Work done:-

![IMG_20180222_181106[1]](https://madhurivishnugadhe.files.wordpress.com/2018/03/img_20180222_1811061-e1521630383810.jpg?w=300&h=258)

1.Before make a perforared tray prototype draw a design in solid work.

2.After solid work desing start work making prototype of perforated tray.

3.First prototype make the Iron flat plate 3 mm thickness and 17 mm width.

4.Cut 975 mm distance four species of Iron flat plate with help of hand grander machine.

![IMG_20180224_121434[1]](https://madhurivishnugadhe.files.wordpress.com/2018/03/img_20180224_1214341-e1521632205290.jpg?w=293&h=300)

5. To support for metal mesh joining the one species middle of frame.

6.Weld four species 975 mm distance using the arc welding accurate making the frame using L-angle.

7. Middle Iron flat plate for support metal mesh join by arc welding.

8.Fix the metal mesh on tray frame join by welding.

9.But tray are heavy as compared to solids tray.

10.Tray is completed.

![IMG_20180208_160754[1]](https://madhurivishnugadhe.files.wordpress.com/2018/03/img_20180208_1607541-e1521632561317.jpg?w=300&h=276)

11.Not select these tray idea for making perforated tray.

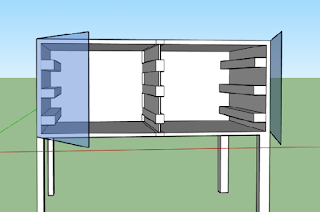

12.Another idea of making perforated tray used M.S.Square Pipe tube for make sqaure frame and support the PPE Mesh use the middle Iron flat plate 3 vertical and 3 horizontal.

Work done:-

1.Before make a perforared tray prototype draw a design in solid work.IMG_20180222_181106[1]2.After solid work desing start work making prototype of perforated tray.

3.First prototype make the Iron flat plate 3 mm thickness and 17 mm width.

4.Cut 975 mm distance four species of Iron flat plate with help of hand grander machine.

IMG_20180224_121434[1]5.To support for metal mesh joining the one species middle of frame.

6.Weld four species 975 mm distance using the arc welding accurate making the frame using L-angle.

- Middle Iron flat plate for support metal mesh join by arc welding.

8.Fix the metal mesh on tray frame join by welding.

9.But tray are heavy as compared to solids tray.

10.Tray is completed.

IMG_20180208_160754[1]11.Not select these tray idea for making perforated tray.

12.Another idea of making perforated tray used M.S.Square Pipe tube for make sqaure frame and support the PPE Mesh use the middle Iron flat plate 3 vertical and 3 horizontal.

13.M.S. Square Pipe tube cut by angle 45 on angle cutter.IMG_20180301_145616[1]14.Iron flat plate 3mm thickness and 12 mm width selected.

15.Iron flat plate cutting done by hand grander machine.

IMG_20180224_121434[1] IMG_20180301_092554[1]

16.Fix the PPE Mesh on frame of tray with help of self lock screw .

17.These tray are light weight as compared to solid tray.

18.These tray idea are selected.

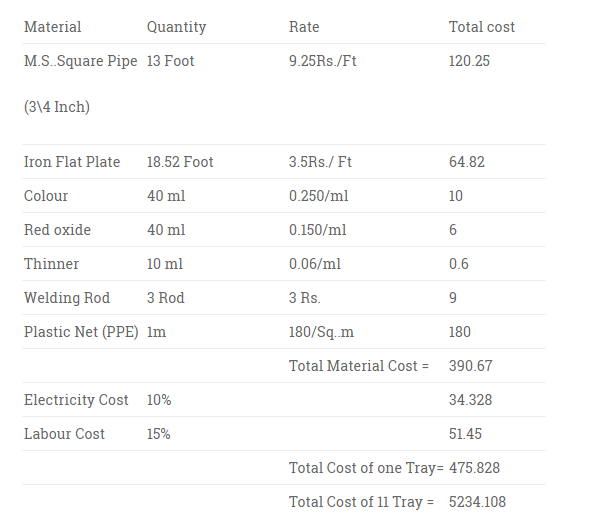

- Calculate the cost one tray and finally calculate total cost of 11 tray perforated tray.

or make sqaure frame and support the PPE Mesh use the middle Iron flat plate 3 vertical and 3 horizontal.

![IMG_20180301_145616[1]](https://madhurivishnugadhe.files.wordpress.com/2018/03/img_20180301_14561611-e1521097284387.jpg?w=300&h=208)

13.M.S. Square Pipe tube cut by angle 45 on angle cutter.14.Iron flat plate 3mm thickness and 12 mm width selected.

15.Iron flat plate cutting done by hand grinder machine.

![IMG_20180224_121434[1]](https://madhurivishnugadhe.files.wordpress.com/2018/03/img_20180224_1214341-e1521632205290.jpg?w=306&h=314)

![IMG_20180301_092554[1]](https://madhurivishnugadhe.files.wordpress.com/2018/03/img_20180301_0925541-e1521632787530.jpg?w=342&h=314)

16.Fix the PPE Mesh on frame of tray with help of self lock screw .

17.These tray are light weight as compared to solid tray.

18.These tray idea are selected.

19. Calculate the cost one tray and finally calculate total cost of 11 tray perforated tray.