Slow speed grinding machine.

Objective:-

1) The main objective of grinding machine is to grind grains like wheat, millet, pearl millet,wet or dry pithi, spices, pulses with slow speed to avoid the losses of nutritional values & flavour due to heat generated in conventional grinding process.

2) Grinding of grains & pulses is a day time operation & hence can be switched to PV cells without battery support. This will cut-down carbon footprints.

3) To develop Automatic feeding mechanism

Literature survey of previous documents of slow speed grinding machine :-

Automatic feeding mechanism for slow grain grinding machine:-

a) RPM for grinding M/C by measuring the revolution of sprocket chain mechanism ( in transmission practically).

- For 1.5 min & 20 rev, Speed = 20/1.5= 13.33 RPM.

- For 3.26 min & 43 rev, Speed= 43/3.26=13 RPM.

- For 6.02 min & 75 rev, Speed = 75/6.02=13 RPM.

Hence, average speed (in RPM) = 12 RPM.

b) Feed rate calculations:- ( Assumptions made on the basis of Ashram’s requirement for making Idly for 60 people)

- I had taken a trial to grind 20 gm rice grins.( On grinding m/c in project )

- To grind 20 gm rice grains, 1 min. 39 sec i.e. 99 sec is require.

- Therefore, required feed = 99 sec/ 20 gm = 4.95 sec/gm ~ 5 sec/gm

- Hence, Feed require in 1 min = 60/5 i.e. 12 gm/min.

c) Total feed rate require for grinding m/c. is,

(12 gm/min)/(12 rev/min)=1 gm/rev.

- Rice require for 60 people in Ashram for making Idly :-

60 people in Ashram requires 12 glass of rice for 1 day. (Fig. told by Maushi)

Where, 1 glass had 308 gm of rice.

Hence, 12 glass = 308*12=3696 gm rice.

Hence, 60 people requires 3696 gm of rice for 1 day in Ashram.( Let us assume that 10 people didn’t eat Idly)

Now,

- Rice requirement for 1 person = ?

=3696/60

=61.6 gm/day/person for making Idly.

- Calculations for the requirement of rice /day for 1,324,171,354 people allover the India:-

Population of India in 2018 = 1,324,171,354 bn

Therefore, per day Rice requirement = 61.1*1,324,171,354.

=81,568,955,406.4 gm/day for 1,324,171,354 peoples in India.

- Calculations for the requirement of wheat/day/person in Ashram :-

70 people in Ashram requires 50 kg (50000 g) of wheat for 4 days (Fig. told by Maushi) :-

= 50000/70

= 714 gm

Wheat requirement for 4 day = 714 gm

therefore, for 1 day wheat requirement = 178.5 gm.

So, 1 person requires 178.5 gm of wheat for 1 day.

Now,

- Calculations for the requirement of wheat/day for 1,324,171,354 people allover the India:-

1,324,171,354 * 178 = 235,702,501,012 gm per day

Now,

Requirement of wheat for 365 day = ?

=365*235,705,501,012

=86,031,412,869,380 gm for 1,324,171,354 people in India.

Requirement of 1,324,171,354 people in India for wheat & rice per day / person is 178 gm & 61.6 gm respectively .

So, my grinding m/c needs to grind around 119.8 gm of grains per day.

d) Had Install 12 volt SMPS on m/c to covert 230 volt AC to 12 volt DC supply.

e) Had replacement of Ball Bearing.

f) Taken the trails of 2 cm long sticks on grinding m/c to know the capacity of grinding m/c.( sticks are given by Colonel Naik )

g) Purchasing of a New Grinding M/C is done.

h) Total Electricity consumption of India during grain grinding process.

i) Comparatively efficient use of solar energy.

New problem is arrived :-

- Driving & driven sprockets of transmission system of grinder are miss aligned.

- Which creates vibrations & ultimately other parts of machine get disturbed .

- So, my task will be to adjust the alignment between driver & driven sprockets.

