Introduction

In recent years, there has been a growing demand for nutritious and convenient ready-to-eat cereal products. Among the various grains available, jowar (sorghum) stands out as a valuable crop due to its gluten-free nature, high fiber content, and rich nutritional profile. Despite its health benefits, jowar remains underutilized in processed food segments.

To promote the consumption and market potential of jowar, efforts are being made to convert it into value-added products such as flakes, which can serve as a healthy alternative to conventional breakfast cereals.

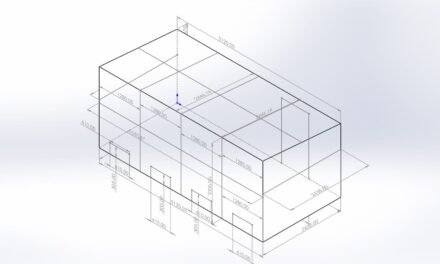

The present study focuses on conducting trials of jowar flakes using the Multigrain Flaker Machine for the client Agrozee Solutions Millets Now Pvt. Ltd. The aim is to optimize processing parameters such as grain conditioning, roller pressure, and moisture content to achieve uniform, crisp, and high-quality jowar flakes suitable for commercial applications.

Objectives

- To study the flaking behavior of jowar grains on the Multigrain Flaker Machine.

- To determine the optimum pre-treatment and processing parameters such as moisture level, steaming time, and roller gap for producing quality flakes.

- To evaluate the final product characteristics including texture, expansion, thickness and overall quality of jowar flakes.

Methodology

Taking reference from the previous trials conducted by fellow researcher Aditya Dudhane, the study was initiated with similar processing parameters. The first trial began by conditioning the cleaned jowar grains to achieve 25% moisture content, which was considered suitable for initial flaking tests.

Trial 1: Jowar Flaking Process and Results with 25% moisture

For the initial trial, 200 g of raw jowar grains were taken as the base sample. The grains were soaked in water for 6 hours to achieve proper hydration, followed by steaming for 20 minutes to soften the endosperm and make the grains suitable for flaking.

After steaming, the sample weight increased to 400 g due to moisture absorption. The steamed grains were then dried at 55 °C for 25 minutes, resulting in a final pre-flaking weight of 250 g, with an approximate moisture content of 25%.

The conditioned sample was passed through the Multigrain Flaker Machine to observe flaking performance and product yield. The results are summarized below:

| Parameter | Weight (gm) | % of Total (without fines) | % of Initial 250 gm |

|---|---|---|---|

| Thin Flakes | 44 gm | 20.1 % | 17.6 % |

| Thick Flakes | 175 gm | 79.9 % | 70.0 % |

| Total (excluding fines) | 219 gm | 100 % | 87.6 % |

Discussion and Further Plan

Based on the results of the first trial, it was observed that while the flakes had good structure and appearance, the higher moisture content (25%) led to a slightly thicker texture and minor stickiness during flaking. To achieve more uniform and lighter flakes, adjustments in moisture level and heat treatment were considered necessary.

After a detailed discussion, it was decided to conduct additional trials with modified pre-treatment parameters. The following changes were planned for optimization:

- Moisture levels: 23% and 20% (to observe the impact of reduced moisture on flake crispness and uniformity).

- Blanching/Steaming time: 10 minutes and 15 minutes (to evaluate the softening effect and ease of flaking).

These trials aim to identify the ideal balance between moisture, heat treatment, and flake texture for achieving high-quality jowar flakes with minimal fines and consistent thickness.

Trial 2: of Jowar Flakes on Multigrain Flaker Machine

Overview

The process began with the selection of clean, graded jowar grains, followed by soaking, steaming, drying, and flaking under controlled conditions. The trials aimed to understand how minor variations in moisture (20–23%) and steaming time (10–15 minutes) influence the flake’s physical structure, such as thickness, expansion, and brittleness, as well as the total yield after processing.

