Introduction:

India, the world’s most populous democracy, has struggled with establishing Emergency Medical Service (EMS) for all sections of society. Fortunately, in recent years, the emergency medical service scenario in urban India has undergone a major transformation and there are now innumerable hospitals, responsive ambulance services, and improved medical facilities available in metropolitan India.

When it comes to healthcare in rural India however, there remain considerable challenges to setting up robust emergency medical services. With more than 70% of the country’s population living in rural areas, the lack of access to these basic facilities have proven to be disastrous. The main challenges to the rural healthcare sector are low quality of care, poor accountability, lack of awareness, limited access to facilities, limited manpower, and reluctant community participation. Additionally, 7% of children under 5 years of age die due to multiple ailments as a result of being underweight. Sanitation is a major concern in rural India and the population needs to be educated appropriately on the need for proper waste disposal facilities and their benefits in terms of health and hygiene. India, when compared to developed countries which have proper emergency systems in place, has no single system which could play a major part in dealing with emergency medical services. While the rural areas have been developing gradually, there needs to be more movement in terms of the infrastructural facilities, increase in the number hospitals, sanitation facilities, etc.There is a severe need to educate the rural inhabitants on the importance of medical services and their rights access them.

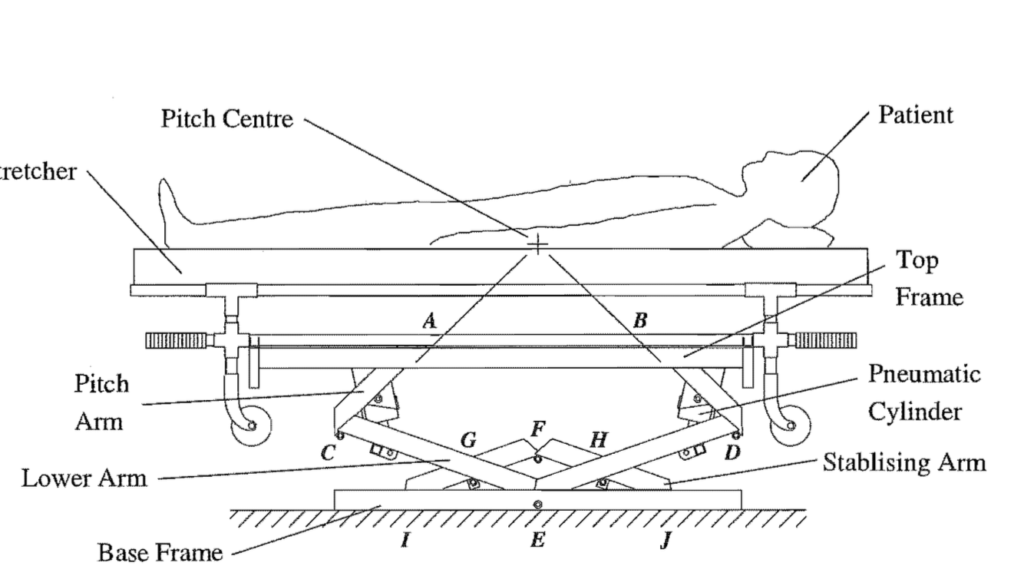

This system work pneumatically. Pneumatic is all about using compressed air to do the work, compressed air is the air from the atmosphere which is reduced in volume by compression thus increasing its pressure. It is used as a working medium normally at a pressure of 6 kg/ sq mm to 8 kg/sq mm. For using pneumatic system , maximum force up to 50 KN can developed.

Keywords: Proof of Concept Stretcher Platform – POCSP , Prototype Stretcher Platform – PSP , Bill of Material-BOM, Prototype Three Wheeler Ambulance – PTWA .

Problem definition:

1] Exist situation of PSP in disassembled condition.

2] Vibrations occurs in PSP.

3] No take any actual trial on vehicles.

4] Design is not proper as per Indian standards.

Objectives of Project:

1] Understand & take over the design & operation of the POCSP .

