INTRODUCTION

This was the second assignment given to me. I was told to make a stool so that I could learn the welding operation.

06/10/2024

First I found out some standard dimensions of the stool on the internet. then I got some range in which standard dimension stools are made. After that I went to workshop where some stools were there to take their measurements.

After taking the measurements I made a sketch of it in the notebook with all the dimensions that I took.

07/10/2024

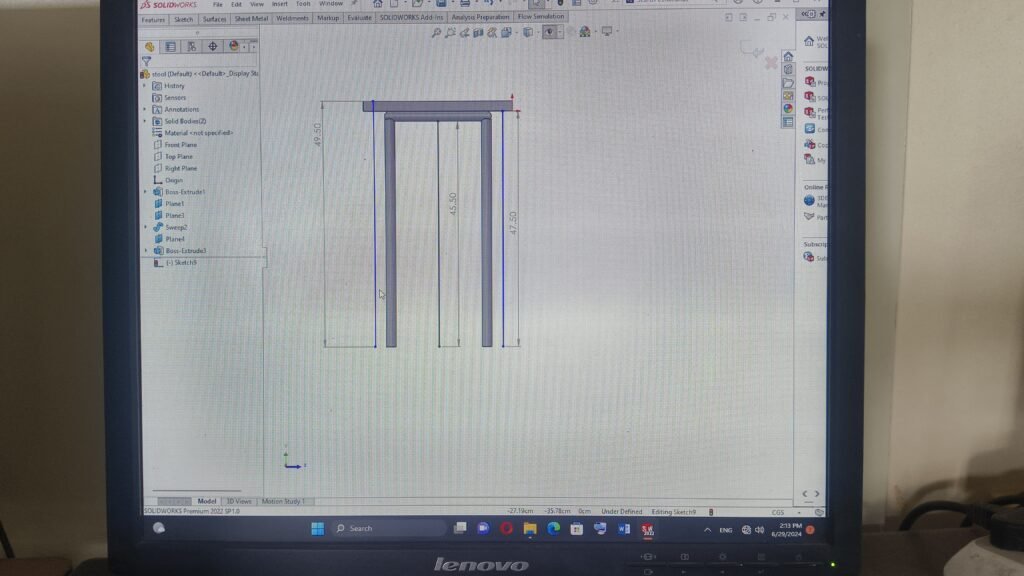

Today I made the design of stool on the solidworks.

