Date: 11/06/2023

Discussion with Dixit sir about the E-rikshaws and their problems.

Today’s discussion with Dr. Arun Dixit revealed that E-Rikshaws were initially provided by IIT for the Vigyan Ashram Campus. However, these vehicles faced frequent mechanical and electronic issues over time. Unfortunately, there was no support or assistance from the Kinetics company or the service center to address these problems.

Due to the lack of support, the E-Rikshaws remained at the service center without any resolution. As a response, Dr. Arun Dixit took the initiative to bring the E-Rikshaws back to the campus to personally address the issues. He assigned the task of starting the E-Rikshaws and creating a comprehensive manual for them.

The current project involves identifying and troubleshooting the problems with the E-Rikshaws to ensure they become operational again. Additionally, there is a need to draft a formal complaint against the Kinetics company, highlighting their lack of support and the issues faced with the E-Rikshaws.

The main objectives are to prepare a manual for the E-Rikshaws and promptly resolve their problems to put them back into service at the Vigyan Ashram Campus.

Date: 12/06/2023 to 16/06/2023

Studying all the problems faced by E-Rikshaws.

Mr. Prasad Patil provided me with the manual of the E-Rickshaw. The manual detailed the problems that occurred in the rickshaws, along with the steps taken to resolve them and the level of support received from the company. I read the entire manual to take note of all the details.

Date: 17/06/2023

Pick up Rikshaws from service center.

Today, we made the decision to bring both E-rikshaws back to the Vigyan Ashram. In the afternoon, we collected both rikshaws from the Chakan service center and transported them to the Vigyan Ashram campus. Once there, we completed all the necessary documentation and conducted a thorough check to ensure that all the parts of the E-rikshaws were properly in place.

Therefore, our main agenda for today was successfully bringing the E-rikshaws back to the campus.

Date:18/06/2023

Checked all connections and parts.

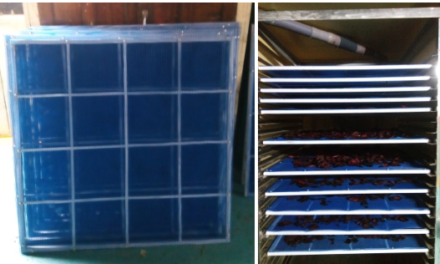

Today, I inspected all the connections of the rickshaws. During the inspection, we noticed that some connections were broken and others were disconnected. We carefully noted down these issues and thoroughly examined the condition of all the apparatus. To prepare for the repair work scheduled for the next day in Alandi, we disconnected the battery connections from both rickshaws and removed them. The batteries were not functioning properly.

Then we started looking for service center for battery repairing. We had contact with Electrowatt service center but when we contacted them they said they have stopped repairing batteries. Then we searched on India Mart, would we get any service center from there we got 3 contact no. Sawant Atumation was lying nearby. so we decided to take them to Alandi for repair. We had already discussed the battery issues with Mr. Sawant from Sawant Automation prior to this decision.

Date: 19/06/2023

Taking the batteries for repairing purpose.

As mentioned in the last blog post, today, Dixit sir and I took the rickshaw batteries to Alandi for repair. We discussed the battery issues with Mr. Sawant and also talked about the quotation for repairing them or possibly getting new batteries. Mr. Sawant assured us that he would contact us once the problems with the batteries are fixed or if new batteries are needed.

Date: 20/06/2023 – 26/06/2023

I have thoroughly inspected all the components of the rickshaw to determine their functionality. Using a multimeter, I checked the ignition, throttle, and display. Firstly, I carefully examined all the wire connections and made notes based on their respective wiring colors. After that, I proceeded to inspect the connections of the controller, motor, GPS, and DC-to-DC converter. Based on my observations, I found that the ignition, display, and throttle were all in good condition.

Checked all the parts and connections

Date: 27/06/2023 – 05/07/2023

Took information about the condition of batteries.

Every day, I have been in contact with Mr. Sawant to get updates about the batteries. On the 27th, he informed me that 5 cells of one battery had been drained, but he managed to recover 3 of them. However, it would take an additional 2-3 days to recover the remaining 2 cells as the process of recovery is slow. He also mentioned that the other battery was completely drained, so they planned to try to recover it using a new machinery they had acquired.

