To review the detail work on baling machine please refer the following blog.

http://vadic.vigyanashram.blog/belling-machine/

Gear Calculations :

Required force to lift the load of 3.5 kg ( Rack , Connecting rod , Plastic Waste , Plunger and Water )

- Lifting Force = mgh

F = 3.5 * 9.8 * 0.2 = 6.86 N

P = F /A

= 6.86 / (0.2*0.2) = 171.5 N/m2

The gears are sized according to market availability and standards of ANSI metric.

- Module = Pitch circle diameter / Number of teeths

Diameter of gear 1 = 70 mm

module = 2

Number of teeth = 70 / 2 = 35

For gear 2 ,

d = 50 , m =2

Number of teeth = 25

for gear 3,

d = 30 mm , m = 2

number of teeth = 15

- Rack calculations:

Length required 200 mm

module = 0.625

teeth on rack = 32

- Speed ratio :

n1 = 1

n1 / n2 = T2 / T1

n2 = 35 / 25 = 1.4

n3 = n2 = 1.4 (Both the gears are mounted on the same shaft)

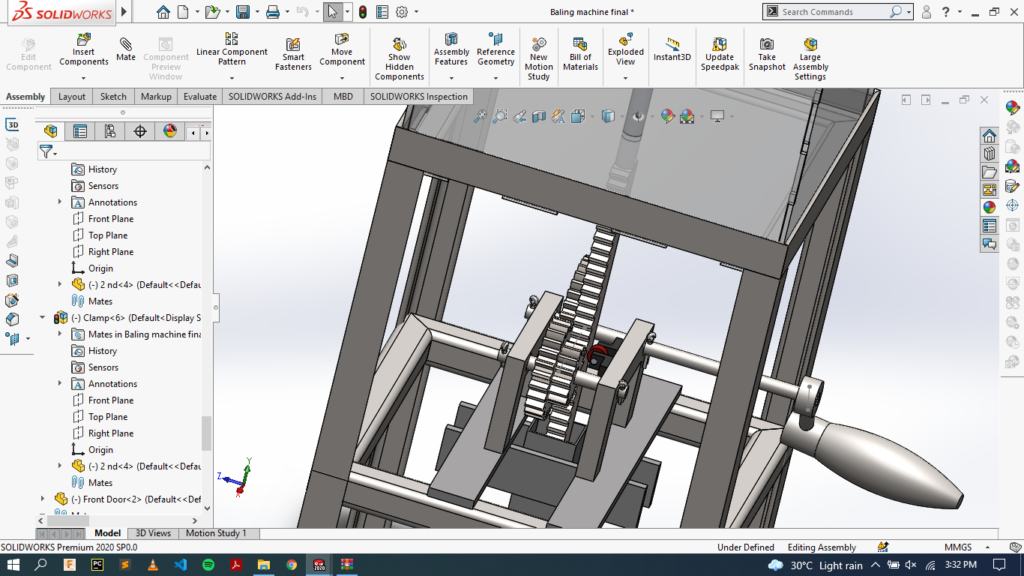

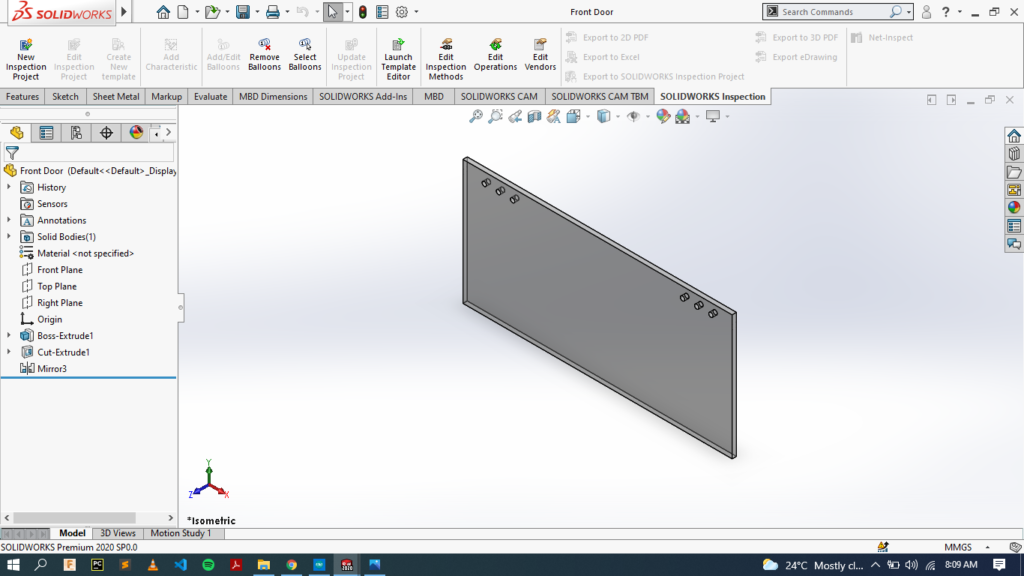

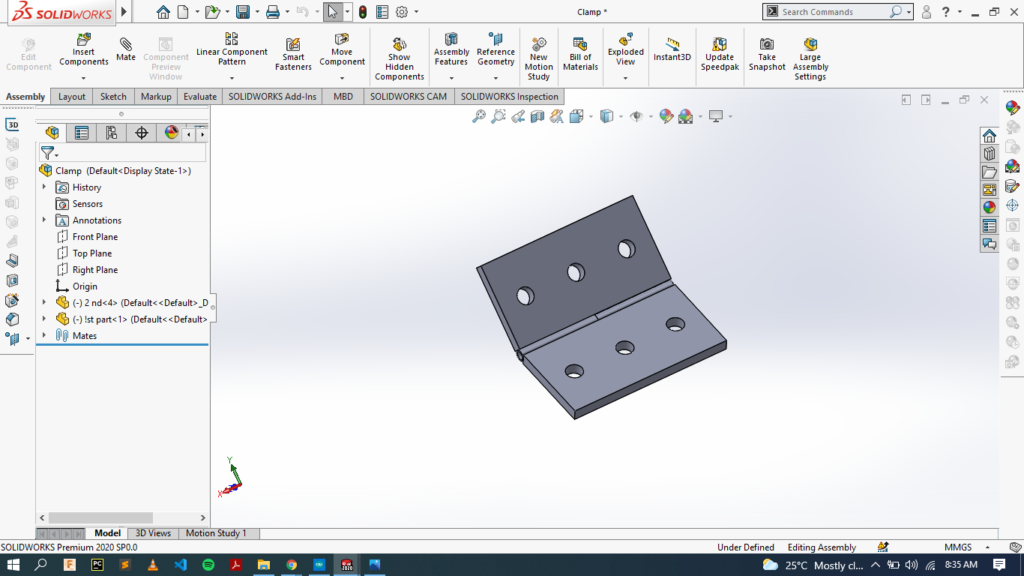

Door And Door Clamp Design :

7 Aug 2021

Design of doors :

