Work shop machine

1. Portable Grinder / Hand Grinder

2. About Portable Grinder

A grinding machine is the grinding or cutting of a metal workpiece by means of a rotating friction wheel that acts as a tool. It is mostly used for grinding or cutting workpieces for greater surface quality, size, and casing accuracy. Mostly, it serves as a finishing function as it is very small in size of bur (chips) 0.25 – 0.5 mm. Removes material

Features

Grinding Wheel : For Grinding

Flap Disc : For Finishing

Cutting wheel: for cutting

Wire wheel: for cleaning

3. About Chop saw

Chop saw wheels are power tools used to cut materials like metal, tiles, concrete etc. These are also known as grinding wheels, cut off wheels and abrasive saws.

It is used for cutting large size structural steel.

Useful for cutting large quantities.

4. Bench Grinder

It is used in the process of grinding iron, if a wheel is attached to it, then it works to remove any iron, metal-based material. Iron is used for grinding and sharpening.

5. Portable Drilling Machine:

Portable Drilling Machine This is a small size drilling machine, which can be easily carried to the workplace for drilling under various conditions. This machine is used for very heavy equipment, which is not possible to take to the machine shop.

Used for drilling holes in iron, RCC, wood, plastic etc.

6. Column Drilling Machine:

Column type drilling machine is a heavy duty drilling machine for drilling large and deep holes. Automatic fit can be given to this machine. This machine consists of a strong rectangular column. On which a carriage is fitted, this carriage is fitted with automatic feed levers.

This machine is used for making holes,

Used for drilling on larger workpieces and on larger scales.

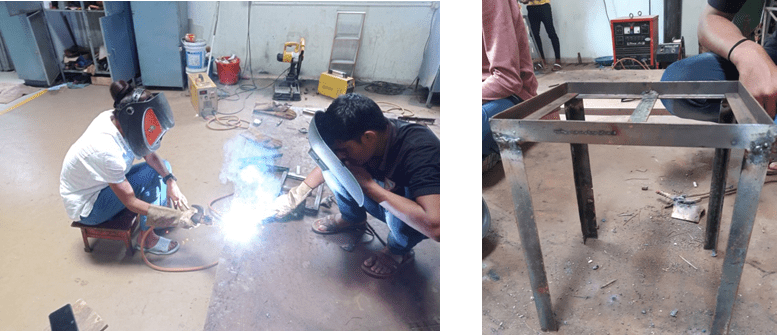

Arc Welding Machine:-

In this type of welding, with the help of electricity, the electric arc is melted at the welding point between the electrode and the base material. So that the electric arc melts and attaches to the welding point and later the molten metal becomes stronger when it cools.

7. lathe machine

A lathe machine is a machine tool that is used to produce objects with a symmetrical design. In this, the metal body keeps rotating on one axis and it is given proper form by applying tools for cutting, piercing and other operations on it as required.(Wikipedia)

PRACTICE

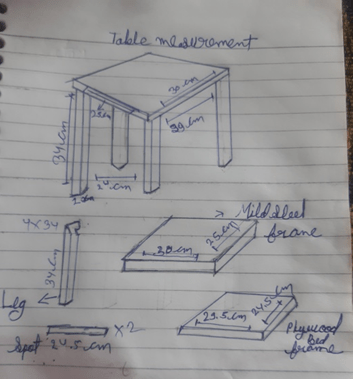

Process flow diagram (Sketches)

Cut mild steel with a chop saw and prepare 4 legs by 12 inches

Making a frame using mild steel

Cleaning Legs and Frame Using Bench and Hand Grinder(for welding)

Hole in frame

(to set the plywood bed to the frame)

Attaching the legs to the frame by welding

Measure Plywood and Cut with Wood Cutter

Set the Plywood Frame to the Table

Final Table