INTRODUCTION:

27/09/2022 to 1/10/2022

Wick irrigation involves using “ropes as wicks to supply water to plant roots below the soil surface and thus minimize evaporation”. We have check whether we can use wick irrigation system instead of drip irrigation system.

OBJECTIVES:

- To setup DOE of the wick irrigation system.

- To suggest appropriate material for wick.

WORK DETAILS:

PROBLEMS IN DRIP IRRIGATION SYSTEM:

1) The drip irrigation system operates at optimum pressure of 1.5 to 2.0 kg/cm2. To maintain this pressure the pump is required. Also, the pump requires electricity to work. Hence, it increases the overall cost of the system.

2) The filters are used in drip irrigation system for removing the impurities from the water. This also increases the cost of the system.

3) In the drip irrigation system, another major problem is clogging of the emitter, which may result from the isolated or combined effects of physical, chemical, and biological agents. The emitter clogging may be caused by bacterial growth and particle deposition. The most common elements that cause emitter clogging through precipitation and sedimentation are calcium, magnesium, iron and manganese – with calcium carbonate being the most common precipitate.

The above problems of the drip can be reduced by replacing the drip irrigation system by the wick irrigation system.

In wick irrigation system, the whole system will operate at the atmospheric pressure. Hence, there is no need of pressure maintenance . There is no requirement of filters in the wick system. In wick system, there is no salt accumulation. Hence, it doesn’t consists the problem of clogging.

Now, we have to find which factors affects the flow of water from through wick to the plants. So, after discussion we had chosen 4 parameters that we have to check how they affect the flow rate of water. That 4 parameters are as follows:

- Material of wick

- Diameter of wick

- Height of the curve of wick from the water level.