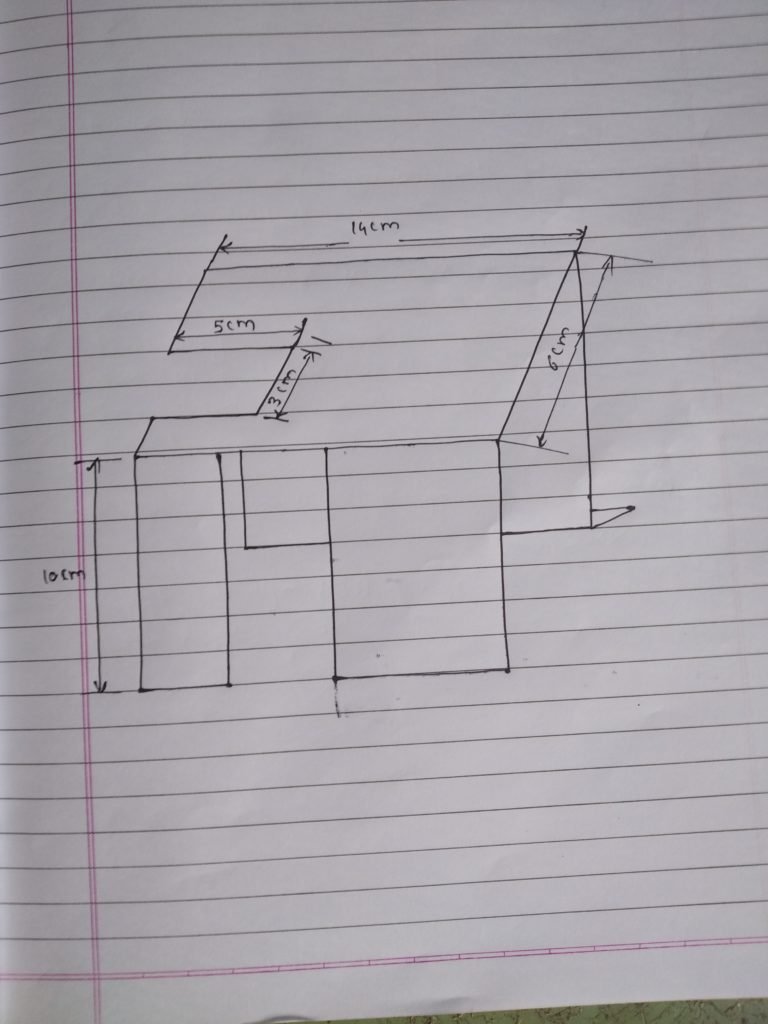

For that I have design a support plate for driven sprocket with 2.5 cm thickness & have cut it on Plasma Cutter.

- I practiced welding , grinding , drilling.

- To adjust the alignment of driver & driven sprocket, I have mount the driven sprocket with support plate 2.5 cm away from motor mounting.

- Which made inline operation of transmission system.

- Machine was not working due to loss motor connections :-

- So, I had provide it with some fix mounting.

“After having a discussion with Kulkarni sir, Arun Dixit sir & Amol sir it was decided to made an Automized flour mill for using the slow grinding technique with reduction in human efforts”.

