What is black Soldier fly ?

Black soldier fly decomposes various types of organic waste and converts them into high-value biomasses such as oils and proteins. Treatment of organic waste using black soldier fly larvae is an environmentally safe and cost-efficient method that has been attracting increasing attention worldwide.

Objective :

To set experimental set up and SOP (standard Operating Procedure) for Biodiesel from Oil extract of black soldier fly.

Need of project :

BSF ( black soldier fly) based oil/fat is thought to be an alternative as biofuel. To study economics BSF larvas were cultivated at Vigyan Ashram/Bombay Sappiars. The oil extracted was available from same. Our methodology could lead to an alternative source of diesel based on food waste.

WHAT IS BIODIESEL ?

Biodiesel is a renewable, biodegradable fuel manufactured domestically from vegetable oils, animal fats. Biodiesel is a domestically produced, clean-burning, renewable substitute for petroleum diesel. Using biodiesel as a vehicle fuel increases energy security, improves air quality and the environment, and provides safety benefits.

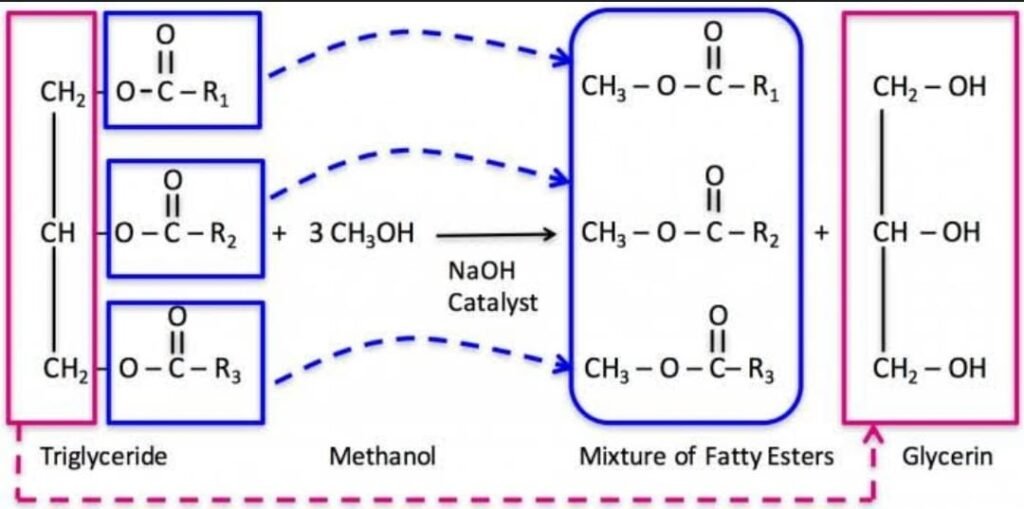

How Biodiesel form ?

Biodiesel is an alternative fuel for diesel engines that is produced by chemically reacting a vegetable oil or animal fat with an alcohol such as methanol or ethanol. In words, the reaction is: Oil + alcohol → biodiesel + glycerin.

Triglycerides :

What are triglycerides? Triglycerides are a type of fat (lipid) found in your blood. When you eat, your body converts any calories it doesn’t need to use right away into triglycerides. The triglycerides are stored in your fat cells. Later, hormones release triglycerides for energy between meals.

Date :14/02/2023

Purification or Drying of Methanol :

Materials :

- Digestion apparatus

- Digestion flask

- condenser 24 joint

- Adapter

- gaurd tube

- calcium chloride 10 gm.

- calcium oxide 100 gm

- Methanol 99 %

Step 1 :

- Took 100 gm Calcium Oxide powder in digestion flask.

- added 200 ml methanol.

- heated at 60 degree celcius for 5-6 hrs.

- gaurd tube fill with 10 gm of calcium chloride and cotton.

Date : 15/02/2023

Step 2 :

Distillation of Methanol 6 hrs

Date : 16/02/2022

Transesterification Reaction

Materials :

- oil bath setup

- 3 neck flask

- condeser

- gaurd tube

- adapter

- thermowell

- stands , clamps

- BSF oil 200 gm

- methanol 200 ml

Procedure :

- Took oil bath setup placed it well.

- added 200 ml methanol in 3 neck flask and 200 gm BSF oil.

- Kept condenser on flask. added adapter which was connected to gaurd tube.

- gaurd tube filled with cotton and calcium chloride.

- heated for 5-6 hrs at 60 degree celcius.

Date :17/02/2023

Separation of biodiesel :

Added distilled water to separate biodiesel and glycerine and unreacted methanol.

140 ml biodiesel recovered from this reaction.

What is Fractional Distillation and Need ?

Fractional distillation is the separation of a mixture into its component parts, or fractions. Chemical compounds are separated by heating them to a temperature at which one or more fractions of the mixture will vaporize. It uses distillation to fractionate Fractional distillation is a process of separating a mixture of chemical compounds. This means that each part (called a “fraction”) of the mixture can be kept apart from the other chemicals. Different chemicals have different boiling points.

Using Fractionating Column Did reaction as same as Distillation

Take Oil from Transesterification reaction and kept in round bottom flask and did set up like above .

Conclusion :

140 ml Raw Biodiesel got from this reaction and 10 ml pure biodiesel.

Date : 16/05/2023

Repeat this reaction of transesterification

and got 15 ml pure biodiesel from above reaction.

Conclusion :

methanol is 60% and contains 40% of water in it so reaction was not happen that way. expecting 60-80 ml pure biodiesel so we decided to dry methanol by fractional distillation process.

Date : 07/06/2023

Set up reaction of methanol drying process by fractional distillation

Methanol purification by Fractional distillation.

Date : 09/06/2023

Reflux action of Transesterification reaction in oil bath.

Temperature during reaction is between 50 degree celcius to 64 degree celcius.

volatility test for diesel identification

| oil | Diesel | |

| Weight of Paper | 0.70 gm | 0.70 gm |

| Weight of dipping | 2.12 gm | 2.01 gm |

| After 10 min | 2.04 gm | 1.81 gm |

oil weight = 1.42 gm It means 0.08 gm oil volatiled. = 5.6 %

Diesel = 1.31 gm It means 0.20 gm diesel volatiled. = 15.26%

difference of both is 9.6 % means total percentage of diesel in mixture is 9.6 %

Costing of Biodiesel Formation :

1 Kg Prepupa = 100/Kg

1 kg BSF prepupa contains approximately 200 ml of oil ( oil extraction cost per Kg is 5 rs )

200 ml oil converts into about 140-180 ml of mixed biodiesel (RAW)

cost of transesterification process is 160rs

its quite expensive as compared to normal diesel.

CONCUSION :

Performed above reaction including methanol purification , distillation, Transesterification and fractional distillation got 180 ml mixture of methanol, oil and diesel but we could not able to separate it. I conducted 3 Sets of reactions for a Methanol oil ratio of 10:1, the yellowish-colored mixture obtained from a reaction we couldn’t separate by fractional distillation because the centrifuge machine is required to separate diesel and methanol and need to optimize or improve the procedure of biodiesel synthesis.