All you need to know about bean sprouting!

Why you should care about bean sprouting?

Beans have been a part of the staple diet in a lot of countries and for a good reason. Beans are a powerhouse of nutrients, offering a wide range of health benefits. Beans, along with other foods like lentils, peas, and soybeans, fall under the category of legumes. Legumes are a rich source of fiber. Incorporating legumes into your diet can provide numerous health benefits. And even among legumes beans are especially good sources of protein. Most kinds of beans provide all nine essential amino acids, making them a complete protein source. Beans are packed with essential vitamins and minerals, including iron, magnesium and potassium.

Bean sprouting is the technique of soilless germination of beans which enhances the accessibility of various amino acids present in beans. Sprouting can significantly increase the levels of vitamins and minerals in beans, including vitamin C, folate, and iron. Sprouted beans often contain higher levels of antioxidants, which can help protect your cells from damage.

Best thing of all, bean sprouts are twice as versatile as unsprouted beans. Used in Pad Thais, Chow Mein, Spring rolls, Pho, stir-fried or tossed into salads, beans provide a variety of flavorful cooking opportunities.

Bean Sprout Production

Mungbean, a versatile legume, is widely cultivated in many developing nations. Its sprouts are a beloved vegetable in China and Southeast Asia, commonly incorporated into various dishes. The simple germination process for mungbean sprouts requires minimal resources, making it a sustainable and accessible agricultural practice.

Unlike traditional crop cultivation, Mungbean sprout production is not dependent on sunlight or soil. This allows for year-round production, regardless of seasonal fluctuations. The entire process can be completed in as little as 4 to 8 days, providing a rapid turnaround time.

The low cost of Mungbean sprout production makes it an attractive option for farmers and entrepreneurs. The only inputs required are Mungbean seeds, sprouting containers, and water. This affordability is particularly beneficial during times of crop failures or shortages of fresh produce, such as the hot, wet summer and rainy seasons in many regions.

September 17, 2024

Introduction

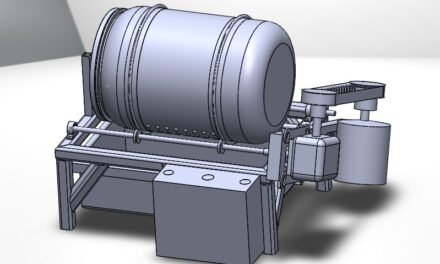

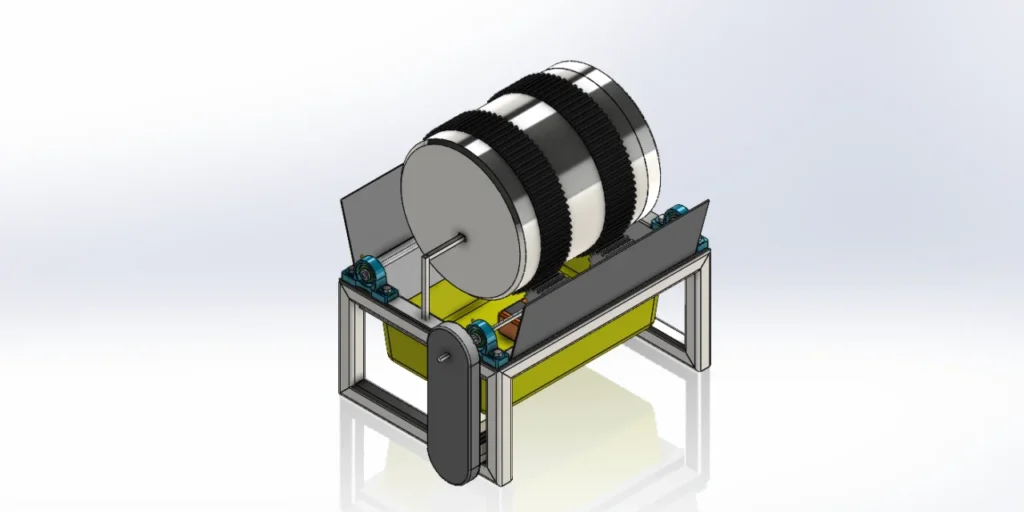

The Automatic Bean Sprouter is a mechanism for automatic irrigation and drainage for bean sprouting.