- Evaporation losses

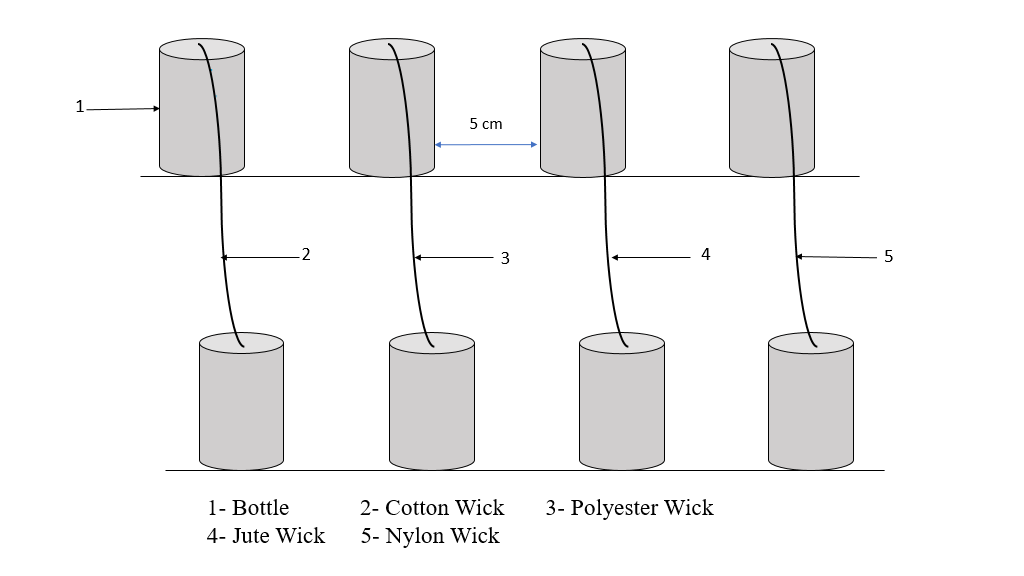

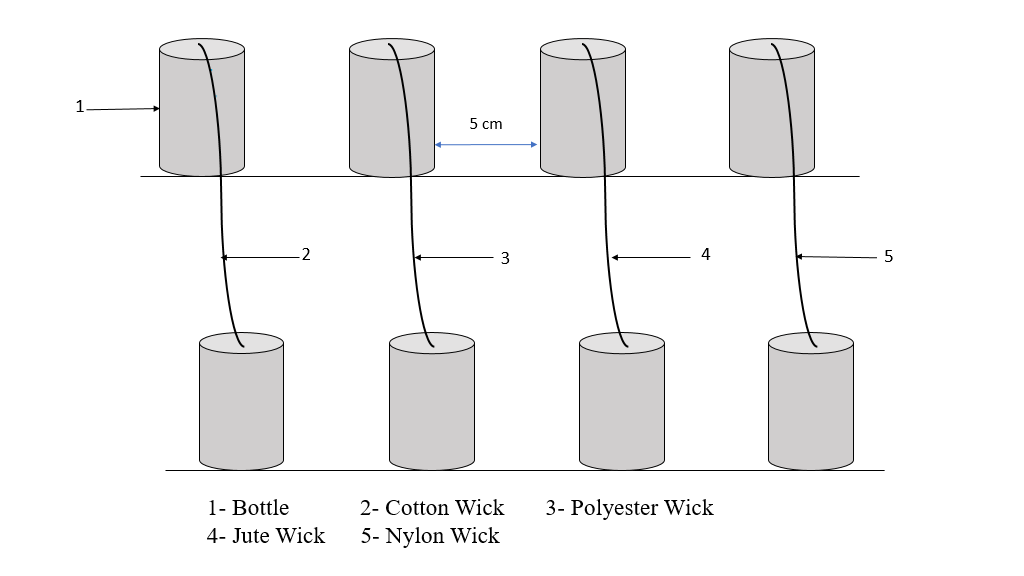

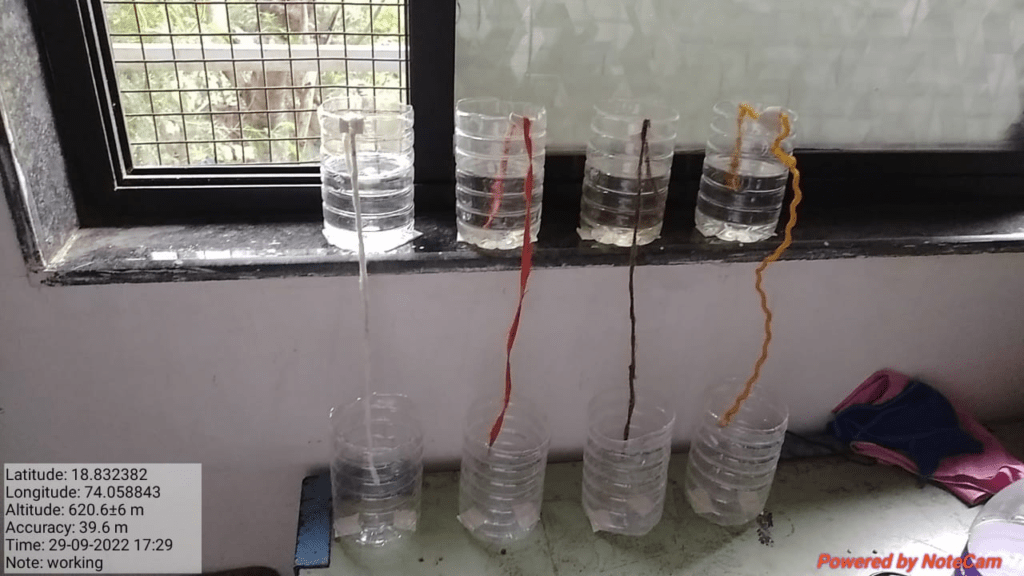

WICK SYSTEM SETUP:

2/10/2022 to 8/10/2022

Decided the materials of the wick and that are:

- Cotton

- Jute

- Polyster

- Nylon

I discussed about height and diameter of wick system with Prasad Sir. Then we decided to consider following diameter and heights for observations.

| Sr. No. | Diameter of wick (mm) | Height of wick (mm) |

| 1. | 4 | 50 |

| 2. | 6 | 55 |

| 3. | 8 | 60 |

| 4. | 10 | 65 |

Done collection of the material required for the wick system setup. Started the experiment by taking diameter 4 mm and height 50 mm of the wick. Made wicks of the four materials considered. Done the setup of the wick system.

The water is only transferring from the jute wick, other wicks do not pass water from it.

