Client : Dr. U. Kharul, Genrich Membranes Pvt. Ltd., Pune.

*Comments in red are unknowns that need to be cleared in the next draft.

Introduction

Genrich Membranes (http://genrichmembranes.com/) has developed a compact unit where a filter containing molecular sieves transforms atmospheric air input to an output of oxygen rich gas. This output can be used as a medical device for patients requiring oxygen supply.

What is the current status of the equipment?If it is still under development, how close is this unit to production? If under production, how many units are under use. Any rural applications as of today?

How does this technology compare to the following products in the market?

- http://medicalbulkbuy.com/product/5l-oxygen-concentrator/

- http://www.shopclues.com/philips-oxygen-concentrator-1.html?mcid=ps&utm_source=google&utm_medium=cpc&utm_campaign=Search%7cAdwords%7cPLA%7cSearch-PLA-Shopping&gclid=CLfo1rS_8M0CFdcRaAodlXEPOw&gclsrc=aw.ds

- http://www.amazon.in/Healthgenie-in-7f-5-Healthgenie-Oxygen-Concentrator/dp/B00VQ1PPM0?tag=googinhydr18418-21&tag=googinkenshoo-21&ascsubtag=a64f8f02-1688-4da5-9c56-e7066e36583d

Application area of OEU

To replace oxygen cylinders used in medical setups. Where is oxygen rich air required and in what concentrations?

| Snake bite patient | Xyz % |

| chronic obstructive pulmonary disease (COPD | 24-28% |

| …others | % |

The current unit supplies from 27- 35% oxygen rich air.

Benefits of OEU

- A low cost alternative to PSA/Cryogenic based air separation systems.

- An efficient alternative to cylinder units where the medical requirement of 27-35% oxygen enriched air is obtained through dilution of >95% pure oxygen from bottles.

- Cost effective solution to provide O2 enriched sterile air for medical applications.

- Adaptable to diversified applications: rural health centers, home care, ambulance, oxygen booths, etc.

- Eco-friendly technology, no need of chemicals, no hazardous emissions.

- Long life of membrane system since there is no fouling.

Challenges of OEU

- Filter life?

- Electricity required to power air compressor. This limits its application to urban areas where electricity supply is reliable and backup available.

- Weight limits portability.

- Many controls, such as a knob for pressurized air inflow or controlling outflow and thus controlling oxygen concentration may not be easy for medical staff at the rural level. A simplified foolproof system could be made.

Example scenarios justifying the development requirement:

- In case of a snake bite, the victim may die much early due to panic instead of the venom. Emergency oxygen can be given to increase oxygen in blood and counter ill effects of panic.

- Accidents can occur wherein the patient need to be transported quickly to a health center. Ambulance services may not be available on time, but motorbikes are usually used.

Emergency oxygen system thus must be small and portable enough in addition to be driven by the motorbike or othr methods that can reach remote places more easily and quickly than ambulance.

Broaddesign challengesof interest at DIC, Vigyan Ashram :

- An air compressor that can be driven by various mechanical power sources in addition to an electric motor.

- Proposed air compressor power sources:

- Motorbike

- Bicycle

- Hand powered

- Portable and compact for easy use.

- User-friendly design for untrained health care providers.

- Proposed platform:

- Air compressor permanently attached to a bike.

- OEU is linked by a pneumatic hose that can be taken inside homes.

- Bike is modified to carry unconscious patient to nearest health center with oxygen support.

Alternative ideas that need brainstorming

- Filling LPG cylinder equivalents with compressed air, instead of using air compressor. The cylinders can be filled at any tire repair shop.

- Filling automobile/truck tires with air and using this for the OEU.

NOTE: Oxygen therapy can be dangerous if practiced by unqualified and uncertified personnel. Therefore, design must include safe oxygen levels.

Specifications of existing OEU

Input/output

Tentative costing for first prototype:

Timeline for first prototype model:

components for driving oxygen enrichment unit:

1) compressor.

2)Stand for setup.

3)Roller.

4)tank for storage.

time for stand design and manufacturing @ stand -4 days.

time for roller design, calculations and manufacturing -4 days

time for compressor purchase -3 days.

time for coupling the roller to the stand, compressor, tank -4 days.

time for trial (Objective: 25lpm@5bar air supply on motorcycle) -3days.

time for connecting OEU unit and Nonelectric compressor setup -1day.

time for trials -5 days.