2] Draw a 3D model & detailed drawings of PSP using Solidworks or other equivalent CAD software.

3] Design the PSP as per standard dimensions.

4] Manufacture the PSP as per Indian ambulance standard dimensions.

5] Carry out field tests using suitable hired vehicle.

6] Based on observations & feedback from field tests, carry out necessary modifications in the PSP and repeat the Field tests.

7] Vibration isolation.

Plan of action:

1st Meeting Outcomes ( 7 Feb. 2020) :

- To know availability of equipment like compressor, pneumatic fittings in Vigyan Ashram, if it is not then contact to Mr. Lalla and get as early as possible.

- Works on Vibration Isolation in first phase which are maintain 0- 1.5 Hz continuous vibration frequency.

- To works under constrain of maximum load on stretcher is 50-70 kg, for bed lifting required pressure is 8 bar.

2nd Meeting Outcome(6 March 2020):

- At the time of assembly there are many problems occured as :

– Used bush not functoing properly .

– All linkages are not align properly.

– C.G ( Center of Gravity) is not good.

– At the starting rohit said for assemble complete parts it requires 1/2 hour but in actual conditon, it takes 4 hours to assemble.

At the time of assembly I found some problems , which is necessary to sort out it before the further action .

- Assume , I think some work is required on literature and Design of PSP and it take some more time.

- We require all the drawings and related data regarding this project.

The PSP received by Vigyan Ashram on 12 March 2020.

Line of Action [Plan for May]:

Assuming that the market will start on 3rd may 2020 then,

5th May – Purchase of Pneumatic hose and bushes.

6 & 7th May – Machine work on bush and maintenance of compressor in VA which is not working conditions.

8th May – Arrangement of all equipment for 1st trial.

9th May – 1st trail on the vehicle.

Current working Plan:

Part A: Vibration Isolation ( Frequency 0.3 HZ and weight 50 kg)

– To select perfect vibration isolator for PSP like i)Air isolator

ii) PU Buffer isolator iii) Tube tyre isolator

– Enquiry of various isolators

– Think about various ideas of vibration isolators

Part B : Manufacturing Design ( Without any changes in dimensions )

– Design the PSP comparing with Indian standards

– Modification and improvement in existing design ( select appropriate sections like -Box, T-angle, Channel etc.)

– Draw 3D design and finalize the design of the stretcher.

– Work on literature.

Proposed Design:

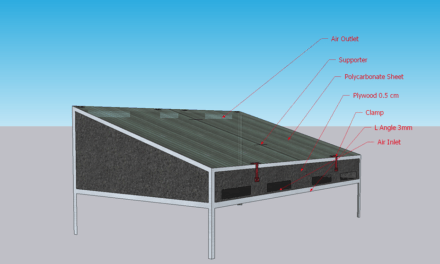

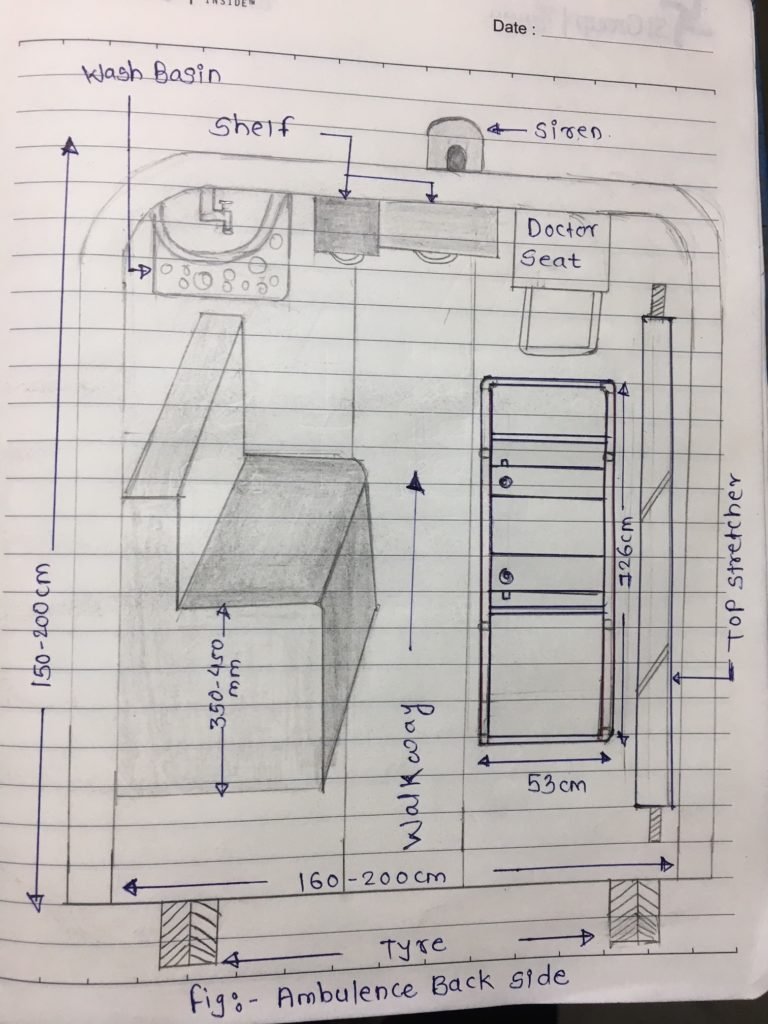

Proposed ambulance design:

This is the standard dimensions of Indian ambulance which is used as per government norms.

Concept Based design :

Indian Standard Dimensions Regarding Ambulance:

Dimensions of patient cabin:

Length: 3200 mm , Width: 1600 mm , Height: 1700 mm , Ground Clearance : 190 mm , GVW: 3.0 T .

Dimensions of stretcher :

Length : 2000 – 2100 mm , Width : 600 – 700 mm , Height: 800 – 900 mm .

Dimensions of TOP Stretcher:

Length: 2200 – 2300 mm , Width : 450- 500 mm , Height: 60-65 mm .