On the 3rd of July, he informed me that a total of 5 cells had been successfully recovered. However, they noticed a problem with the Battery Management System (BMS) and were planning to repair it. He provided two options for the cost: if the BMS could be repaired, it would be Rs. 7000; otherwise, if they had to replace the BMS, it would be Rs. 10000. Additionally, they mentioned that they would provide an official quotation for the new battery after fixing one of the batteries.

On the 5th of July, they updated me that it would take another 2 days to fix the batteries, and I could pick them up on the 9th.

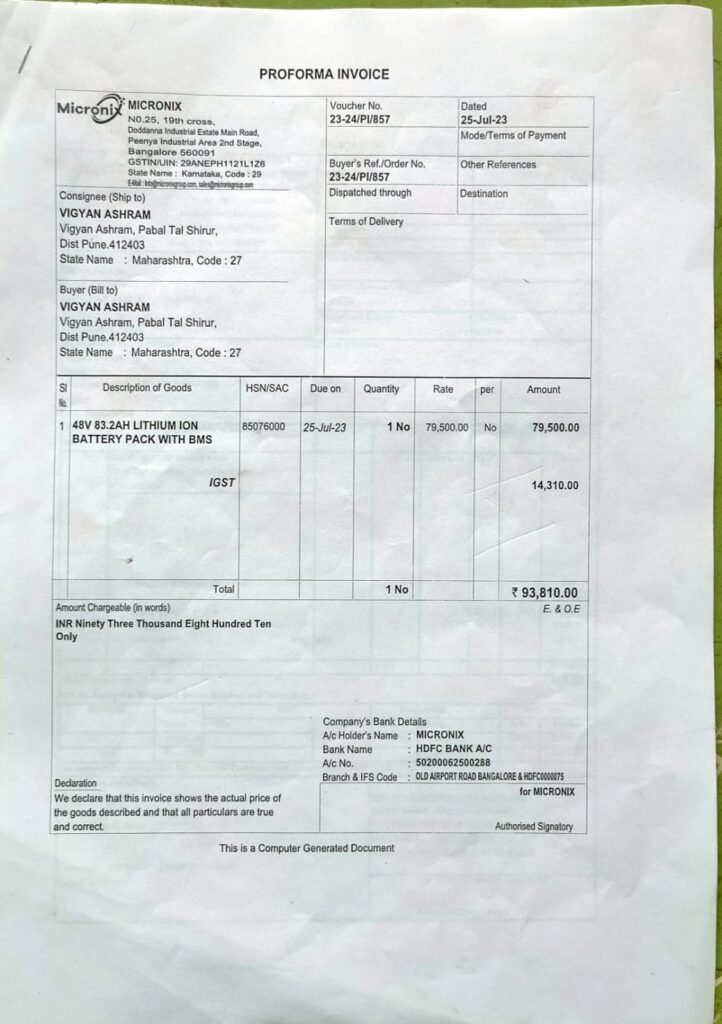

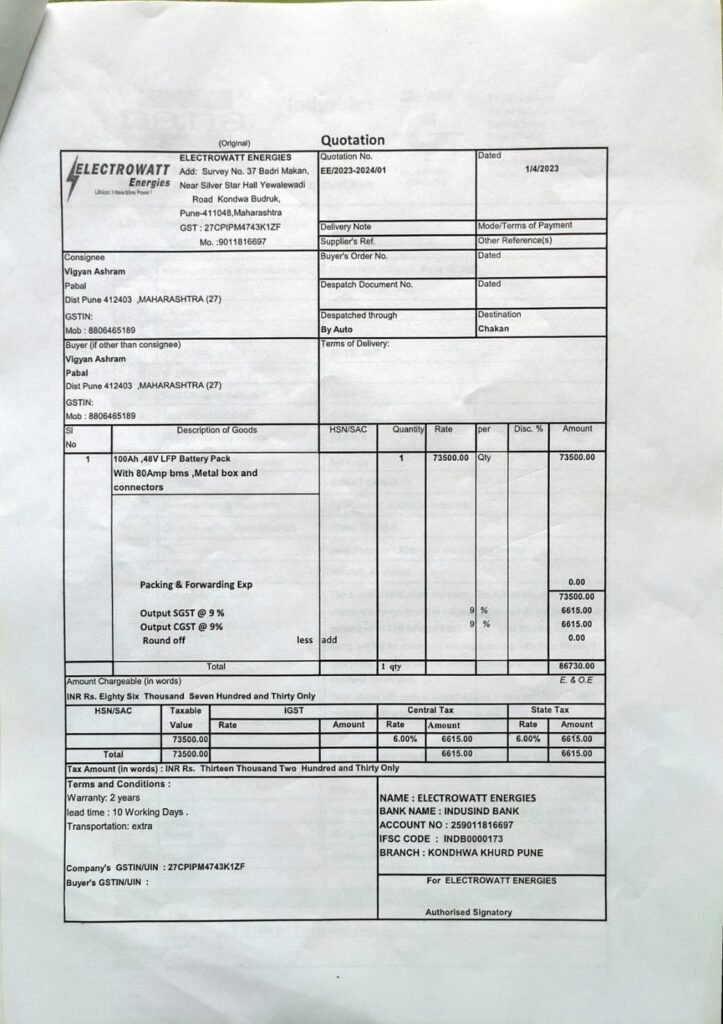

When I informed Dixit sir about the battery status, he expressed the decision to procure a new battery for our rickshaw. To proceed with the purchase, he told that we gather quotations from different dealers for comparison. Then I started collecting quotation of batteries and I got 3 quotation from different companies. One is from Micronixs, second is from Electrowatts and third is from NANA batteries