Total time -24 days.

Project survey and Doctors review about oxygen Cylinder

Last week I have visited Dr. Bhosale, who is operate Oxygen cylinder during emergency in Rural areas . I asked some questions about Oxygen cylinder and oxygen therapy. Then I realize that only provision of oxygen (during accidents and obvious snake bites ) human can live at least few hours before actual treatment. But oxygen cylinder is costlier and there is some risk during handling that unit.

Also, I asked a query about mixing of correct proportion of oxygen gas and nitrogen gas. He told me when oxygen provides to the patient, nitrogen will be mixed at the proper level. And then supply through the mask to the patient. The quantity of mixture decided by patients pulse meter which is display on the monitor.

In Oxygen enrichment unit , we use atmospheric air ( freely available). My task is to produce at least 5 bar pressure without using electrical energy and minimize the size of setup. We can use this apparatus as first aid treatment. At anywhere and at anytime.

So according to my plan next step of this project is apply suitable ideas such as bike driven unit or hand pump to drive 3000 rpm compressor. And maintain 5 bar pressure throughout the process

Oxygen therapy cylinder setup.

Monitor which is operating during oxygen therapy .

g

Concept draft(2)

13th July 2016

The first draft of Concept Notes on

Multi-drive Oxygen Enrichment Unit (OEU)

Client: Dr. U. Kharul, Genrich Membranes Pvt. Ltd., Pune.

Principle Investigator: Miss. Dipali Kambale, DIC, Vigyan Ashram

Introduction

Genrich Membranes (http://genrichmembranes.com/) has developed a compact unit where a filter containing polymeric membrane transforms atmospheric air input to an output of oxygen rich gas. This device can be used for oxygen therapy in medical cases (COPD, asthma, neonatal, etc.).

What is the current status of the equipment? The prototype is developed and is close to production. Any rural applications as of today: This is designed for rural / BoP population?

How does this technology compare to the following products in the market?

- http://medicalbulkbuy.com/product/5l-oxygen-concentrator/

- http://www.shopclues.com/philips-oxygen-concentrator-1.html?mcid=ps&utm_source=google&utm_medium=cpc&utm_campaign=Search%7cAdwords%7cPLA%7cSearch-PLA-Shopping&gclid=CLfo1rS_8M0CFdcRaAodlXEPOw&gclsrc=aw.ds

- http://www.amazon.in/Healthgenie-in-7f-5-Healthgenie-Oxygen-Concentrator/dp/B00VQ1PPM0?tag=googinhydr18418-21&tag=googinkenshoo-21&ascsubtag=a64f8f02-1688-4da5-9c56-e7066e36583d

Application area of OEU

To replace oxygen cylinders used in medical setups. Where is oxygen rich air required and in what concentrations?

| In critical operation cases (threat of life) | Upto 85 % |

| COPD, Astma | 35% |

| Neonatal | 27% |

| High concentration of oxygen is toxic to various cells (brain, eye, ….) | |

| Snake bite patient | Xyz % |

| chronic obstructive pulmonary disease (COPD | 24-28% |

| …others | % |

The current unit supplies from 21- 35% oxygen rich air.

Benefits of OEU

- A low cost alternative to PSA/Cryogenic based air separation systems.

- An efficient alternative to cylinder units where the medical requirement of 27-35% oxygen enriched air is obtained through dilution of >95% pure oxygen from bottles.

- Cost effective solution to provide O2 enriched sterile air for medical applications.

- Adaptable to diversified applications: rural health centers, home care, ambulance, oxygen booths, etc.

- Eco-friendly technology, no need of chemicals, no hazardous emissions.

- Long life of membrane system since there is no fouling.

Challenges of OEU

- Filter life? >5yr

- Electricity required to power air compressor. This limits its application to urban areas where electricity supply is reliable and backup available.

- Weight limits, portability.

- Many controls, such as a knob for pressurized air inflow or controlling outflow and thus controlling oxygen concentration may not be easy for medical staff at the rural level. A simplified foolproof system could be made.

Example scenarios justifying the development requirement:

- In case of a snake bite, the victim may die much early due to panic instead of the venom. Emergency oxygen can be given to increase oxygen in blood and counter ill effects of panic.

- Accidents can occur wherein the patient need to be transported quickly to a health center. Ambulance services may not be available on time, but motorbikes are usually used.

