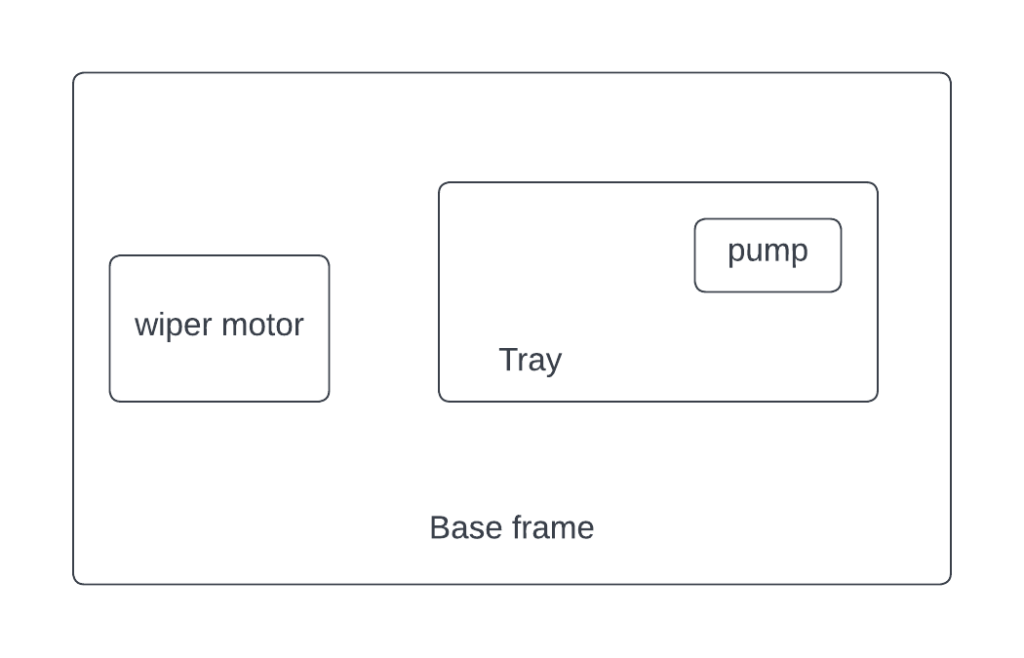

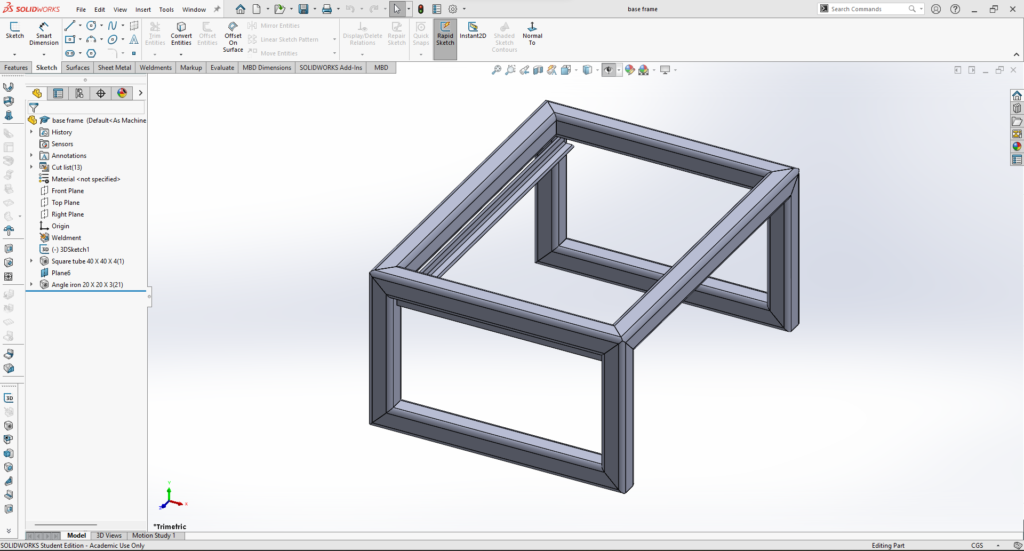

C)Base Frame System :