The Automatic Bean Sprouter at Vigyan Ashram, Grocubator V2 is a 2kg capacity Automatic Sprouter for sprouting mung beans, grams, kidney beans, etc. for the Vigyan Ashram Kitchen. This mechanism was designed and developed by Mr. Nachiket Adamane.

I took up this project as a part of my internship work at Vigyan Ashram. To start with the Empathy Phase of Design Thinking, I read all literature available at Vigyan Ashram on the Grocubator projects. The blogs created by the previous DIC members had detailed information on the design, development and testing of the Automatic Bean Sprouter Mechanism.

September 18, 2024

Grocubator: What is it?

The Grocubator is an Automatic Bean Sprouter at Vigyan Ashram. It works on the principle of a rotating drum mechanism which rotates and flips the bean sprouts to slowly drain the water from the sprouts.

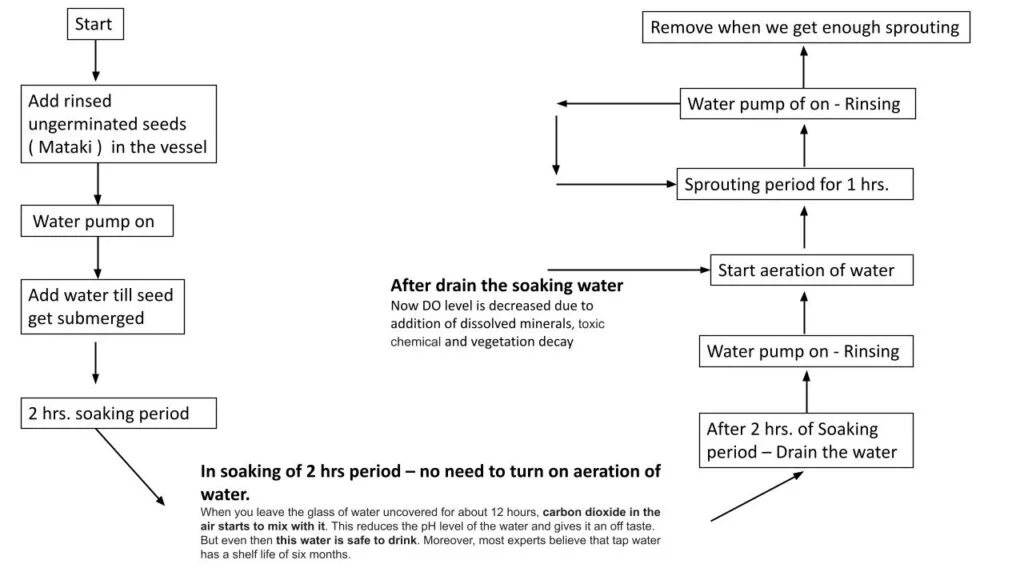

The Grocubator works on the following operational cycle:

By referring to the above process flow, the following sub-systems were identified :

- Driving system

- Sprouting Vessel system

- Water Recirculation system

The system has been successfully utilized for bean sprouting in kitchen at various occasions for beans weighing 2-3kg. The Grocubator is a significant improvement over the tedious and time-consuming traditional method of bean sprouting in kitchens.

