The dome of the Dome Dryer is a most important part of the system. It has multiple roles to play. It acts as a drying chamber as well as captures solar heat and radiate inside. It has holes for ventilation and fan is mounted on dome for sucking air from the system.

Unlike version 2.0, dome in version 2.1 is made out of Galvanized Steel sheet. This will be painted with HR Black paint which has Absorptivity more than 0.9. The inner side of the dome will be painted with Red Oxide primer which has a high emissivity of 0.88. Below is reference for the data.

https://www.design1st.com/Design-Resource-Library/engineering_data/ThermalEmissivityValues.pdf

The dome is made out of sheet panels joined together with rivets in sequence such that when finished they form a hemisphere dome. The Solid works part file for the panel is given below.

https://drive.google.com/open?id=18RxwwK-1s8hL6gk7ClIxWiM-ST18bqHO

https://drive.google.com/open?id=1LWKvszyodnscpCBrl1YPIlWseHn0679E

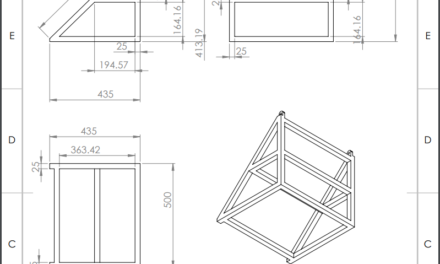

The all the panels are supported or fixed on base ring. the Base ring is made of Mild steel square tube of ISO 25 X 25 X 1.2 mm section. The major function of this ring is to provide rigid support to the thin dome structure. handlebars for lifting and handling dome will be mounted on this plate. Pictures of those will come in a future blog. The drawing file for Base ring is given below.

https://drive.google.com/open?id=1LWKvszyodnscpCBrl1YPIlWseHn0679E