- 9TH AUG – 14TH AUG 2021

Fab16 challenge is opportunity to learn and experience the lot of things including design thinking apporach, 3D Designing, rapid prototyping, fabrication, team collaboration, presentation and many more. The challange of Dynamic Hand Othrosis creating problem defining, ideation and rapid prototyping.

The previous workdone by Mr. Prathmesh Darwade on Forearm ( http://vadic.vigyanashram.blog/existing-exoskeleton-and-mechanisms/ )

We already made a prototype for Forearm but now we need to shift on the next upcoming part that is shoulder joint.

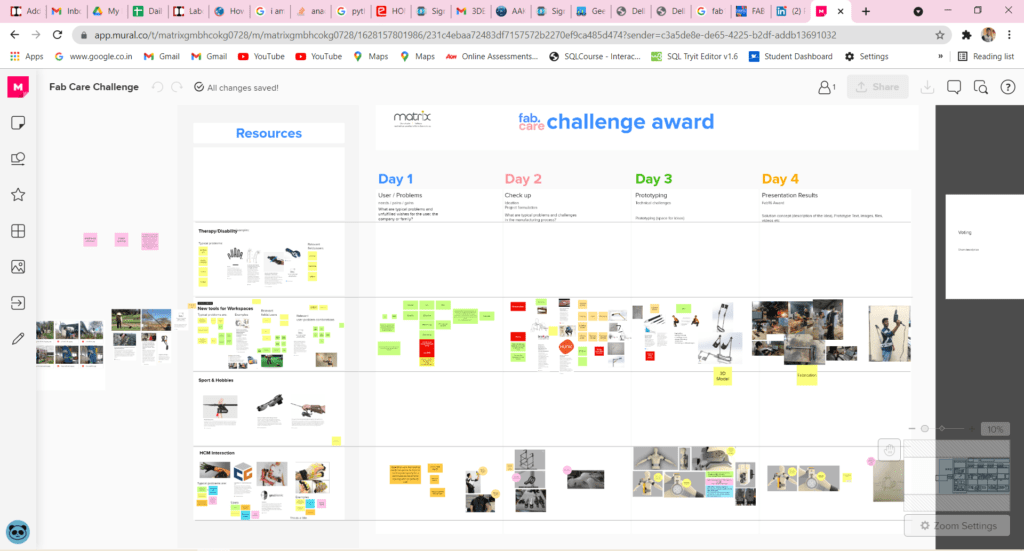

Here we have our day to day Challenges we have completed/ milestone achieved.

- DAY 1: EMPATHIES. (11/08/2021)

