Objective:

The objective

Procedure:

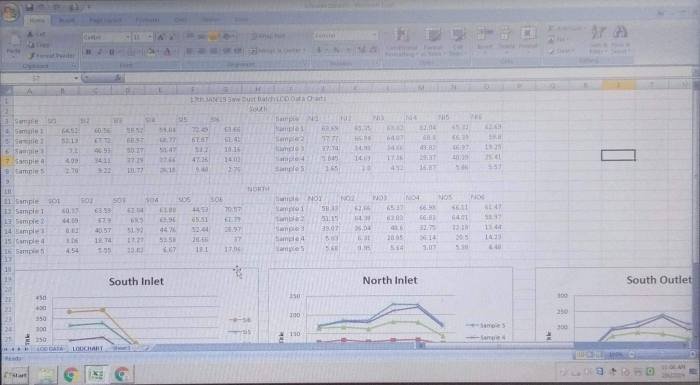

This batch started on 17th JAN’19. The procedure followed as follows,

- I had taken 3 of.5 kg sawdust.

- I mixed 11-liter water in sawdust.

- I kept the mixture as it is for half an hour.

- After that, I did the weight of it.

- I took 10 gm sample for LOD.

- After I had evenly distributed wet sawdust on each plate.

- As follows, Plate One- 1 kg, Plate Two- 1.5 kg, Plate Three- 2 kg, Plate Four- 2.4 kg, Plate Five-2.6 kg, Plate Six- 2.6 kg.

- I noted down the time when the batch was loaded.

- I took samples from the south side and north side after every six

hour from batch loaded.

Conclusion:

Shubham added support to open dome dryer easily. After batch unloaded I processed data and I got drying patterns which show sawdust is dried in 40 hours. 16 hour

Next Plan:

Plates were very heavy so next plan is to minimize plate weight.