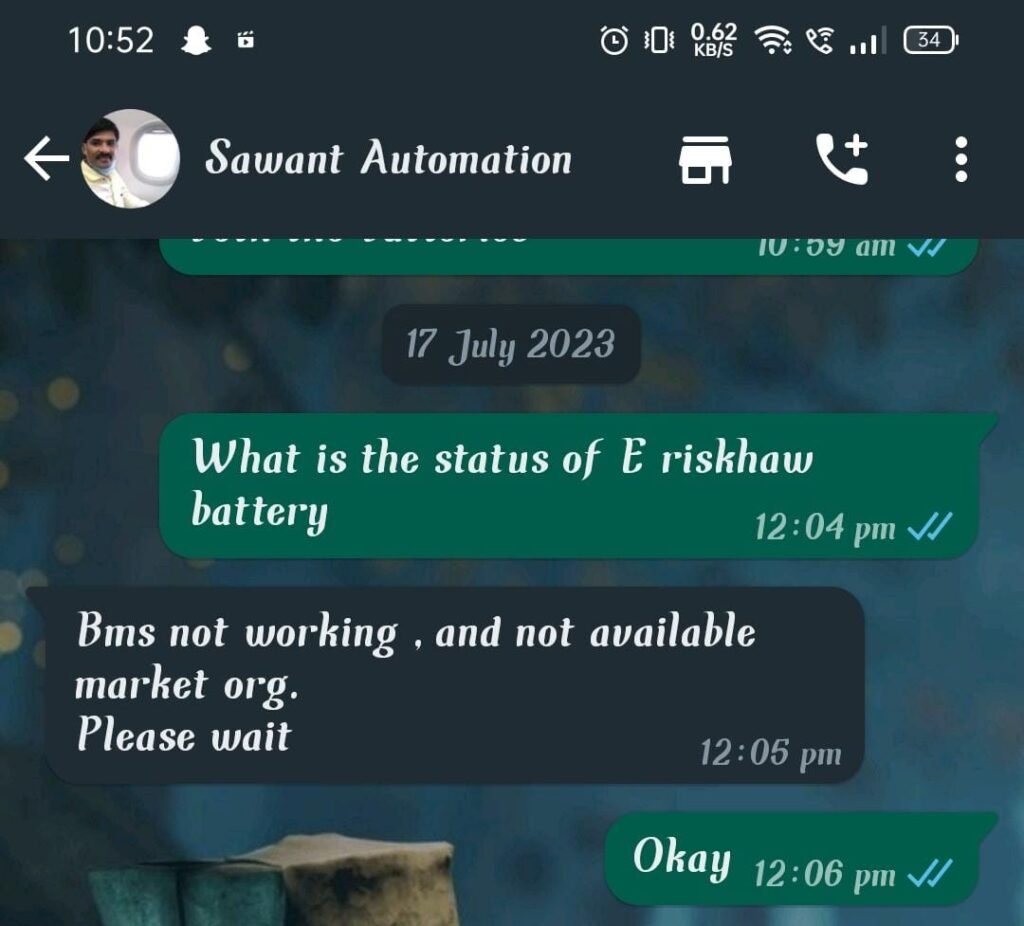

On July 17th, I spoke with Mr. Sawant regarding the battery status. He informed me that the battery is fully charged and all cells are functioning properly. However, there are two issues that need attention. Firstly, there is a problem with the Battery Management System (BMS). Secondly, during the setup process, one cell’s thread got damaged.

After careful consideration, we came up with a solution. Our college team possesses a suitable BMS, the DALY BMS, which we can send to Vigyan Ashram to be used for our battery. I immediately contacted our team member, Lokesh, and requested him to arrange for the safe transportation of the BMS to Vigyan Ashram through a reliable travel service. This would address the BMS-related concern and enable us to make the necessary repairs and improvements to the battery for optimal performance. We also asked to our college team for our Electric Go Kart battery and our team was ready to send it.

The DALY BMS (Battery Management System) for LiFePO4 (Lithium Iron Phosphate) batteries with specifications “15s 48v 60A” is designed to manage a 15-series cell configuration with a nominal voltage of 48 volts and a maximum continuous discharge current of 60 amps.

Here’s a breakdown of the specifications:

- Cell Configuration: 15s – This means the BMS is suitable for managing a battery pack consisting of 15 LiFePO4 cells connected in series.

- Nominal Voltage: 48V – The combined voltage of all 15 cells in series would result in a nominal voltage of 48 volts, which is a common voltage level for various applications.

- Continuous Discharge Current: 60A – The BMS is capable of handling a continuous discharge current of up to 60 amps, which defines the maximum current that can be drawn from the battery pack without triggering any protection mechanisms.

