IDLI

Idli is a type of savory rice cake, originating from South India, popular as a breakfast food in Southern India. The cakes are made by steaming a batter consisting of fermented black lentils (de-husked) and rice. The fermentation process breaks down the starches so that they are more readily metabolized by the body.

Fermentation of idli batter results in both leavening caused by the generation of carbon dioxide as well as an increase in acidity. This fermentation is performed by lactic acid bacteria especially the heterofermentative strain Leuconostoc mesenteroides and the homofermentative strain Enterococcus faecalis (formerly classified as Streptococcus faecalis). Heterofermentative lactic acid bacteria such as L. mesenteroides generate both lactic acid as well as carbon dioxide whereas homofermentative lactic acid bacteria only generate lactic acid.

Both L. mesenteroides and E. faecalis are predominantly delivered to the batter by the black gram. Both strains start multiplying while the grains are soaking and continue to do so after grinding.

L. mesenteroides tolerates high concentrations of salt unlike most other bacteria. Hence the salt in the batter and the ongoing generation of lactic acid both suppress the growth of other undesirable micro-organisms.

Objective

- To optimize and formulate the fermented dehydrated idly premix.

2. To study the fermentation of idli batter at different temperature range and time.

3. To study the dehydration and form dehydrated premix.

4. To optimize the proportion of Salt, baking soda, citric acid and water, etc.

Problem Statement:

Already in market, there are various brands which sales the idli/ dosa instant premix like gits, katdare, etc. but these premixes are not fermented. These are only rice flour and black gram dhal flour with excessive amount of leavening agents like baking soda (Sodium bicarbonate), baking powder (Sodium hydrogen bicarbonate; baking soda + edible acids like tartaric acid), for puffiness of idli. Baking soda can be harmful to our health if taken into large doses or for a long time. About 5% leavening agents used in idli premixes which are not fermented.

Being food technologist; it is task for me to standardize and formulate the fermented dehydrated idly premixes.

Material

- Raw material :

- Rice

- black gram dhal

- Instruments:

- Incubator

- Weighing balance

- Digital Thermometer.

- Digital pH meter.

- Hot air oven

- Glassware’s and utensils:

- Burette stand

- burette

- Beakers

- Measuring cylinder

- Measuring cups.

Methodology

After the discussion with Mr. dixit, we were decided that; first we are going to standardization of general recipe of idli batter and study the fermentation of idly batter at various time and temperature.

Firstly, I was studied literature about idli and fermentation; and went through using these information.

I. FERMENTATION:

I. A. FIRST TRIAL:

27 and 28 November 2023

Generally, for idli and dosa batter rice to dehusked black gram dhal ratio is 2:1 ideal. First step of idli making is soaking of rice and black gram dhal for at least 4 hrs to maximum 12 hrs; I was following the measurements used in research paper. In that they used 1:3 to 1:4 w/v ratio of rice or dhal: water. but I used 1:2 w/v.

Soaking:

- Rice (60 gm) in 120 ml of water.

- black gram dhal (30gm) in 60 ml of water

- Soaking time: 14 hrs.

After 14 hrs of soaking;

Grinding seperately with soaking water: rice was coarsely grinded and black gram dhal was finely grinded,

Mixing together,

Kept for fermentation at room temperature (Soil lab’s incubator we cants used for fermentation due to contamination and second incubator which is used for curd formation their was problem in it.

Observation:

- The batter was not fermented due to atmosphere change (rainy and cloudy weather) and contaminated after 10-12 hrs.)

- Black gram dhal soaks more water than rice that means water absorption capacity of black gram dhal is higher than rice.

Then I will decide to control the temperature of incubator (used for curd formation) manually using hot water and thermometer.

II. B. SECOND TRIAL:

29 and 30 November 2023

Soaking:

(Rice or Black gram dhal: water:: 1:3 w/v)

1.Rice 60 gm in 180 ml of water)

2. Black gram dhal 30 gm in 90ml of water

3. Soaking time : 4 hrs

Grinding separately with soaking water: rice was coarsely grinded and black gram dhal was finely grinded .

Mixing together:

Fermentation in incubator: at 30 degree , by controlling manually using hot water and thermometer.

| Sr. no. | Time interval | Burette reading | Mean | Acidity in K2CO3 gm/ 100 gm of sample | Acidity in mol | pH |

| 1. | Initial | 1.2, 1.1 | 1.15 | 0.317 | 0.000115 | 6.98 |

| 2. | After 10 hrs | 4.9, 4.7 | 4.8 | 1.32 | 0.000480 | 4.98 |

| 3. | After 12 hrs | 5.3, 5.5 | 5.4 | 1.48 | 0.000540 | 4.93 |

Fig., Ckecking titrable acidity.

After checking titrable acidity and pH; remained idly batter was used for idli making. Idli was prepared after 14 hrs. of fermentation. Salt was added to it Idli batter was poured in pre-greased idli mold and steamed for 10-15 mins.

Note: Leavening agents like baking powder or baking soda were not used

Observation:

- Controlling temperature of incubator by hot water and thermometer was too difficult because there were various fluctuations in temperature.

- The mold which is used for idli steaming has not small holes.

- Batter consistency was thin (more amount of water).

- Idli was too much sour (due to overfermentation 14 hrs).

- Idli was not good in taste and texture (does not fluffy or spongy).

