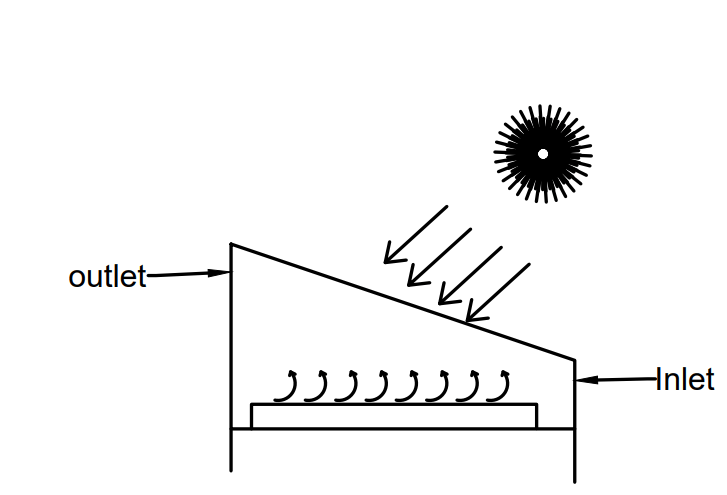

Solar dryer receives the energy from sun and it dry the crops vegetable fruit

Solar dryer consists with different main parts

Black material is coated on heating element inside the box to absorb more heat from solar radiation . outer frame of made up of heat insulating material to maintain the temperature .when direct or diffuse solar radiation will incident then it will not exit .

There are holes at upper and lower portion of the box for circulation of air .

First of all we keep the fooding material inside the box and close the roof glass

When solar radiation incident on black coating through transparent glass then heating aliment absorb the heat from solar radiation due to heat moisture of fooding material get vaporized and vapor droplets accumulates on the roof glass

As well as cold air enter from lower portion of the box and that air get heated

Due to hot air fooding material rapidly get dry and heated air exit throught upper hole

Vaporized water droplets also remove with hot air in the atmosphere and placed fooding material like vegetables get dry

Steps.

PROCESS FLOW DIAGRAM

· MATERIAL FLOW DIAGRAM

· DESIGN MODELLING

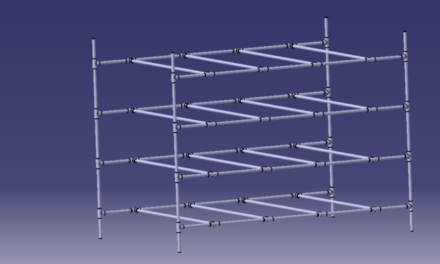

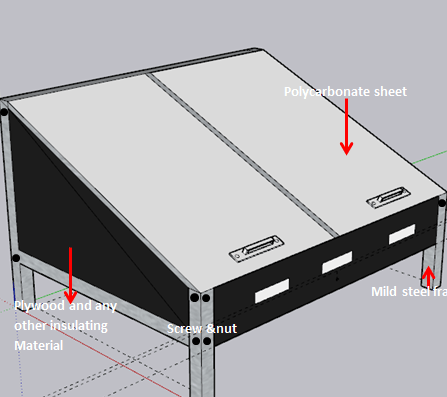

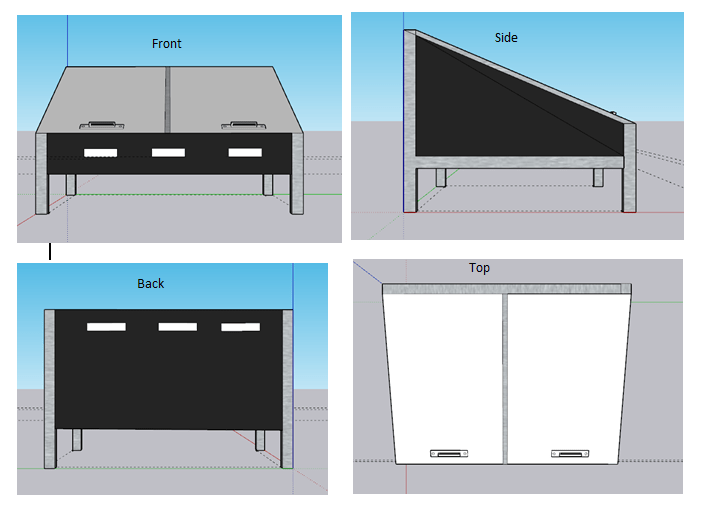

· 3D MODELLING

- BILL OF MATERIAL (BOM)

- PROCUREMENT

- FABRICATION

Process Flow Diagram

Solar dryer receives the energy from sun and it dry the crops vegetable fruit

Solar dryer consists with different main parts

Black material is coated on heating element inside the box to absorb more heat from solar radiation . outer frame of made up of heat insulating material to maintain the temperature .when direct or diffuse solar radiation will incident then it will not exit .