Each trial was carried out by carefully adjusting pre-treatment conditions while keeping the machine’s operational parameters—roller pressure, feed rate, and flaking speed—constant. The flakes were evaluated for their appearance, integrity, crispness, and proportion of thin to thick flakes.

These systematic trials helped in identifying the most suitable processing window that delivers consistent quality and minimal losses, paving the way for commercial-scale production of nutritious ready-to-eat jowar flakes.

Results and Analysis

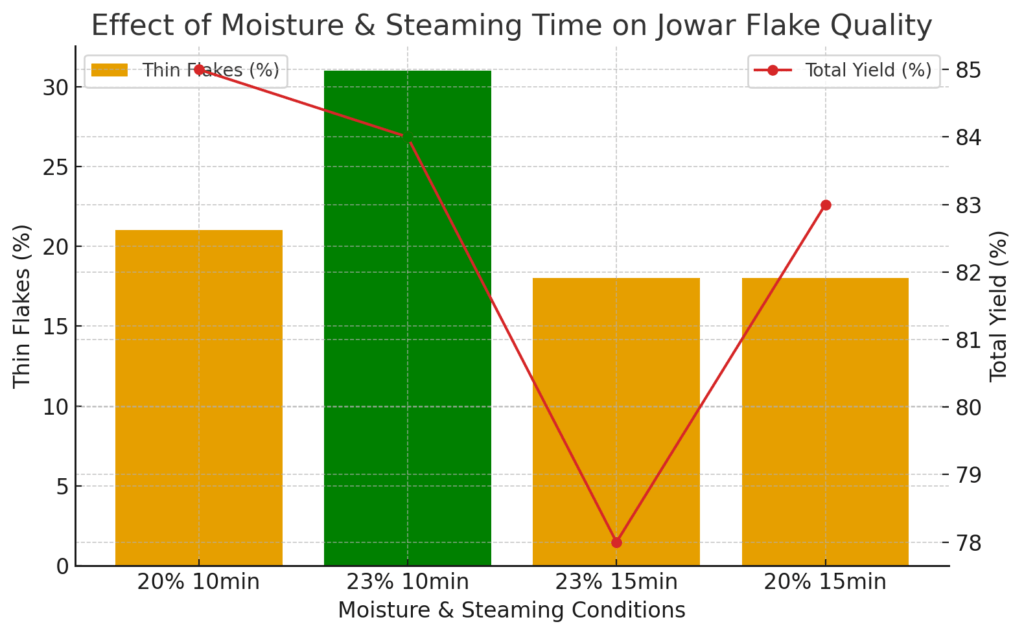

The comparative results of all four trials are summarized below:

| Trial | Moisture Before Flaking | Steaming Time | Final Total Weight (gm) | Thin Flakes (gm) | Thick Flakes (gm) | Total Yield (%) | Thin Flakes (%) |

|---|---|---|---|---|---|---|---|

| 1 | 20% | 10 min | 256 gm | 54 gm | 202 gm | 85% | 21% |

| 2 | 23% | 10 min | 252 gm | 80 gm | 172 gm | 84% | 31% |

| 3 | 23% | 15 min | 235 gm | 44 gm | 191 gm | 78% | 18% |

| 4 | 20% | 15 min | 249 gm | 45 gm | 204 gm | 83% | 18% |

Key Findings

- Moisture Effect:

Increasing the pre-flaking moisture to 23% resulted in smoother flakes but also made them thicker and slightly less crisp. In contrast, 20% moisture produced flakes that were more uniform, crisp, and easy to handle post-drying. - Steaming Effect:

Shorter steaming times (10 min) helped retain grain integrity, giving better yield and balanced flake texture. Longer steaming (15 min) improved smoothness but slightly reduced yield due to over-softening. - Flake Composition:

The ratio of thin to thick flakes varied significantly. Trial 2 (23%, 10 min) had the highest thin flake percentage (31%), while others ranged around 18–21%. This suggests that higher moisture facilitates spreading during flaking but compromises crispness.