08/10/2024

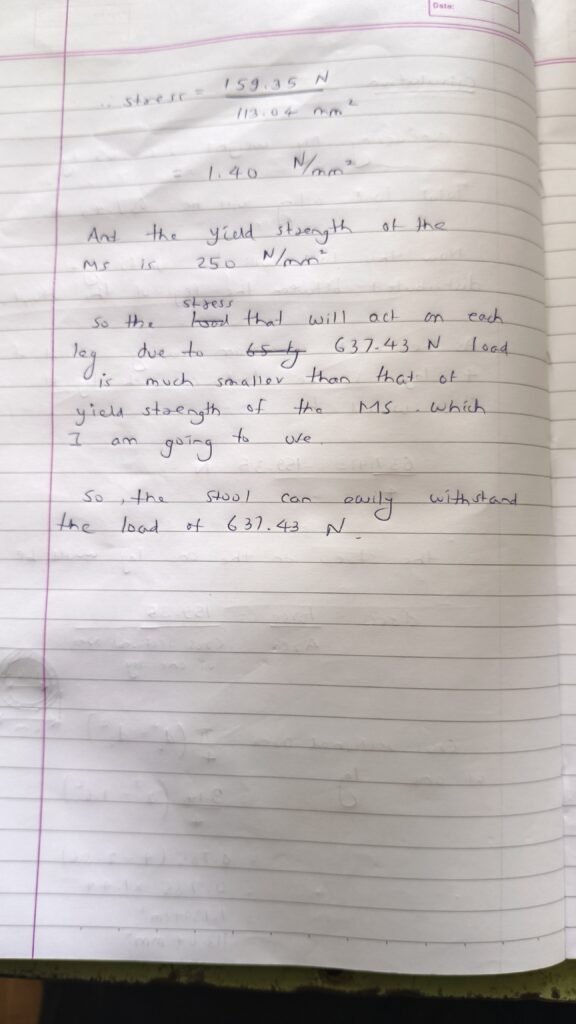

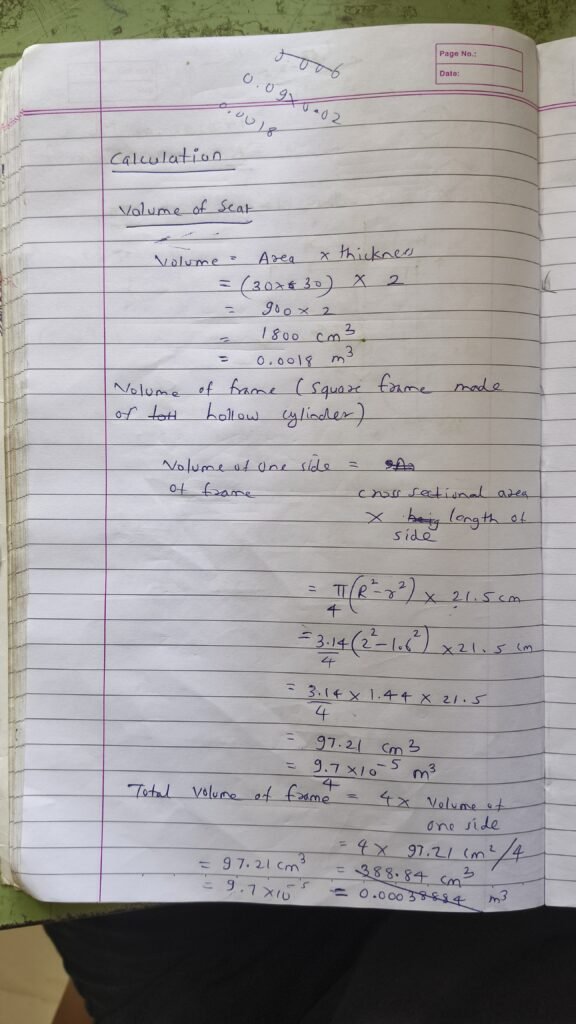

I showed this design to Prasad sir then he told me to calculate the stress that the stool of the dimensions I have made can bear. For that I first understood some concepts about Strength of Materials which were not cleared to me. I learned about yield strength which is nothing but amount of load or force that is acting on body beyond which the body starts to deform. Then I calculated the stress that could act on my stool. For that purpose I assumed my weight as Prasad sir told me to make it according to my weight.

09/10/2024

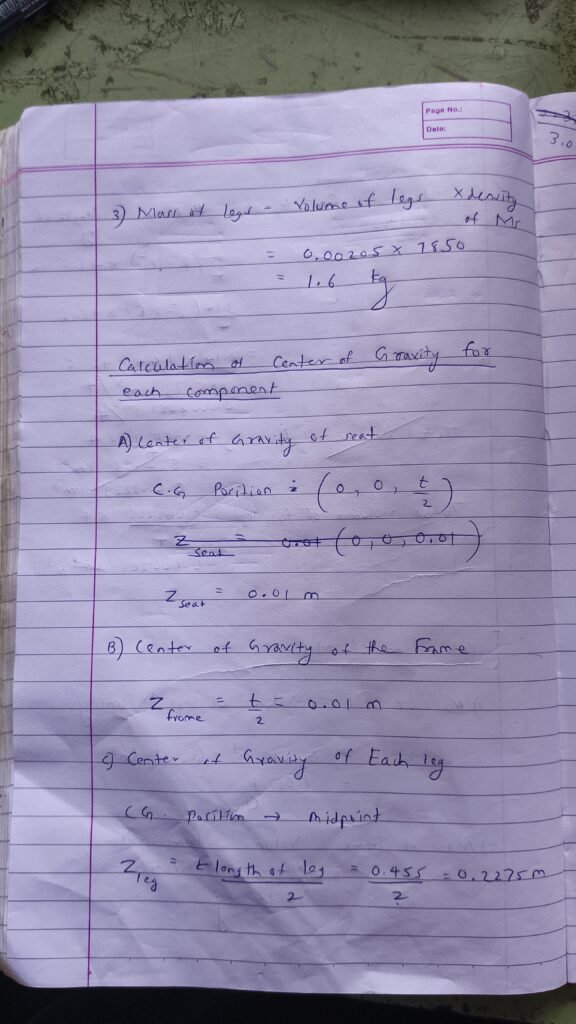

Today I showed my calculations to Prasad sir then he also told me to calculate the at what point Center of Gravity of my design will be located so that to check the stability of the structure. Then I calculated the Center of gravity of my design.

Then I check what should be the limit of Center of Gravity for Stability and it came out to be 15.83 cm and the center of gravity that I calculated was 11 cm which was under the limit. Then I showed it to Prasad sir and he told me to start making the stool. Then I went behind the workshop where all scrap is kept to find the material. I got the pipes of ms of required dimensions there.

11/10/2024

The materials I found from the scrap were not of required lengths. So I cut the pipes according to my required dimensions. After cutting I also grinded them because the edges were too sharp.

13/10/2024

As I wanted to make the square frame from the small pipe pieces. For that I made 450 cut at the each end of all the small pipes.

After cutting I again grinded the edges of it. Then I started the welding operation. First I welded the square frame. And then again grinded it.

After that I welded the legs of the stools on the square frame.

14/10/2024

As I welded the stool completely but CO2 gas was not available so I did arc welding. By arc welding the stool got some holes in the joints and the welding was not done proper that is why I did welding again. Today CO2 gas was refilled so I did gas welding again. Now the welding was done properly.

15/10/2024

Today I did grinding of the stool. The corners were rough due to welding so for making them smooth I did grinding operation.

16/10/2024

Today I did powder coating. For that first I cleaned the stool with 3 in one acid to remove rust. After that I sprayed the powder on it then I put it in a container till the temperature reached 150 degrees. After that I switched off the heater and kept it for a while to be cooled down. In this way the powder coating was done.

After powder coating was done I cut the ply wood in square shape for the seat of the stool.

19/10/2024

I drilled the holes in the stools to fix the seat.

Then I did marking on the seat by keeping the stool frame on it to drill holes on the seat.

Then I drilled holes in the the seat of the stool.

After drilling holes I fixed the seat on the stool frame with nuts and bolts.

21/10/2024

I cut the ‘sanmika’ according to the measurements of the seat of stool.

After that I stick it on the seat of stool using fevicol and kept it for dry overnight.