INTRODUCTION

At our Vigyan Ashram, we have around 50-60 members always available in our campus .Everyday at the lunch we require approximately 200-250 rotis ,so it is not easy to make these rotis by hand. It require lots of time and effort.

So we are using the AUTOMATIC ROTI MAKING MACHINE that is driven by both electricity and L.P.G gas.

COMPONENTS OF ROTI MAKER

- Frame and body

- Gas burner (4 L.P.G burners)

- Roti pressing mechanism consist of coil heaters.

- 3 layer conveyor system consist of metal strips (that works as tawa) and steel mesh (that work as griddle).

- Control unit for heaters showing temperatures.

Regulators for burners .

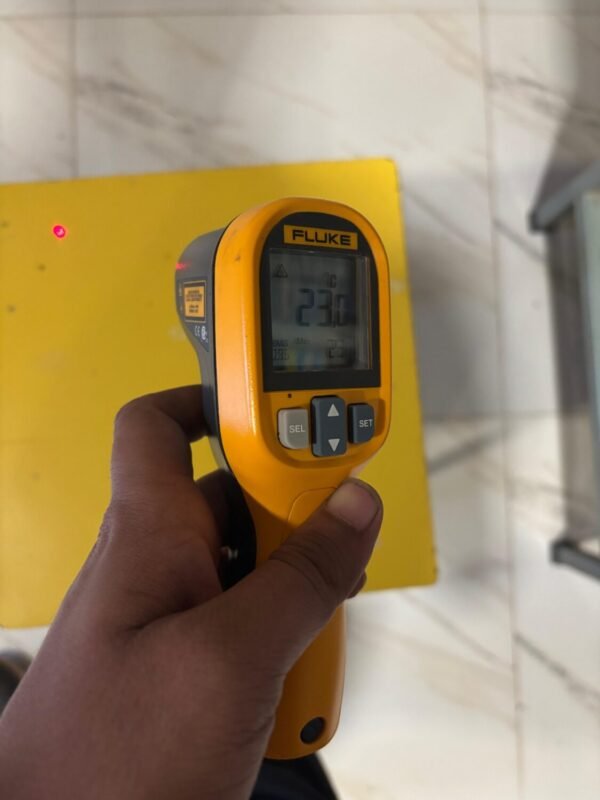

COST ESTIMATION OF PER ROTI

So I have done a simple cost performance of roti maker machine for cost of per roti , by having simple instruments like weighing balance (class 4) which is kind of less accurate and time watch etc

CHALLENGES/PROBLEMS IN ROTI MAKER

➢ In Roti pressing mechanism.

1. wire is burning all the time.

2. Detachment of roti from pressing mechanism is not proper due to temperature

➢ Required high amount of energy /efficiency is low because of following reasons.

1. High amount of LPG required for running 4 large burners.

2. We required power for conveying system (about 570w motor).

3. Heat energy waste in conduction through plates of conveyors.

4. Heat energy waste in surrounding.

➢ Due to not proper oxygen mixing with LPG gas the unburnt flame is used that reduce the efficiency, that is due to wrong placement of entering system of oxygen.

➢ The entering time of dough ball is very less this is due to constant speed of cam.

➢ Cost of the machine is very high about 1.88 lacks.

➢ According to machine capability of 500 rotis per hour, but we required only 200-300 rotis only so we under utilised this machine.

➢ This machine is kind of complex for use.