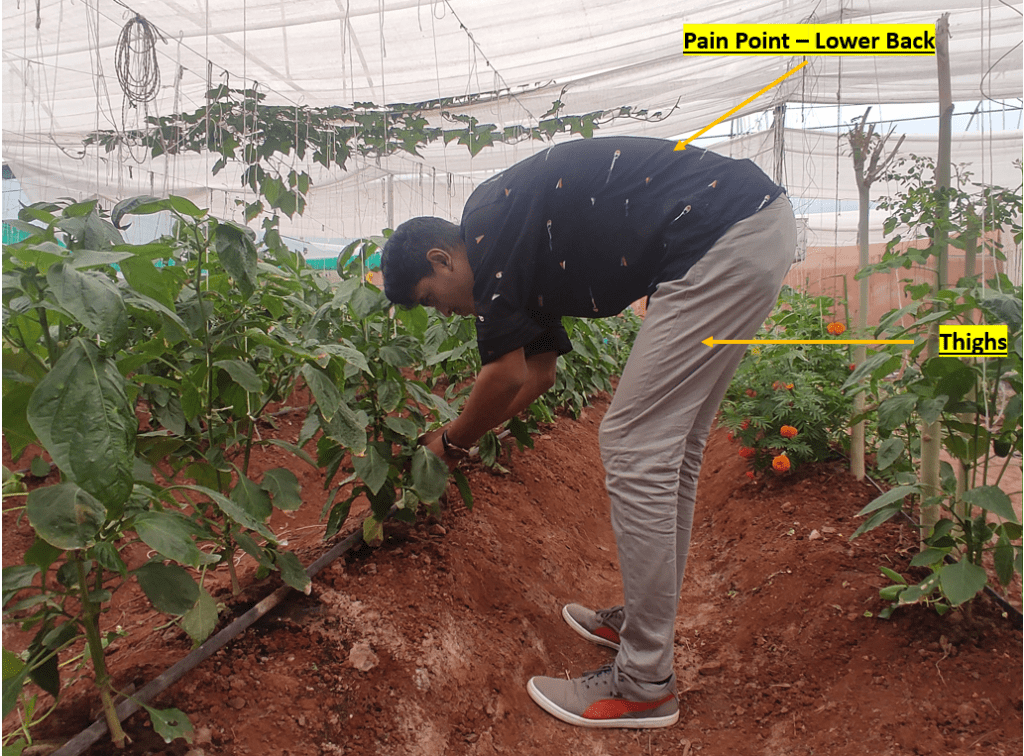

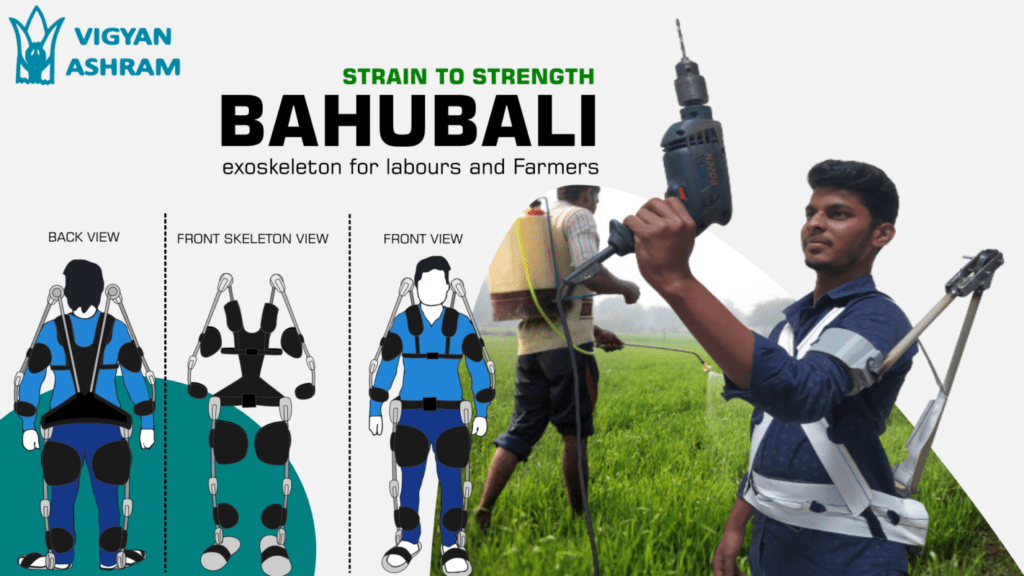

Problem identified in repetative work by farmers and labours lead to muscular disorders. Work like over head drilling, grass cutting machine, heavy weight lifting etc.

We identifed some pain points while working in our Vigyan Ashram. Also experienced some some repitative work to understand where the pain points & support needed and ” We take a walk in our customer’s shoes ”

We found multiple areas where the working person is facing fatigue due to repetitive work, at our campus we rarely need some person to do the repetitive work, but similar kind of works are happening in the farming sector, and industrial sector the workers need to do same repetitive task for 6-8 hours a day and for at least a week for farming sector or may be multiple years in the industry.

We define to work on The dynamic shoulder joint exoskeleton prototype designed for labours/farmers who do over head work repetatively.

- DAY 2: IDEATION (12/08/2021)

In ideation phase we take 5 – 6 different ideas from every team members. Idea of different mechanism, design for same functionality and concluded final idea by taking brainstroming session.

Ideas :

- Spiral spring ( Using potential energy of spring ) .