There are holes at upper and lower portion of the box for circulation of air .

First of all we keep the fooding material inside the box and close the roof glass

When solar radiation incident on black coating through transparent glass then heating aliment absorb the heat from solar radiation due to heat moisture of fooding material get vaporized and vapor droplets accumulates on the roof glass

As well as cold air enter from lower portion of the box and that air get heated

Due to hot air fooding material rapidly get dry and heated air exit throught upper hole

Vaporized water droplets also remove with hot air in the atmosphere and placed fooding material like vegetables get dry

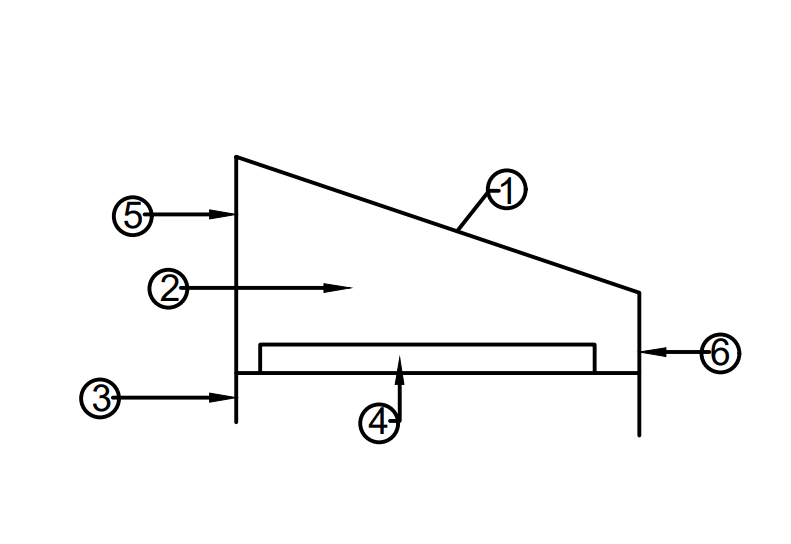

Material Flow Diagram

1 Polycarbonate sheet

2 Side Wall (Polycarbonate sheet )

3 Legs ( MS Angle)

4 Bottom ( Polycarbonate sheet)

5 Back Wall ( Polycarbonate sheet)

6 Front wall ( Polycarbonate sheet)

- Polycarbonate sheet

Polycarbonate sheet is a type of plastic that can withstand high temperature and high pressure. Polycarbonate sheet is used for solar dryers because it can withstand the heat from the sun and allow you to dry agricultural products without any electricity or gas.

The polycarbonate sheet for solar dryer is a thin, transparent, and durable material that has excellent light transmission properties.

It is often used in the construction of greenhouses and solar dryers. The polycarbonate sheet for solar dryer also offers protection from UV rays and provides insulation against heat loss.

This material is made from polycarbonates, which are thermoplastic polymers. Polycarbonates are used in many applications that require a durable material that is resistant to heat and UV light. Polycarbonate sheets can be used as a substrate for solar dryers.

2. Side Wall

Polycarbonate sheets

3. MS angles

MS angle or mild steel angle is an L-shaped cross-section used in the construction of various structures and buildings. The most commonly used MS angle or metal angle is the one that forms a 90-degree angle with two sides of equal length and width

4 MS Nut & bolts

In physics, in the theory of general relativity, spacetimes with at least a 1-parameter group of isometries can be classified according to the fixed point-sets of the action. Isolated fixed points are called nuts. The other possibility is that the fixed point set is a metric 2-sphere, called bolt.