The primary function of a BMS is to ensure the safe and efficient operation of lithium battery packs. It monitors individual cell voltages, balances the cells during charging, protects against overcharging and over-discharging, and provides various safety features to prevent potential hazards such as thermal runaway.

Keep in mind that the DALY BMS you have can be a suitable replacement for the battery you mentioned in your previous message, provided it is compatible with the battery pack’s specifications and charging/discharging requirements. Always ensure that the BMS matches the battery chemistry (LiFePO4 in this case) and is properly configured to avoid any potential issues.

On July 21st, we handed over the DALY BMS to Mr. Sawant and informed him that it could be used with the battery, though it was designed for a 15-cell configuration, and our battery pack consisted of 16 cells. To address this, Mr. Sawant suggested reconfiguring the battery pack to 15 cells and then connecting it to the BMS.

After making the necessary adjustments, on July 24th, with the assistance of Jadhav sir and Sumit sir, we retrieved both batteries from Sawant Automation. During the collection, Mr. Sawant demonstrated that the battery was providing a reading of 50 volts on the multimeter.

By resolving the cell count mismatch and integrating the DALY BMS, we have taken significant steps towards ensuring the safe and efficient operation of our battery pack. We appreciate the support and guidance provided by Mr. Sawant, Jadhav sir, and Sumit sir throughout this process.

Testing and checking of E rikshaw

On July 25th, we commenced our work on the rickshaw. As the first step, I carefully inspected all the connections on the rickshaw to identify the inputs and outputs. Additionally, I thoroughly checked for any open circuits to ensure safety. And I Also checked all the fuse with the help of multimeter that it is good or not.

