To understand Ragi Flour Roaster and Help Intern to make it operative

Posted by AMOL KHAMKAR on 17 JUN 2018EDIT

Problem Identification –

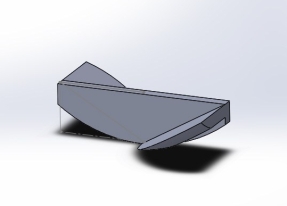

As a solution to the problem of roasting Ragi (Nachani) flour, Intern Komal Pund designed and fabricated stirrer. This stirrer works well but there was problem related to scrapping the flour completely from the surface of Vessel( Kadhai). The stirrer profile is made as following.

Fig.1 Stirrer Profile CAD image

Fig. 2 Actual Prototype Model

The nature of assignment given to me is to help Komal in making the model which can overcome the current issues and try it to check at different parameters like –

- Maximum roasting capacity ( quantity of flour)

- Time required to roast the flour at different capacities

- Mixing of the flour( to check by taking flour appearing in two colors)

“As described above the scrapping of the flour at the surface of kadai was not happening well was a main issue to solve for us”.

Actions Taken –

- As we started to think on the above mentioned problem we understood one thing that is, while stirrer rotates there was uneven contact between the stirrer profile edge and the surface of kadai. -To overcome this problem we adjust the clearance between stirrer and surface but the stirrer was stuck and motor stopped.

After above experience we got an idea of using flexible strip like material at the stirrer blade profile edge.

2. So we check the various materials for there temperature sensitivity or temperature resisting property.

We get Aluminium foil which is food grade material and also can work in the hot material like flour.

We made the strips of Aluminium foil by folding them to get sufficient stiffness. Then by using Fevicol we paste the Strips of Aluminium foil to the stirrer edge on both sides.

Trial 1 –

We perform a trial for Nachani flour.

– In this trial we get improved results than previous trials.

– One problem we found was, the roasting at the bottom centre was not happening well.

– By removing Aluminium foil Layers from half blade profile we taken second trial.

Trial 2 –

We perform a trial for Nachani flour.

– In this trial we got good results as we required.

Trial 3 –

This trial we have taken using Bhusa with two different colors to check the stirrer results for mixing.

The mixing was really good.

Trial 4 –

This trial we have taken for roasting Suji.

This trial was resulted well.

Trial 5 –

In these trial we roasted the peanuts.

Peanuts were roasted properly.

Conclusion –

- The prototype model performed well for approx. upto 500 gm capacity.

- We can improve its capacity by using high torque motor.

- We can improve its ease of handling.

“Now currently I am working on the system of Nachani/ Besan ladoo flour roasting which will be of 2 to 3 kg capacity batch process roasting and can be considerable as a product……….”