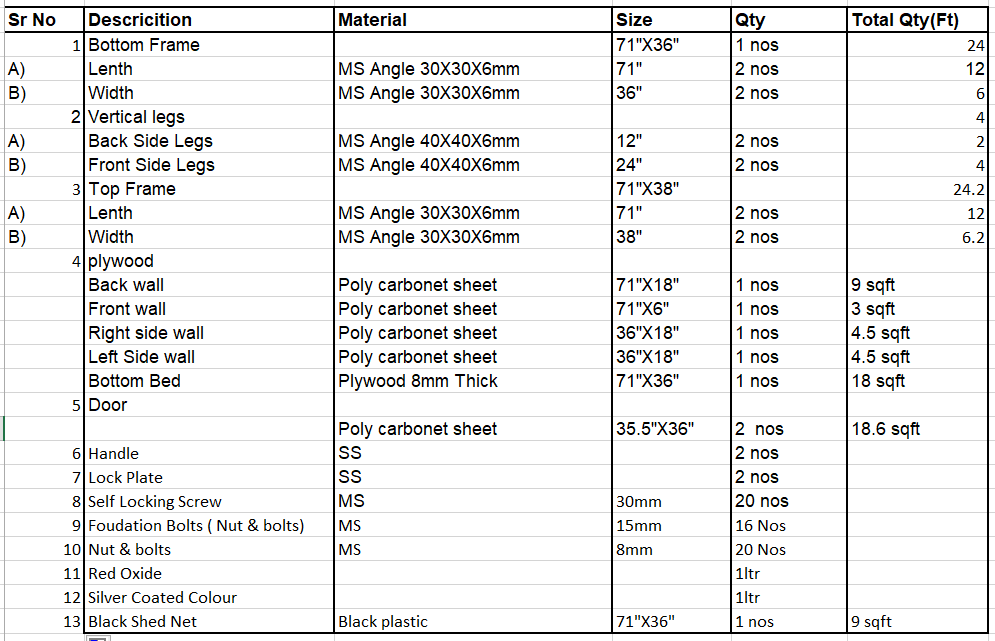

Bill Of Material

We Find Out BOM & Material rate Different Types of material Using

is given below

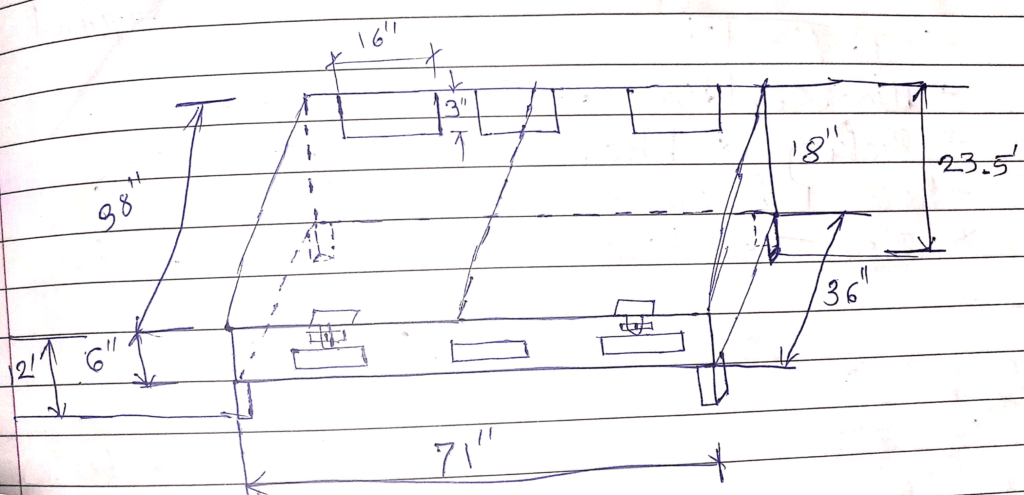

Rough Drawing ( Hand Sketch)