CALCULATION FOR EFFICIENCY OF ROTI MAKER

Firstly we are calculating for burner

So average water loss by 1 roti is 3.3gm and for 150 rotis we have loss 150*3.3 = 495gm of water

So heat required for increasing temperature from 30degree Celsius to 100 degree Celsius for whole roti whose mass is 24 gm of 1 roti so mass(m) of 150 rotis =3600

Q1=m.s.(t1-t2) and we assume specific heat of dough to be s = specific heat of water =4.186 joules per gram degree Celsius

Q1=3600gm*4.186*(100-30) = 1054872 joules

So heat required to evaporate water

Q2=m.L L= latent heat of vapourisation =2.25*10^6 joules per kilogram

Q2= 495gm*2.25*10^6 j/kg =1113750 joules

So total energy loss is q1+q2 =2168622 joules=2.168622 mega joules

And we consume 1kg of LPG gas and calorific value of LPG is 50 MJ/KG

So the efficiency of burner is 4.33%

So Q= q1+q2+q3+q4…..+q

So we applied heat Q (50 MJ) and q1,q2,q3,q4…. are the losses and q= heat required to bake rotis

so the cost of LPG gas to be around 100 rupees for 1kg

And we used machine for 2 times a day so the cost of LPG for 1 day 100*2=200 rupees

and for a month the cost of LPG to be 200*30=6000 rupees

and for a year the cost of LPG gas to be 12*6000=72000 rupees

Lets say we have efficiency now around 4.33 or we can say 5%

or if our target is to take is 5% efficiency to 10%

then we can save 36000 rupees a year

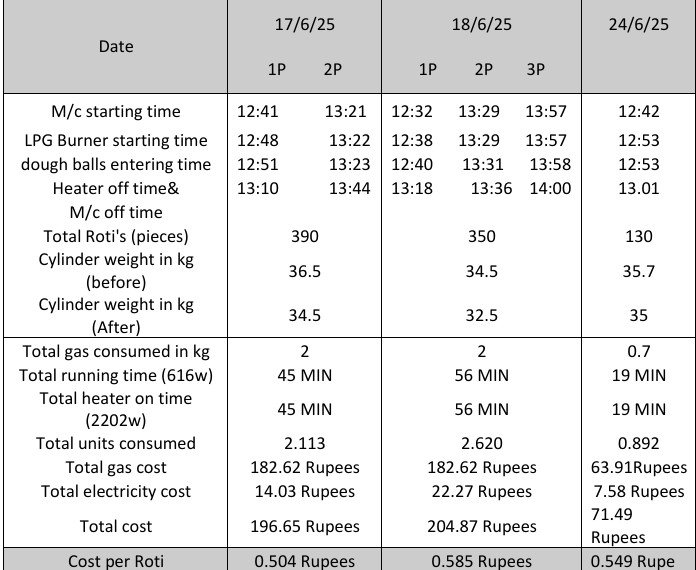

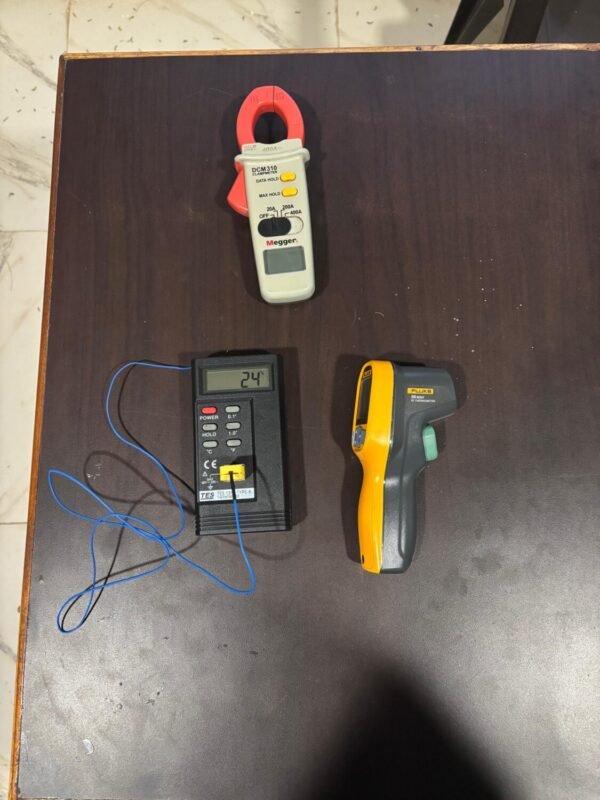

instruments selection

K TYPE THERMOCOUPLE It has ranged between -50°to 1300° celsius and has a bead type of prope.