Isometric View

Front View

Clamp

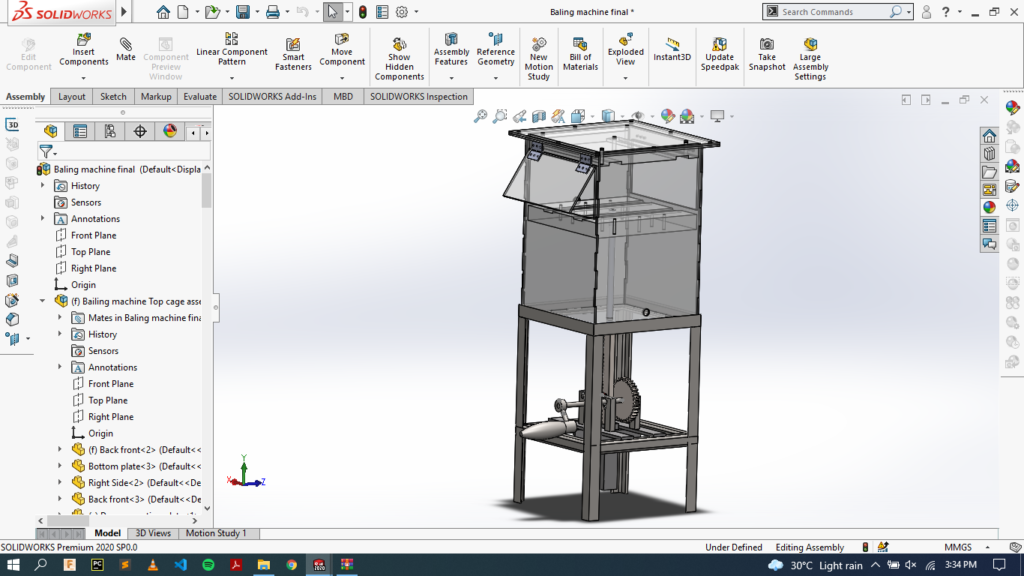

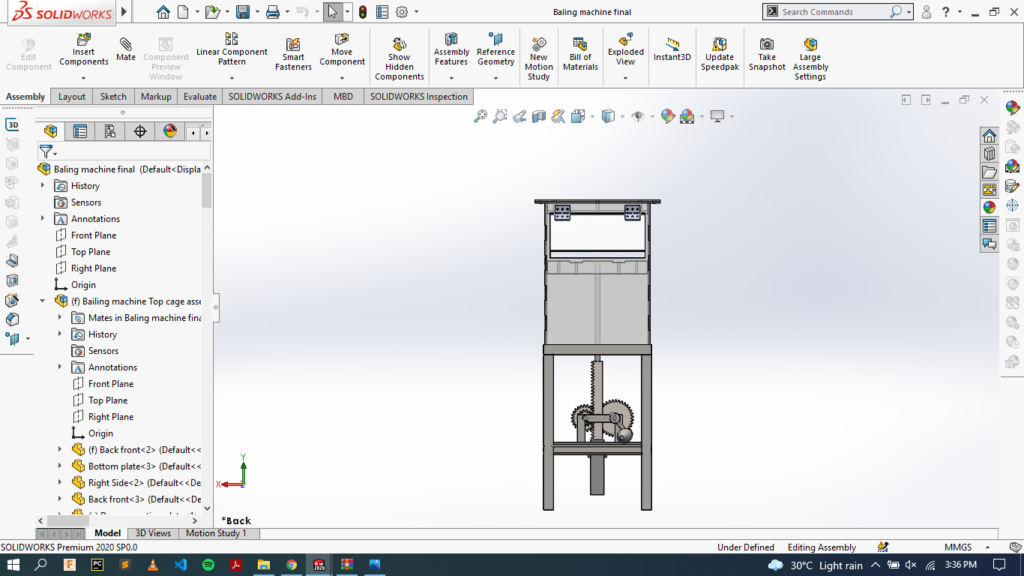

Final Assembly :

