Definition/ Concept

Dome dryer is a hemisphere lying on ground enclosing volume which is used as a drying chamber. It has an exhaust fan at its apex and inlet vents on spherical surface at determined positions. The spherical surface of the dome is the solar heat absorber surface to capture maximum solar energy. Unlike other solar drying equipment available in the market, Dome Dryer V2 is opaque and only allows heat inside. Air flows in the dome are designed so as to maximize contact with the food product. It is designed to have higher capacity in order to increase throughput. Being a sphere construction cost of the dryer has also reduced.

Design Procedure

Shape Selection

The shape and geometry of any solar dryer have a crucial effect on working parameters such as throughput and cycle time. The major contributing factor in the design of a solar dryer is Average Exposed Surface Area [AESA] to sunlight during the day time and Volume Load Capacity [VLC]. Also, factors like Cost of Construction, Fluid Dynamics, Structural Stability are significant.

Table 1 shows comparisons of such these factors on the performance and selection of shape for the dryer.

Here is some study was done for shape selection of Dome Dryer 2.0. Click the link below for a comparison of the Projected area of different shape normal to the sun at different time intervals in a day.

https://drive.google.com/open?id=0B3ElqgKr9ynBQUJlcHBJZ1NuZ3J4VkkwbnI4blQ1LW5mbnBr

These are the condition and details about the calculation

S1; S2; S3; S4; S5 are the position of the sun on the track from east to west. I assume the surface area which is supposed to face the sun at these specific positions during day time. The Different positions (orientations) of Shapes have been mentions with the dimensions. I have not considered the base area or bottom area.

According to the above analysis, hemisphere has the highest score in importance matrix hence we selected it as the shape for a dryer.

Higher energy capture

An advantage of a hemisphere is it has a maximum average exposed surface area to the sun during the day time. By calculation for a Hemisphere resting in the ground on its plane face, the AESA is 70% of its total surface area. Which is higher compared to other competing shapes.

Higher Volumetric Capacity

It also gives the maximum Volumetric loading capacity as it has maximum volume occupied for a given surface area. This allows us to process bulk quantities in similar cycle times. This increases the throughput of the system

Cost wise Advantage

The Construction cost of the dome dryer is also less as less material is required to enclosed design volume.

Fluid Dynamic advantage

Since the dome has radial symmetry around its axis the chances of formation of inactive pockets in air flow are very less. The design of the dome dryer includes a central duct which is connected to the exhaust. The dome is radially symmetric about this duct hence the there is no pocket formation in the dome.

Below Table 2 shows a comparison between airflows inside Dome Dryer V1 and a Tunnel dryer

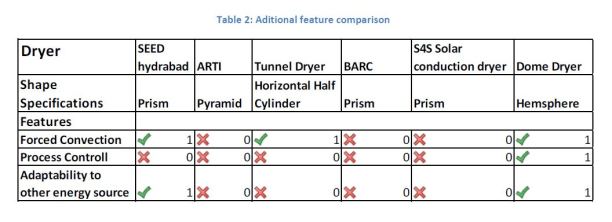

Additional features comparison with Market ready Dryers

Process Control

Process parameter control has a crucial effect on product quality. In dome dryer V2 we have used an IR temperature sensor to sense the temperature of a substrate and with respect control the fan to reduce or increase temperature. The temperature of a substrate while drying has a key effect on the quality of drying. Controlling the temperature of a product helps in restoring heat sensitive content in food such as essential oils and vitamins. This was achieved in Dome Dryer V1 where we were able to maintain fragrance of Pudina, the temperature was regulated below 50 degree Celsius using a temperature sensor and controlling fan on and off frequency.

Air Flow Method

Method of air flow generation, in terms of Natural convection or forced convection, has a contributing role in determining throughput and cycle-time of a dryer. Dome dryer has an exhaust fan to generate forced convection current. It is also part of the process control system.

Adaptability to other energy sources

Since the performance and working on solar dryer completely depend on climatic conditions. The design of dome dryer includes a facility to be connected to an external energy source for heating process air. Thus we achieve drying in unfavorable conditions such as cloudy weather.

An advantage of an opaque dryer

The dome dryer has a black surface from inside and radiating surface inside. Thus it has the advantage of using all the heat including visible light for drying purpose.