9/10/2022 to 16/10/2022

Observations:

CASE 1:

Height 5 cm and diameter 0.4 cm

The container is filled up to 6.8 cm height by water.

The volume of water filled in the container is

V = Πr2 h

= 3.14 x (3.5) ^2 x 6.8

= 261.69 cc

| Hr | Jute | Polyester | Cotton | Nylon | Evaporation | |||||

| Height (cm) | Volume of water (ml) | Height (cm) | Volume of water (ml) | Height (cm) | Volume of water (ml) | Height (cm) | Volume of water (ml) | Height (cm) | Volume of water (ml) | |

| 17 | 5 | 192.4 | 6.8 | 261.69 | 6.8 | 261.69 | 6.8 | 261.69 | 6.8 | 261.69 |

| 24 | 4 | 153.9 | 6.3 | 242.5 | 6.5 | 234.7 | 6.5 | 234.7 | 6.5 | 234.7 |

| 42 | 2.8 | 107.7 | 5.8 | 223.2 | 5.9 | 227.4 | 5.9 | 227.0 | 5.9 | 227.4 |

| 54 | 2.2 | 84.7 | 5.4 | 207.8 | 5.8 | 223.2 | 5.8 | 223.2 | 5.8 | 223.2 |

| 72 | 1.6 | 61.7 | 5.2 | 200.1 | 5.6 | 215.5 | 5.6 | 215.5 | 5.6 | 215.5 |

| Hours | Volume of water evaporated (ml) | Water remaining in the container (ml) |

| 17 | 0 | 261.69 |

| 24 | 26.9 | 234.7 |

| 42 | 30.8 | 227.0 |

| 54 | 38.5 | 223.2 |

| 72 | 46.2 | 215.5 |

Flow rate per min

| Hours | Jute | Polyester |

| 17 | (261-192) / (17×60) = 0.067 | (261-261) / (17×60) = 0 |

| 24 | (261-127) / (24×60) = 0.093 | (261-215) / (24×60) = 0.03 |

| 42 | (261-77) / (42×60) = 0.07 | (261-192) / (42×60) = 0.03 |

| 54 | (261-46) / (54×60) = 0.066 | (261-169) / (54×60) = 0.02 |

| 72 | (261-15) / (72×60) = 0.056 | (261-154) / (72×60) = 0.02 |

17/10/2022 and 18/10/2022

From above observations, we found that water doesn’t flows through nylon and cotton wick. Hence, we decided to take only two materials for the next trials i.e. Jute and polyester. After discussion with Dixit sir, Sir told me to check when the flow rate becomes constant and calculate that flow rate. Also, after discussion with Prasad sir we decided to take volume of water after every 1 hour to check the saturation point of the wick to pass the water through it and the flow rate after saturation point becomes constant. Hence, I again prepared setup by using wicks of jute and polyester and taken weight of water after every 1 hour.

Observations:

CASE 1:

Diameter= 4 mm and Height = 5 cm.

| Time in hours | Weight of water in Jute wick container (in mg) | Weight of water in Polyester wick container (in mg) |

| 1 | 298 | 298 |

| 2 | 290 | 280 |

| 3 | 281 | 260 |

| 4 | 296 | 285 |

| 6 | 295 | 267 |

| 19 | 293 | 210 |

| 20 | 296 | 285 |

| 21 | 296 | 281 |

| 22 | 296 | 281 |

| 23 | 296 | 281 |

| 24 | 296 | 281 |

Flow rate:

- Jute = 2 gm/day

i.e. 0.08 g/hr

2. Polyester = 15 gm/day

i.e. 0.63 g/hr

28/10/2022 to 5/11/2022

CASE 2:

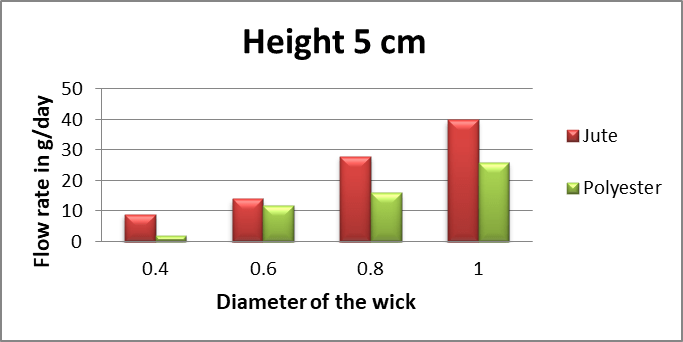

JUTE HEIGHT 5CM

| Hours | 0.4 | 0.6 | 0.8 | 1 |

| 1 | 298 | 290 | 273 | 247 |

| 2 | 295 | 283 | 268 | 233 |

| 3 | 292 | 276 | 270 | 256 |

| 4 | 290 | 280 | 268 | 272 |

| 5 | 289 | 278 | 262 | 264 |

| 6 | 286 | 276 | 276 | 250 |

| 19 | 280 | 266 | 266 | 257 |

| 20 | 290 | 284 | 270 | 258 |

| 21 | 289 | 284 | 270 | 258 |

| 22 | 289 | 284 | 270 | 258 |

| 23 | 289 | 284 | 270 | 258 |

| 24 | 289 | 284 | 270 | 258 |

| Jute 5 cm | ||

| Diameter(cm) | Flow rate/day (g/day) | Flow rate/Hr (g/hr) |

| 0.4 | 9 | 0.083 |

| 0.6 | 14 | 0.58 |

| 0.8 | 28 | 1.16 |

| 1 | 40 | 1.67 |

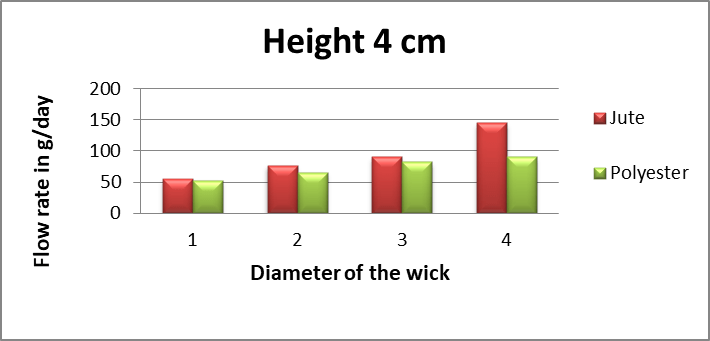

JUTE HEIGHT 4CM

| Diameter in cm | ||||

| Hours | 0.4 | 0.6 | 0.8 | 1 |

| 1 | 290 | 287 | 279 | 237 |

| 2 | 286 | 278 | 260 | 204 |

| 3 | 245 | 228 | 207 | 178 |

| 4 | 223 | 201 | 184 | 139 |

| 5 | 207 | 192 | 153 | 104 |

| 6 | 178 | 154 | 127 | 87 |

| 19 | 75 | 49 | 32 | 0 |

| 20 | 276 | 247 | 196 | 184 |

| 21 | 261 | 232 | 180 | 173 |

| 22 | 243 | 221 | 207 | 153 |

| 23 | 243 | 221 | 207 | 153 |

| 24 | 243 | 221 | 207 | 153 |

| Jute 4 cm | ||

| Diameter(cm) | Flow rate/day (g/day) | Flow rate/Hr (g/hr) |

| 0.4 | 55 | 0.083 |

| 0.6 | 77 | 0.58 |

| 0.8 | 91 | 1.16 |

| 1 | 145 | 1.67 |

POLYESTER 4 CM

| Diameter in cm | ||||

| Hours | 0.4 | 0.6 | 0.8 | 1.0 |

| 1 | 296 | 295 | 294 | 233 |

| 2 | 295 | 294 | 292 | 290 |

| 3 | 291 | 290 | 287 | 285 |

| 4 | 289 | 287 | 285 | 284 |

| 5 | 287 | 284 | 281 | 279 |

| 6 | 282 | 278 | 274 | 271 |

| 19 | 207 | 233 | 200 | 192 |

| 20 | 279 | 267 | 253 | 237 |

| 21 | 245 | 232 | 215 | 207 |

| 22 | 245 | 232 | 215 | 207 |

| 23 | 245 | 232 | 215 | 207 |

| 24 | 245 | 232 | 215 | 207 |

| Polyester 4 cm | ||

| Diameter(cm) | Flow rate/day (g/day) | Flow rate/Hr (g/hr) |

| 0.4 | 53 | 0.083 |

| 0.6 | 66 | 0.58 |

| 0.8 | 83 | 1.16 |

| 1 | 91 | 1.67 |

POLYESTER 5 CM

| hours | 0.4 | 0.6 | 0.8 | 1 |

| 1 | 298 | 296 | 294 | 293 |

| 2 | 290 | 293 | 292 | 290 |

| 3 | 281 | 290 | 287 | 283 |

| 4 | 296 | 288 | 286 | 281 |

| 5 | 294 | 287 | 284 | 278 |

| 6 | 295 | 285 | 282 | 275 |

| 19 | 293 | 279 | 276 | 273 |

| 20 | 294 | 287 | 285 | 281 |

| 21 | 296 | 286 | 282 | 278 |

| 22 | 296 | 286 | 282 | 278 |

| 23 | 296 | 286 | 282 | 278 |

| 24 | 296 | 286 | 282 | 278 |

| Polyester 5 cm | ||

| Diameter(cm) | Flow rate/day (g/day) | Flow rate/Hr (g/hr) |

| 0.4 | 2 | 0.083 |

| 0.6 | 12 | 0.58 |

| 0.8 | 16 | 1.16 |

| 1 | 26 | 1.67 |

From above observations, we can say that the highest flow rate is observed in jute with diameter 1 cm and height of the curve of the wick 4 cm and it is 145 g/day .i.e. 6.04 g/hr.

After discussion with Dixit Sir, he told to take 3 trials of the each height. So, I taken trails according to that.

6/11/2022 to 13/11/2022

OBSERVATIONS:

HEIGHT 5 cm

| Flow rate/day | |||

| Trials | Diameter | Jute | Polyester |

| 1 | 0.4 | 2 | 9 |

| 0.6 | 14 | 12 | |

| 0.8 | 28 | 16 | |

| 1 | 40 | 26 | |

| 2 | 0.4 | 3 | 13 |

| 0.6 | 10 | 10 | |

| 0.8 | 26 | 18 | |

| 1 | 42 | 29 | |

| 3 | 0.4 | 6 | 8 |

| 0.6 | 18 | 13 | |

| 0.8 | 31 | 14 | |

| 1 | 45 | 23 |

HEIGHT 4 CM

| Flow rate/day | |||

| Trials | Diameter | Jute | Polyester |

| 1 | 0.4 | 55 | 53 |

| 0.6 | 77 | 66 | |

| 0.8 | 91 | 83 | |

| 1 | 145 | 91 | |

| 2 | 0.4 | 58 | 50 |

| 0.6 | 73 | 68 | |

| 0.8 | 93 | 86 | |

| 1 | 141 | 93 | |

| 3 | 0.4 | 53 | 55 |

| 0.6 | 80 | 63 | |

| 0.8 | 96 | 87 | |

| 1 | 148 | 91 |

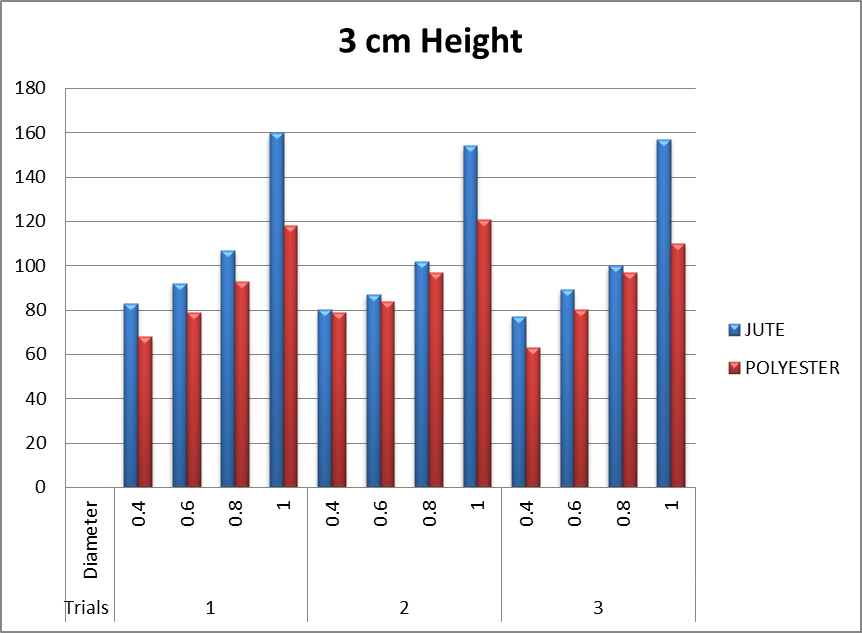

HEIGHT 3 cm

| Flow rate/day | |||

| Trials | Diameter | Jute | Polyester |

| 1 | 0.4 | 83 | 68 |

| 0.6 | 92 | 79 | |

| 0.8 | 107 | 93 | |

| 1 | 160 | 118 | |

| 2 | 0.4 | 80 | 79 |

| 0.6 | 87 | 84 | |

| 0.8 | 102 | 97 | |

| 1 | 154 | 121 | |

| 3 | 0.4 | 77 | 63 |

| 0.6 | 89 | 80 | |

| 0.8 | 100 | 97 | |

| 1 | 157 | 110 |

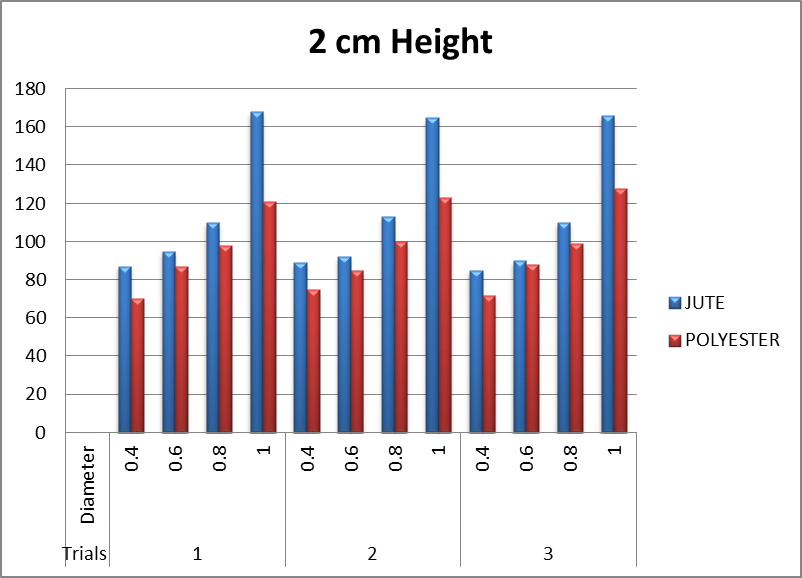

HEIGHT 2 cm

| Flow rate/day | |||