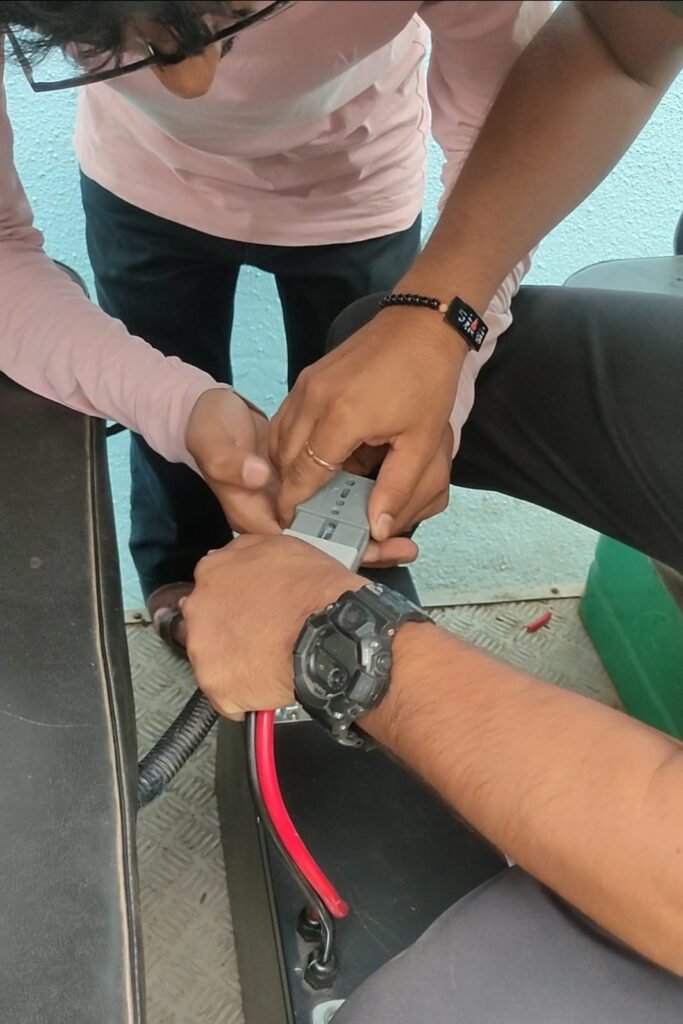

Next, I proceeded to connect the battery to the controller using an SB50 Wire Male Female Connector. With everything in place, I switched on the ignition. Upon doing so, the dashboard lit up, indicating successful power supply.

This initial progress has set the foundation for further work, and we will continue to ensure that all connections are secure and functional, making certain that the rickshaw operates smoothly and safely.

After confirming that all the components on the dashboard, including indicators, front and back lights, and horn, were functioning correctly, we attempted to move the vehicle by pressing the accelerator. However, the rickshaw did not respond. Suspecting a motor issue, we ruled out problems with the forward and reverse buttons on the throttle, as they seemed to be working fine.

As part of the troubleshooting process, we thoroughly inspected the connections on another rickshaw and discovered that the connections of the DC to DC converter were damaged. Due to time constraints, we decided to remove the motor from this rickshaw and transfer it to the first rickshaw for further testing and examination.

This decision allowed us to focus our efforts on diagnosing the problem and addressing the issue more efficiently. With the motor transferred, we aimed to identify and resolve the root cause of the rickshaw’s non-movement.

Then we reversed the rickshaw and removed the motor from the differential Then we reversed the rickshaw and removed the motor from the differential. After that we gave the connections of motor 2 to the controller 1 and started the rickshaw even after that when we gave the accelerator the motor did not turn.

After suspecting a problem with the throttle, we decided to conduct a motor test by connecting a cycle throttle to the rickshaw. We made the necessary connections, linking the three connections of the cycle throttle to the rickshaw’s system. Once everything was properly set up, we switched on the ignition and activated the accelerator. As a result, the motor started rotating, indicating that motor2 was indeed functioning correctly.

With this test, we confirmed that the issue did not lie with the motor itself; instead, it pointed to a problem with the original rickshaw’s throttle.

After identifying loose connections in the throttle, I proceeded to open it up to inspect the wiring and hall sensor. Once the issues were pinpointed, I took the throttle to the fablab to properly solder all the connections. After completing the soldering work, we rechecked the throttle, and to our satisfaction, it started functioning correctly. Subsequently, we tested the motor, and it ran smoothly and properly. With the throttle repaired and the motor working as expected, we successfully resolved the previous issue.