1)Sq Tube 40*40*2

2)Sheet 1.5mm

3)L Angle 20*20*2

16 July 2022

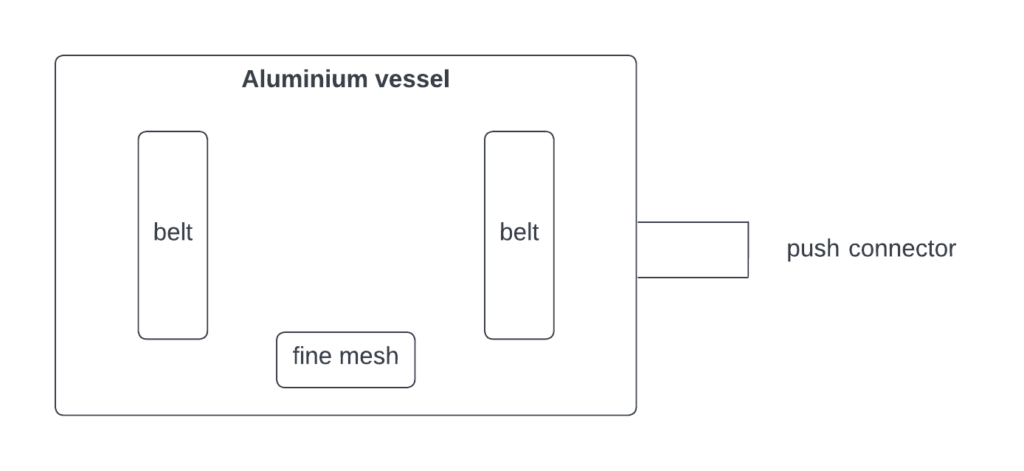

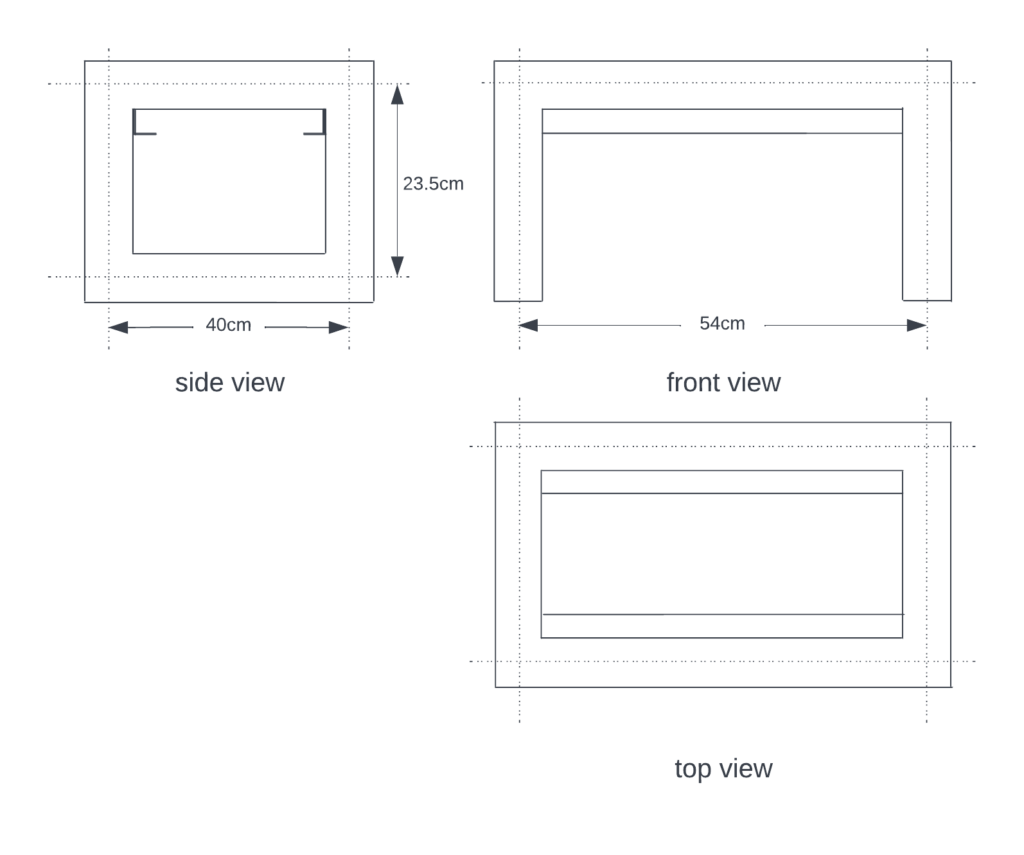

D)Vessel System:

1)Aluminum vessel 34.5cm dia

2)Fine mesh 0.5*0.5*3mm

3)Belt

4)Push Connector

18 July 2022

Part List

A)Driving System

1)Wiper motor

2)Sprocket

3)Chain

4)Shaft

5)Bearing

6)Nylon roller

7)Belt

B)Water System

1)Water Container (tray)

2)Water Pump

3)Water Tube

4)Pneumatic hose

C)Base Frame System

1)Sq tube

2)Sheet

3)L Angle

D)Vessel System

1)Aluminium vessel

2)Fine mesh

3)Belt

4)Push Connector

19 July 2022

1)Base frame:

For the base frame Sq tube, L angle is used ,this procedure is completed by welding, in that first we have drawn 3D sketch then according to calculation dimension is given .then part is prepared.