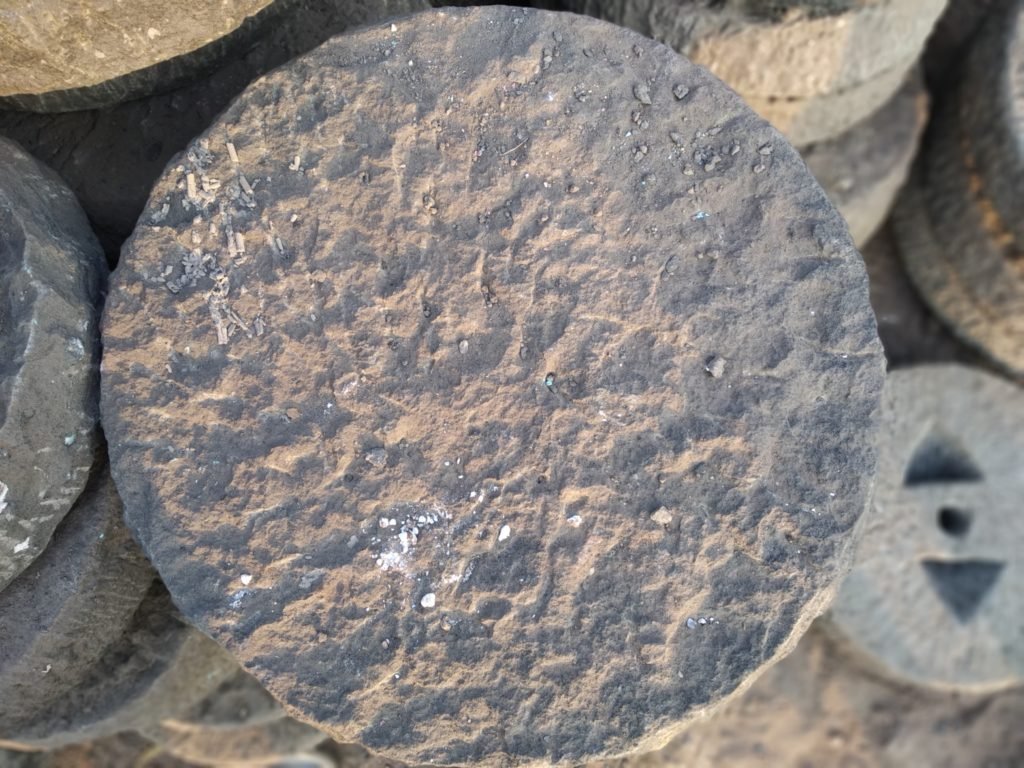

Mill stone purchasing for Automized flour Mill :-

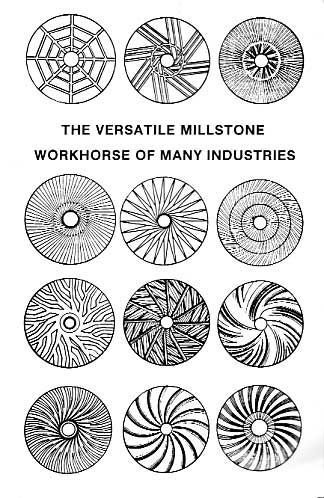

- Different types of mill stones patterns available:-

Mill Stones Purchasing :-

Different rough surface of millstone :-

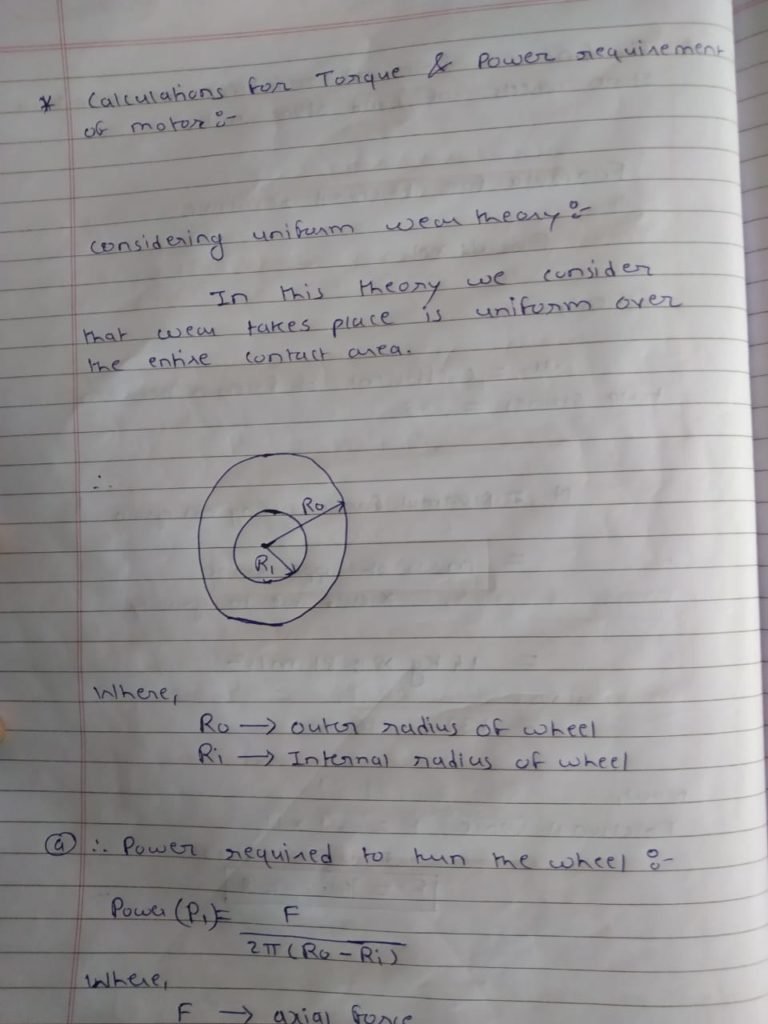

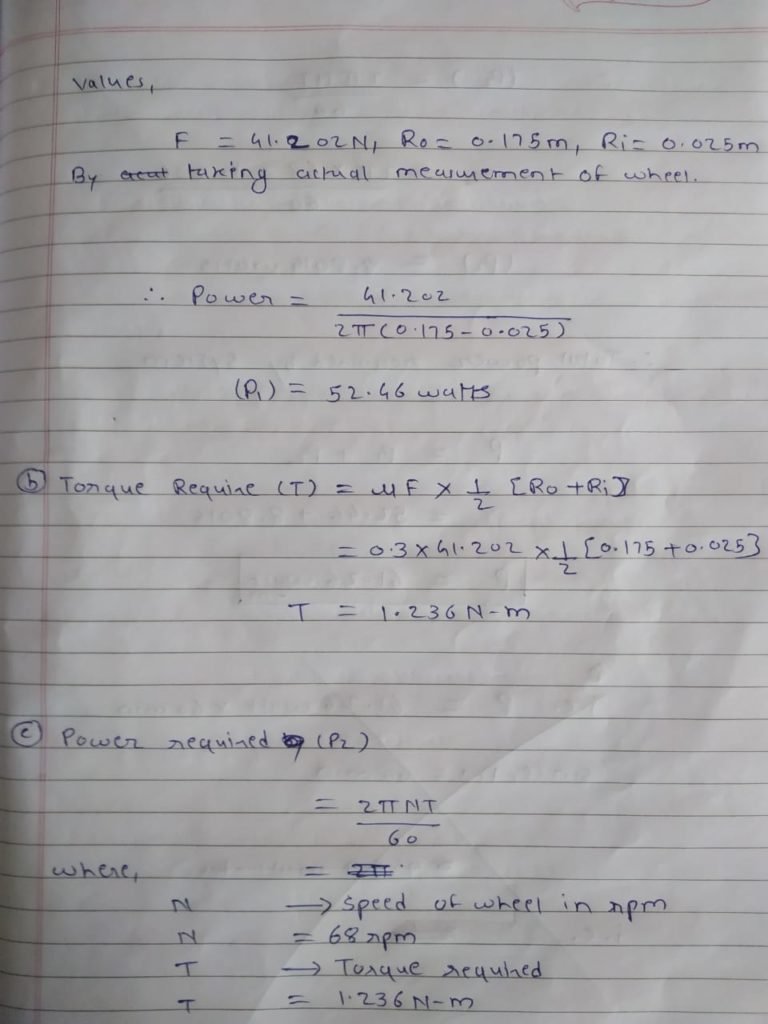