I. C. THIRD TRIAL:

02 December 2023

From above observation I understood that the amount of water we used in batter should be low. I discussed with Mr. Dixit sir and we decided that; water used for soaking of rice and black gram dhal will be 1:1w/v and 1:2w/v respectively.

Soaking :

(Rice : water :: 1:1 and Black gram dhal: water :: 1:2)

- Rice: 60 gm in 120 ml of water

- Black gram dhal : 30 gm in 60 ml of water

- Soaking time: 6 hrs.

Grinding separately with soaking water; rice was coarsely grinded and black gram dhal was finely grinded,.

Mixing together.

Fermentation in incubator at 35 degree

Observation: Readings of titrable acidity and pH were not taken due to temperature fluctuations caused by incubator maintenance by FabLab department.

I. D. FORTH TRIAL:

06 December 2023

I studied some research papers on idli and discussed with Mr. dixit sir and we decided to determine the moisture content in rice and black gram dhal after and before soaking to understand the what amount of water exactly used in batter. also we decide to drain out the soaking water from rice and black gram dhal and additionally add necessary amount of water during grinding.

I was determined the moisture content dry ingredients that is rice and dehusked black gram dhal also wet ingredients (after soaking ) that is soaked rice and black gram dhal.

| Sr. no. | Ingredient | Moisture Content (%) |

| 1. | Dry rice | 12.27 |

| 2. | Dry black gram dhal | 12.8 |

Fig., Moisture Content of dry rice and Black gram dhal

Soaking:

- Rice 60 gm in 100 ml of water.

- Black gram dhal 30 gm in 100 ml of water.

- Soaking time: 12 hrs.

Fig., Soaking

Draining:

- Water was drained from rice and dhal after 12 hrs of soaking by using strainer.

- Drained water was measured using measuring cup (Measuring cylinder not available in food lab)

| sr. no. | Ingredient | Weight before soaking. | Weight after soaking | Drained water | Moisture content after soaking |

| 1. | Rice | 60 gm | 77 gm | 85 ml | 33.06 % |

| 2. | Black gram dhal | 30gm | 53 gm | 75 ml | 57.17 % |

fig., Draining using strainer

Grinding:

- Soaked rice was grinded coarsely with 30 ml of water.

- Soaked black gram dhal was grinded finely with 60 ml of water.

Fig., Grinding of Soaked rice and black gram dhal

Mixing together:

Fig., Mixed batter

Fermentation: at 40 degree in incubator

| Sr. no. | Time Interval | Burette reading | Acidity in K2CO3 gm/ 100 gm sample | Acidity in mol | pH |

| 1. | Initial | 1.4 | 0.112 | 0.00014 | 6.45 |

| 2. | 3 hrs | 2.4 | 0.6624 | 0.00024 | 5.40 |

| 3. | 6 hrs | 4.1 | 1.1316 | 0.00041 | 5.13 |

| 4. | 7 hrs | 4.7 | 1.2972 | 0.00047 | 5.02 |

I.E. TRIAL FIFTH:

08 and 09 December 2023

Soaking:

- Rice 60 gm in 100 ml of water.

- Black gram dhal 30 gm in 100 ml of water.

- Soaking time: 12 hrs.

Draining:

Grinding:

- Soaked rice was grinded coarsely with 30 ml of water

- Soaked black gram dhal was grinded finely with 60 ml of water.

Mixing together:

Fermentation at 35 degree in incubator

| Sr. no. | Time Interval | Burette reading | Mean | Acidity in K2CO3 gm/ 100 gm sample | Acidity in mol | pH |

| 1. | Initial | 1.3,1.2 | 1.25 | 0.9936 | 0.000125 | 6.70 |

| 2. | 7 hrs | 4.9, 5.0 | 4.95 | 1.3662 | 0.000495 | 4.80 |

| 3. | 9 hrs | 5.6, 5.7 | 5.65 | 1.5594 | 0.000565 | 4.25 |

II. Sensory evaluation of idli prepared with batter fermented at various time and temperature and having different level of Baking soda:

11 and12 December 2023

II. A. Fermentation at 300C (steaming without leavening agent):

- Soaking:

Rice: 80 gm

Black gram dhal: 40 gm

Soaking Time: 12hrs.

2. Grinding: Grinding separately.

Added water in soaked rice during grinding: 40ml.

Added water in soaked black gram dhal during grinding: 80 ml.