September 21, 2024

Design parameters

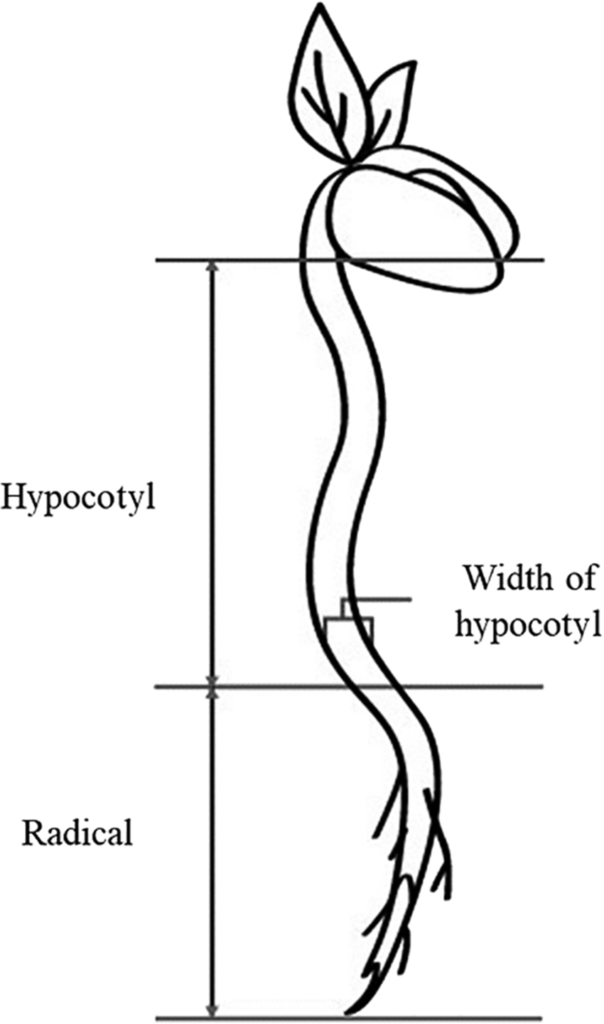

Germination of Mung Beans

The Average mung bean is 4mm thick and 6mm long. The Dry weight density of mung beans is 1200 kg/m3. Thus an average mung bean weighs 0.09 grams. Mung bean sprouting to commercial germination takes 72 hours regardless of the sprouting technique, given sufficient water is supplied for germination.

September 22, 2024

Design parameters

Key Performance Indicators

Key Performance Indicators for bean sprouting include:

- Sprout Yield: The sprout yield of the system depends on the soaking time, water consumption, Irrigation intervals and Humidity in the system.

- Water Consumption: The water consumption of the system is dependent on the amount of water supplied each irrigation cycle and the irrigation intervals.

- Water Volume: The volume of water required for full submersion of the beans throughout the sprouting process depends on the packing density of the beans, before and after sprouting.

- Sprout Quality: The physical and nutritional quality of the bean sprouts is of importance.

- Ease of Use: The ease of use of the system includes the ease in operation and cleaning of the mechanism.

September 24, 2024

Problem with the existing system?

Problem Identification

The existing mechanism for Bean Sprouter at Vigyan Ashram faces certain issues in operation which need to be fixed.

- Slippage of the timing belt results in operational failure of the system.

- The vessel is unable to stop rotating at the given angular position due to inertia.

- Motors unable to meet the dynamic torque requirement of the system.

- Lack of an external chamber for physical safety of the system.

The major issues in the Bean Sprouter pertain especially to the ineffective driving mechanism. Precision control of the driving mechanism allows for proper rinsing of the sprouts.

September 25, 2024

How are these problems related?

Problem Definition

The problems with the Automatic Bean Sprouter mechanism can be solved by relating each with their respective Subsystem and understanding the ways those Subsystems work and can be designed to overcome these problems.

- Driving system: The Driving system comprises of the Mechanical and Electronics drive system. The existing Mechanical drive system is a combination of belt drive and chain drive, driven by wiper motor. Meanwhile, the electronics drive system is a relay based control mechanism with an IR proximity sensor feedback loop.

- The belt used in the mechanical drive system often slips due to insufficient traction between the toothed belt and nylon rollers.

- The wiper motor used in the existing Sprouter has been unable to meet the high torque requirement of the system.

- The IR sensor is redundant at times due to it accidentally missing the mark on the rotating drum. The drum is unable to stop rotating at the given angular position due to inertia.

- Sprouting Vessel system: The Sprouting vessel used in the existing Sprouter is an Aluminum container obtained from the local market. The vessel has holes on a small portion of its surface allowing for aeration.

- The Sprouting Vessel is directly exposed causing water spillage

- Water Recirculation System: The Water Recirculation System consists of a simple plastic water container which acts as the sump and a 18watt submersible pump to recirculate the water. 4 liters/hr/kg of beans is supplied by use of the pump. The water consumption of the beans for required growth is met sufficiently.

- After some time the water becomes murky due to microbial growth.

September 28, 2024

Types of Soilless germination

Several existing automatic sprouting machines solve approach soilless germination in various ways. The three basic ways of soilless germination of beans are:

- Flood and Drain Hydroponics: This is a modern method adopted by hobbyists. In this method the beans are germinated in a grow bed either filled with media or water and the grow bed is flooded in fixed time intervals up to the desired level and then drained with the help of a bell siphon mechanism. This method does involves least mechanical parts and hence does not require precise control. The method is water efficient and when designed properly provides sufficient aeration by diffusion when water is supplied at a height from the surface.