Design Modeling

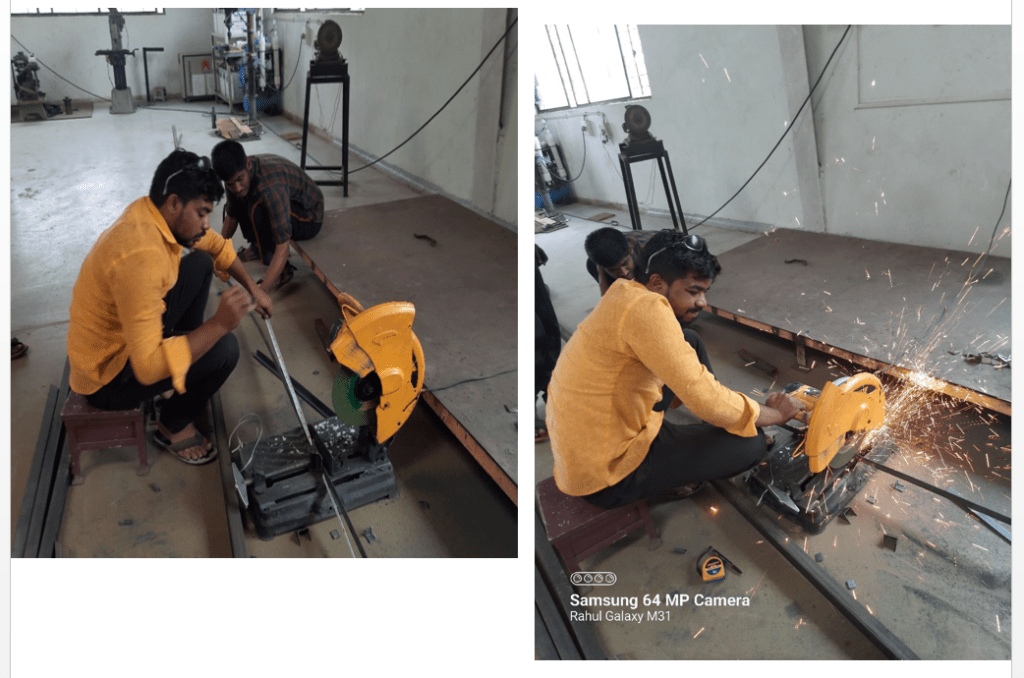

Fabrication

Step 1.

Material Purchasing

purchased All materials Like a bill of material.