We proceeded to open both the differential and motor of Rickshaw 1, and then we connected them with the differential and motor from Rickshaw 2. Additionally, we connected the battery to controller 1 and switched on the ignition. As a result, Rickshaw 1 started successfully. With everything in place, we tested the rickshaw by giving it throttle, and it started running smoothly.

This process allowed us to successfully start our first E rickshaw. The hard work, troubleshooting, and component replacements paid off, leading to a fully operational electric rickshaw.

On July 26th, when I opened motor 1, I discovered that water had seeped into the motor, causing it to short circuit and get damaged. On this day we got our college battery also. After successfully starting the first E rickshaw yesterday night, I promptly informed Ranjeet sir and Dixit sir about the achievement. They were thrilled to hear the news and appreciated our efforts in getting the rickshaw up and running. We shared the details of the troubleshooting process and the repairs we made to make it possible. Then I assemble the differential to the rikshaw 2 and made that rickshaw stand properly.

On July 27th, Ranjeet sir bring 2 new throttle and large battery male / female connector for because our college battery has large connector. Then we connect new throttle to the rikshaw, then we departed from the workshop to conduct rickshaw testing. We had to test whether the rickshaw climbs uphill or not, at what speed it gives and works properly or not. We started the rickshaw by taking its old battery for testing. So while taking the test, we came to our notice that after going some distance, the rikshaw would stop and the voltage of the battery would drop. After that the connector of the battery had to be removed and put back. And when we increase the speed all of a sudden then this issue happens.

At first we thought it was a battery issue but when we changed the battery, we got the same issue. Then we changed the controller of rickshaw and installed controller 2 in the rickshaw. After changing the controller, we noticed that the issue of stopping the rickshaw did not come and the speed of the rickshaw became good and the rickshaw started climbing the mountain smoothly.

On July 28th, we conducted another test drive with the rickshaw, but this time we measured the battery voltage using a multimeter before starting. The initial voltage reading was 47V. After driving for approximately 2.5 km, we rechecked the voltage, and it showed a drop to 46.7V, indicating a slight discharge.

Upon returning to the workshop, we connected the college battery to the charger for charging. It took approximately 2 hours to charge the battery back up to 53V.

After testing, when we connected the old battery of the rickshaw to the charger, the charging stopped automatically after 5th charge. When we checked the voltage, it was showing 50V. Then we connected the battery to the rickshaw, then automatically the voltage was dropping .Because of that the controller was showing only 26V supply and for the same reason the vehicle was not starting. Then we opened the battery and checked the voltage of all the cells then the voltage of all the cells was showing properly 3.2V. Then I took out the wires of the BMS and put it back, after that the battery was showing proper 50V. But when the battery is connected to the rickshaw, the voltage drops again. I contacted Sawant regarding this issue and he said that the voltage drop must have been due to a short cell and a loose wire. After that we connected the college battery to the vehicle.

On 3rd August we tested the rickshaw back on the college battery and after testing concluded that the rickshaw is working properly all components are ok. And we called Kulkarni sir, Ranjit sir, Prasad sir, Mahesh sir and Sumit sir showed them the rickshaw and took photographs with them.

And we had a meeting with Kulkarni sir at 2:30 pm on the new battery quotations that we got. Dixit Sir Ranjit Sir Suhas Sir Prasad Sir and Sumit Sir were present in the meeting. It was discussed in the meeting that which battery should we take, I prepared a chart of which battery would be good, according to which Micronix Li-ion battery would be good. Because the warranty of that battery is more, even after its life span, its cells keep on doing it and its weight is also less.

So in the meeting it was decided that we will take Li-ion 48 and 83ah batteries from Micronics. And we will keep such a proposal to Micronics company that we will give 70% payment at the time of battery order and remaining 30% after 3 days of delivery.

After that Suhas Sir made the battery PO and scanned it and mailed it to Micronixus company.

On 4th August we sent the college battery back to the college.

Electronics component of E-Rikshaw and How to check it.