- Sprinkler Irrigation: This is a popular method used in Mungbean Sprout Production. In this method, the Mungbeans are germinated in perforated trays and are irrigated with the help of sprinklers. The sprinklers operate for a set time period and up to specified air humidity levels. The water slowly drains from the topmost trays to the bottommost trays. This method requires precise control of the sprinklers for effective irrigation.

- Rotating Drum-Type Irrigation: This is modern method of sprout production pioneered by Murakami Farms, Japan in which the beans are constantly tumbled in a rotating drum which rotates slowly with the help of a gear drive system. This method allows for adequate aeration and prevents microbial growth. The existing Sprouter at Vigyan Ashram operates on a similar principle but instead uses periodic rinsing and draining cycles for irrigation.

October 01, 2024

What changes are to be made to the Sprouter?

Today, we had a brief discussion of the possible ways we can solve our problems in the Automatic Bean Sprouter. I presented my analysis of the Automatic Bean Sprouter project to Dr. Arun Dixit and also of the ways these problems are addressed in existing types of Bean Sprouters.

We went over all the different types of Sprouters and realized that ours, which provided the highest yield second only to sprinkler irrigation, was actually a combination of the two types; Flood and Drain Hydroponics Type and Rotating Drum Type. Arun Sir also presented a Sprouter previously developed by Vigyan Ashram which was a Sprinkler Irrigation Type. This Sprouter gave excellent yield but resulted in high CO2 diffusion in water.

We then realized that the current design provided sufficient degasification due to increased agitation of beans and hence was an overall better performing system. The main issue with our system lied in the driving system only and these issues can be addressed with help of an improved Driving System and Vessel System Design.

The needs of the Driving System:

- Higher Torque Motors.

- More Precise Rotation.

The needs of the Vessel System:

- Less Dynamic Torque

- External Chamber for Water Collection

October 02, 2024

Ideation!

The next stage in the Design Thinking process is that of Ideation, where we working simultaneously on the design of various possible approaches to solve the problems keeping in mind the needs of the system. For coming up with innovative ideas for our Automatic Bean Sprouter I used various strategies.

Brainstorming Techniques:

- Mind mapping: I started with a central Idea of “Automatic Bean Sprouter” and explored the various correlating concepts like Hydroponics, Aeroponics and Drip Irrigation. I also correlated the needs of the system to other mixing and drying machines.

Analogical Thinking

- Biomimicry: I looked at how nature solves similar problems. For example, how do plants regulate their water intake?

- Product analogy: I considered similar products that are used for agitation in similar size particle mixing like various Drum Rollers and Sievers used in pharmaceutical industry.

October 4, 2024

Analogous approaches for Water Draining-1

From my study of the various techniques used in industry I realized that for water draining in the Bean Sprouter there are various analogous approaches for agitation.

- Stationary Drum with rotating perforated blades: In this approach, the drum would have various perforated blades which by rotating about the drum’s central axis would regularly flip the beans. the drum would have a drain at the bottom for water. This approach is similar to that of sand Dryers, Composters and Agitators.

October 05, 2024

Analogous approaches for Water Draining-2

- Stationary Chamber with rotating perforated drum: In this approach, there would be a concentric inner perforated drum in the stationary chamber which by rotation would tumble the beans. Another approach used in washer dryers in cloth washing machines uses the same mechanism by a higher angular velocity and acceleration.

This could potentially drain the beans faster as the water is expelled by centrifugal forces but would require a more powerful motor. This approach is most similar to our current system

October 06, 2024

Analogous approaches for Water Draining-3

- Rotating Chamber with slits: Just as the previous approach this can be used for draining the water out of the bean irrigation chamber. This water can be guided through the channels to exit from a specific location beneath which the water container may be placed. This kind of Rotating Sprouter, developed by Sentrex “ISS Rota-Tech Rotary Drum” has been used in various Bean Spout Producers.

October 11, 2024

Back to the First Principle

I had a discussion with Dr. Arun Dixit Sir regarding the working principle of the Bean Sprouter through which I came to realize the actual biological mechanism which is the core function of the Automatic Bean Sprouter.