20 July 2022

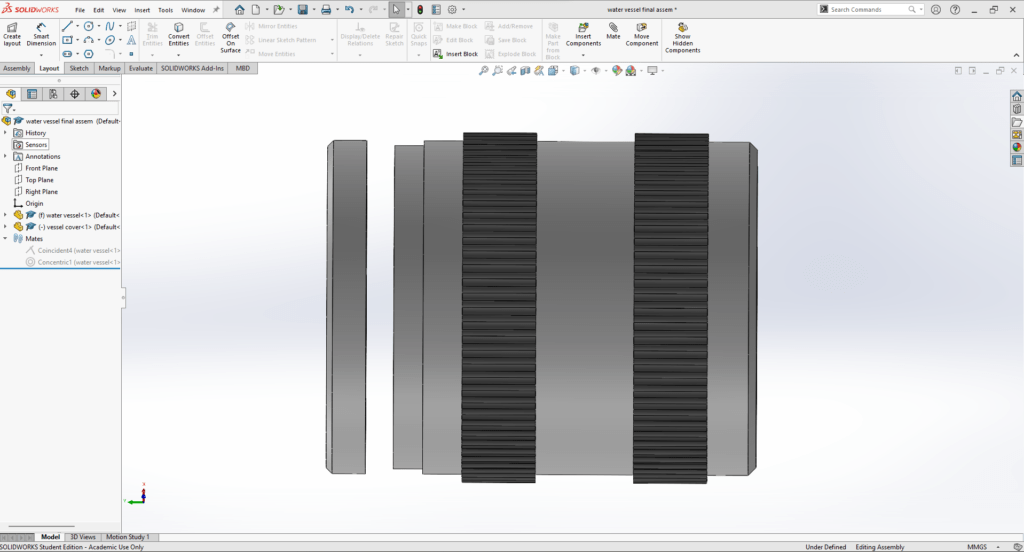

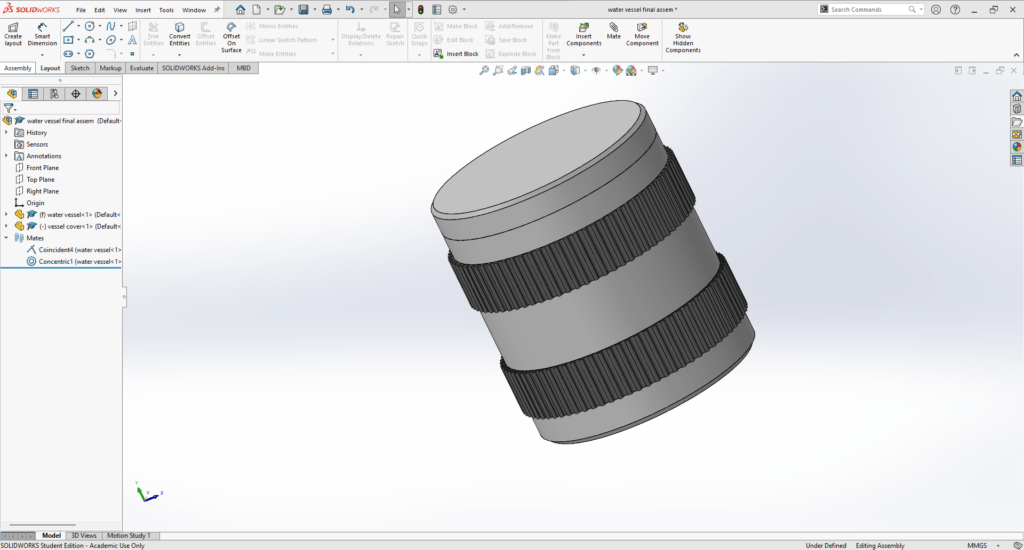

2)Vessel System:

For the Vessel system extruded base, extruded cuts ,fillets and champers and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

21 July 2022

3) Water container:

For the Water container extruded base, extruded cuts ,fillets and champers and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