3. Mixing together:

Prepared batter: 240 gm

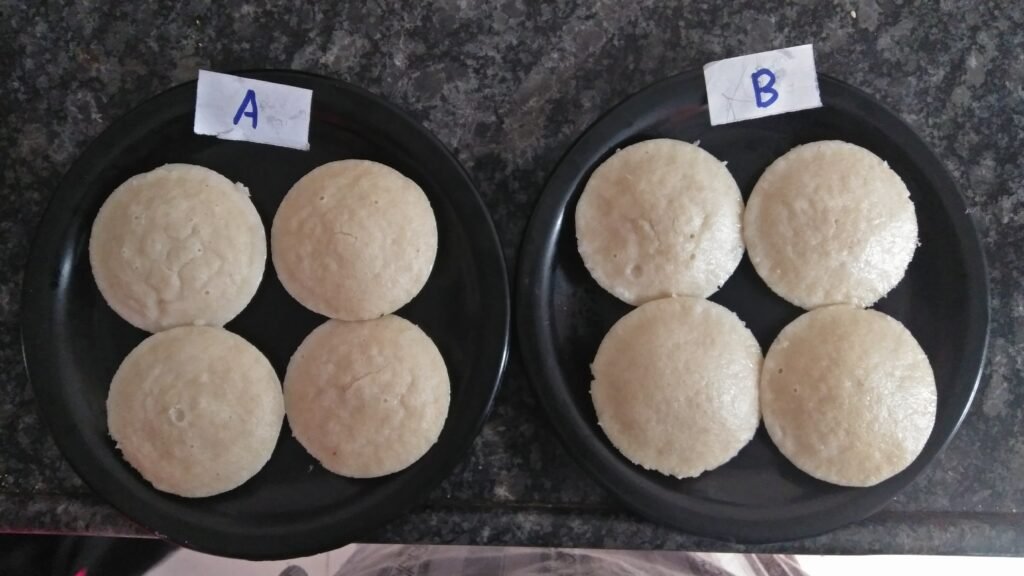

240 gm of sample divided into two: Sample A (120g) and Sample B (120gm).

4. Fermentation:

| Sr. no. | Sample | Fermentation Temperature | Fermentation Time |

| 1 | Sample A | 300C | 10hrs |

| 2 | Sample B | 300C | 12hrs |

5. Steaming:

| Sr. no. | Sample | Addition of salt in batter | Addition of water in batter | Addition of leavening agent into batter | Cooking time |

| 1. | A | 1 gm | 15 ml | – | 10 min |

| 2. | B | 2gm | 15 ml | – | 10 min |

6. Sensory evaluation:

Sensory assessment is a scientific approach for evoking, measuring, and interpreting products reactions as experienced via the senses of sight, smell, touch, taste and hearing. On a 9-point hedonic scale, 8 semi-trained panel members comprised of DIC members of the Vigyan Ashram, Pabal, evaluated freshly prepared Idli developed with batter which is fermented at different time with same temperature, for sensory characteristics like appearance, color, taste, flavor, texture, and overall. Products were rated on a 9-point hedonic scale with associated descriptive words ranging from 9 (very like) to 1 (strongly detest).

Sensory score:

- Dislike extremely

- Dislike very much,

- Dislike moderately,

- Dislike slightly,

- Neither like nor dislike,

- Like slightly,

- Like moderately,

- Like very much,

- Like extremely.

| Sr. no, | Sample | Color | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 1 | A | 7.42 | 7.14 | 3.14 | 6 | 5.71 | 5.88 |

| 2 | B | 7.42 | 7.42 | 5 | 6.42 | 7 | 6.65 |

7. Observations:

- As leavening agents (baking soda) was not added into batter, the texture of idli was not good (as per sensory evaluation).

- Sample B was salty in taste, as we added 2gm salt in 100 gm of batter.

- Sample B which fermented at 300C for 12 was better, having 6.65 Overall acceptability than sample A having 5.88 overall acceptability.

15 and 16 December 2023

II. B. Fermentation at 300C (steaming 1 mol leavening agent):

1.Soaking :

Rice: 120 gm

Black gram dhal: 60 gm

Soaking Time: 12hrs.

2. Grinding:

Grinding separately.

Added water in soaked rice during grinding: 60 ml

Added water in soaked black gram dhal during grinding: 120 ml.

