Title:-Selection of solar powered sewage pump for primary screening of 3000L grey water recycling at Dingrajwadi.

Introduction: The project is for 50+ household’s water (grey water).Approximately 3000 liter water consider for this project. The water comes from 1km distance. There is a wastewater tank. Due to wall falling on outlet of tank the outlet got chocked. The sludge is accumulated in the tank.

Need of Project :

1.To remove phosphorous,Nitrogen and Carbon from grey water.

2.To maintain cod and Dissolve oxygen in water.

3.To reduce the cost of electricity using solar panels.

Objectives:-

1) Selection of solar powered sewage pump for 3000 L grey water recycling at Dingrajwadi.

2) To fabricate appropriate structure for solar modules.

3) To doing coagulation treatment in 5000 L grey water tank.

Date 2/03/2022

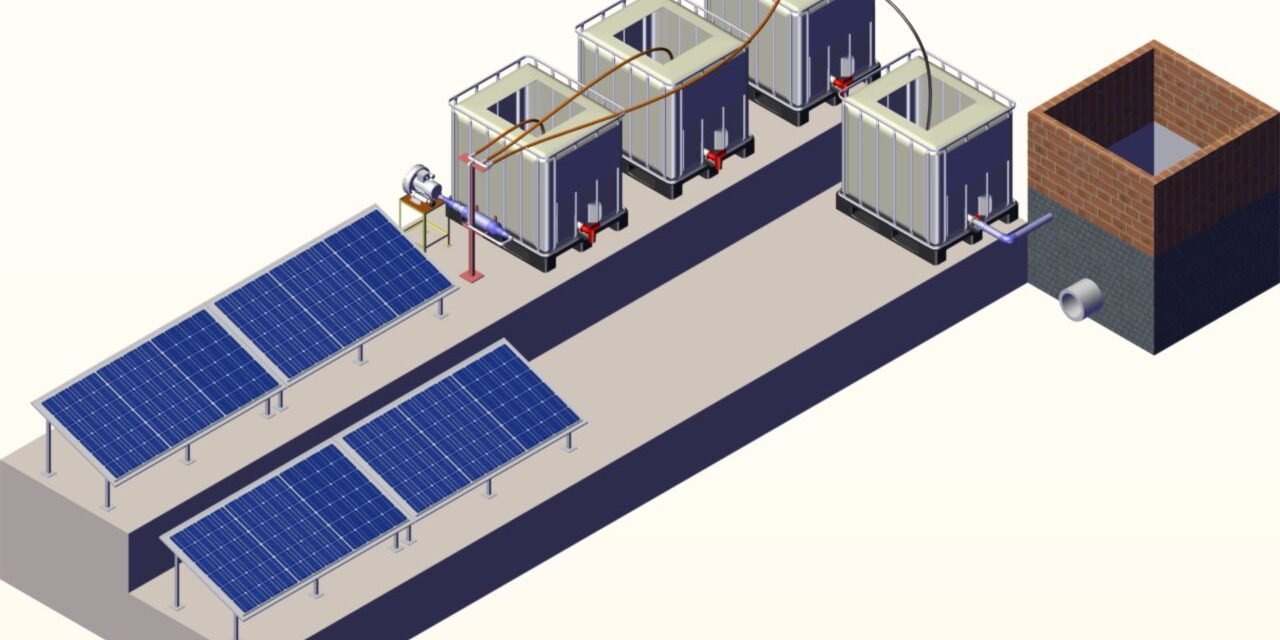

Process flow diagram :

Primary Treatment

Design of solar powered grey water recycling system

: All dimensions are in ft

Pump selection criteria

There are two types of sewage pump work effectively with good efficiency i.e centrifugal sewage pump and submersible sewage pump.The working of these two pumps are same but difference in their applications. centrifugal pump requires separate room /concrete base construction.also these pumps installing cost is high.on other hand submersible sewage pumps requires no suction head.the installing cost is less as compare to centrifugal sewage pump.Due to easy handling we choose submersible sewage pump.

I finding the details of sewage pumps and range of pumps available in online market.