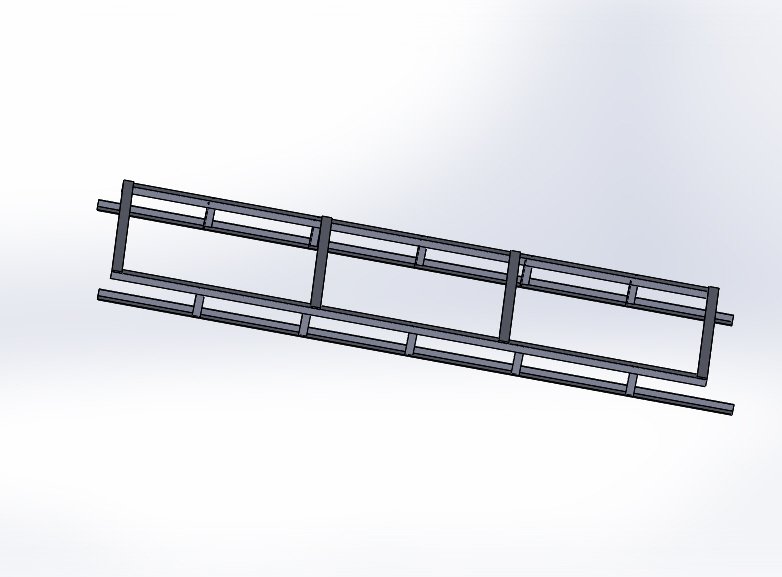

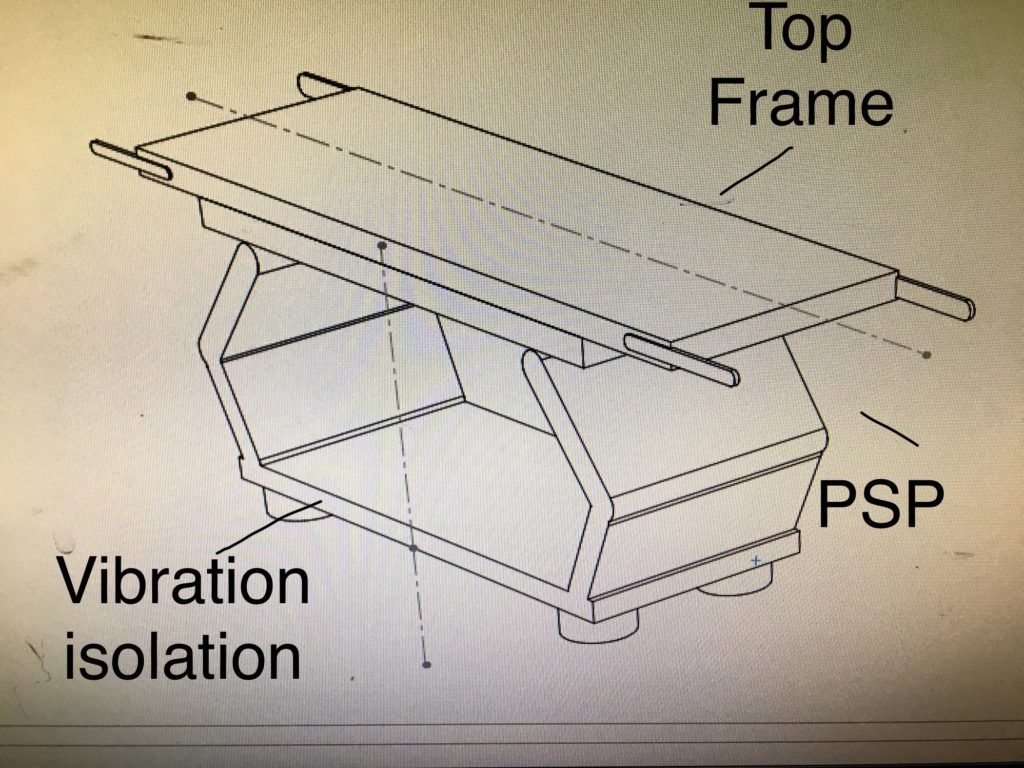

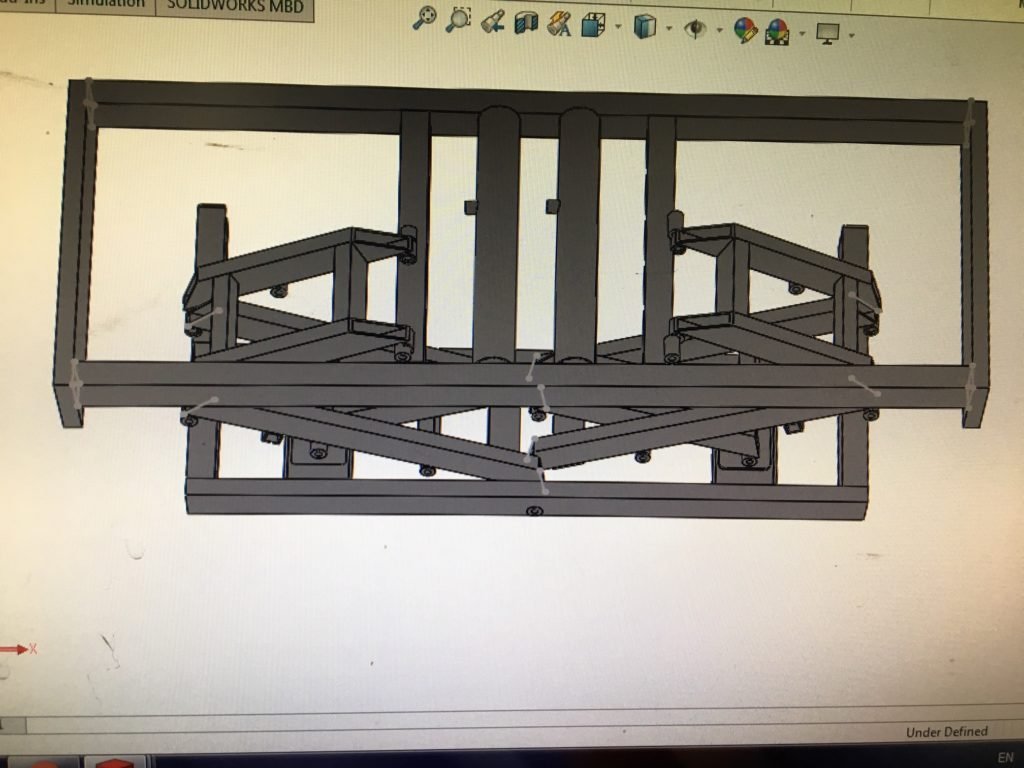

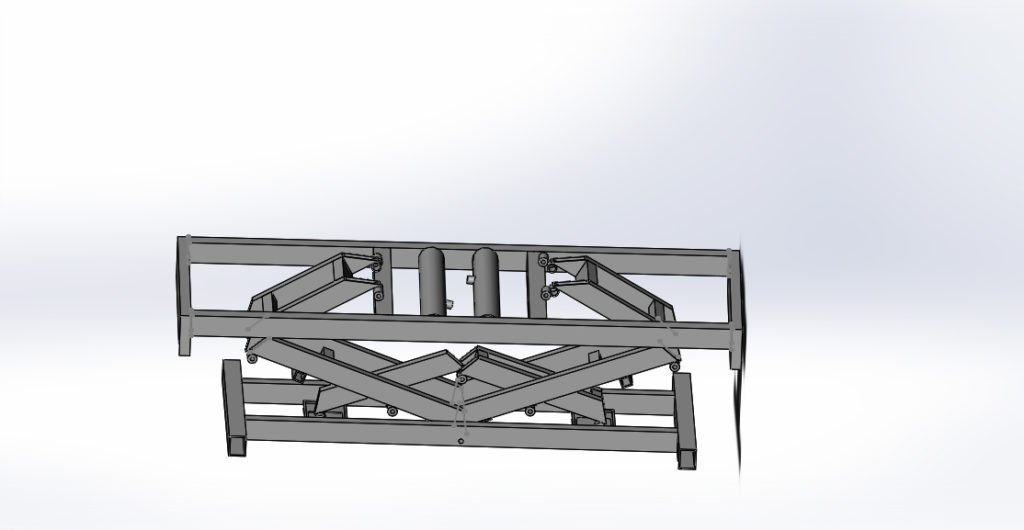

3D Design of PSP (Offset Assembly):

The above 3D design reconstruct / rebuild as per changes with the help of pdf drawing , which was given by SMD systems.In existing PSP there is a offset in top frame and base frame that changes overcome in next 3D design called as ‘Symmetric Design’.

Symmetric 3D Design:

To eliminate unbalanced load and achieve for equal load distribution on PSP the Symmetric design is formed.