Next Step: Scale-Up Trial

After analyzing the four small-scale trials, the results indicated that 23% moisture and 10 minutes of blanching (steaming) produced flakes with good softness and spread during flaking. Although the flakes were slightly thicker, they maintained good integrity and visual appeal, showing potential for scale-up.

To further validate these findings under practical processing conditions, the next step involves conducting a scale-up trial with a 1 kg batch of jowar grains. This larger trial will help assess how the optimized parameters perform on higher quantities and determine:

- The uniformity and consistency of flakes in bulk processing,

- The machine efficiency and output rate under continuous operation, and

- Any adjustments required in drying time or temperature to maintain ideal crispness.

The 1 kg batch trial at 23% moisture with 10 minutes blanching aims to confirm whether these optimized pre-treatment parameters can be directly applied for commercial-scale production while maintaining the same product quality and yield observed in small-scale trials.

Trial 3: 23% Moisture with 10 min Steaming (1 kg Batch)

Step 1: Soaking

The process began with 1 kg of cleaned raw jowar grains, which were soaked in water for 6 hours to ensure uniform hydration.

After soaking, the grain weight increased to 1.33 kg, indicating proper water absorption and swelling — essential for softening the grain structure before steaming.

Step 2: Steaming

The soaked jowar was then divided into two equal portions for easier handling and steamed for 10 minutes each.

This two-phase steaming helped achieve even gelatinization across the batch.

After steaming, the combined weight reached 1.372 kg, showing slight water retention and expansion due to the heat treatment.

Step 3: Drying

Post steaming, the grains were dried at 55 °C for 40 minutes to bring the moisture level down to around 23 %, which is suitable for flaking.

The final conditioned grain weight was 1.23 kg. The texture at this stage was firm yet flexible, showing readiness for flaking without cracking.

Step 4: Flaking

The dried grains were passed through the Multigrain Flaker Machine.

Results and Analysis

The total output obtained was 1.035 kg

Out of this, good thin flakes (0.6–0.7 mm) weighed 113 g, while the remaining portion consisted mostly of thick or partially flattened flakes (~922 g).

The good flake efficiency was ≈11% of the total output.

Observations

The machine took 9 minutes to process 1 kg, compared to its rated speed of 50–60 kg/hr, giving an actual efficiency of only ~10–12%.

Flakes showed significant non-uniformity in thickness.

Pressure steaming for 10 minutes resulted in over-softening of grains, causing the majority to compress unevenly during flaking.

Discussion and Further Plan

After the 1 kg steaming trial, it was observed that 10 minutes of pressure steaming at 23 % moisture produced excessive softening, resulting in low good-flake efficiency (≈ 11 %) and uneven flake thickness. To overcome this issue, it was decided to reduce the intensity of heat treatment and try a hot water treatment method instead of steaming. The aim was to achieve partial gelatinization with better flaking texture while avoiding overcooked grains and improving overall yield quality.

Trial 4 : Hot Water Treatment Trials (85 °C & 95 °C)

Common Procedure

Step 1: Took 600 g of soaked jowar grains (after soaking for 6 hours).

Step 2: Divided the soaked grains into two portions — one for 85 °C and one for 95 °C hot-water treatment.

Trial 1 – 85 °C for 10 min

Step 3: Treated 300 g grains in 85 °C hot water for 10 minutes.

Step 4: Drained and cooled the grains at room temperature.

Step 5: Dried to reach 23 % moisture, with final weight before flaking = 369 g.

Step 6: Flaked using the same flaker setting.

Observations:

• Final total weight – 190 g

• Good flakes – 50 g

Trial 2 – 95 °C for 10 min

Step 3: Treated 300 g grains in 95 °C hot water for 10 minutes.