- Artificial Muscles

- Hydralic system

- Pnumatics system

- Compression / tention springs

Spiral spring design

Pnumatics system design

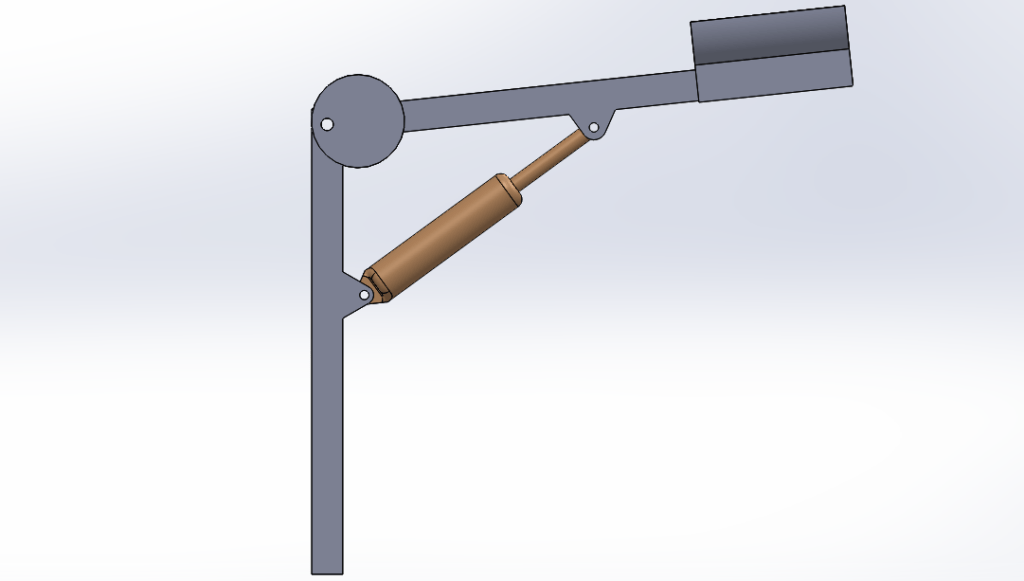

Finalize : Spiral spring based system.

This system uses spiral spring to store the potential energy due to weight of hand into spring as it gets wind and unwinding the spring will give the supportive force to the arm.

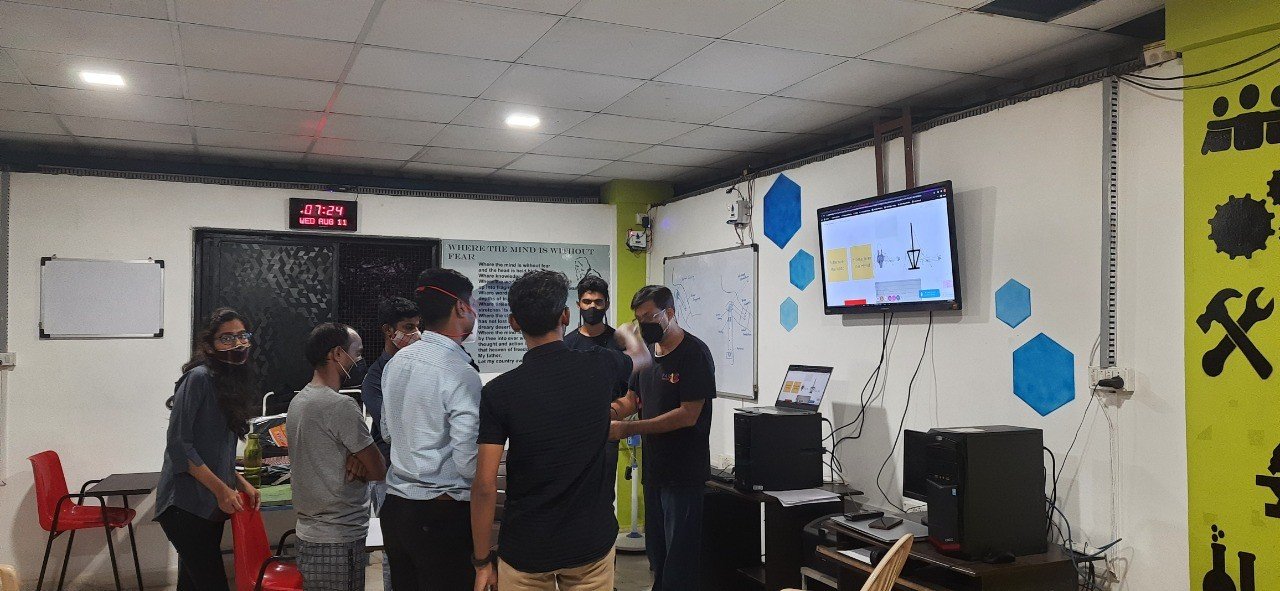

- Discussion in meeting regarding work and progress :

- DAY 3 : PROTOTYPING AND FABRICATION (13/08/2021)

