On June 20th, Mr. Vikrant Katekar visited Vigyan Ashram and collected our report. He also informed us that on June 21st, Michael from Technical University Munich, Omkar Bua from IIT Bombay, and Adwait from Aseem Foundation would be visiting for his water wheel project. He called me and Uttara to join his project.

On June 21st, Michael, Omkar, and Adwait A were introduced to us, and later they visited DIC lab to explain their project to everyone.

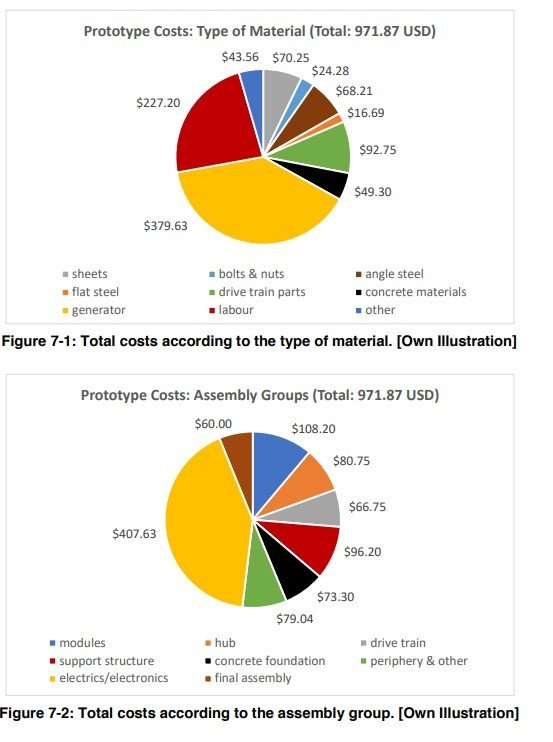

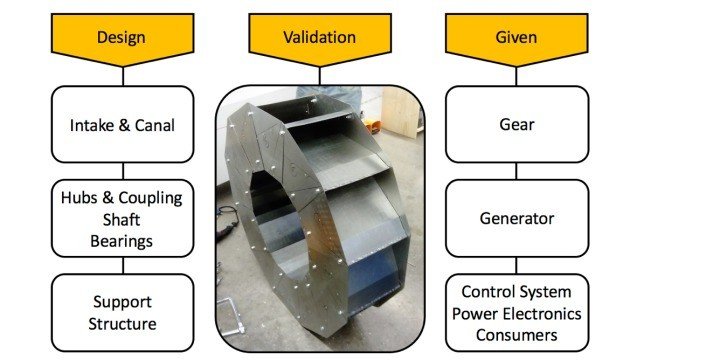

And he told about his project that he has to make a prototype of a water wheel here so that he can test its efficiency. They have to install that water wheel in Kashmir Ladakh area where there is water flowing from springs and it flows. The flow from which that water wheel rotates for and an alternator will be installed on one side of that water wheel from which electricity will be generated. And there will be supplied in the nearby village where electricity is less. And this type of project has already been installed in Nepal, he also told that the total cost of making this project complete is 80 to 90 thousand.

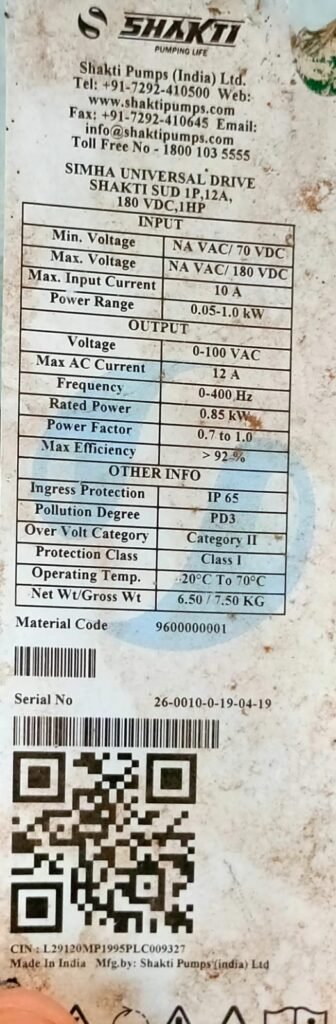

After understanding everyone and after discussion, we went for the survey of where we can set this prototype in the ashram. Prasad sir told us 2 locations, which are located at the Backside pond of the ashram, out of which we did not choose 1st Pond due to lack of space. And since there is proper space on the other side of the pond, we decided it. This project needs water, so we decide this pond side. Prasad sir also told us about the solar panels available there which we can use in our project. After that we had to have a water pump for water supply. So Prasad sir told us about the water pump available in the ashram of 1-1.5 HP. But Prasad sir told that the pump is closed since many months. Then he gave me the task to see whether the solar DC water pump is operational or not.