Step 4: Drained, cooled, and dried to 23 % moisture (final weight = 369 g).

Step 5: Flaked the treated grains.

Observations:

• Final total weight – 210 g

• Good flakes – 45 g

Trial 3 – 85 °C for 15 min

Step 3: Treated another 300 g batch in 85 °C hot water for 15 minutes.

Step 4: Drained, cooled, and dried to 23 % moisture (final weight = 369 g).

Step 5: Flaked using the same machine setting.

Observations:

• Final total weight – 223 g

• Good flakes – 43 g

Trial 4 – 95 °C for 15 min

Step 3: Treated 300 g grains in 95 °C hot water for 15 minutes.

Step 4: Drained and cooled to ambient temperature.

Step 5: Dried to 23 % moisture, final pre-flaking weight = 369 g.

Step 6: Flaked under same conditions.

Observations:

• Final total weight – 231 g

• Good flakes – 46 g

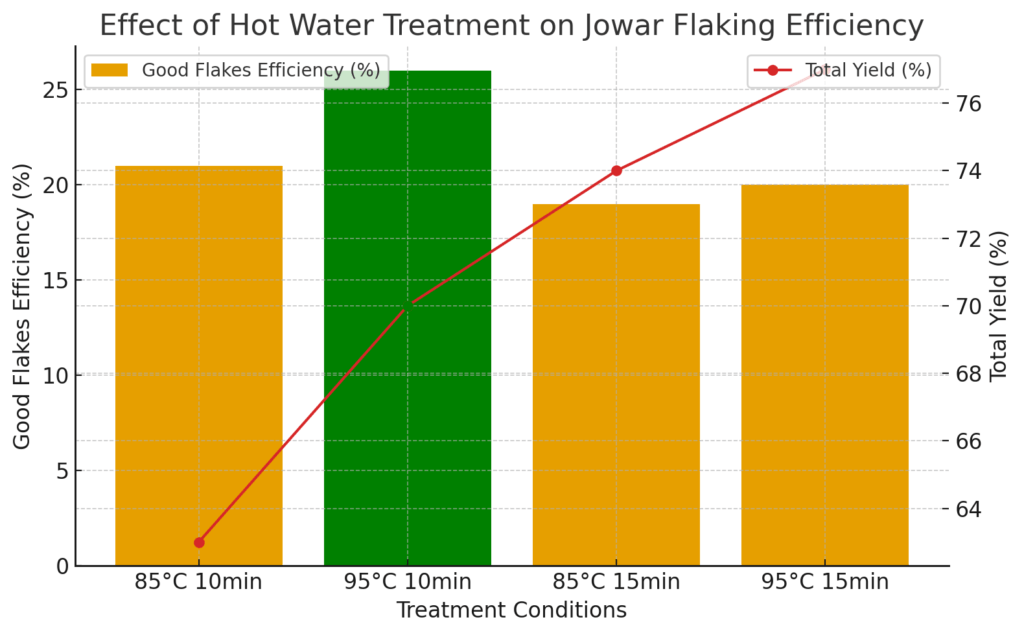

Results and Analysis

| Trial | Temperature (°C) | Treatment Time (min) | Final Total Weight (g) | Good Flakes (g) | Total Yield (%) | Good Flakes Efficiency (%) |

| 1 | 85 | 10 | 190gm | 50gm | 63% | 21% |

| 2 | 95 | 10 | 210gm | 45gm | 70% | 26% |

| 3 | 85 | 15 | 223gm | 43gm | 74% | 19% |

| 4 | 95 | 15 | 211gm | 46gm | 77% | 20% |

Discussion & Further Plan

From the previous trials, it was observed that the 95°C hot water treatment for 10 minutes gave comparatively better results in terms of good flake formation (26%) and overall yield (70%), though still below the expected efficiency. The texture and uniformity of flakes were slightly improved compared to other treatments. However, uneven drying after treatment was identified as a possible factor affecting flake quality and expansion.