22 July 2022

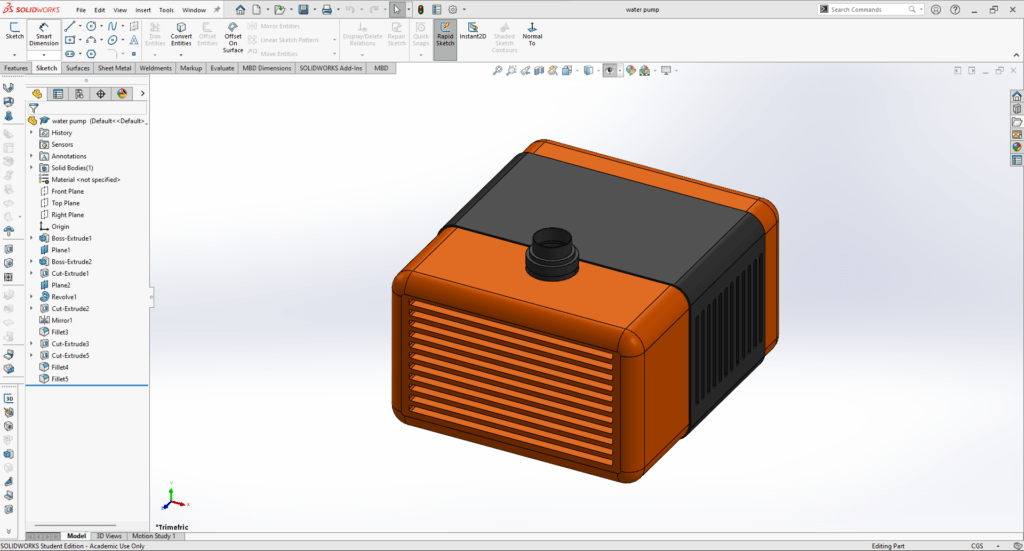

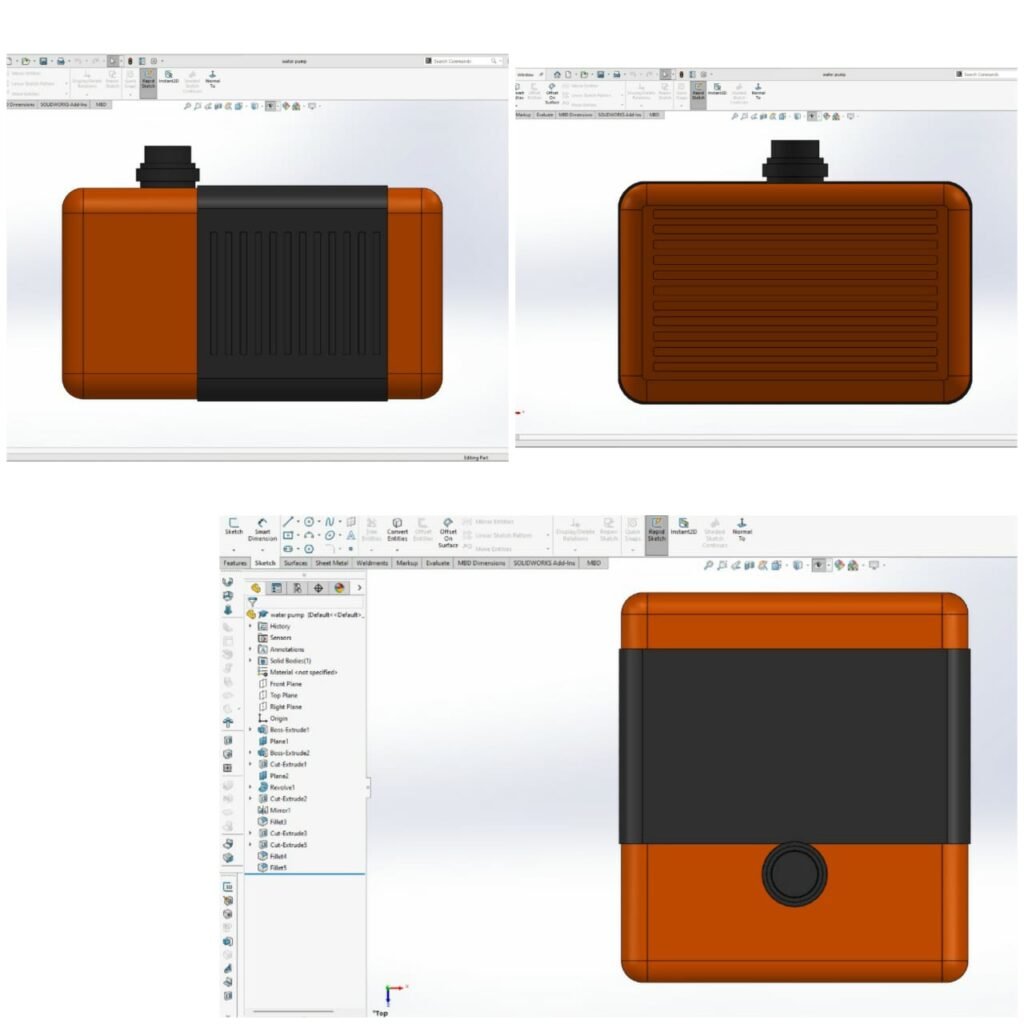

4) Water pump:

For the Water pump extruded base, extruded cuts ,fillets and champers and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

22 July 2022

Assembly of Water System:

This assembly is done in a such way that all parts assemble in one manner some parts are fully constraints some are not fully constraints , for two parts mates we used mate.