Aerobic Respiration of the bean plays a significant role in its growth before germination. Up till the growth of leaves on the bean stalk the bean is engaged in respiration where it inhales oxygen and exhales carbon dioxide. This forms the core of metabolic reactions in the bean which leads to germination. This also changes the nutrient profile of the beans and makes it easier for humans to digest the various nutrients in it.

As this process requires a lot of oxygen, germination is often better in aerated soil. A well aerated soil has 25% air in it of which 21% is oxygen, thus has >5% oxygen around the bean. Water on the other hand has a oxygen holding capacity of 14.6 mg/L at 0 °C and approximately 9.1, 8.3, and 7.0 mg/L at 20, 25, and 35 °C, which is 0.1% by volume. When using water as a medium the amount of oxygen required for respiration has to be supplemented by either diffusion or by direct contact with air.

Thus, in the Automatic Bean Sprouter through agitation water is dried from the surface of the beans exposing it to the atmospheric oxygen which is used by the bean for respiration improving the growth of bean sprouts. This is ultimately the first principle of the project.

October 20, 2024

Brainstorming new ideas!

On October 20, 2024 I has a very fruitful discussion with Dr. Arun Dixit and Mr. Prasad. We brainstormed together possible approaches to the Bean Sprouting and How these approaches can be Analyzed to select the best possible approach for building a solution or integrate a variety of these approaches into the solution.

These included but were not limited to various types of rotary and translational oscillations like Swaying, Rolling, Pitching of the bean sprouts to drain water.

So as discussed previously the first principle lies in exposing the bean to enough water around it’s surface for effective fertigation and allow for enough surface to be exposed to atmospheric oxygen for respiration. For soil based irrigation this usually means the creation of a well aerated soil mixture with the Volumetric proportion of soil, water and air are specifically 2:1:1.

On the other hand, when the surface of the beans are completely drenched in water, it doesn’t allow for enough respiration. And also causes the propagation of the anaerobic bacteria in the water. So the water needs to be drained periodically to expose the surface of the bean. Also, the water absorption rate as well as the respiration rate need to be considered while designing a new system.

October 23, 2024

Pros and cons of each approach

Irrigation Methods:

- Flooding: Water required for complete submersion of mung beans is found to be 550 mL/kg. The water consumed by the beans by absorption would need to be replenished by adding more water to maintain water level.

- Sprinkling: This would require only enough water for fertigation which is 250 mL/kg. As the water is drained completely when it flows away, this would require constant sprinkling.

- Flooding + Sprinkling: In this approach, the chamber would be first flooded with water to submerged the beans for required period and then would be drained and later irrigation would be done by sprinklers.

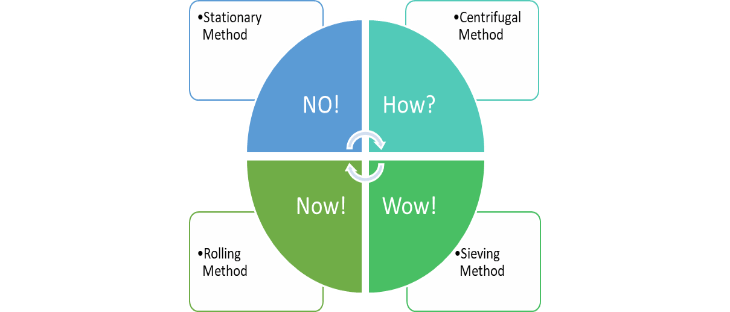

Draining methods:

- Existing Method: The chamber rotates 180 degrees to submerge and drain water, aiding fertigation, but is complex and has torque issues.

- Sieving Method: Water drains by moving sieves back and forth. Simple to operate and build with a four-bar linkage.

- Centrifugal Drying Method: Uses centrifugal force, like a washing machine dryer, to remove water. Effective but may damage bean sprouts.

- Stationary Draining Method: Common in commercial sprouting; easy to use but can harbor anaerobic bacteria due to low agitation.

Container Type:

- A Single Closed Chamber: A single chamber houses the entire load. This may have higher water retention and in turn also higher risk to microbial safety of the product. Simple and easy to fabricate.

- Vertical Stacks of Trays: Number of perforated trays can be used to store layers of bean sprouts of specific thickness. This allows for better water drainage but at the cost of increased complexity. Has scope for increased functionality due to the modular approach.

