Background:

Vigyan Ashram has been working on composting for a long time in its efforts to provide better waste management alternatives compared to conventional ones. Vigyan Ashram has developed many prototypes of composters for single households as well as large housing societies.

The composting works in two stages. In the first stage, the wet waste is mixed with a microbial culture developed by BARC and in the second stage, the mixture is stored or stacked for a time period of approximately 4 weeks to turn into compost.

The ‘Akshay Home Composter’ designed for single households acts as a mixer as well as a stacking device since the amount of wet waste produced per day in a single household is low. In the case of society composters, the amount of wet waste produced is so high that mixing and stacking cant be done in the same device.

In order to offer a solution to this problem Vigyan Ashram is developing a stacking device that can store the wet waste + microbial culture mixture till complete composting.

Design and Fabrication:

The compost stacking rack will have 7 compartments each with a 50 kg storing capacity for each day of the week. Each compartment will have a door through which waste can be inserted and removed, the doors will be arranged on alternate sides i.e. no neighbouring compartments will have doors on same side.

The compost stacking rack will rotate on a stand with the help of pulleys and the rack will only have to be rotated half a turn once a day. The design of the rack and the stand can be viewed by clicking following link,

The fabrication of the project began in late November 2020 due to unavailability of a fabricator. We decided to go ahead with the DBRT students as fabricators.

DBRT students Vikas, Ganesh, Pramod and Saurabh fabricated the frame of 3 units of rack.

Omprakash another student of DBRT fabricated 8 units of stand, 2 for each compost stacking rack

Ghanashyam a former DBRT student took over after the frames were fabricated and finished the rest of the project with the help of other DBRT students.

Problems with the project:

The compost stacking rack took 2 months to fabricate and still wasn’t done well due to the following reasons,

- The design of the rack wasn’t complete, only the dimensions of the outer frame were provided.

- The most difficult part during fabrication of the rack was the fixing of the mesh to the frame. The suggested way of using nut-bolts was time consuming and labourous, hence we used self drilling screws to fix the mesh which was also very difficult and time consuming.

- The non availability of skilled fabricator during the early period resulted in the delay and poor quality of the project.

- The cost estimation was incorrect. The project was made at 25% more cost than the estimated one.

Delivery of the project:

The project was finally delivered to Dassault systems, Hinjewadi on 26 January 2021.

Rectification of the composting system:

Visit to Dassault systems:

A visit to Dassault systems, Hinjewadi along with Dr. Arun Dixit was made on 03 February 2020 after learning about their concerns regarding the composting system. Following is the list of their concerns,

- The rack is not easy to rotate,

- The mesh is not properly fixed to the frame, the self-drilling screws are projecting out,

- The paint is not properly applied,

- The chain sprocket is not properly aligned with the gearbox of the motor,

- The overall finishing is not good

We decided to work on their concerns and rectify the system at Vigyan Ashram’s campus.

Later, Mr. Anil Gosawi owner of ‘Climbers Systems’ and a friend of Vigyan Ashram paid a visit to Ashram’s Pune office where a similar composting system is installed. After discussion, it was decided that the system will be shifted and rectified in his workshop at Katraj.

Finally the system was shifted to Climbers Systems, Katraj on 08 February 2021.

Rectification of the system:

Following changes were made in the composting system.

- The SS mesh was replaced by a perforated GI sheet of 1mm thickness. Dr. Dixit had concerns about the open area of the sheet since composting requires at least 30% open area. The open was later found to be approximately 32%.

- The stands were connected using a frame made of 25mm X 25mm square tube and leveling screws were also attached at their base. This insured comparatively smoother rolling of the rack.

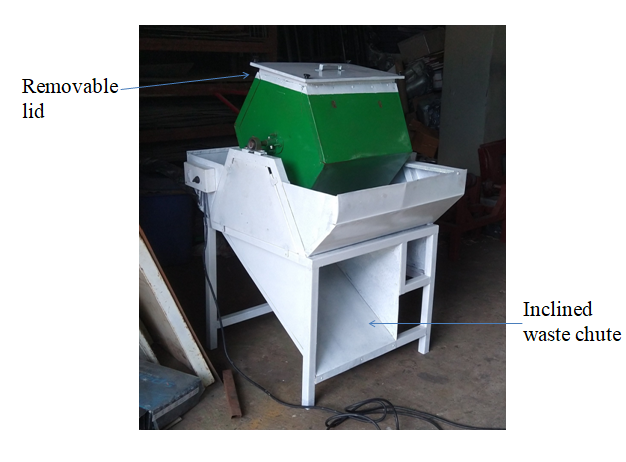

- An inclined waste chut was fabricated to the mixer for easier unloading of the waste.

- The chain sprocket was properly aligned and the motor was fixed while making use of spring washers to dampen the vibrations and reduce noise.

- The hinged door of the mixer was replaced by a removable lid fixed using knob screws.

Following photos show the above mentioned rectifications.

Visit to climbers systems with Dr. Arun Dixit:

Dr. Dixit and I visited Climbers Systems workshop at Katraj for the inspection of the composting system on 26 /02/2021. Following are our observations,

- The present system is far better than the system before modification,

- Finishing and painting is pending,

- Basket 1 and 7 can not be opened completely for downloading, but downloading can be done in a partial tilting position,

- Few tower bolts still look a bit shabby due to improper finishing,

- Rings: welds are nicely polished and have reduced friction and jerks,

- The stand play has been removed using a frame as a tie rod,

- The mixing drum has been modified, and the mixing operation is noise-free,

Following are the suggestions for more improvement in the composting system,

- There is a considerable gap between door and the racks frame which if eliminated will reduce chances of waste spillage,

- The rack while rolling gets rubbed against the rings of the roller, a simple restricting/guiding mechanism for the rack in the form of small wheels or balls will make the rolling even more easier.

According to Dr. Dixit the system is up to VA standards and he feels we can go ahead with either of the following two options,

- Calling Solidworks authority for inspection at Mr. Anil Gosavi’s workshop,

- Operate drum in present condition at Kothrud office and demonstrate functional operation to Solidworks authority.

Later a discussion was held with Dr. Kulkarni and Mr. Ranajeet on above observations and a decision was taken to go ahead with the first option.

Accordingly, the concerned people from Solidworks were contacted and asked to visit Mr. Gosavi’s workshop.