23 July 2022

6)Wiper motor:

For the Wiper motor extruded base, extruded cuts ,fillets and champers and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

23 July 2022

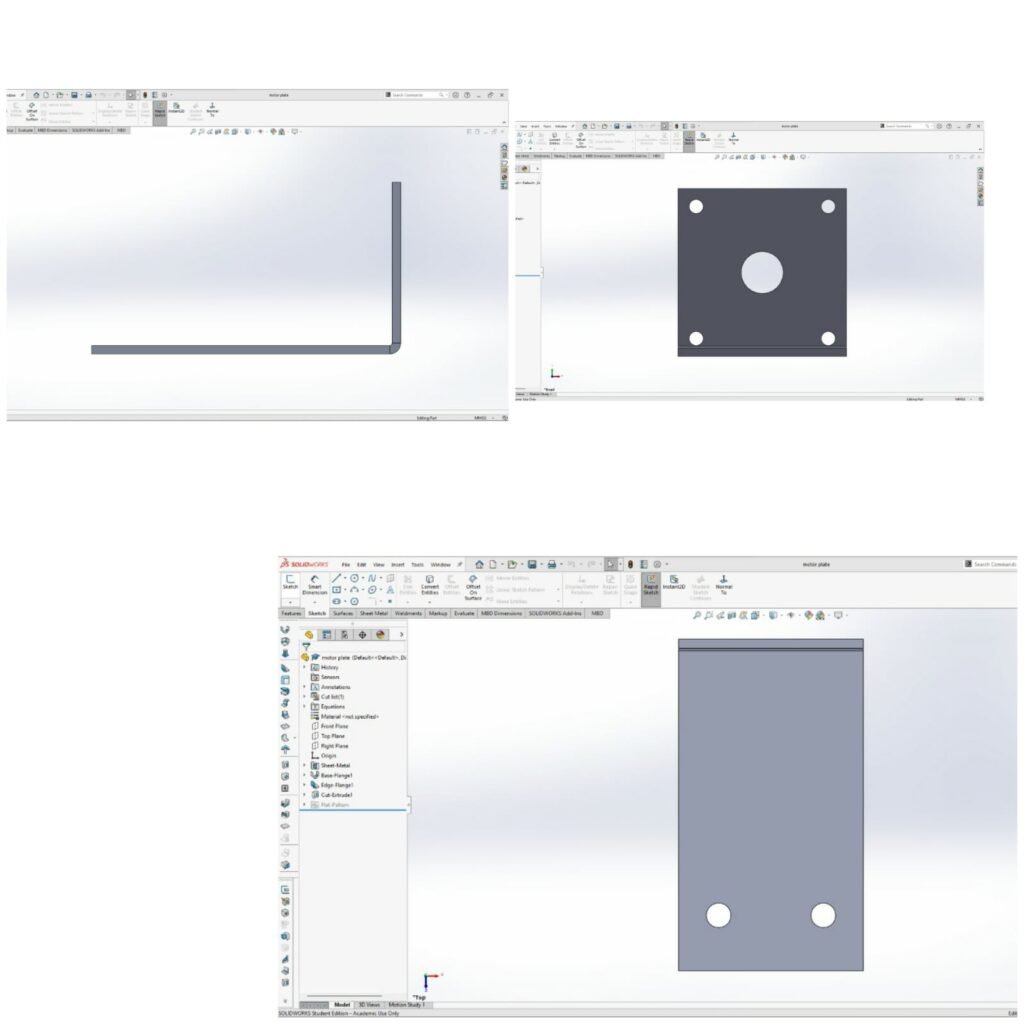

7)Motor Plate:

For the motor plate extruded base, extruded cuts ,sheet matel , base flange, Edge flange and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

25 July 2022

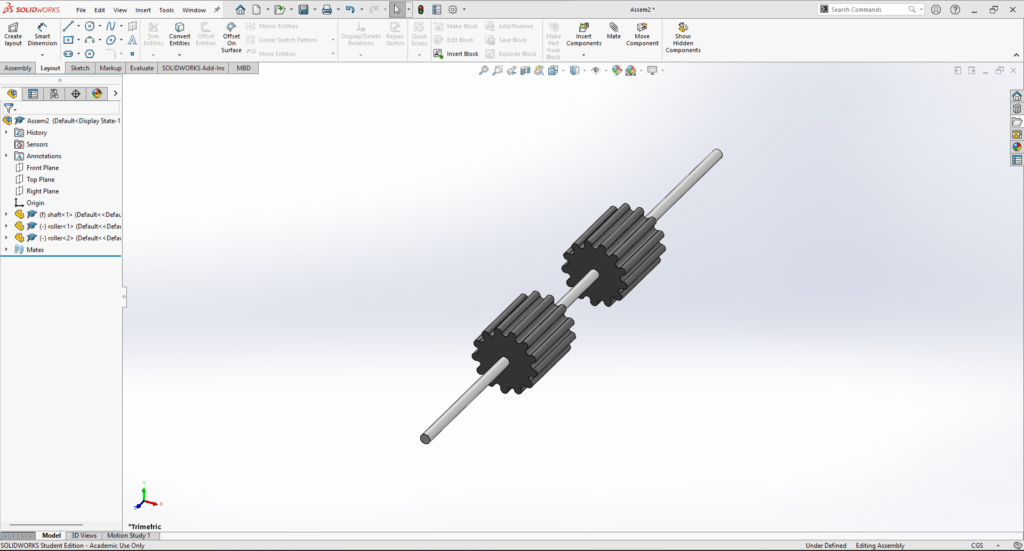

8)Roller with shaft (Assembly):