Date 4/03/2022

1 hp = 746 watt /hr

. Means the power required for operating 1 hp pump is 746 watt so,our pump is submersible 0.5 hp to 1 hp sludge pump.the pump required 373 w/hr power (Kw) to 746 watt/hr according to solar radiation falling on pv panel.I observe power specifications of 335 w Vikram solar panel set into vigyan ashram campus.

. Rated voltage=38.1v/hr,Rated current=8.80A/hr

Power=v×I

. =38.1×8.80

. =335 watt/hr

There are three panels we will install in dingrajwadi.I find out the material required for 3 panels installment.

Date 5/03/2022

I was collect some information about specifications of materials. after that I visited to Samarth hardware pabal for knowing cost and availability of that material.

Date 08/03/22

Drawings of sub assemblies of solar photovoltaic structure

Design parameters: 1.tilt angle 2.Dead load

(:- H2 angle and H1 angle are tilt angles)

H2 angle=sinQ=opposite side/ hypotenius.

=(h1-h2)/4.2cm

=(66.3-65.2)/4.2

. =1.1/4.2

. SinQ=0.2619

. Q=sin^-1(0.2619)

. Q=15.1°

H1 angle=sinQ=opposite side/hypotenius

. = (h1-h2)/4.2 cm

. =(94.6-93.5)/4.2

. =1.1/4.2

. SinQ=0.2619

. Q=sin^-1(0.2619)

. Q=15.1°

Date 09/03/22

Load calculation of structure

Dead load: The load is constant all over time

Weight of individual solar panel=22 kg

Dimension of solar panel=0.992m×1.9956m×0.035m

Number of solar panel used=3

Area of solar panel=1.94 m^2

Total are of solar panels=5.82 m^2

Dead load on structure=wt.of 1 solar panel×no.of solar panels =22×3 =66 kg

Taking 1 kg =9.81 N

The total dead load of solar panel is 66×9.81=647.46 N

This load act on structure.

Date 11/03/22

Making Bill of material of PV structure of 3 panels installment of grey water recycle system at Dingrajwadi.

Date 14/03/22

We use variable frequency Drive in this system for protection of pump motor from damage.

VFD market survey with their range.

Date 28/03/22

Final Bill of Material of solar panel structure

| Sr.no | Material Name | Quantity | Cost/unit | cost |

| 1 | Square tube (1.5”*1.5”)9kg | 2 | 83.33 Rs/kg | 1500 |

| 2 | L Angle (30*3mm) | 3 (9 ft) | 80 | 240 |

| 3 | Base Plate (6”*6”) | 4 | 80 | 320 |

| 4 | Foundation bolt (M10) | 16 | 5 | 80 |

| 5 | Foundation nut(M10) | 16 | 5 | 80 |

| 6 | Bolt (M6) 4” | 24 | 5 | 120 |

| 7 | bolt (M6) 2.5” | 24 | 3 | 72 |

| 8 | Nut (M6) | 50 | 4 | 200 |

| 9 | Silver paint 1liter | 1 | 200/liter | 200 |

| 10 | Metal primer 1 liter | 1 | 200/liter | 200 |

| Total | 3012 Rs |

Date 17/05/22

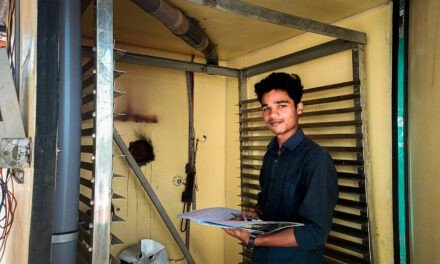

The fabrication design is changed due to new panels.we took measurement of the all materials of fabrication.

cutting the square tubes,L angles in determined size.Drilling on square tubes.

Date 18/05/22

cutting the square tubes,L angles in determined size.Drilling on square tubes

Date 19/05/22

cutting the square tubes stand at tilt angle of 33° in which latitude of Dingrajwadi is 18°+15=33°.we choose the tilt angle by winter season basis.polishing of base plates

Date 20/05/22

Welding operations on base plates and square tubes for making stands. Making holes on square tubes for giving support to the structure.

Date 21/05/22

Transporting 5000 liter tank and stands to the project site.installing tank to the 7×7 ft dug out pit.