October 25, 2024

Selection Criteria

Points for Consideration:

Once an ideation session like brainstorming, brainwriting or cheatstorming has finished, it’s time to collect, categorize, refine and narrow down the best idea, solution or strategy. Points are decided for analyzing the suitability of Ideas. Some general points on which the suitability of the solution would depend are listed below based on their order of significance:

- Agitation (5 points)

- Ease of Operation (4 points)

- Ease of Fabrication (3 points)

- Complexity (2 points)

- Economy (1 point)

October 26, 2024

Funneling the Ideas through the First Principle

The First Principle that we had in mind while going into the project prioritizes the agitation of the bean sprouts to promote aeration for sufficient oxygen for cellular respiration of the mung beans.

What this means?

- This means that all ideas for a single closed chamber for sprouting would require a higher agitation.

- Also, all ideas for vertical stacks of trays would require more frequent irrigation.

- Opting for sprinkler irrigation reduces overall mass of water requiring less force for agitation.

- Stationary draining is assumed to be the worst possible solution as it has least agitation but may still work with vertical stacks of trays irrigated by sprinklers.

November 13, 2024

Evaluation of Ideas

Based on the points of Agitation, Ease of Operation, Ease of Fabrication, Complexity and Economy, the ideas for Irrigation, Draining and Container design would be evaluated for their suitability to be integrated into the solution.

- Draining Method:

| Ideas | Agitation | Ease of Operation | Ease of fabrication | Complexity | Economy |

| Existing Method | |||||

| Sieving Method | |||||

| Centrifugal Drying Method | |||||

| Stationary Draining Method |

November 17, 2024

Selection of Idea

- Convergence

First we converge the set of best ideas to form best possible solutions. In this way we get a clearer picture of the feasibility of the idea to be integrated into the solution. e.g. Single Chamber Sprouter with Sprinkler irrigation and sieving method of draining.

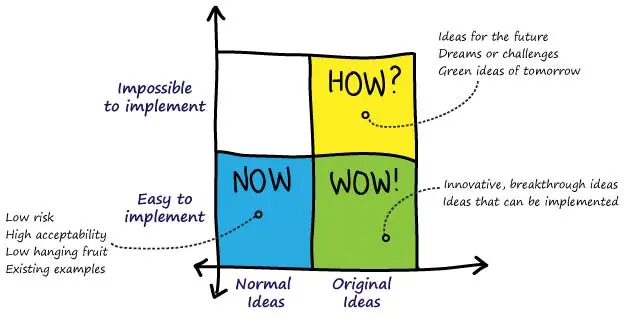

- Now! Wow! How? Matrix

For the selection of ideas for the design of the Sprouter I have used a technique which judges the suitability of the idea based on how it can be implemented in our solution. This approach is called the “Now! Wow! How?” approach of Idea selection. In this the idea is judged on the basic of it’s originality as well as how easy it is to implement for easier decision making.