- 30X30X3 MS angle,

- 40X40X5 MS Angle,

- 30X3 MS Flat Plate

- 8mm Plywood

- 12mm Plywood

- 6mm Polycarbonet sheet

- 15mm NUT & BOLTS

- lock plate

- handle

Step 2

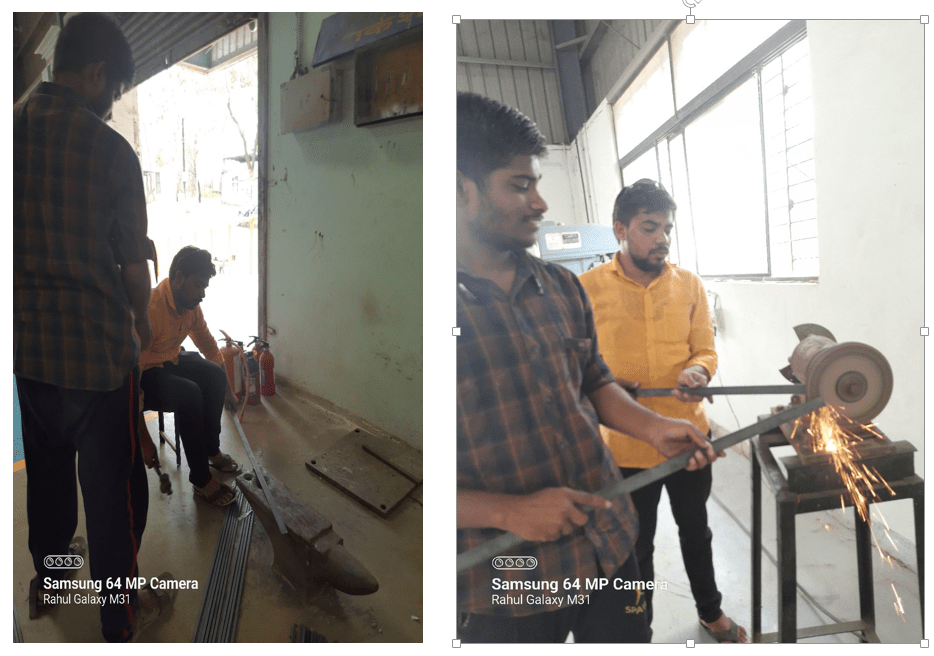

Cutting & Drilling

An MS Angle Cut as per our measurement & then Drilled & finishing by grinding

Step 3

welding work

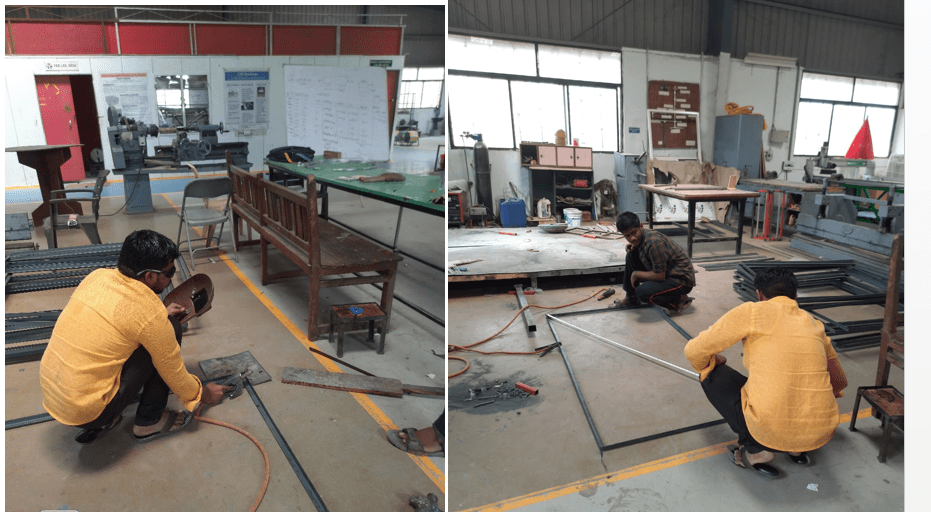

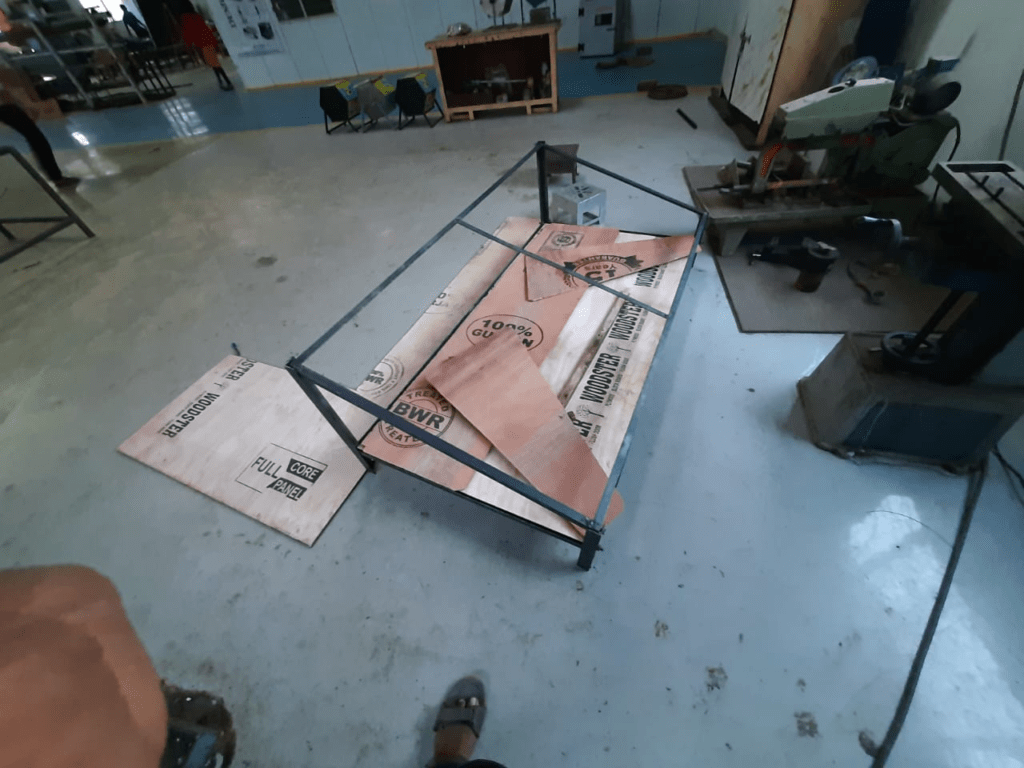

Frame of 30X30X3 MS angle was fabricated Total two Frames were fabricated one top and other bottom frame was welded