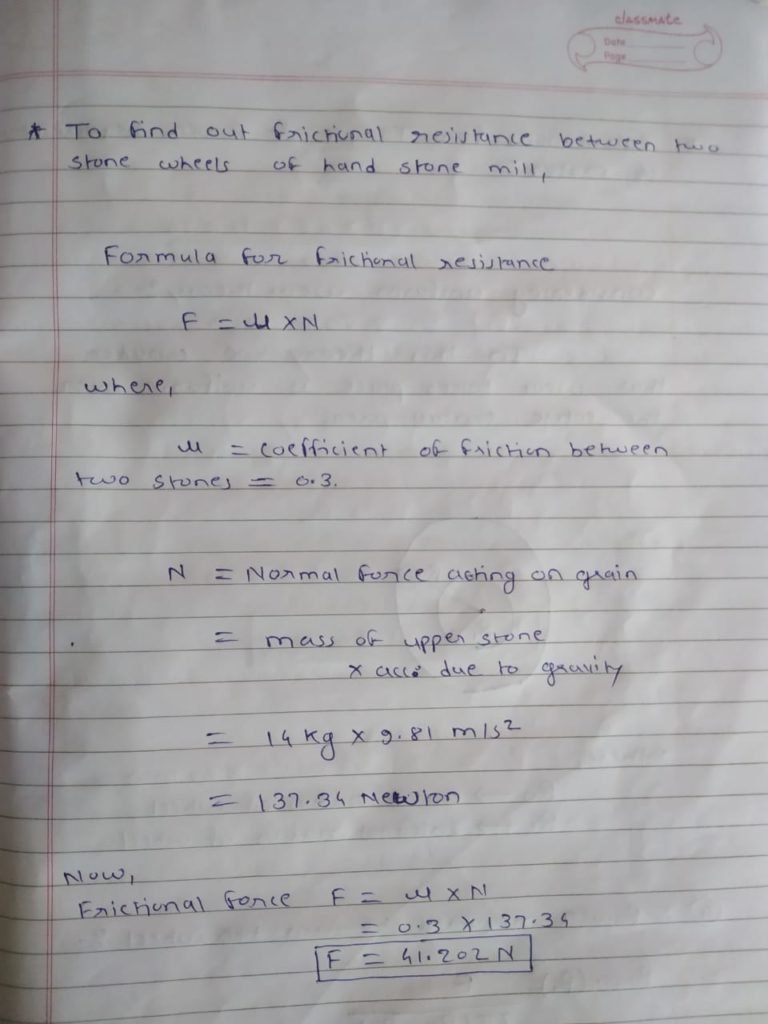

3) Different parameters to be find while selection of mechanism for Automized of Flour Mill :-

a) Weight of rotary mill stone = 13.938 kg ~ 14 kg.

b) Diameter of millstones = 35 cm.

c) Speed in RPM (During hand operation) = 68 rpm.

d) Frictional resistance/Frictional load = 41.202 N.