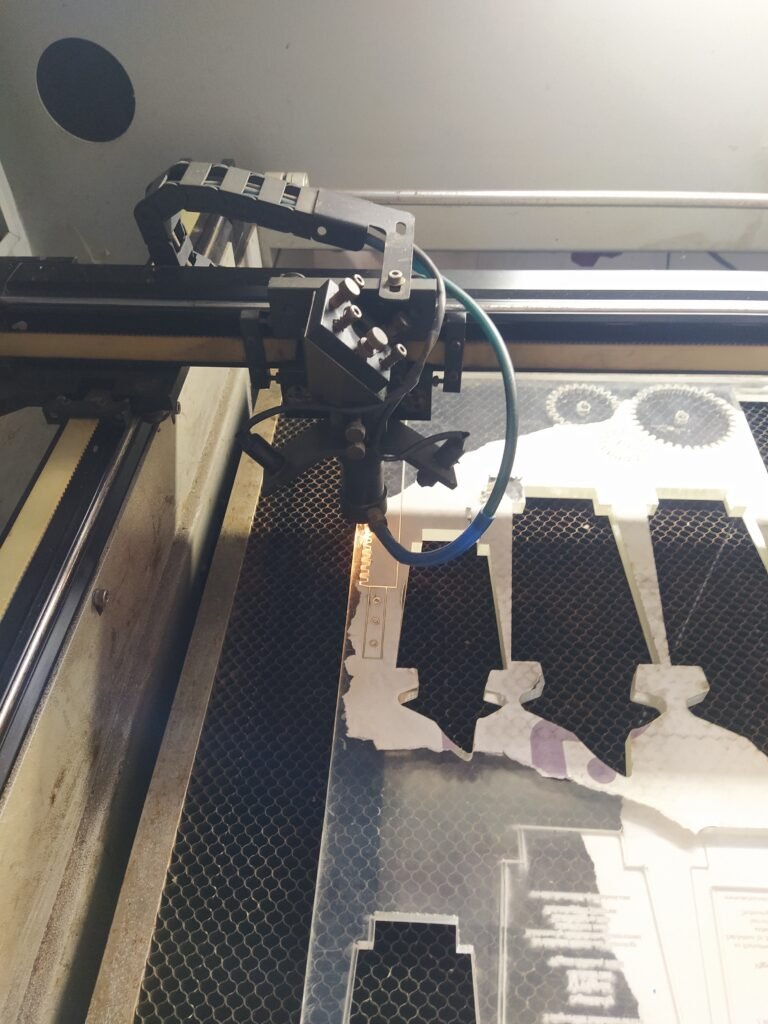

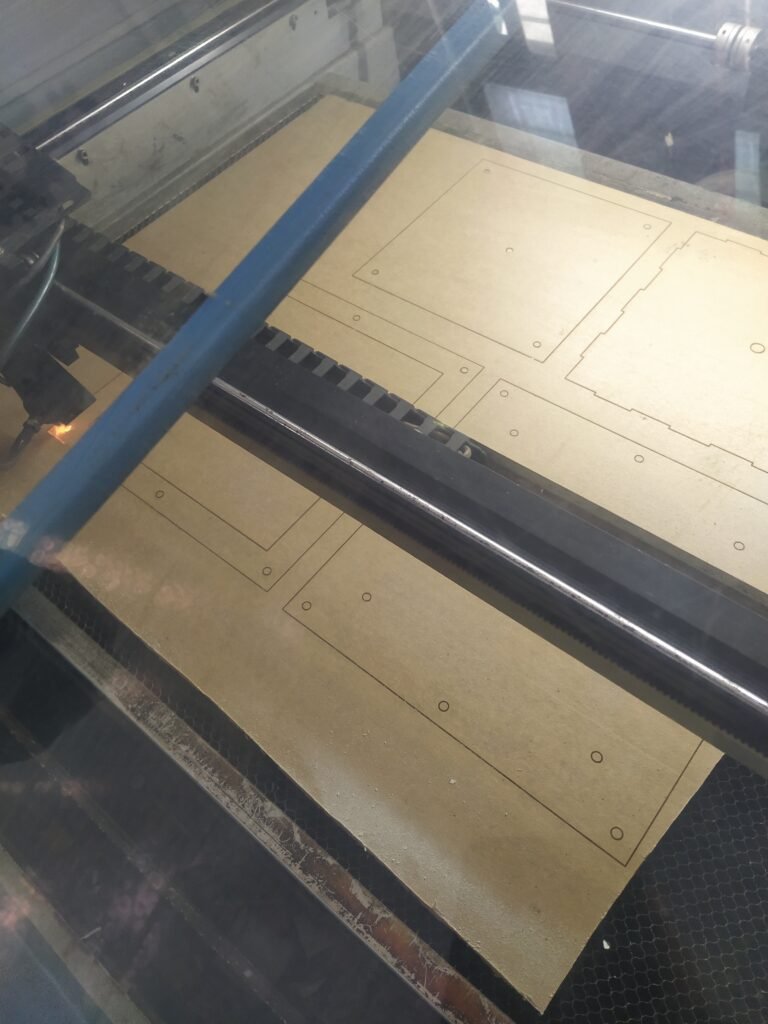

Digital Fabrication : ( Laser Cutting , 3d Printing )

8 Aug 2021

All the parts were created converted into dxf format and digitally fabrication using laser cutter on acrylic sheet.