Top Frame Size 71″X38″

Bottom Frame 71″X36″

Step 4

Frame & vertical legs Join

step 5

Side wall Cutting work

Back wall polycarbonate 6mm thick 18″X71″

Front wall polycarbonate 6mm thick 6″X71″

Side wall polycarbonate 6mm thick 38″X6″X18″ 2 Nos

we cut all side of polycarbonate

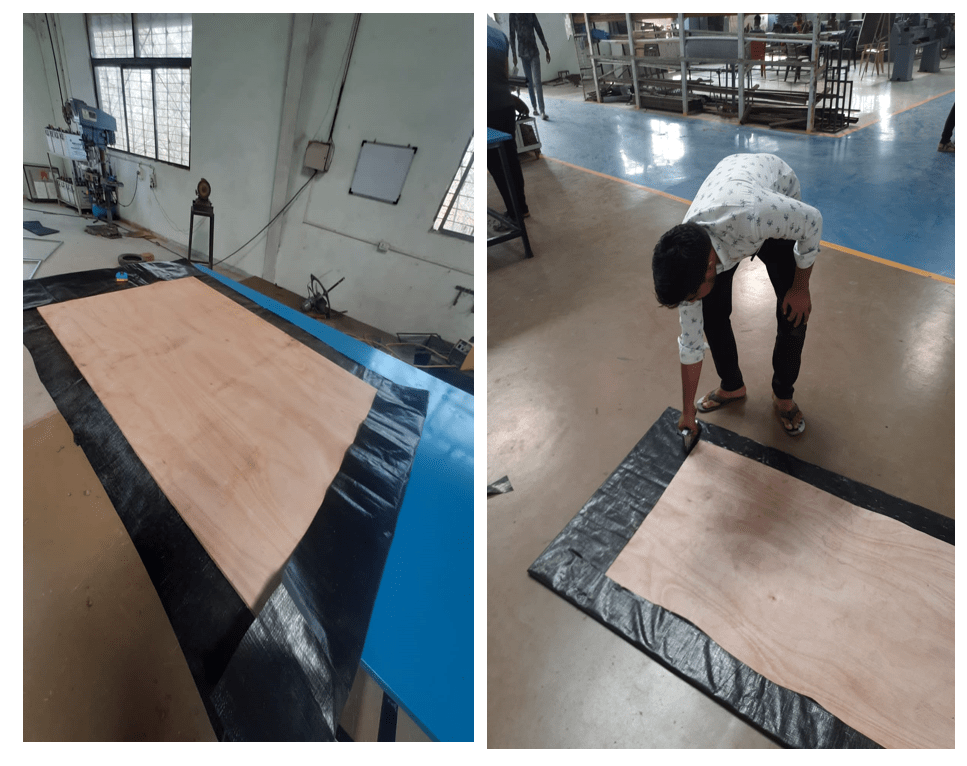

Bottom Plywood Cutting work

12mm Plywood

Step 6

Painting work

Structure Painting work

Structure = Red oxide + Silver coated color

Step 7

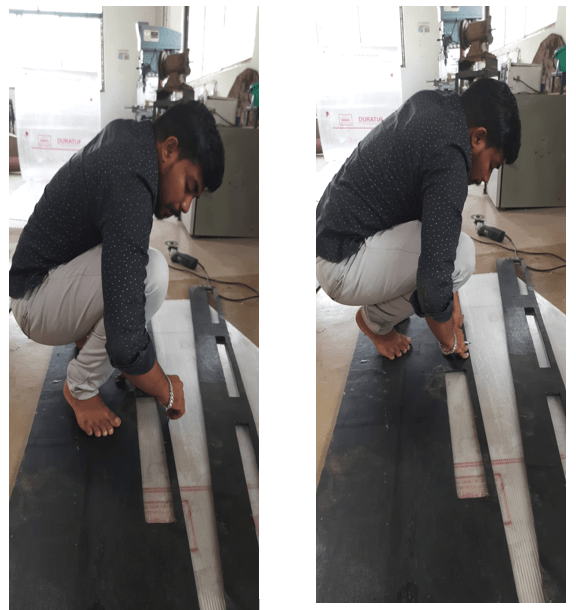

Bottom Plywood Cutting & Black Covering.