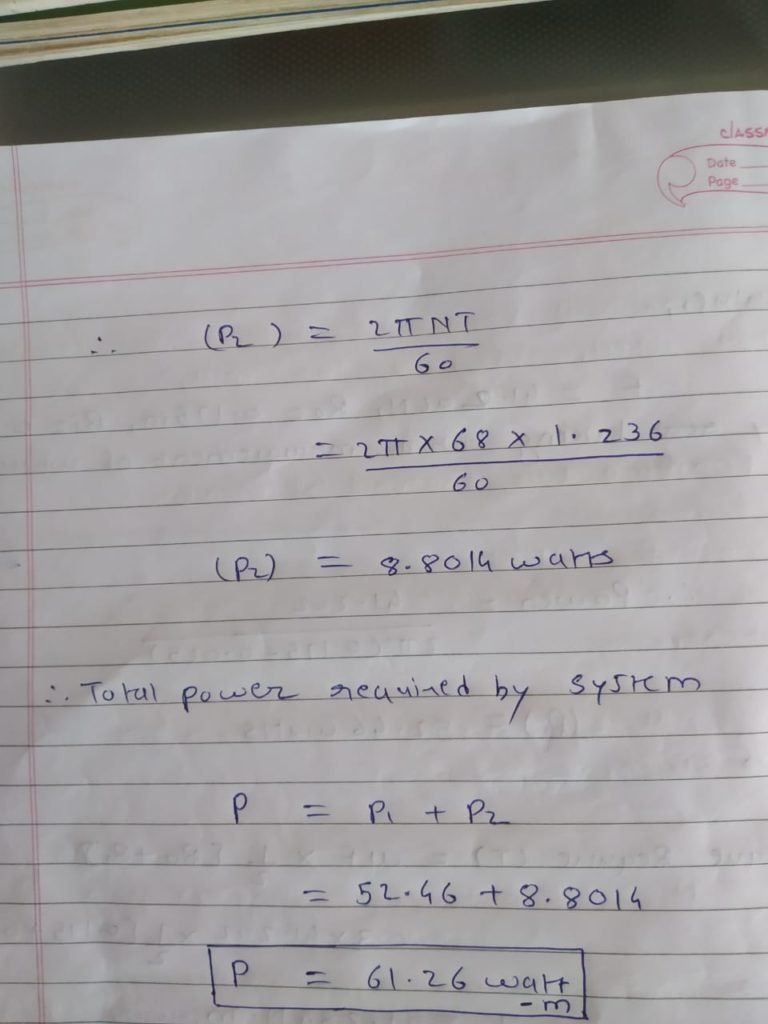

e) Power require:-

4) Proposed mechanisms after having discussion with Amol sir :-

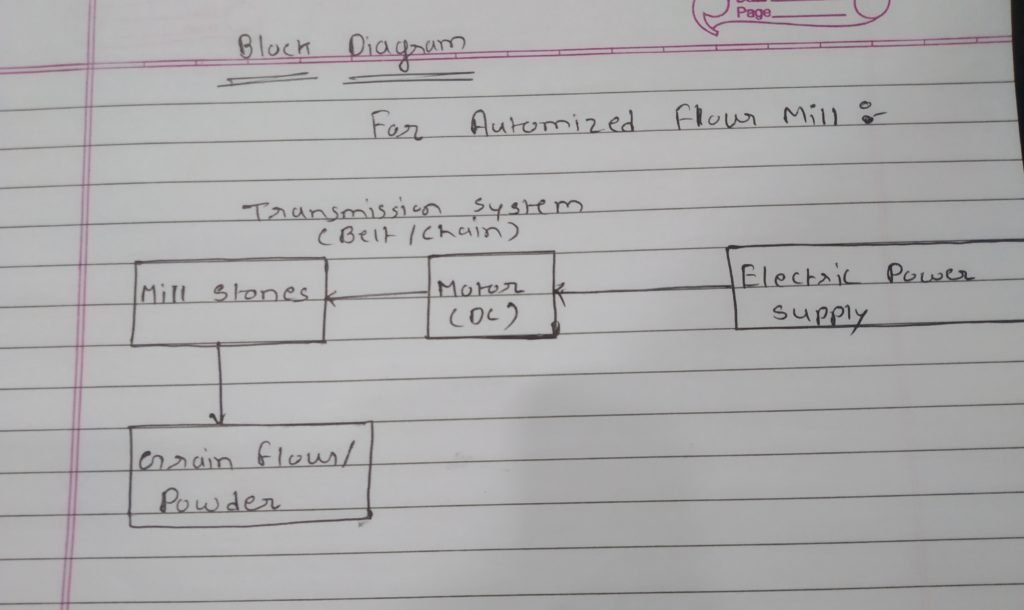

a) Block diagram of Automized flour mill :-

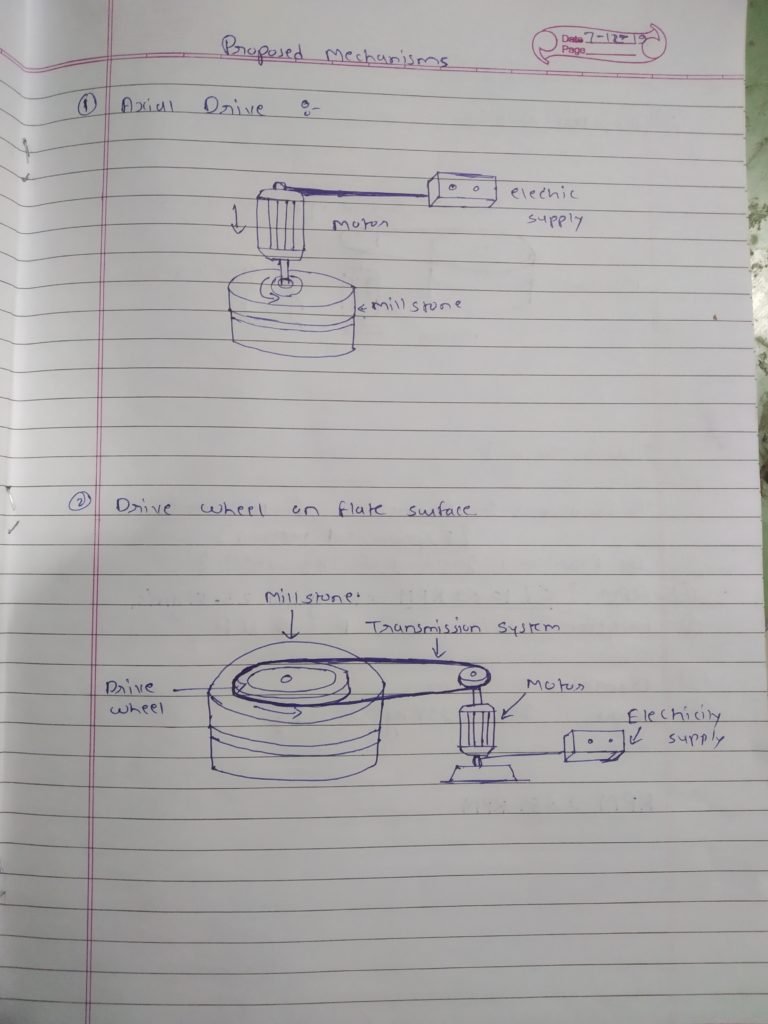

b) Axial drive & drive wheel on drive surface mechanism :-