On 22nd June I went to test whether the solar water pump is working or not. This solar DC pump is submersible water pump. This water pump used to run on solar energy. For this, 4 solar panels of 300 watts were installed. Total 1200 watt energy was given to that 1 HP solar pump. When we used to switch on that solar pump, it used to write a notification that DC bus undervoltage. After that I checked the supply coming from solar but it was proper. When we contacted Shakti Pump, they told that either the connection is out or there is a wire break. But when I checked all the connections and wires they were proper there was no problem. After that I contacted Suhas sir, he called his contact person for repairing it.

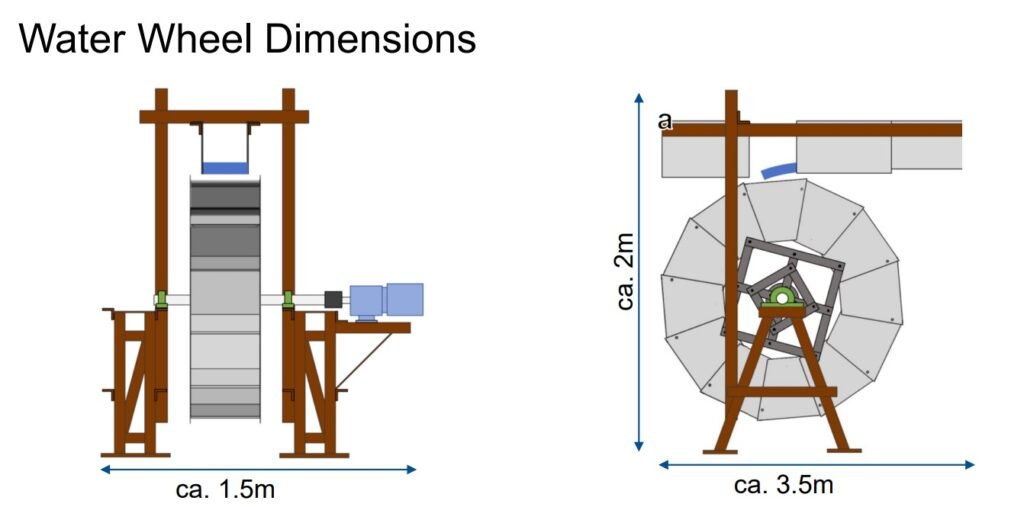

After that in afternoon I, Afzal ser, Micheal and Uttara sat in Fablab and discussed on the foundation of water wheel . As per our discussion the weight of the water wheel is approximately 500kg including water weight also. We decide height of the water wheell is 2m, length is 3.5m and width is 1.5m.

LOAD CALCULATION

Task was given to me to calculate the Dead Load of the Wheel:

Components:

| Component | Weight (KG) | Quantity | Total Weight |

| Wheel Cell (GI) | 1KG | 12 | 12KG |

| Spokes | 10KG | 2 | 20KG |

| Shaft | 10KG | 1 | 10KG |

Iron Support Weight: 93KG (4*4cm Box Iron Rod)

Dry weight of Wheel + Iron Support: 135KG

Dimension Calculation of the structure of Water Wheel:

Dimensions:

Outer Diameter of Wheel: 60cm

Inner Diameter of Wheel: 30cm

Thickness of Wheel: 30cm

Height of Wheel: 60cm

Height between wheel and ground: 20cm

Distance between two supports: 100cm

Bearing: 20*5*9cm

Material required for the Water Wheel is:

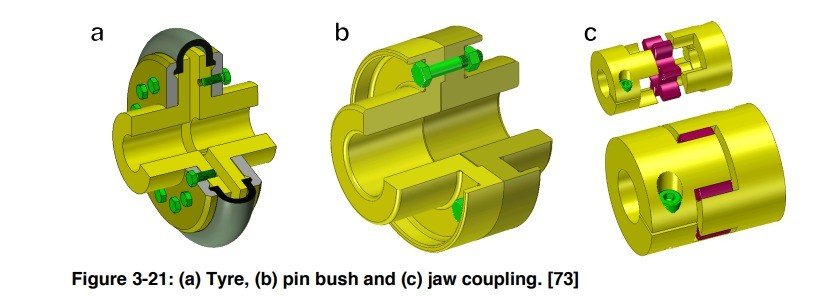

Mild Steel , Steels sheet, Shafts, Hubs, Coupling, Bearing.