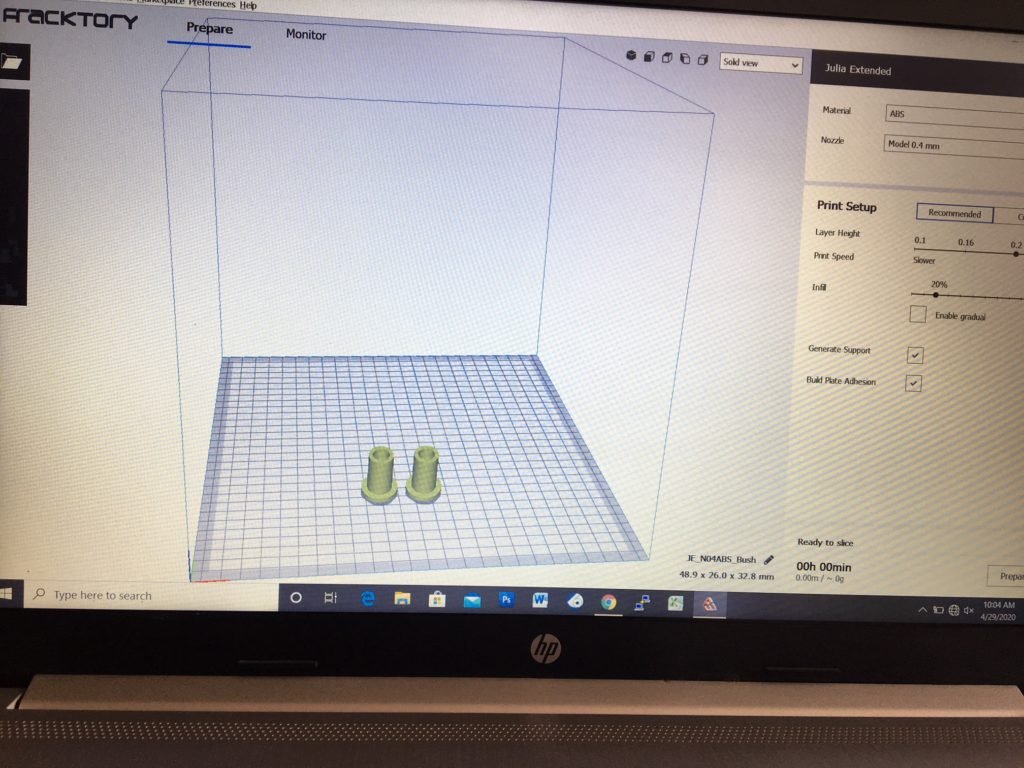

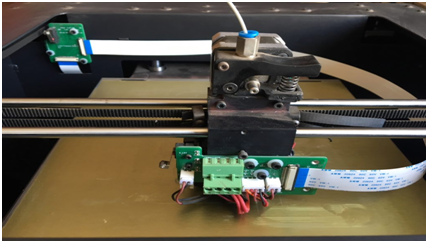

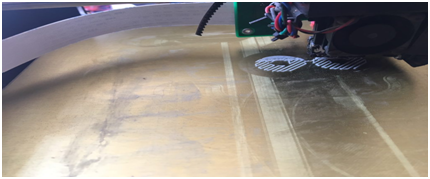

3 D Bush Make on 3D Printing Machine

In the existing stretcher there is no symmetrical bush due to that we want make symmetrical bush for trials and also due to lock down market is closed this difficulties over come by making bush on 3D printing machine.

Actual bush as:

- Make the 3D drawing as per dimensions in by using solid works software.

- Convert this file into STL format(Save as).

- This STL file open in ‘FRACKTORY’ software , In which the design gives some basic instructions as: Move object, Length,Material selections, layer of material, Nozzle size, print speed, Infill(Layer %), Generate support, Build plate adhesion etc. and finally save file name & show time duration for completion of object.

Then completion of G -code this file give to 3D printing machine to actual make object.Here we take ABS material for making bush.

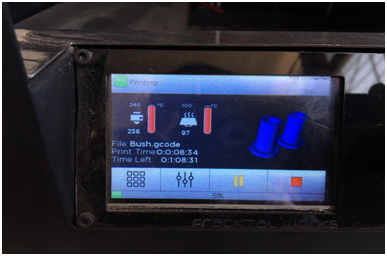

On 3D printing machine display set

Temperature of Nozzle : 210

Temperature of Bed : 60

Nozzle position w.r.t. X & Y direction & Bed position w.r.t. Z direction.

Actual Starting the Bush Making:

Design and Fabrication of Top Stretcher

Problem Definition:

To take trials on an actual rural road, there is a flat and Proper base was

necessary on the main stretcher. This difficulty overcome by following ways.

Step – 1] Find out available material from the scrap section and sort

out it.

Dimensions of Stretcher: Length-: 157 cm, Width-: 52 cm, Height-: 12

cm.

At the time of welding, at beginning two parts are not weld together as

proper contact. I understood, “when the maximum surface area of contact

with each other then welding was good”.