c) Peripheral drive system :-

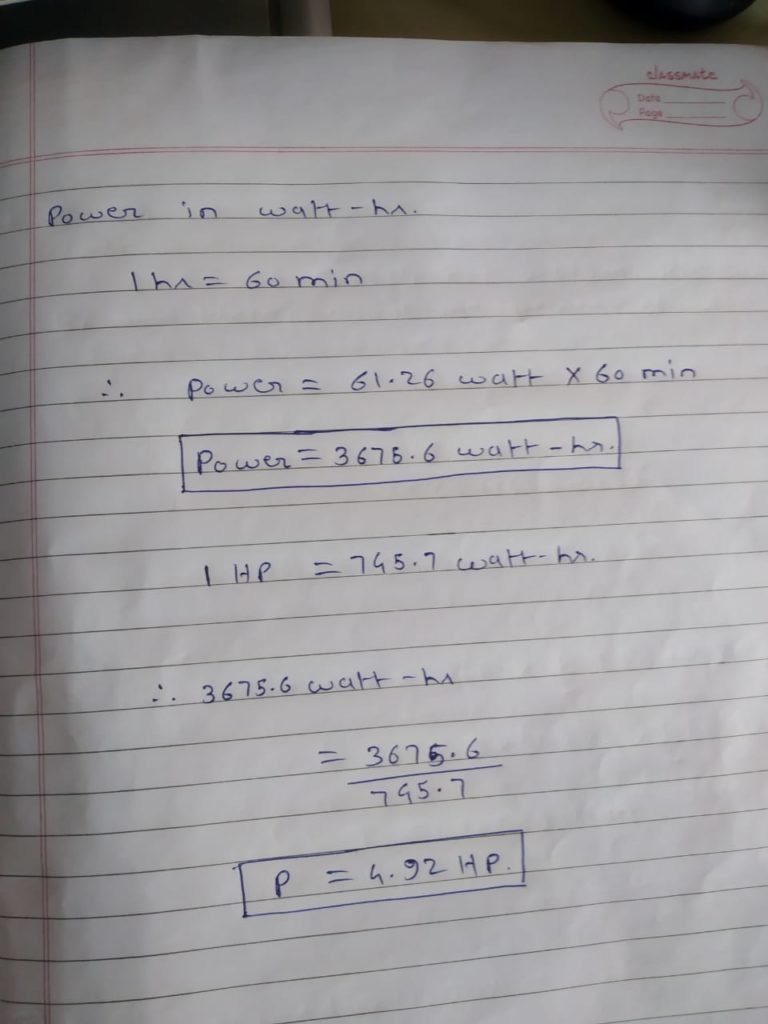

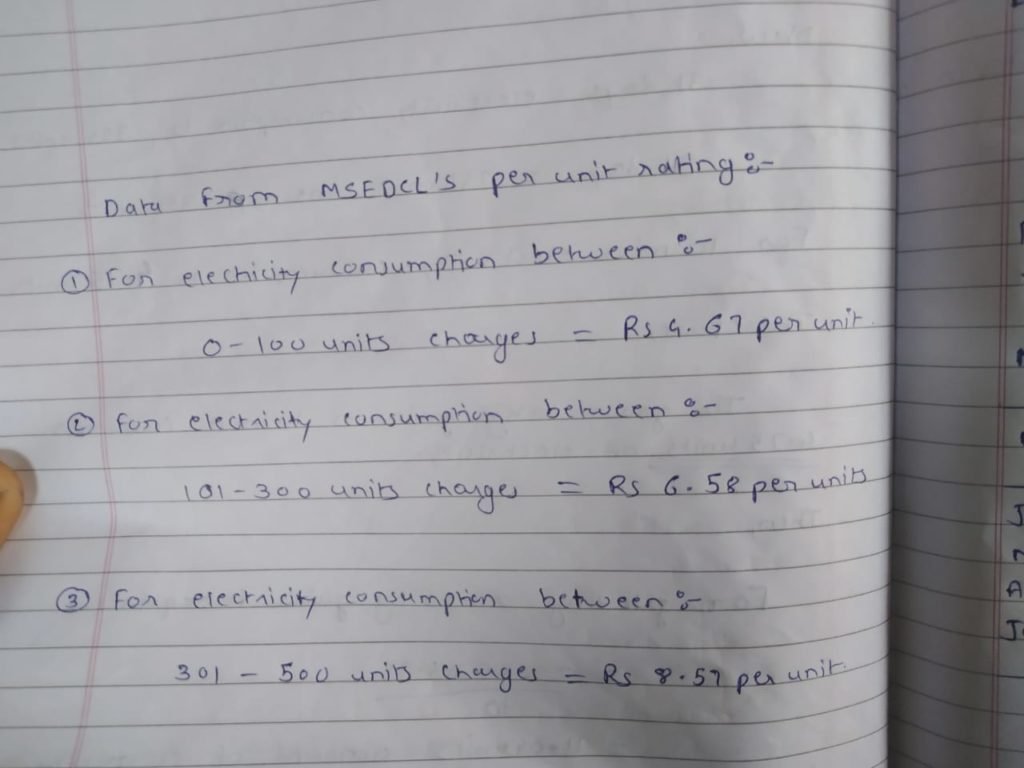

MSDCL’S data available on internet:-

- Data of motor & energy bill of Pabal’s flour mill:-

I have visited Pabal’s Flour mill for collecting data :-

Therefore,

For 31 days electricity consumption is 354 units which charges Rs. 2999.