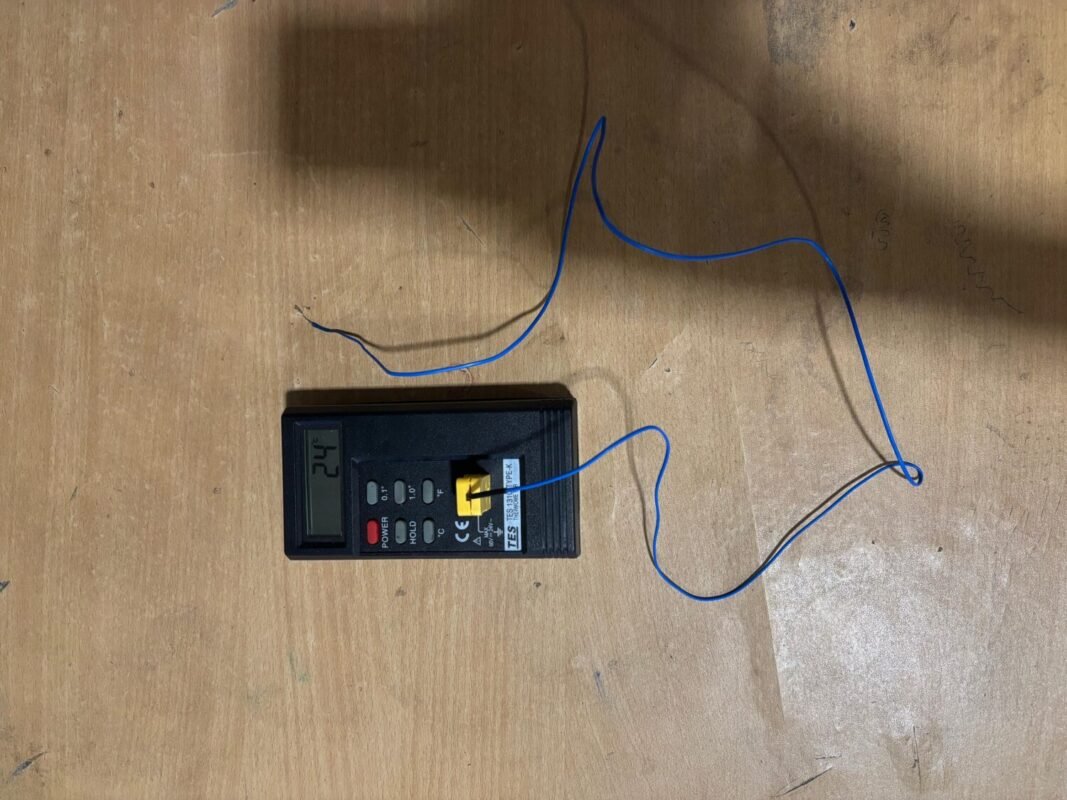

INFRARED TEMPERATURE GUN This temperature gun is help to find out object temperature.

CLAMPMETER for measurement of current flow in a conducting wire

TAKING PARAMETERS FROM TRADITIONAL WAY OF ROTI MAKING

So for anology of this tradional way of roti making with the automatic roti machine , i have taken some parameters, like temperature of pan(tawa),total retention time that roti being on pan,and minimum no. of flips of roti on pan.

- temperature of pan(tawa) =around 250° celsius

- total retiontion time=27 seconds

- minimum no. of flips=3

Mechanical Issues Encountered

During a night-time operation for roti-making, the conveyor and motor assembly got stuck. The next morning, I began troubleshooting

STEP 1: INSPECTION OF MOTOR AND GEARBOX AND RESISTANCE TEST OF MOTOR

when machine got stuck, we have doubt on the motor ,so we take the resisting test by multimeter/clampmeter

-

we set the multimeter to the Ω (ohms) setting (lowest range, 200 Ω, i).

