Modular design, or “modularity in design”, is an approach that subdivides a system into smaller parts that can be independently created and then used in different systems to drive multiple functionalities. With modular designs that can be tessellated into patterns you could alter your wardrobe on the go. So, let’s go to design…

The Design

Coming up with a simple design that can be laser cut and endlessly repeated in different sizes and combinations can be tricky.

I started to experimenting with circular designs . My favorite is based on bags and shape of bags. I made different design in different way and shape.

Once design in Corel Draw, I laser cut paper samples to check the durability of the interlock and if it was possible to combine different dimensions of the same design to a fabric structure.

Advantages of this design

The great thing about this design is that;

- By having the male and female shapes on opposite sides, both shapes can fold up and connect to itself.

- Having slots enables you to not only connect one but multiple male and female to tie up.

- By weaving parts through the 2 parts in the middle of the design, different layers and rows of modules can interlock and tie up — as garments made out of this module do not require sewing

Production & Assembling the Modules

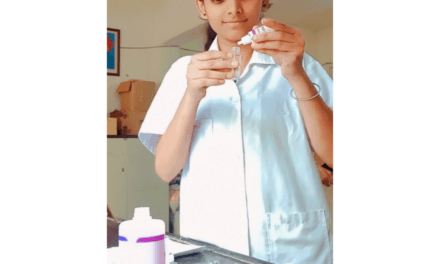

All pieces were cut by the laser cutter

Settings:

Paper Test

Power: 25 | Speed: 100

Cotton silk

Power: 30 | Speed: 100

Before I start mixing and matching different sizes of the module I created a kind of web interlocking different rows and checked its resistance to pulling and stretching.

The interlock can stand normal slight pulling and stretching the more pieces are connected the more the movement within the slots supports the pieces that are directly being pulled.

To know about more projects please see – https://class.textile-academy.org/2019/harshada.raut/assignments/week03/