November 18, 2024

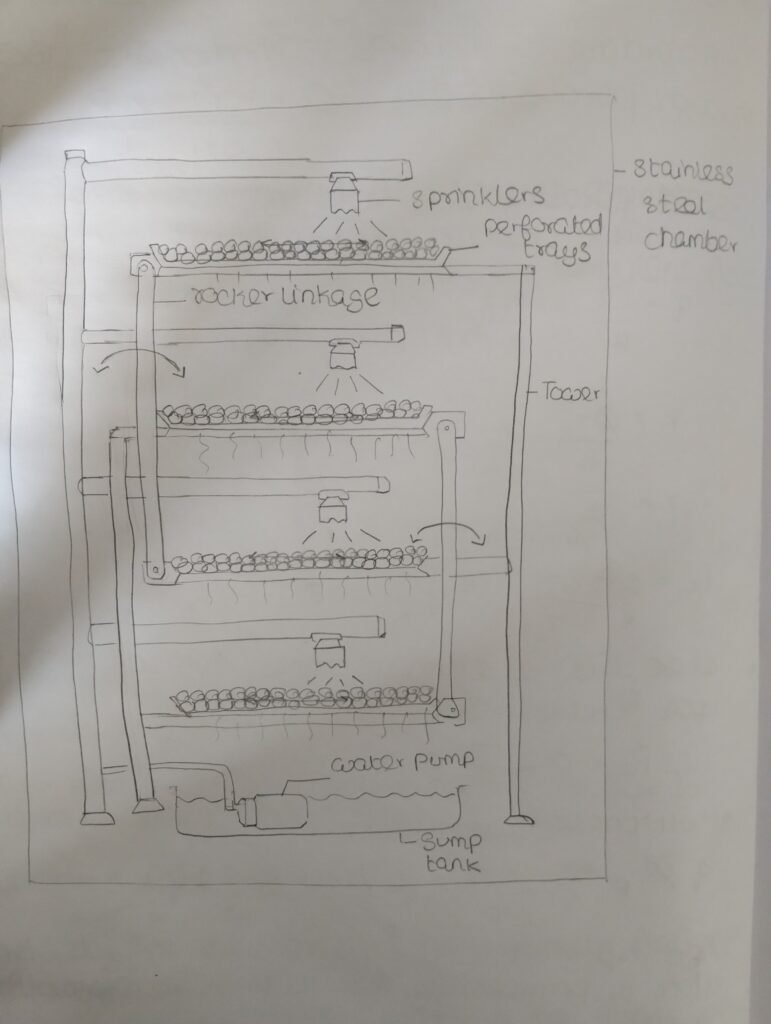

Converged Idea

Upon Discussion and Evaluation of the ideas we converged on the idea of a Multistage Sieve Tray Tower Design which utilizes sprinklers for irrigation and Sieve Draining for Drainage of the Water. The Results of the evaluation can be viewed over here : https://docs.google.com/spreadsheets/d/16PLn-OYFnMn92wWofWPJEzMzQzh7X5hc/edit?usp=sharing&ouid=106425719235086437898&rtpof=true&sd=true

December 03, 2024

Design Components

The Main Parameters or Steps for the Design of the Bean Sprouter were then decided to be as follows:

- Determining System Capacity:

- Objective: Design the system to handle a specific dry bean weight, such as 2.5 kg of mung beans.

- Process:

- Account for water absorption, where the beans expand to 1.5-2 times their original size.

- Calculate the total volume of the soaked beans to determine the tray dimensions and number of trays required.

- Designing the Sieve Trays

- Objective: Create perforated trays that allow effective water retention and drainage.

- Process:

- Determine the Number of Trays required.

- Determine the tray area based on the bean volume and desired layer thickness.

- Use Darcy’s Law to calculate the optimal perforation size, density, and distribution for controlled water drainage over a specific time (e.g., 2 hours).

- Test prototypes to validate performance and make adjustments for better water flow and structural integrity

- Designing the Vibratory Mechanism

- Objective: Enable effective secondary drainage using controlled vibrations.

- Process:

- Choose between a linear electromagnetic vibrator or an unbalanced vibration motor based on power requirements, ease of implementation, and cost.

- Calculate the required vibration frequency and amplitude to drain water effectively without disturbing the beans.

- Design the vibration system to minimize noise and ensure stability using dampers or isolators.

- Designing the Tower and Outer Chamber

- Objective: Provide a stable and hygienic structure that integrates all system components.

- Process:

- Determine the tower height based on the number of trays, tray spacing, and irrigation mechanisms.

- Design the outer chamber to protect the system from contamination while offering user-friendly features like clear panels, removable parts, and easy cleaning mechanisms.

- Incorporate drainage systems to redirect excess water efficiently.

- Automation and Control

- Objective: Automate water irrigation, soaking, and vibration cycles for a hassle-free experience.

- Process:

- Use a microcontroller (e.g., ESP32) to program cycles for water sprinkling, soaking, and vibration.

- Integrate sensors to monitor water levels, flow rates, and system performance, ensuring optimal operation without manual intervention.

December 05, 2024

Determining System Capacity

To design an efficient bean sprouting system, we must understand how the sprouting process impacts the mass and volume of beans. Since the system is designed for 2.5 kg of dry mung beans, the capacity of the system and its components, such as the sieve trays and container, needs to accommodate the growth in both mass and volume during the 24-hour sprouting process. Here’s how we determine the required system capacity step-by-step:

Step1 Initial parameters: Since, the actual density of Mungbeans is 1200 kg/m3 or 1.2 kg/liter. and the packing density of the beans is assumed to be 60% upon loading.