| Trials | Diameter | Jute | Polyester |

| 1 | 0.4 | 87 | 70 |

| 0.6 | 95 | 87 | |

| 0.8 | 110 | 98 | |

| 1 | 168 | 121 | |

| 2 | 0.4 | 89 | 75 |

| 0.6 | 92 | 85 | |

| 0.8 | 113 | 100 | |

| 1 | 165 | 123 | |

| 3 | 0.4 | 85 | 72 |

| 0.6 | 90 | 88 | |

| 0.8 | 110 | 99 | |

| 1 | 166 | 128 |

Graphs of flow rate of water in the wick system:

RESULTS:

| Parameters | Jute | Polyester |

| Minimum flow rate | 2gm/day at 5 cm height of wick’s curve from water level and 0.4 cm diameter of the wick. | 8 gm/day at 5 cm height of wick’s curve from water level and 0.4 cm diameter of the wick. |

| Maximum flow rate | 168 gm/day at 2 cm height of wick’s curve from water level and 1 cm diameter of the wick. | 128 gm/day at 2 cm height of wick’s curve from water level and 1 cm diameter of the wick. |

| Cost | Low | High |

| Durability | High | Low |

Conclusion:

- The Jute wick has maximum flow rate of 168 gm/day at 2 cm height from water level and having 1 cm diameter.

- According to cost, jute can be preferred as a material for wick.

- According to durability, polyester is more durable in comparison with jute wick.