For the Roller with shaft extruded base, extruded cuts ,fillets and champers and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

25 July 2022

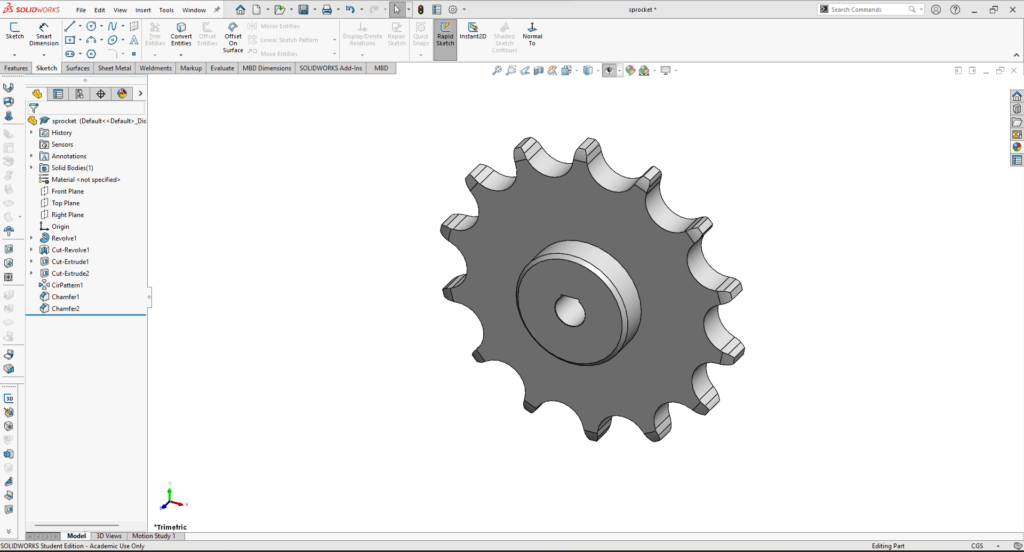

9)Sprocket:

For the Sprocket extruded base, extruded cuts ,fillets and champers and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

25 July 2022

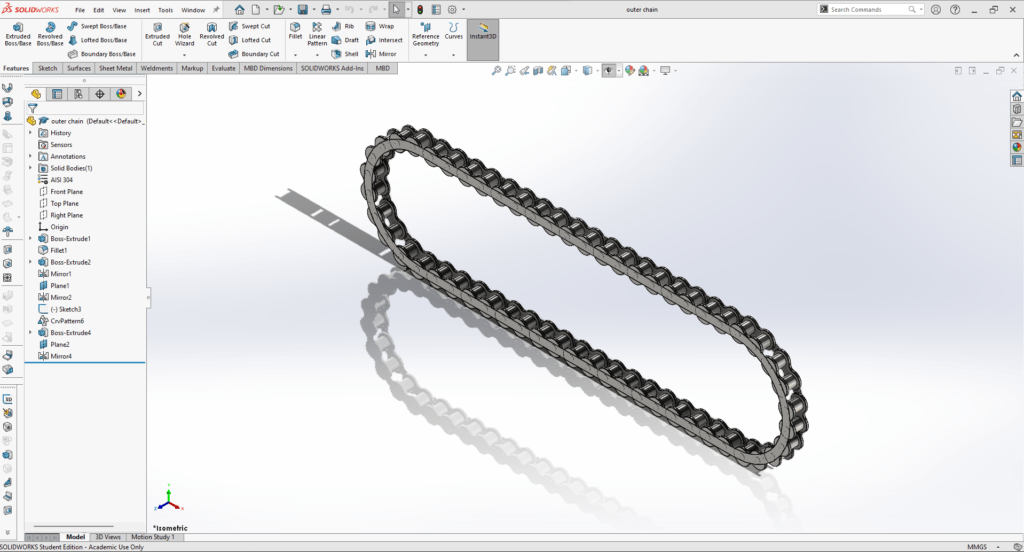

10)Chain:

For the Chain extruded base, extruded cuts ,curved pattern and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