Hence, as the next step, two repeat trials of 95°C for 10 minutes will be conducted — one with room-temperature drying and another as a replicate under the same conditions — to evaluate the impact of natural drying on flake structure, yield, and texture consistency.

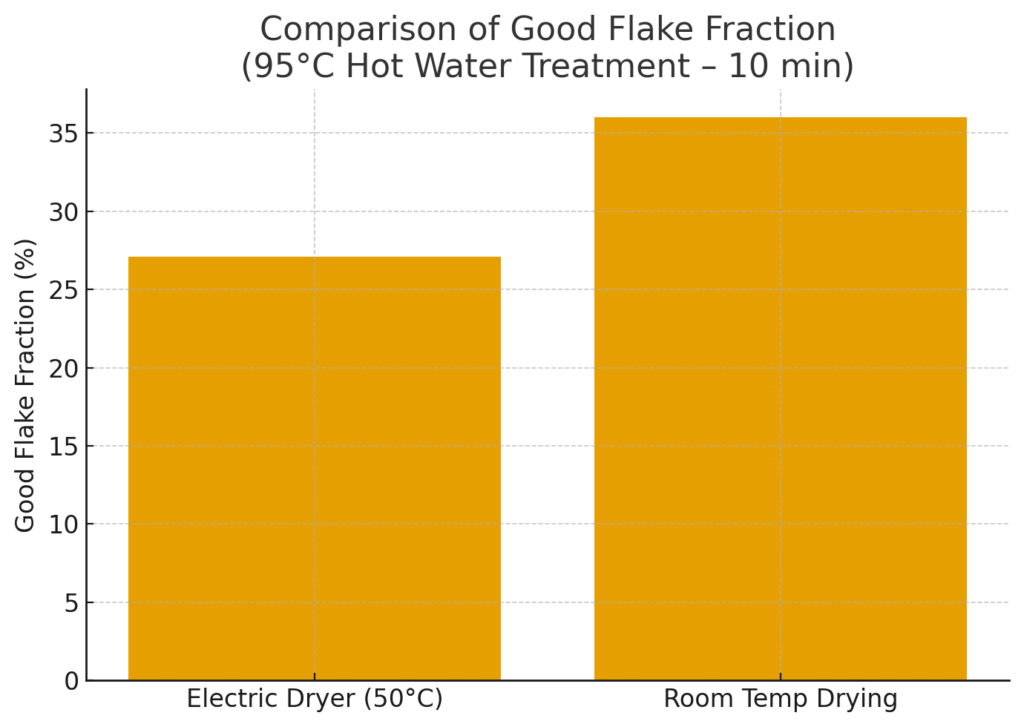

Trial 5 : Hot Water Treatment Trials (95°C, 10 min) – Drying Method Comparison

| Parameter | Trial 1 – Electric Dryer (50°C) | Trial 2 – Room Temp. Drying |

|---|---|---|

| Input weight (soaked) | 300 g | 300 g |

| Pre-flaking weight (at 23% moisture) | 370 g | 370 g |

| Weight after flaking (immediate) | 340–345 g | 340–345 g |

| Overnight stabilized weight | 280 g | 250 g |

| Good flakes weight | 76 g | 90 g |

| Good Flake Fraction (% of stabilized wt) | 27.1% | 36.0% |

| Observations | More uniform drying but slightly harder flakes | Better expansion, softer flakes, higher good-flake yield |

Conclusion

The comparative evaluation of steaming and hot-water treatments showed that flake quality is highly dependent on internal moisture gradients and thermal softening levels. Among all conditions tested, 95°C for 10 minutes combined with room-temperature drying yielded the highest thin-flake fraction. The outcomes of this study establish a clear process pathway for further refinement of flaking efficiency and product uniformity.

As my internship period comes to an end, the ongoing work and findings will now be handed over for further continuation and refinement.