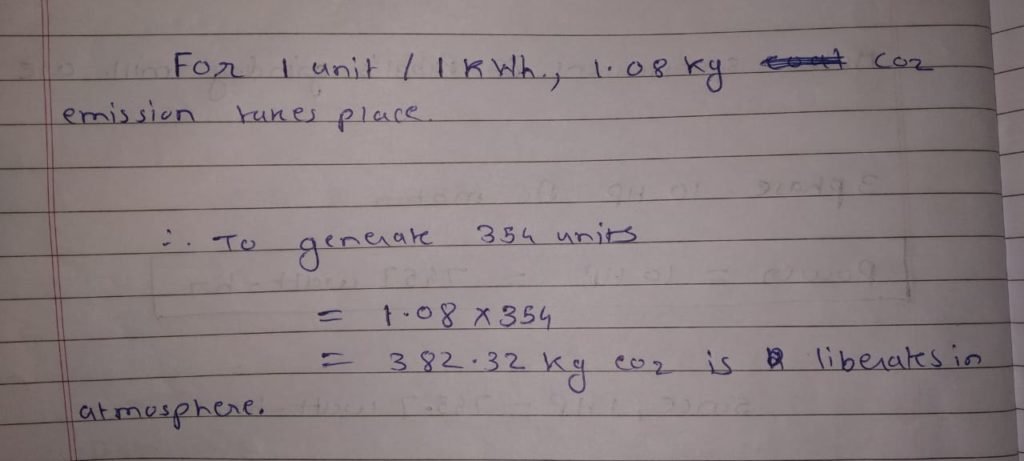

- Carbon emission in atmosphere :-

The study claimed the average efficiency of the plants, it assessed, was 32.8 per cent, one of the lowest among major coal -based power producing countries. It claimed that average CO2 emission was 1.08 kg per kWh.