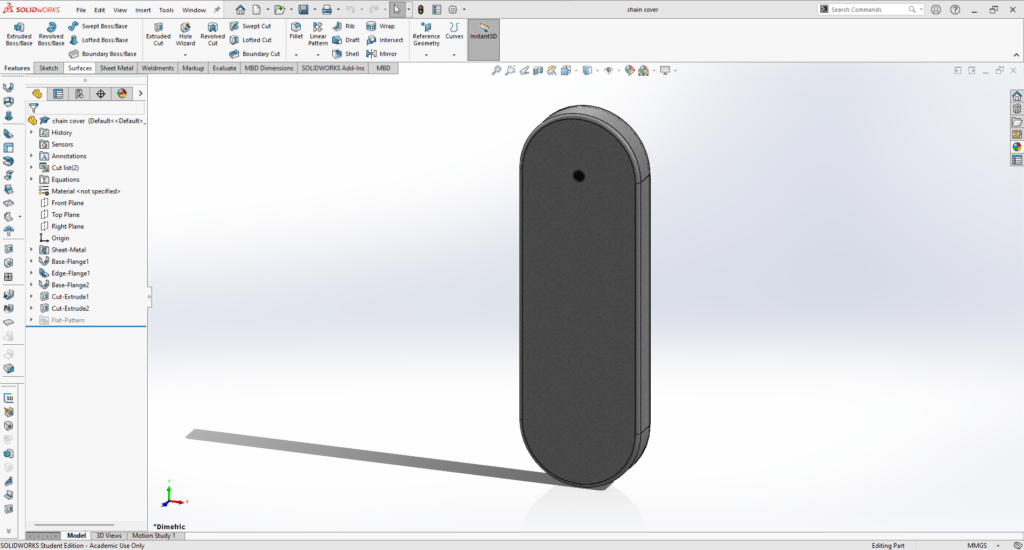

11) Chain Cover:

For the Chain Cover extruded base, extruded cuts ,sheet matel , base flange, Edge flange and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

27 July 2022

12)Bearing:

For the Bearing extruded base, extruded cuts ,fillets and champers and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