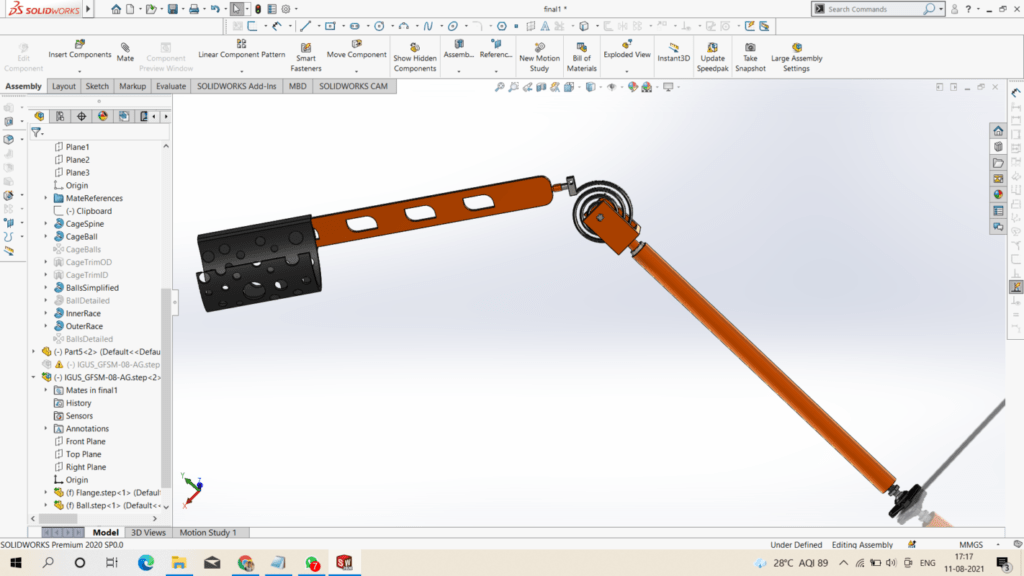

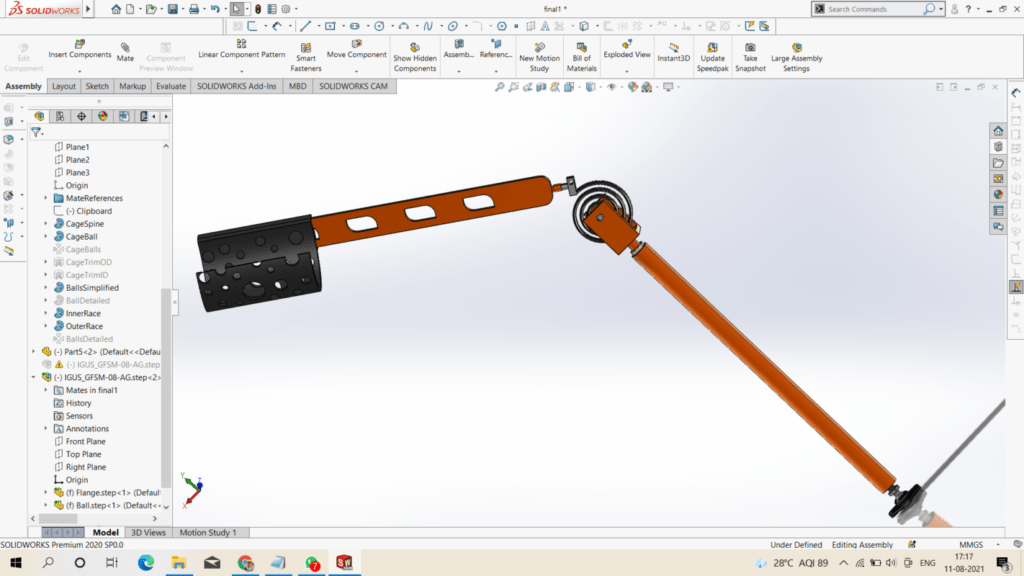

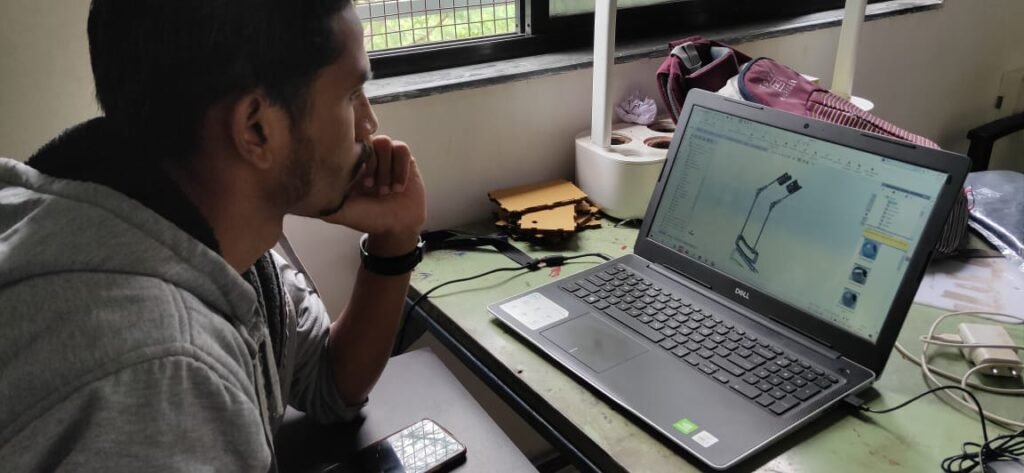

With available material we set our flow process and start sketching and CAD Modelling with solidworks.

Idea Sketch

First CAD Modelling

Second CAD Modelling

Working Animation

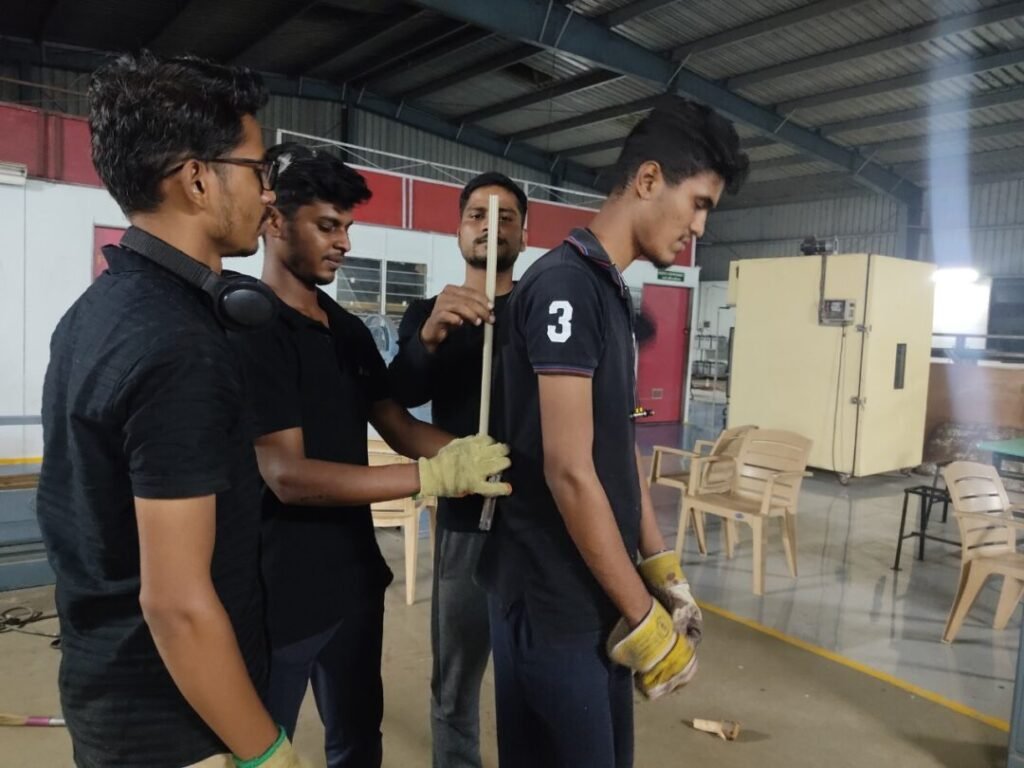

Fabrication Work : with available material and time.

Team Discussion

CAD Modelling

Presentation Preparation

Fabrication

Fabrication

Instant Testing

As working whole night, here is our prototype ready till morning with presentation :

DAY 5: PRESENTATION (14/08/2021)

Final presentaion for FAB16 Challange :

Hip Hip Hurray ! …….. Hip Hip Hurray ! ………. Lets Celebrate !

Vigyan Ashram won the Fab16 challange of Dynamic Hand Othrosis creating problem defining, ideation and rapid prototyping.

Here is final announcement of winner :

Thank you !