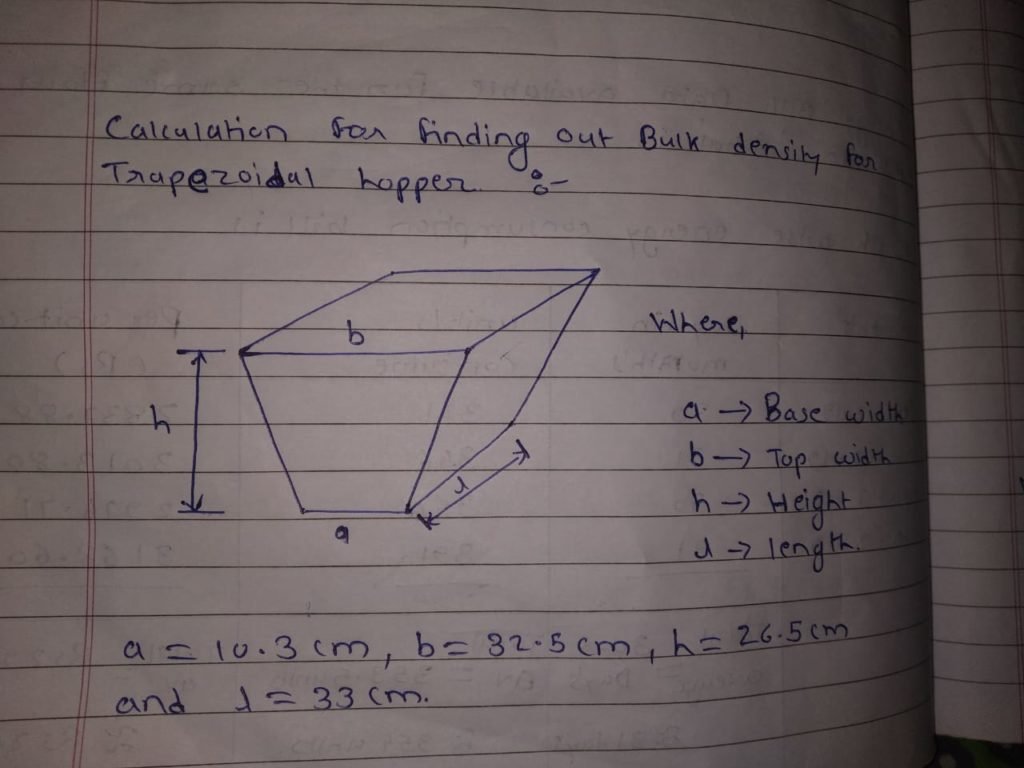

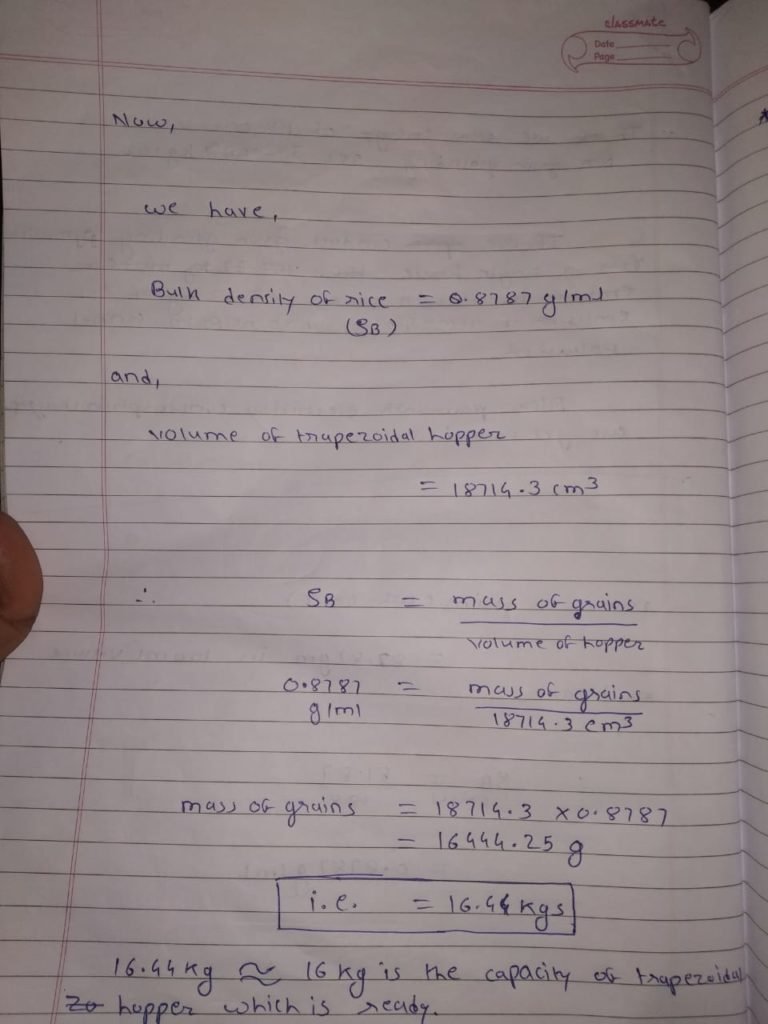

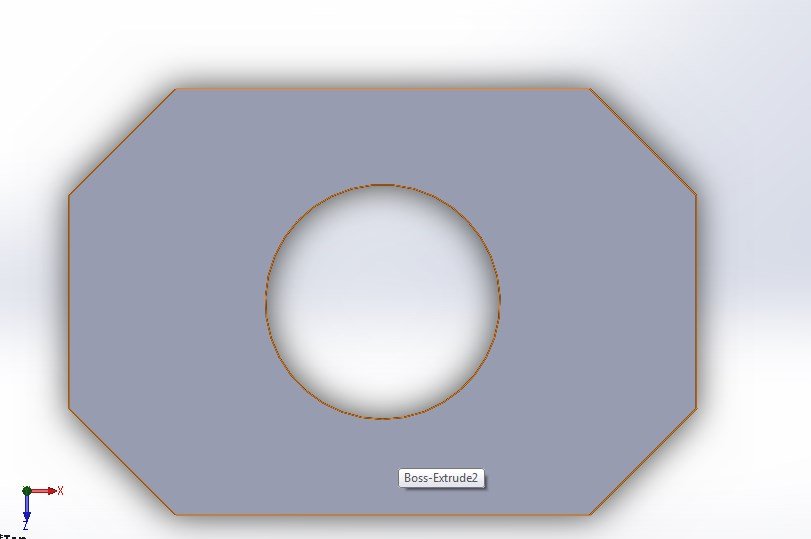

Capacity of available hopper :-