Workshop instruments for water wheel projects

bending benches for processing sheets, Bending clamp, Shear Cutting, Lathing, Boring, Sawing, Milling, Grinding / Abrasive Cutting, Autogenous Fuel Cutting, Bolted Joint, Hemming, Riveting, Welding, Autogenous Welding, Manual Arc Welding, Resistance Spot Welding,

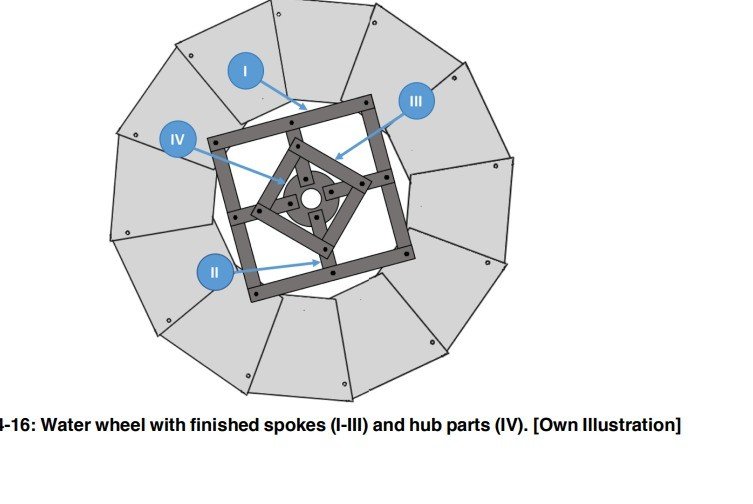

The design for the water wheel is already ready by micheal. Then micheal and Afzal went to pune for the cutting of sheet as per our cell design.

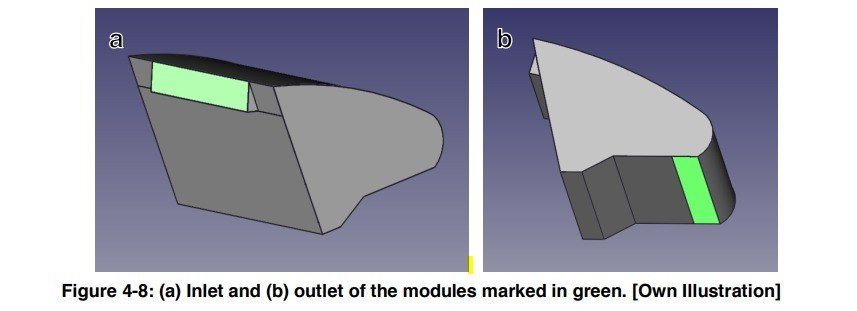

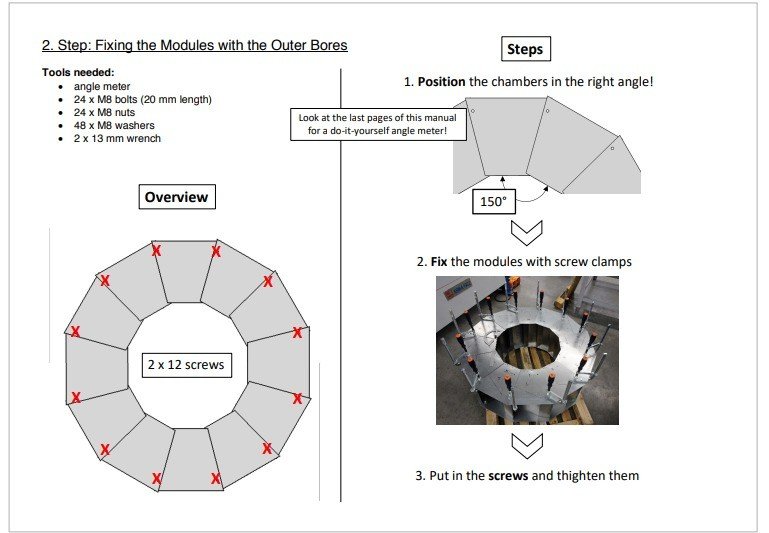

On 25th June Micheal and Afzal came to vigyan ashram with cutting sheet then we started to attach all cells one by one

Steps to make one cell with dimentions

Steps to make one modules

How we made it.

After completion of total 12 cells we made a stand for it and attach all the cells properly with constant angle.

After succesfully completion of all assembly finally we made it. properly but there is unavailability of alternator and lack of time we cancel the plan to assemble this prototype in Vigyan Ashram and Afzal sir told that they will take this prototype later.

On 4th August Adwait sir send one person to take this water wheel.