3. Mixing together:

Prepared batter: 370 gm

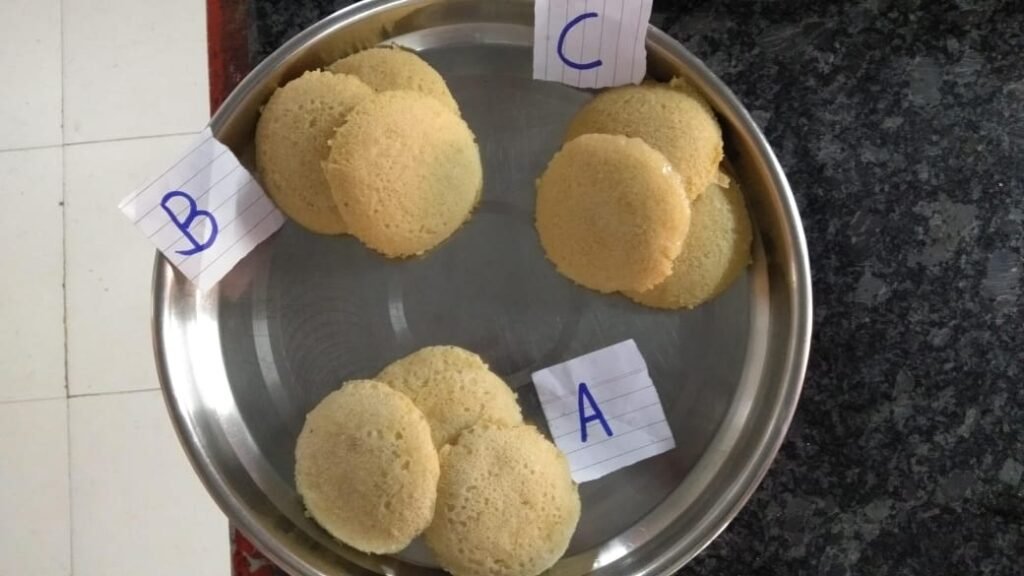

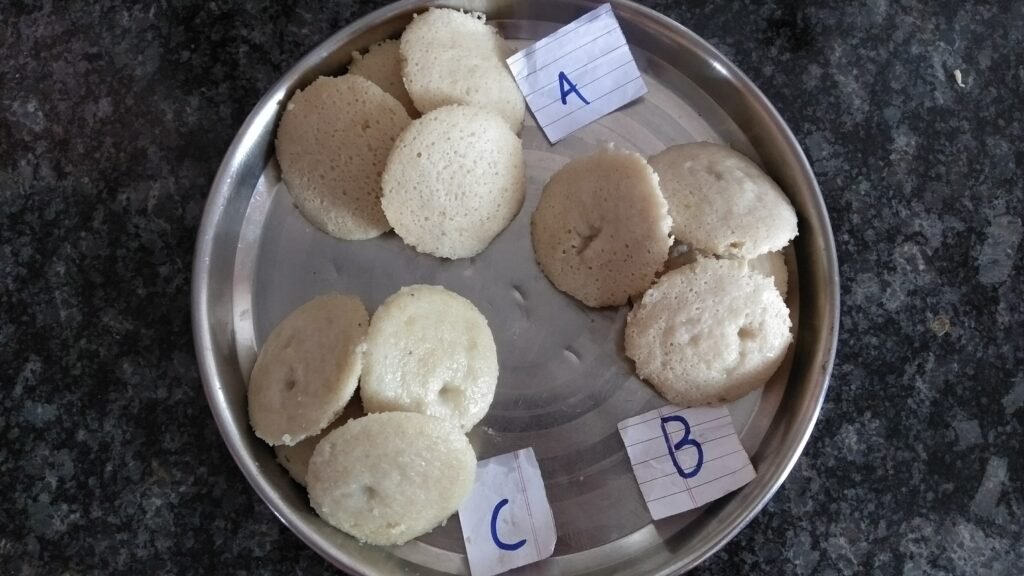

370 gm of sample divided into three: Sample A (120g), Sample B (125gm) and Sample C (125gm).

4. Fermentation: at 300C

| Sr. no. | Sample | Fermentation Temperature | Fermentation Time | Burette reading | Acidity in K2CO3 gm/ 100 gm sample | Acidity in mol | pH |

| 1 | Sample A | 300C | 10hrs | 4.9 | 1.3524 | 0.00049 | 3.86 |

| 2 | Sample B | 300C | 12hrs | 5.3 | 1.4628 | 0.00053 | 3.75 |

| 3. | Sample C | 300C | 14 hrs | 5.7 | 1.5732 | 0.00057 | 3.66 |

5. Steaming:

In fermented idli batter 1 mol baking soda is added

| Sr. no. | Sample | Addition of salt in batter | Addition of water in batter | Addition of NaHCO3/ 120 gm batter | Cooking time |

| 1. | A | 2gm | 15 ml | 0.9879 | 15 min |

| 2. | B | 2gm | 15 ml | 1.0686 | 15 min |

| 3. | C | 2 gm | 15 ml | 1.8878 | 15 min |

6. Sensory evaluation:

Sensory evaluation is carried out by 9 point hedonic scale.

| Sr. no, | Sample | Color | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 1 | A | 6.8 | 7.2 | 7.4 | 6.4 | 6.4 | 6.8 |

| 2 | B | 7.6 | 7.6 | 7.6 | 7.2 | 7 | 7.24 |

| 3 | C | 5.8 | 6.4 | 7.4 | 6.6 | 6 | 6.44 |

7. Observations:

- Sample B was good which was fermented at 300C for 12 hrs. (acidity 1.46 gm K2CO3 / 100 gm of sample), having 7.24 overall acceptability.

- Proportion of Baking Soda (1 mol) was more in batter that result in yellowish color of idli and slightly flavor of baking soda.

- Proportion of water was slightly more.

20-21 December 2023

II.C. Fermentation at 350C (Steaming with 0.75 mol baking soda)

1.Soaking :

Rice: 120 gm

Black gram dhal: 60 gm

Soaking Time: 12hrs.

2. Grinding:

Grinding separately.

Added water in soaked rice during grinding: 60 ml

Added water in soaked black gram dhal during grinding: 120 ml.

3. Mixing together:

Prepared batter: 370 gm

370 gm of sample divided into three: Sample A (120g), Sample B (125gm) and Sample C (125gm).

4. Fermentation: at 350C

| Sr. no. | Sample | Fermentation Temperature | Fermentation Time | Burette reading | Acidity in K2CO3 gm/ 100 gm sample | Acidity in mol | pH |

| 1 | Sample A | 350C | 9hrs | 5.1 | 1.4076 | 0.00051 | 4.91 |

| 2 | Sample B | 350C | 11hrs | 5.4 | 1.4904 | 0.00054 | 4.76 |

| 3. | Sample C | 350C | 13 hrs | 5.7 | 1.5732 | 0.00057 | 4.59 |

5. Steaming:

In fermented idli batter 0.75 mol baking soda is added

| Sr. no. | Sample | Addition of salt in batter | Addition of water in batter | Addition of NaHCO3/ 120 gm batter | Cooking time |

| 1. | A | 1gm | 15 ml | 0.1767 | 15 min |

| 2. | B | 1gm | 15 ml | 0.6804 | 15 min |

| 3. | C | 1 gm | 15 ml | 1.17 | 15 min |

6. Sensory evaluation:

Sensory evaluation is carried out by 9 point hedonic scale.

| Sr. no, | Sample | Color | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 1 | A | 8.55 | 7.66 | 7 | 7.66 | 7.66 | 7.70 |

| 2 | B | 7.33 | 7.33 | 6.66 | 7.66 | 7.33 | 7.26 |

| 3 | C | 7.33 | 7.33 | 7.66 | 8.33 | 7.66 | 7.67 |

7. Observations:

24-25 December 2023

II.D. Fermentation at 400C (Steaming with 0.50 mol Baking Soda)

1.Soaking :

Rice: 120 gm

Black gram dhal: 60 gm

Soaking Time: 12hrs.