Emergency oxygen system thus must be small and portable enough in addition to be driven by the motorbike or othr methods that can reach remote places more easily and quickly than ambulance.

Broad design challenges of interest at DIC, Vigyan Ashram :

- An air compressor that can be driven by various mechanical power sources in addition to an electric motor.

- Proposed air compressor power sources:

- Motorbike

- Bicycle

- Hand powered

- Portable and compact for easy use.

- User-friendly design for untrained health care providers.

- Proposed platform:

- Air compressor permanently attached to a bike.

- OEU is linked by a pneumatic hose that can be taken inside homes.

- Bike is modified to carry unconscious patient to nearest health center with oxygen support.

Alternative ideas that need brainstorming

- Filling LPG cylinder equivalents with compressed air, instead of using air compressor. The cylinders can be filled at any tire repair shop.

Filling automobile/truck tires with air and using this for the OEU.

NOTE: Oxygen therapy can be dangerous if practiced by personnel. Therefore, design must include safe oxygen levels.

Specifications of existing OEU

Input/output

| Input / Output | Compressor output flow rate | 25-30 lpm |

| Compressor output flow pressure | 5 bar (g) | |

| Oxygen mask flow rate | 5 lpm | |

| Oxygen mask pressure | Atmospheric | |

| Oxygen concentration range | 25-35% by volume | |

| Other specs | Tank capacity | 5 liters |

| OEU dimensions | ? | |

| Filter volume | ? | |

| Number of filters | 2 |

Making list of componants

COMPONENTS FOR MULTI -DRIVE OXYGEN ENRICHMENT UNIT

| COMPONENTS | SPECIFICATIONS & prices |

| Compressor | 0.5 hp |

| Wheel roller | 34mm (by calculation) |

| Compressed air storage tank | 5 liter |

| Bolts & nuts | Unknown quantity |

| Angeltouch Oxygen Mask for Adult | 1 mask |

| Bearings (2) | 34 mm @ roller diameter |

| Headless screw | Unknown quantity. |

Yet, I am preparing specific list of components…

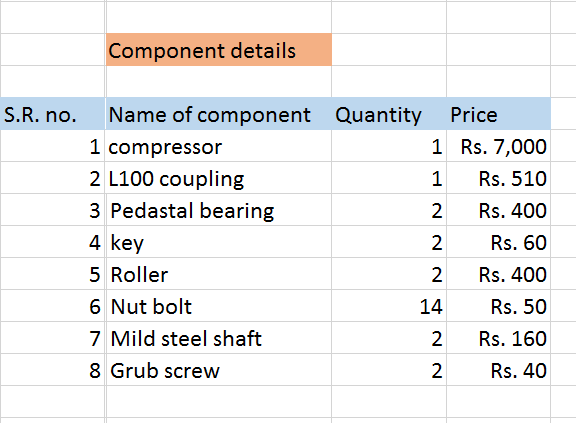

First setup for multi drive oxygen enrichment unit

I purchase material for multi drive oxygen enrichment unit from pune.

Details are below,

The market survey is too much hectic because of exact compressor specifications. And am new too. But machining is an interesting part of this project. I use various machines for developing first setup.

First trial of setup is successful.We run the compressor by using rare wheel of two wheeler.

Compressor is running as per there specifications and still I do modification in this setup.

My aim is to make setup portable and user- friendly when the time factor is so small.

First step of this project is successful.

Final testing of the non-electric oxygen enrichment unit.

Hi…

It is a great experience with this project. As I earlier said that research and development of this project is very interesting. Project is almost done….!! some finishing and vibration problems occurs during testing the unit.

After the first prototype trial, we are working on a modified setup which is suggested from the client. We modified roller geometry considering tyre surface contact. Our first roller geometry was only cylindrical in shape. We change the design of roller into the v-shape roller.

It helps in taking rare wheel balanced and increases traction. But we struggling with roller material. This project is not completed yet…We grab specifications of membrane inputs.

We achieve 8 bar pressure and 40 LPM air flow rate with 38% oxygen enriched gas.

Setup arrangement

Designed unit

Tank pressure during trial

Regulator pressure during trial

Air flow rate during testing

First prototype trial and modifications

Hi,

Its long time to updating about Multi drive oxygen enrichment unit. So, the first prototype is ready after lots of modifications and with different ideas. Research and development of this project is very interesting and I am enjoying each and every task of this project.

Here I would like to share with you client meeting report…

Actual costing of project after final trial