Step – 4] Clean the frame and see all the joints.

For looking good (aesthetic view) paint the stretcher.

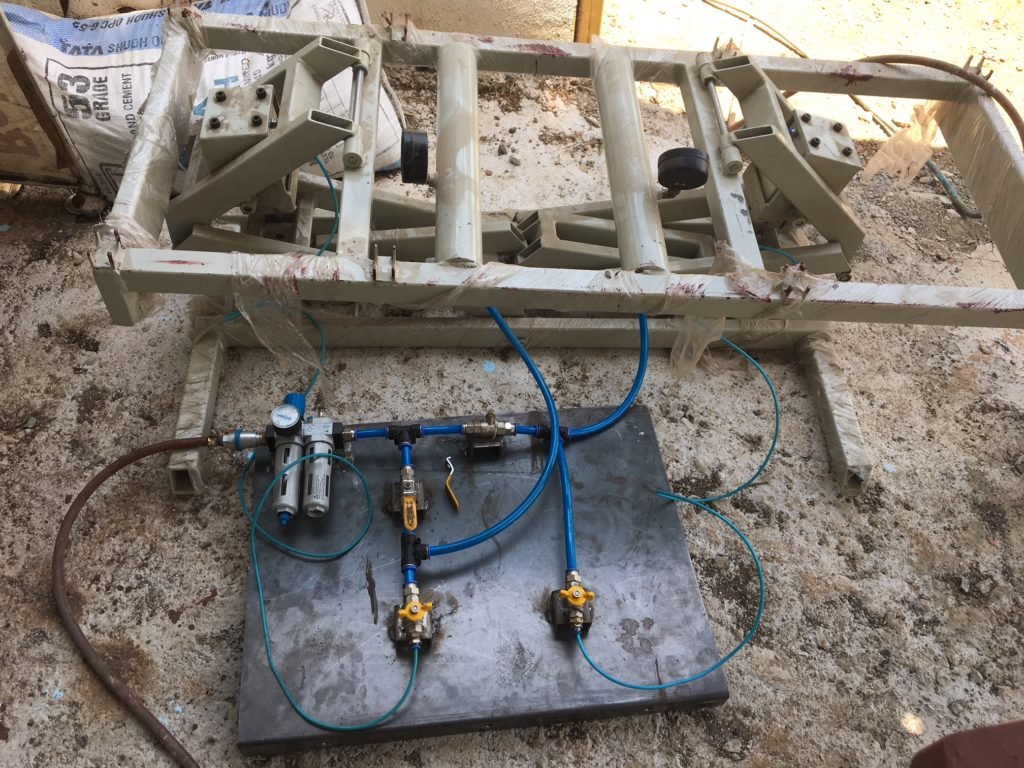

Maintenance of Compressor

From last 2 years compressor was not restarted due to its critical maintenance and unavailability of parts.This compressor was started for reuse solving its issues by me and my friend Ghanysham.

Work done in compressor maintenance

- Set all electrical connections properly

- Fill oil for compressor

- Connect pipe for air outlet

- Alignment of belt and motor shaft

- Pressure gauge repair

The air filter was not available in the market overcome this problem by Indian Jugad method to use cotton cloth for filtration of air as temporary solution.

This compressor used for-

- Fill the air in PSP.

- Fill air in tractor, motorcycle, cycle etc.

- Use air for spray painting.

- Use compressed air for other projects as per requirements.

First Trail of PSP

Due to lockdown first trail of psp extended.This trail finally conducted after purchasing a pneumatic material and complete the pneumatic circuit.