2. Grinding:

Grinding separately.

Added water in soaked rice during grinding: 60 ml

Added water in soaked black gram dhal during grinding: 120 ml.

3. Mixing together:

Prepared batter: 370 gm

370 gm of sample divided into three: Sample A (120g), Sample B (125gm) and Sample C (125gm).

4. Fermentation: at 400C

| Sr. no. | Sample | Fermentation Temperature | Fermentation Time | Burette reading | Acidity in K2CO3 gm/ 100 gm sample | Acidity in mol | pH |

| 1 | Sample A | 400C | 8hrs | 4.9 | 1.3524 | 0.00049 | 4.83 |

| 2 | Sample B | 400C | 9hrs | 5.3 | 1.4628 | 0.00053 | 4.33 |

| 3. | Sample C | 400C | 11hrs | 5.7 | 1.5732 | 0.00057 | 4.17 |

5. Steaming:

In fermented idli batter 0.50 mol baking soda is added

| Sr. no. | Sample | Addition of salt in batter | Addition of water in batter | Addition of NaHCO3/ 120 gm batter | Cooking time |

| 1. | A | 2gm | 15 ml | 0.9879 | 15 min |

| 2. | B | 2gm | 15 ml | 1.0686 | 15 min |

| 3. | C | 2 gm | 15 ml | 1.8878 | 15 min |

6. Sensory evaluation:

Sensory evaluation is carried out by 9 point hedonic scale.

| Sr. no, | Sample | Color | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 1 | A | 7.66 | 7.33 | 7.33 | 8 | 6.66 | 7.39 |

| 2 | B | 7.66 | 7.66 | 7.33 | 8.66 | 6.66 | 7.59 |

| 3 | C | 7.33 | 7.33 | 6.33 | 8.66 | 7 | 7.33 |

7. Observation:

30 -31 December 2023

II.E. Fermentation at 400C (with 0.25 mol baking soda)

1.Soaking :

Rice: 120 gm

Black gram dhal: 60 gm

Soaking Time: 8 hrs.

2. Grinding:

Grinding separately.

Added water in soaked rice during grinding: 60 ml

Added water in soaked black gram dhal during grinding: 120 ml.

3. Mixing together:

Prepared batter: 430 gm

370 gm of sample divided into three: Sample A (140g), Sample B (145gm) and Sample C (14 5gm).

4. Fermentation: at 400C

| Sr. no. | Sample | Fermentation Temperature | Fermentation Time | Burette reading | Acidity in K2CO3 gm/ 100 gm sample | Acidity in mol | pH |

| 1 | Sample A | 400C | 8hrs | 5.2 | 0.4352 | 0.00052 | 4.66 |

| 2 | Sample B | 400C | 9hrs | 5.4 | 1.4904 | 0.00054 | 4.34 |

| 3. | Sample C | 400C | 11hrs. | 5.8 | 1.6008 | 0.00058 | 4.08 |

5. Steaming:

In fermented idli batter 0.25 mol baking soda is added

| Sr. no. | Sample | Addition of salt in batter | Addition of water in batter | Addition of NaHCO3/ 120 gm batter | Cooking time |

| 1. | A | 1gm | 10 ml | 0.1769 | 15 min |

| 2. | B | 1gm | 10 ml | 0.6804 | 15 min |

| 3. | C | 1gm | 10 ml | 1.17 | 15 min |

6. Sensory evaluation:

Sensory evaluation is carried out by 9 point hedonic scale.

| Sr. no, | Sample | Color | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 1 | A | 8.33 | 7.66 | 7.66 | 8.33 | 7.33 | 7.86 |

| 2 | B | 8.33 | 8.33 | 7.66 | 8.66 | 7.66 | 8.12 |

| 3 | C | 7.66 | 8.33 | 7 | 7.33 | 7.66 | 7.59 |

7. Observations:

2-4 January 2024

II.F. Fermentation at 400C (With 0.12 mol baking soda)

1.Soaking :

Rice: 120 gm

Black gram dhal: 60 gm

Soaking Time: 12hrs.

2. Grinding:

Grinding separately.

Added water in soaked rice during grinding: 60 ml

Added water in soaked black gram dhal during grinding: 120 ml.

3. Mixing together:

Prepared batter: 370 gm

370 gm of sample divided into three: Sample A (120g), Sample B (125gm) and Sample C (125gm).