Step 8

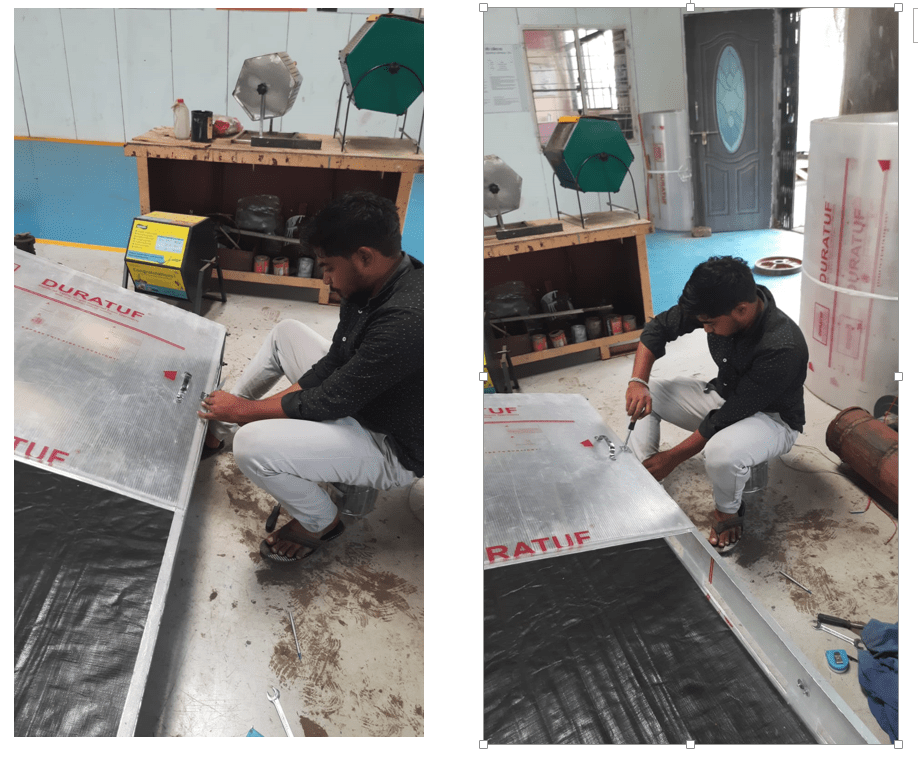

polycarbonate sheet fitting & Structure fitting work

Step 9

Door Work

Polycarbonate Sheet two Sheet cutting work

36″X38″

Step 10

Door Fitting Work

Door fitting work with help of hinges

Step 11

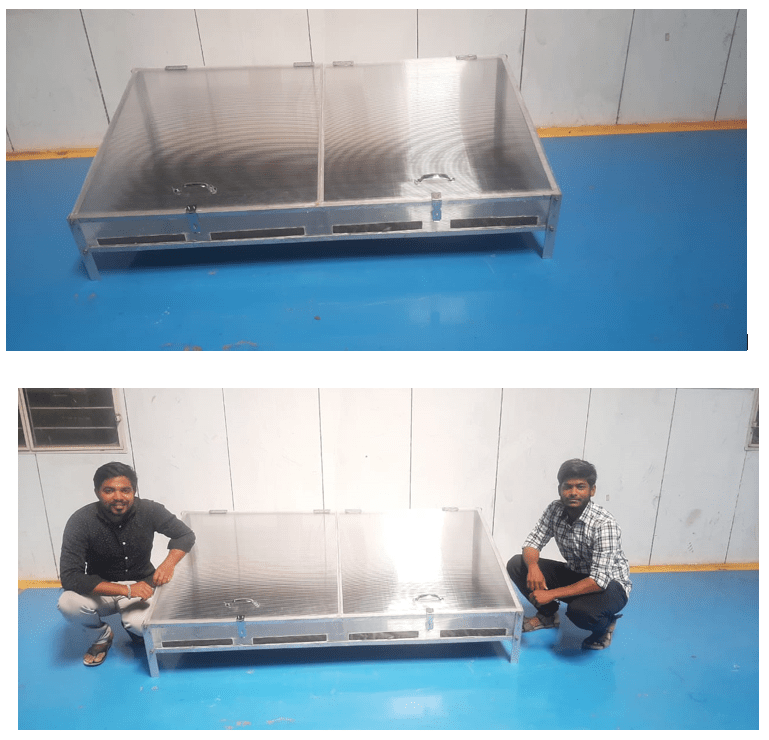

Cleaning & Finishing Work

Dryer Clean work

Finally Completed to dryer.