Conduct Leak Check test at 26 May 2020 in that some points to be noted as:-

- All pneumatic connections are leak

- Pneumatic hoses (pipes) are shorter in some connections

- Bushes are unequal in size

- C.G. is improper

- Pressure is suddenly drop at trail time

- Minimum 6 Bar pressure required for lifting of PSP

- Cylinder bracket design is incorrect

Modifications after completion leak test:-

- Sealed the all connections by taplon tape

- Use 3D bushes for trail

- Keep pressure constant

- Lubrication at friction areas

- Keep top frame symmetric

- Increase length of pneumatic hoses

1st Road Trail Reports

First road trials of POCSP conducted at 31 May 2020 in tractor. In that results achieved as follows:

Considerations –i) Keep 50 Kg weight on the top of frame ii) Pressure –

6 Bar

| Parameters

Roads |

1st Gear Speed- 10 kmph |

2nd Gear Speed-15 to 20 kmph |

3rd Gear Speed- 25 to 30 kmph |

Average Value |

| Off Road(Rough Road) Frequency (PSP) Frequency ( Tractor) |

12 Hz

14 Hz |

3.48 Hz

5 Hz |

3.17 Hz

4.40 Hz |

6.21 Hz 7.8 Hz |

| ON Road(Main Road)

|

5 Hz

9 Hz |

3.30 Hz

4.5 Hz |

3 Hz

3.50 Hz |

3.76 Hz 5.66 Hz |

1st Road trial outcomes

- At one end top frame was

tilting after 10-15 minute. - Top stretcher was not

properly fixed on PSP (Stability of top stretcher was weak due to improper

welding). - Only 50 Kg weight was apply

as load and also load distribution was not uniform. - No sleep any person on

stretcher to feel vibrations. - Option device was not used

for measure vibrations (Only one mobile used as vibration measuring

instrument).

2nd Road trial improvements / Necessary modifications for 2nd road trials

- Make top stretcher

strong and keep in mind it is fix properly on PSP. - Fix or clamp

vibration measuring devices properly. - Measure the

amplitude. - Record and

save the all readings. - Apply 70-80 Kg

load with uniform distribution on top stretcher. - Sleep a person

on stretcher to feel producing vibrations. - Record small

length videos. - Keep bed /

foam sheet on top stretcher.

For conducting second road trial some activity are necessary as:

| Sr.No. | Activity | ||

| Road Trail – II | Design of PSP | Constant Pressure Arrengement | |

| 1 | Leakage Test- | Modifications in connections | Vigyan Ashram Compressor |

| Pneumatic connections | Use individual pins | ||

| Bush Inspections | Self lubricating bush | Nitrogen Cylinder | |

| Cylinder leakage | Make it as per indain dimesions | ||

| Oil in FRL unit | Modified cylinder resting bracket | ||

| Use proper box sections and thickness as per load distribution | |||

| 2 | Vibration & amplitude measuring device | Modify top frame as per top stretcher | |

| Accelorometer | Bush modification – Increase length and add circlip at one end | ||

| Mobile Application | |||

| 3 | Fabrication of Top Stretcher | ||

| 4 | Constant pressure test by without cut the supply of compressor | ||

–The leakage problem was solved by the help of soap solution and replacement of bush.

Previous top stretcher was not strong and enough for more load (Which was made from circular pipe in that welding at connecting section is not good) sustainable.Due that I made / fabricate a new top stretcher from L- angle rod.

After completion of top stretcher and solve the problem of leakage I conduct second road trail on 23 June 2020.

2nd Road Trail Reports-:

Date: 23/06/2020

Second road trials of POCSP

conducted at 23 June 2020 in tractor. In that results achieved as follows:

Considerations

–i) Keep 50 Kg weight on the top of frame ii) Pressure – 8 Bar

| Parameters

Roads |

1st Gear Speed- 10 kmph |

2nd Gear Speed-15 to 20 kmph |

3rd Gear Speed- 25 to 30 kmph |

Average Value |

| Off Road(Rough Road) Frequency (PSP) Frequency ( Tractor) |

5.09 Hz

17 Hz |

4.90 Hz

22.04 Hz |

5.49 Hz

24.17 Hz |

5.16 Hz 21.07 Hz |

| ON Road(Main Road)

|

4.59 Hz

12.55 Hz |

4.79 Hz

11 Hz |

5.18 Hz

13.04 Hz |

5.11 Hz 12.19 Hz |