4. Fermentation: at 400C

| Sr. no. | Sample | Fermentation Temperature | Fermentation Time | Burette reading | Acidity in K2CO3 gm/ 100 gm sample | Acidity in mol | pH |

| 1 | Sample A | 400C | 8hrs | 5.1 | 1.4076 | 0.00051 | 3.86 |

| 2 | Sample B | 400C | 9hrs | 5.3 | 1.4628 | 0.00053 | 3.75 |

| 3. | Sample C | 400C | 11 hrs | 5.6 | 1.5456 | 0.00056 | 3.66 |

5. Steaming:

In fermented idli batter 0.12 mol baking soda is added

| Sr. no. | Sample | Addition of salt in batter | Addition of water in batter | Addition of NaHCO3/ 120 gm batter | Cooking time |

| 1. | A | 1gm | 10ml | 0.10 | 15 min |

| 2. | B | 1gm | 10ml | 0.10 | 15 min |

| 3. | C | 1 gm | 10ml | 0.11 | 15 min |

6. Sensory evaluation:

Sensory evaluation is carried out by 9 point hedonic scale.

| Sr. no, | Sample | Color | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 1 | A | 8.66 | 6.66 | 4.33 | 4.33 | 3.33 | 5.46 |

| 2 | B | 8.66 | 5.33 | 4.33 | 3.33 | 3.66 | 5.06 |

| 3 | C | 5.66 | 4.33 | 3.33 | 3.66 | 3.66 | 4.12 |

7. Observation:

5-6 January 2024

II.F. Fermentation at 400C (With 0.20 mol baking soda)

1.Soaking :

Rice: 120 gm

Black gram dhal: 60 gm

Soaking Time: 12hrs.

2. Grinding:

Grinding separately.

Added water in soaked rice during grinding: 60 ml

Added water in soaked black gram dhal during grinding: 120 ml.

3. Mixing together:

Prepared batter: 370 gm

370 gm of sample divided into three: Sample A (120g), Sample B (125gm) and Sample C (125gm).

4. Fermentation: at 400C

| Sr. no. | Sample | Fermentation Temperature | Fermentation Time | Burette reading | Acidity in K2CO3 gm/ 100 gm sample | Acidity in mol | pH |

| 1 | Sample A | 400C | 8hrs | 5.2 | 1.4352 | 0.00052 | 4.60 |

| 2 | Sample B | 400C | 9hrs | 5.5 | 1.518 | 0.00055 | 4.52 |

| 3. | Sample C | 400C | 11 hrs | 5.7 | 1.5732 | 0.00057 | 4.48 |

5. Steaming:

In fermented idli batter 0.20 mol baking soda is added.

| Sr. no, | Sample | Color | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 1 | A | 8.66 | 7.33 | 7.33 | 7.33 | 6.33 | 7.39 |

| 2 | B | 8.33 | 8 | 7.33 | 7.33 | 6.66 | 7.53 |

| 3 | C | 8.66 | 6.66 | 9 | 8.66 | 7.33 | 9.52 |

7. Observation:

- From above readings of sensory evaluation, it is observed that the idli prepared with 0.20 mol baking soda was good in taste, texture and had no flavour of baking soda.

III. Dehydration of Prepared idli batter:

7,8,9 January 2024

III. A. FIRST TRIAL

1.Soaking :

Rice: 50 gm in 100 ml of water

Black gram dhal: 25 gm in 100 ml of water

Soaking Time: 12hrs.

2.Draining:

Drained water from rice 79 gm

Drained water from black gram dhal 69 gm

3. Grinding:

Grinding separately.

Added water in soaked rice during grinding: 25 gm

Added water in soaked black gram dhal during grinding: 50 gm

Prepared batter 192gm

4.Fermentation:

400C for 8 hrs

| Burette reading | Acidity in K2CO3 | Acidity in Mol | pH |

| 2.8 | 0.77 | 0.00028 | 5.20 |

5. Drying:

Drying was carried out in hot air oven at 63 0C for 5 min, because we have to stop the fermentation during fermentation and 63 0C is the temperature of LTLT sterlization

Baking soda 0.20 mol (0.09 gm) and 1 gm salt was added to the before drying.

Thickness : 0.2 cm

Weight of batter : 163 gm

Prepared dry batter was grind using mixer grinder

Prepared mixture was 55 gm and used as ready to cook

Moisture content in it is 66.25 %

6. Cooking

55 gm premix

85 gm water

cooking time : 15 min

7. Sensory analysis:

| Colour | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 8 | 7.66 | 2 | 5.33 | 2.66 | 5.13 |

8. Observations:

The batter was not better fermented because temperature controller of incubator was not properly worked.

According to above readings and some observation the overall acceptability of the idli prepared with instant premix was not good.

Prepared idli was not good in texture and mouthfeel.

Prepared batter was so thick that’s why idli’s become hard.

I was added 0.20 mol leavening agents before drying.

After the discussion with Mr Arun Dixit sir, we will decided that the leavening agents and salt will add after the drying and grinding. In last trial I was used 0.20 mol baking soda in second we will decide to add 0.25 mol baking soda. Also we discussed that when baking soda reacted with citric acid produce CO2 which will help to rise the idli and produce fluffy idli’s.

C6H807 + 3 NaHCO3 = H2O + 3 CO2 + Na3C6O7

14,15,16 January

III. B. SECOND TRIAL

1.Soaking :

Rice: 50 gm in 100 ml of water

Black gram dhal: 25 gm in 100 ml of water

Soaking Time: 12hrs.