28 July 2022

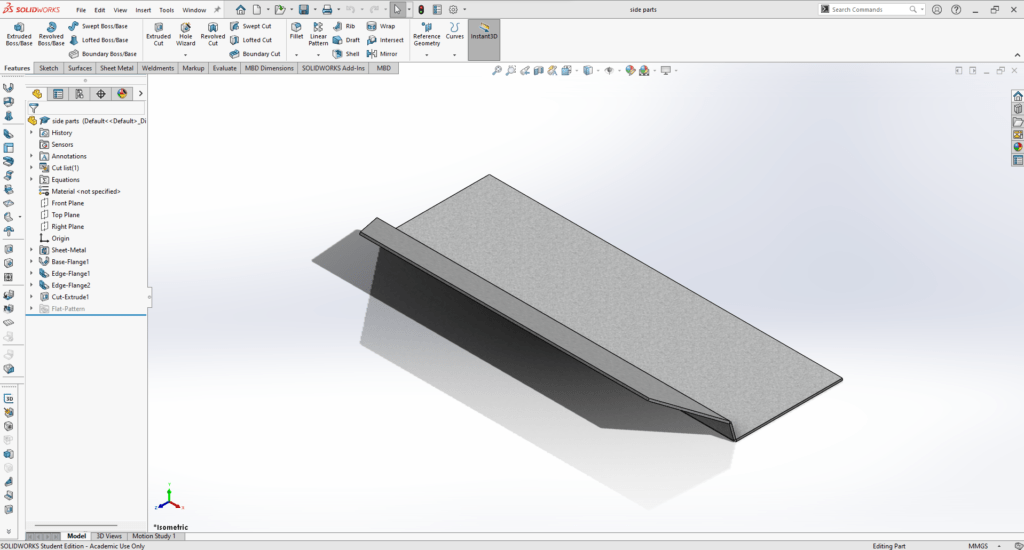

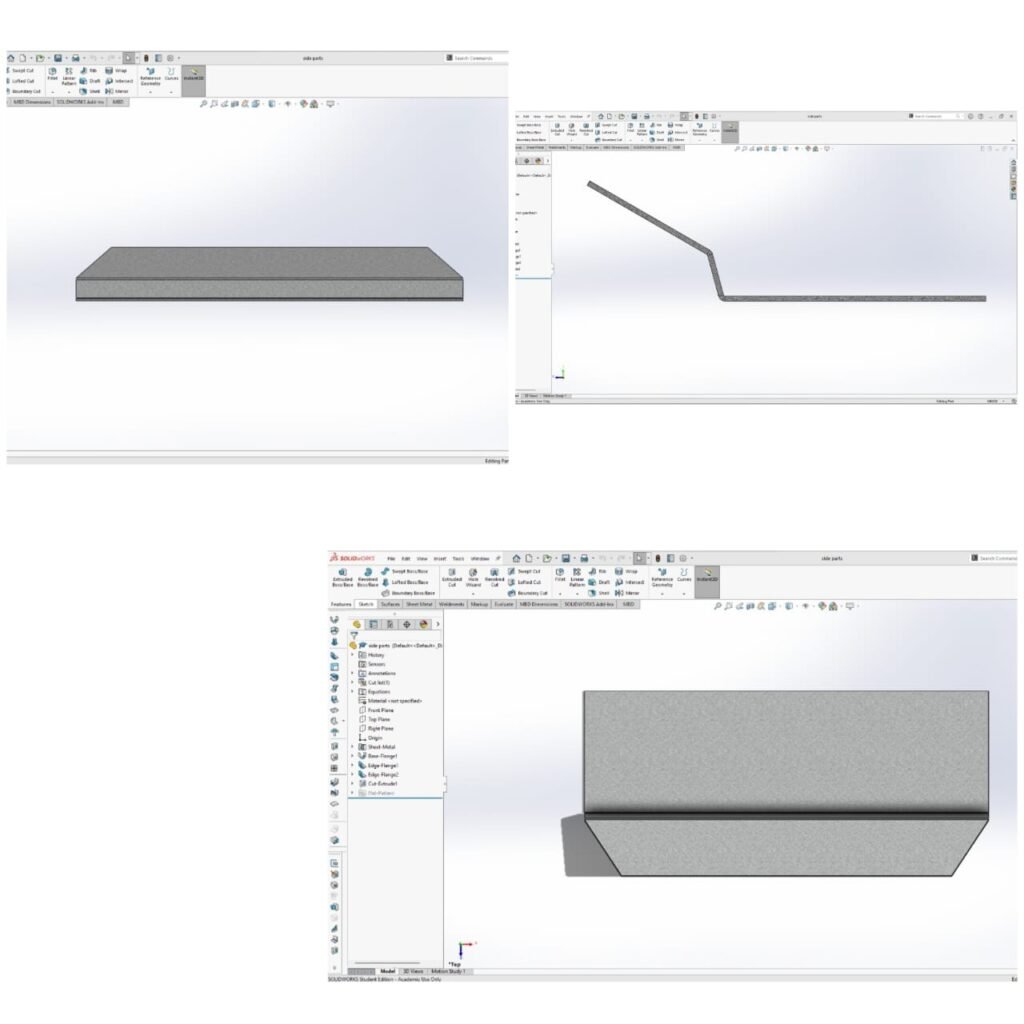

13)Sides parts:

For the sides parts extruded base, extruded cuts ,sheet matel , base flange, Edge flange and appearances and color is used, in that first we have drawn sketch then according to calculation dimension is given .then made the part.

01 Aug 2022

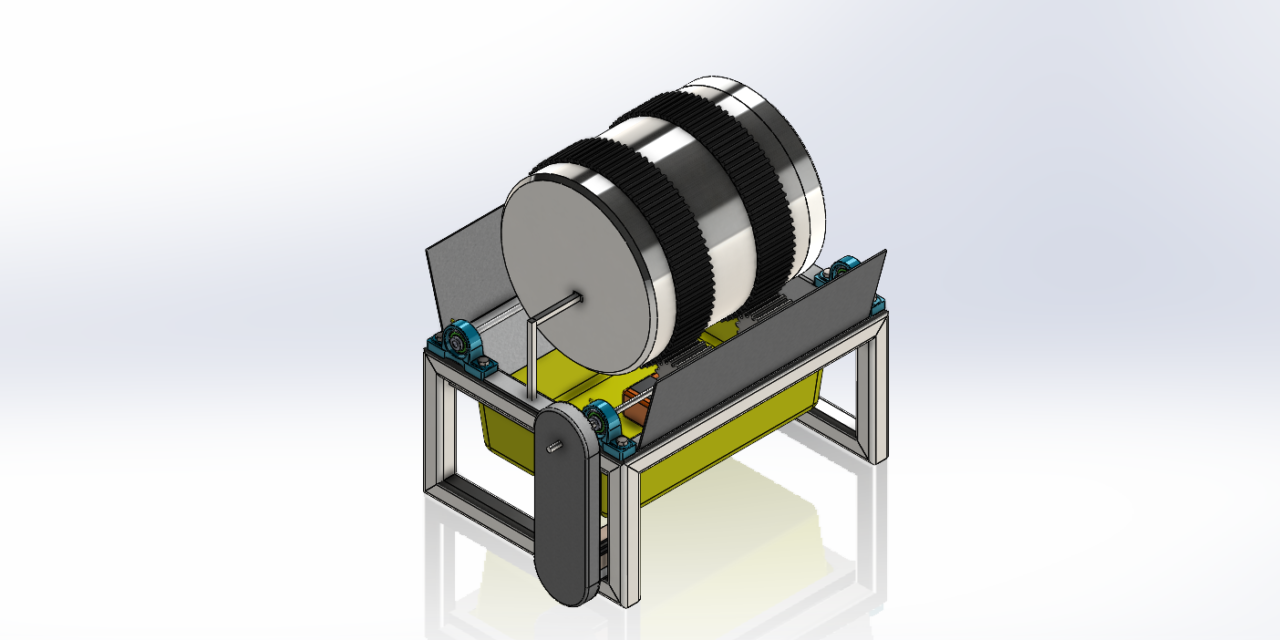

Assembly:

This assembly is done in a such way that all parts assemble in one manner some parts are fully constraints some are not fully constraints , for two parts mates we used mate.

08 Aug 2022

Updated Assembly:

Presentation:

30 July Exhibition

On 30 July for purpose of open house exhibition I showcased the grocubator.