Hand Over To food Lab

Trail Work

we load the 5kg Onion, we take some readings

we take Readings

24/04/2023

Temp 39

| Sr no | Time | Thermometer (Degree Celsius) | |

| 1 | 10:00 AM | 47 | |

| 2 | 11:00 AM | 36 | |

| 3 | 12:00 AM | 35 | |

| 4 | 01:00 PM | 39 | |

| 5 | 02:00 PM | 35 | |

| 6 | 03:00 PM | 34 | |

| 7 | |||

| 8 | |||

| 9 | |||

| 10 | After Drying wtg | ||

| Wtg | 1536g |

2 nd day

25/03/2023

Temp 39

| Sr no | Time | | Thermometer (Degree Celsius) |

| 1 | 10:00 AM | | 43 |

| 2 | 11:00 AM | | 44 |

| 3 | 12:00 AM | | 47 |

| 4 | 01:00 PM | | 48 |

| 5 | 02:00 PM | | 46 |

| 6 | 03:00 PM | | 45 |

| 7 | 04:00 PM | | 41 |

| 8 | 05:00 PM | | 38 |

| 9 | | | |

| 10 | | | after Drying wtg |

| | Wtg | | 775g |

Total 4245 gm water has gone out of it

Dryer Efficiency

polycarbonate sheet 20.26%

plywood sheet 19.53%

dome 18.66%

Chikku Dry

We took the second trial on Chikku., We put 5 kg chikku in it

26/04/2023

temp 40

| Sr no | Time | | Thermometer (Degree Celsius) |

| 1 | 10:00 AM | | 42 |

| 2 | 11:00 AM | | 44 |

| 3 | 12:00 AM | | 48 |

| 4 | 01:00 PM | | 49 |

| 5 | 02:00 PM | | 47 |

| 6 | 03:00 PM | | 45 |

| 7 | 04:00 PM | | 42 |

| 8 | 05:00 PM | | 39 |

| 9 | | | |

| 10 | | | |

| | Wtg | | 2304 g |

2 nd Day

27/04/2023

temp 40

| Sr no | Time | | Thermometer (Degree Celsius) |

| 1 | 10:00 AM | | 41 |

| 2 | 11:00 AM | | 43 |

| 3 | 12:00 AM | | 48 |

| 4 | 01:00 PM | | 48 |

| 5 | 02:00 PM | | 46 |

| 6 | 03:00 PM | | 45 |

| 7 | 04:00 PM | | 42 |

| 8 | 05:00 PM | | 38 |

| 9 | | | |

| 10 | | | |

| | Wtg | | 1804 g |

3 Rd Day

28/03/2023

Temp 39

| Sr no | Time | | Thermometer (Degree Celsius) |

| 1 | 10:00 AM | | 42 |

| 2 | 11:00 AM | | 44 |

| 3 | 12:00 AM | | 48 |

| 4 | 01:00 PM | | 49 |

| 5 | 02:00 PM | | 47 |

| 6 | 03:00 PM | | 45 |

| 7 | 04:00 PM | | 42 |

| 8 | 05:00 PM | | 39 |

| 9 | | | |

| 10 | | | |

| | Wtg | | 1687 g |

4 th Day

29/03/2023

Temp 39

| Sr no | Time | | Thermometer (Degree Celsius) |

| 1 | 10:00 AM | | 42 |

| 2 | 11:00 AM | | 44 |

| 3 | 12:00 AM | | 48 |

| 4 | 01:00 PM | | 49 |

| 5 | 02:00 PM | | 47 |

| 6 | 03:00 PM | | 45 |

| 7 | 04:00 PM | | 42 |

| 8 | 05:00 PM | | 39 |

| 9 | | | |

| 10 | | | |

| | Wtg | | 1601 gm |

From here on, the water did not go away. It is as well as the weight will remain in it

5kg chikku – 1601gm

water removing the 3399gm