2.Grinding:

Grinding separately.

Added water in soaked rice during grinding: 25 gm

Added water in soaked black gram dhal during grinding: 50 gm

Prepared batter 194gm

3.Fermentation:

Fermentation at 40 0C for 8 hrs

| Burette reading | Acidity in K2CO3 | Acidity in Mol | pH |

| 5.2 | 1.4352 | 0.00052 | 4.60 |

5. Drying:

Drying was carried out in hot air oven at 63 0C for Half hour and & 73 0C for 4 hrs.

Thickness : 0.2 cm

Weight of batter : 160 gm

Prepared dry batter was grind using mixer grinder

Prepared mixture was 55 gm and used as ready to cook

Moisture content in batter is 68.75 %

6. Cooking:

50 gm premix

85 gm water

As we decided, I was added Baking soda 0.25 mol (0.17 gm) , citric acid 0.09 gm and Salt 1.5 gm during the cooking.

Cooking Time – 15 minutes.

7.Sensory analysis:

| Colour | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 9 | 8.5 | 8.25 | 8.75 | 9 | 8.7 |

8. Observations:

The taste, texture, aroma, colour, mouthfeel and overaall acceptability of idli was good, i was felt like i got one milestone after so much trials.

21,22,23 January 2024

III.C. THIRD TRIAL:

1.Soaking :

Rice: 120 gm in 200 ml of water

Black gram dhal: 60 gm in 200 ml of water

Soaking Time: 12hrs.

2.Grinding:

Grinding separately.

Added water in soaked rice during grinding: 60 gm

Added water in soaked black gram dhal during grinding: 120 gm

Prepared batter 350 gm

3.Fermentation:

Fermentation at 40 0C for 8 hrs

| Burette reading | Acidity in K2CO3 | Acidity in Mol | pH |

| 5.1 | 1.4076 | 0.00051 | 4.70 |

4. Drying:

Drying was carried out in hot air oven at 63 0C for Half hour and & 73 0C for 4 hrs.

Thickness : 0.2 cm

Weight of batter : 160 gm

Prepared dry batter was grind using mixer grinder

Prepared mixture was 157 gm and used as ready to cook

Moisture content in batter is 60.66 %

5. Cooking:

Cooking was carried out for 2 sample having water content difference in batter .

| Parameter | Sample A | Sample B |

| Dehydrated premix | 50 gm | 50 gm |

| Salt | 1.5 gm | 1.5 gm |

| Baking soda | 0.21 gm | 0.21 gm |

| Citric acid | 0.10 gm | 0.10 |

| water | 80 gm | 90 gm |

| cooking time | 15 min | 15 min |

6. Sensory analysis:

| Sensory parameters | Sample A | Sample B |

| Colour | 7 | 7.33 |

| Aroma | 4.5 | 6.33 |

| Texture | 7 | 7.33 |

| taste | 8.75 | 9 |

| Mouthfeel | 9 | 8 |

| Overall acceptability | 7.25 | 7.59 |

7. Observations:

Sample B having good overall acceptability than sample A .

Aroma of idli (both samples) were not good due to over fermentation during drying in hot air oven.

In discussion with Mr. Arun Dixit sir and Himanshu sir, we will decide that reduction of fermentation time upto 4-5 hrs from 8-9 hrs due to over fermentation was carried out during dehydration it will controlled by reducing time of fermentation of batter.

Still we are not confident about how much water should added into premix to prepare good batter and also for grinding size of soaked rice and soaked black gram dhal. And this not acceptable when we saying that we are working on standardization.

We will decide that the particle size we are not able to determine at our level without any equipment’s, so we have to set the time for mixer grinding on first or second speed

In Vigyan ashram, electrical dehydrator or drier are not available. In previous work i was used hot air oven from microbiology dept for drying of batter. this hot air oven worked for sterilization of glassware’s and media used in micro and tissue culture lab, but contaminations were occurred in tissue culture lab. so i cannot use this hot aur oven for drying.

After the diuscussion with Dixit sir, we will decided to take trial of dehydration on microwave oven. I took 10 gm peanuts for determine moisture content or LOD using microwave oven but peanuts get burned .

After that we find out the rotary evaporator in soil lab which can be used for idli batter dehydration. But the condenser of rotary evaporator was missing. so we couldn’t used it without condenser.

After discussion and permission of Mr. Ranjeet Shanbhag, Mr. Arun Dixit Sir and Miss. Vedika Warghade, I have restarted the working on project Fermented Instant idli premix

20- 23 May 2014

I took trial after 3.5 months of interval as same as 22nd January.

1.Soaking :

Rice: 60 gm in water

Black gram dhal: 30 gm in water

Soaking Time: 12hrs.

2.Grinding:

Grinding separately.

Added water in soaked rice during grinding: 30gm

Added water in soaked black gram dhal: 60 gm

3.Fermentation:

Fermentation at 40 0C for 8 hrs

| Burette reading | Acidity in K2CO3 | Acidity in Mol | pH |

| 5.1 | 1.4076 | 0.00051 | 4.60 |

5. Drying:

Drying was carried out in hot air oven at 75 0C for 5 hrs.

Thickness : 0.2 cm

Weight of batter: 55 gm

Prepared dry batter was grind using mixer grinder

Prepared mixture was 50 gm and used as ready to cook

6. Cooking:

50 gm premix

90 gm water

baking soda 0.25 mol (0.26 gm),

citric acid 0.13 gm

Salt 1.5 gm

Cooking Time – 15 minutes.