Identify Start (S), Run (R), and Common (C).

-

Measure:

-

C–S (start winding)

-

C–R (run winding)

-

S–R (combined windings)

-

- then we find the reading of 5 ohms

if we get reading of 0 ohm means there is a short of wire/winding, i we get infinity reading means opening of winding, but we get reading of 5 ohm ,so means there is no fault in the motor winding.

then we take away motor with gearbox from motor to electical lab ,for operating seperately , by giving power to the motor.so here it run properly with gearbox.

Conclusion is that there is no issue in the motor and gearbox.

STEP 2: INSPECTION OF MECHANICAL PART

After the inspection of motor and gearbox, with DBRT students ,we check the movability of chains,sprockets and pedestal wheel on shaft, by rotating all of us by manual.

then discover that one shaft is jammed in the pedestal wheels, we solve this.

then lubricating all 12 pedestal wheel with lubricating by semi solid lubrication( grease).

THEN FINALLY We solve this problem and assemble motor and gearbox in the machine. then machine get run well.

ENCOUNTERED/REPAIRED THE GEARBOX

after one day during the operation of roti making ,the machine again stuck between the operation.

This time, the gearbox itself malfunctioned.

means by giving power to the motor ,the motor get started,the fan of motor roating but the gearbox is stucked.then steps we have taken are as follows:

SEPERATELY GIVING POWER TO THE MOTOR

again we have take out this motor and gearbox assembly for inspection, after giving the power to the motor, then gearbox shaft is rotating but again stuck ,we have to give the twist to its shaft ,then again rotate then again stuck, then we have observed that after taking one round it get stuck.

GEARBOX SPECIFICATIONS (it is worm and wheel type )

| Label Field | Value | Explanation |

|---|---|---|

| Type | NMRV 030 | NMRV = standard worm gearbox series, 030 = size/frame number |

| i (Ratio) | 100 | Gear reduction ratio is 100:1, meaning the output shaft rotates once for every 100 input shaft revolutions |

| PAM | 71B5 | Motor flange size (IEC 71 frame with B5 flange mounting) – suitable for motors up to ~0.5 HP |

| Nr | 20231092 | Serial or production number for traceability |

OPEN/DISASSEMBLE THE GEAR BOX

It consist of worm type gear,wheel type gear,bearings,oil seals, lubricating oil that is not change for two years,etc.

I am trying to find the problem in the gearbox.

its wheel gear having the grooved shaped teeth ,so the are worn by rubbing ,means the gap is incresed ,so we have to replaced this assembly of gears.

THEN ORDERING OF GEARBOX COMPONENTS

then i discussed this problem eith Anil sir and Prasad sir,after discussion we have decided to order this components,then discussed with the eternal gears company salesmen we got the prices of components,and compare with the price of new gearbox,so components price is around 5000 rupees and new gearbox price is around 10000 rupees.

so we decided to order a components of gearbox,it consist of gears( worm and wheel both),bearings,oil seals.

ASSEMBLING AND SELECTING SUITABLE LUBRICATING OIL

- Firstly we have to arrange bearings on the gears

- then setting up the worm and wheel gears in the casing without breaking any teeths on the gears.

- then setting or assembling the oil seals precisely

- we have sure about no leak in the cassing.

- then pour the lubricating oil from oil inlet ,fill at the height of this mark window.

- then seal closed the all openings.

FOR SELECTING LUBRICATING OIL

we required high grade synthetic oil because it required high viscosity oil,but due to unavailable at PABLE, i find out alternative fuel of SAE 140 ( grade for viscosity classification) and EL 4(

EL → Extra Load (extreme-pressure formulation, for high load conditions).

So i decide to use this lubrication oil.

FINAL TESTING AND ASSEMBLE ON THE MACHINE

after pouring lubrication oil then i mount motor on the gearbox and giving power to the motor ,then finally it started and rotating smoothly .

then we assemble this set up on the roti maker machine and now we get the rotis from this machine.