Step 2 Mass of beans: Since there is observed to be a trend of 10% water absorption per hour per kg of initial weight of the beans and subsequent increase in the mass and volume of the beans during the sprouting process, during the 24 hour window of bean sprouting we can assume a 240%. Thus the Mass of the beans after sprouting for 24 hours is 340% the original mass.

December 06, 2024

Determining System Capacity

Step 3 Mass and Volume after Sprouting: Change in Volume due to water absorption is accompanied by a slight decrease in density as the water absorbed has a density of 1000 kg/m3, the overall density of the sprouted beans thus falls to approximately 1050 kg/m3 also as the shape of the beans changes the packing density is expected to decrease to 40%. Thus for a 2.5 kg initial mass the final mass is found to be 8.5 kg, which equates to a volume of 8.1 liters of volume occupied by the sprouted beans in the container.

Step 4 The Overall Volume: This needs to account for the 40% packing density or 60% void space which would be filled by water for submersing the beans and also it needs to take into account a factor of safety of 1.5. This gives us a volumetric capacity of approximately 30 Liters.

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Dry Bean Weight | Mdry | 2.5 | kg |

| Final Bean Weight | Msprouted | 8.5 | kg |

| Bean Density (Dry) | ρdry | 1200 | kg/m³ |

| Bean Density (Sprouted) | ρsprouted | 1050 | kg/m³ |

| Packing Density (Initial) | Pinitial | 0.6 | — |

| Packing Density (Final) | Pfinal | 0.4 | __ |

| Final Volume (Sprouted) | Vsprouted | 8.1 | liters |

| Factor of safety | FoS | 1.5 | __ |

| Total System Volume | Vsystem | 30 | liters |

December 07, 2024

Designing the Sieve Trays

The Design of the Sieve Trays has essentially two parameters, a) the height of Trays and b) the Percentage Open Surface Area of the Trays. The Height of the trays can be simply determined as the volume of the tray divided by the desired area of the tray.

To determine the area of the Trays I observed everyday flat vessel objects like Plates, Refrigerator Chiller Trays, Oven Trays, etc. and notice that an area between 0.0.6 m2 to 0.15 m2 was the optimal while also being easiest to carry when the length to breadth ratio was <2.

Thus, for our Sieve Tray Design we determined the tray dimensions to be 0.5 x 0.25 m2 or 0.125 m2. The number of trays was determined to be 4 which gives a tray volume of 7.5 liters or 0.0075 m3.

Thus, the height of the tray is determined to be 0.06 m.

To determine the Percentage Open Surface Area of the Trays:

We know that, A(hole) = pi *r^2

Thus, A(hole) = 3.14 * 10^-6 m2

where, r = radius of hole is assumed as 1mm

By Torricelli’s Law, Q(hole) = Cd * A(hole) * sqrt (2*g*h)

where, Cd = coefficient of discharge is assumed to be 0.6

A(hole) = 3.14 * 10^-6 m2

g = 9.81 m/s2

h = 0.06 m

Thus, Q(hole) = 2.04 * 10^-6 m3/s

For draining the net volume of 2.975 liters of water in 1 minute we would require approx. 24 holes.

Which gives us a Percentage Open Surface Area of 0.06 %.

Some water may still be trapped in pores between the beans which can be drained by slight vibrations.

December 08, 2024

Designing the Vibratory Mechanism

After researching the Vibratory requirements for sieving and dewatering various food products it is understood that there exists mainly two types of vibratory drives:

- Direct Drive: A direct drive mechanism is one which creates oscillatory motion in the sieve screens by use of an unbalanced electromechanical device like an eccentric motor or an electromagnetic actuator. This is mostly used for vibrating tables used for concrete sieving or setting of cement or clay molds. Also, this kind of drive is used in dewatering various washed food products for speeding up the drying process. This is a quite and effective way for dewatering substances. It has a low amplitude but a higher frequency of vibration. The amplitude can be increased by adding a driven shaft with unbalanced weights.

- Four Bar Linkage: A four bar linkage of the slider crank formation can be used where the linearly oscillating screen acts as the slider. This mechanism is highly effective for sieving products with high viscosity or for materials which require high jerk for removing stuck impurities. The mechanism has a higher rate of wear and can be extremely noisy due to the moving parts.

It was seen that a direct drive mechanism like an eccentric mass motor can be used to create vibrations in sieving trays for effective draining. This allows for a simple and effective design of the vibratory mechanism which is easy to operate and maintain as well.