7.Sensory analysis:

| Colour | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| 7 | 8.5 | 8.25 | 8.80 | 9 | 8.7 |

8. Observations:

The taste, texture, aroma, colour, mouthfeel and overall acceptability of idli was good.

Still we are using hot air oven for dehydration, we don’t have electrical dryer . We have only solar flat bed dryer, it’s temperature depends on exposure of sunlight, it doesn’t exceed more than 50 ° C. This temperature is favorable for growth of microorganisms which are responsible for fermentation. So, we couldn’t use it because increase fermentation. So we decided to preheat the batter to pasteurization.

24-25 May

1.Soaking :

Rice: 120 gm in water

Black gram dhal: 60 gm in water

Soaking Time: 12hrs.

2.Grinding:

Grinding separately.

Added water in soaked rice during grinding: 60gm

Added water in soaked black gram dhal: 120 gm

3.Fermentation:

Fermentation at 40 0C for 8 hrs

Check acidity and pH.

5. Drying:

| Pre heated sample | Normal sample |

| # Boil the water and put plate on boil water vessel. # On plate put fermented Batter and spread like dosa. # Then dehydrate | # Pour batter into plain plate and put into electric dryer/ hot air oven. # Dehydrate at 75 degree celcius (more than pasteurization temperature) |

Prepared dry batter was grind separately using mixer grinder.

Prepared mixture was used as ready to cook.

6. Cooking:

Cook separately with adding 0.25 mol baking soda & citric acid, water and salt.

Cooking Time – 15 minutes.

7.Sensory analysis:

| Parameter | Colour | Aroma | Texture | Taste | Mouthfeel | Overall acceptability |

| Sample 1 ( Preheated) | 7.66 | 5 | 4 | 4 | 3.33 | 4.79 |

| Sample 2 ( Normal) | 7.33 | 8.33 | 7.33 | 8 | 7.66 | 7.73 |

8. Observations:

- Sample 1 was not good in taste, aroma , texture and mouthfeel , and also had bad overall acceptability.

- Sample 1 was cooked during pre heating.

- Sample 2 was good.

- From This trial we concluded that, pre-heating was not suitable pre treatment to pasteurize batter.

Mr. Ranjeet Shanbhag sir and Mr. Dixit sir told me to prepare 2 packets of idli premix and take feedback from people.

26-27th May

I prepared two packets of 150 gm of Fermented dehydrated idli premix by followed same procedure and give to Mr. Prasad Patil sir. He prepared idli from that idli premix at his home. Feedback from his home was very positive, taste of idli was very good.

Particle Size:

As we work on standardization of Fermented dehydrated idly premix, we started working on particle size of rice and black gram dhal. Mr. Dixit sir and Mr. Prasad Patil suggest me ideas about particle size. They both suggest me to make rice suji and then kept for fermentation. I studied some literature about idli and I got particle size of rice suji 60 mesh and 18 mesh.

I ordered 60 mesh filter cloth and purchased plastic mesh from local market.

For Rice Suji:

Rice

↓

Cleaning & sorting

↓

Washing with water and draining.

↓

Dry in shadow on cotton cloth ( Use fan)

↓

Coarsely grinding of dried rice.

↓

Sieve the coarsely ground rice flour firstly with 18 mesh sieve and then 60 mesh sieve.

( To obtain 18-60 mesh size rice suji)

Fig., Flow chart of Preparation Rice suji.

I started taking trial of idli using rice suji. Overall acceptability of Idli prepared using rice suji was good.

Mr. Ranjeet Shanbhag sir, Mr. Dixit sir suggest me to prepare 5 packets of this Fermented Dehydrated idli premix and took feed-back from consumers. To collect feedback I Prepared Google form and sent the link to all consumers.

Feedback from consumer :

- Good in taste

- work on colour

- In case of some consumer, Idli was not fluffy. We suggest them to steam idli within 5 min after water adding into premix.

Final Protocol:

Soak black gram dhal in water

(12 hrs)

↓

Grind fine using mixer grinder

( Dry Black gram dhal: water :: 1: 2 w/w)

↓

Filter the prepared batter with small sieve

↓

Grounded dhal + Rice suji + water

(Dry black gram dhal: Rice suji::1:2 w/w & Rice suji: water:: 1:1 w/w)

↓

Mix properly

↓

Fermentation of batter at 40 degree celsius for 8 hrs)

↓

Check acidity and pH of batter

↓

Pour into plate and make thin layer

↓

Drying at 75 degree celsius for 7-8 hrs

( Time depends on thickness of better

↓

Grinding of dehydrated batter ( Coarsely like semolina)

↓

Add 25 mol of baking soda & citric acid,

1.5 gm of salt/ 50 gm of premix

↓

Pack into air tight pouch

Fig. Flow chart of preparation of idli

Direction for use:

- Preheat the idli cooker.

- Grease the idli mold.

- Pour idli premix into bowl and add 90 gm water for 50 gm premix. ( This prepared batter must be steam within 5 min)

- Pour into pre-greased mold.

- Steam for 15 min on medium flame.

- Demold the prepared idli and its ready to eat.

- Enjoy 🙂

Future aspect :

- Working on colour of Idli.

- Texture of idli