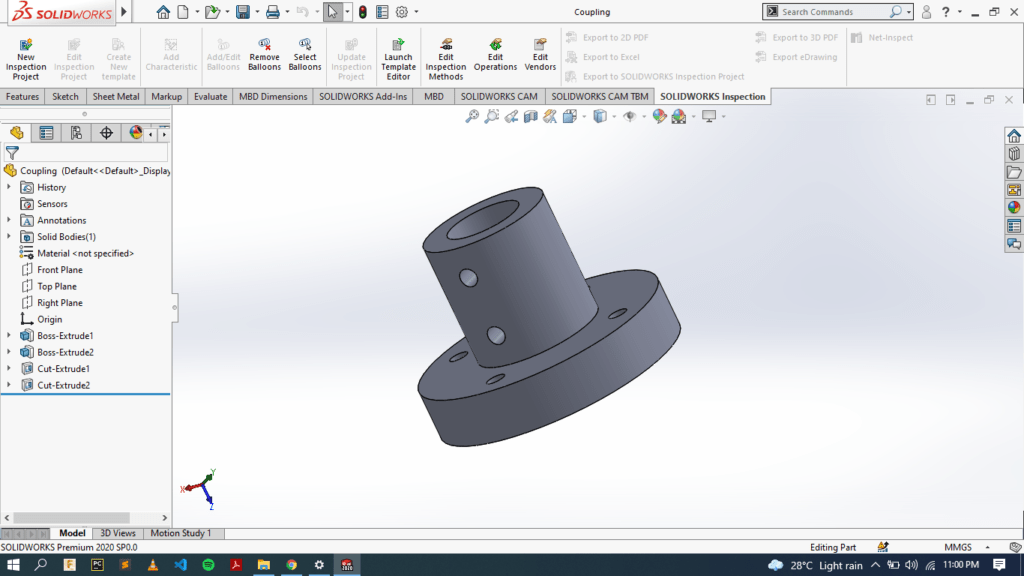

Coupling For Plunger and Shaft :

9 Aug 2021

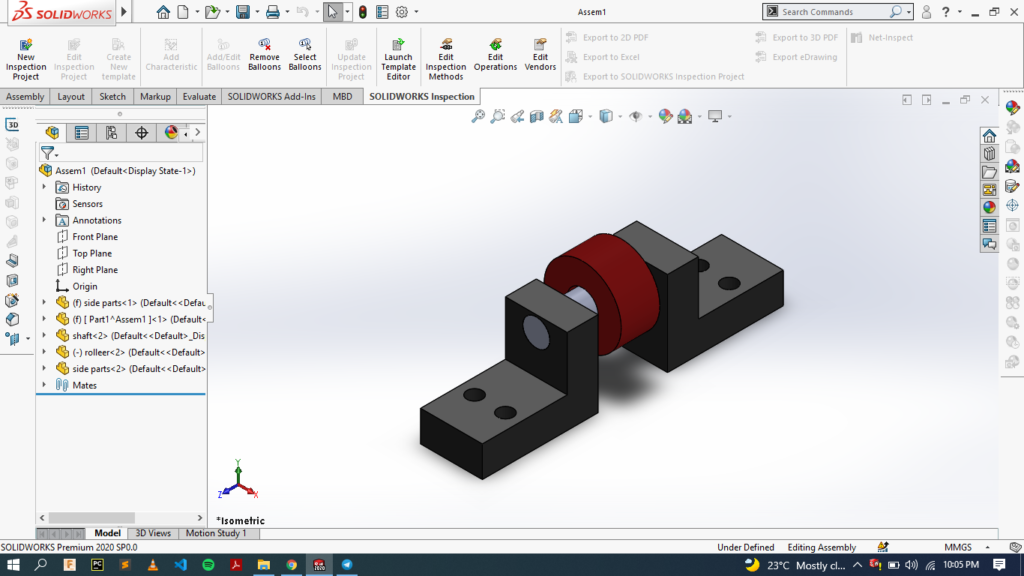

CAD Model

3D printing

Final Part

New Structure Fabricated using Available Material :

11 Aug 2021

After first trial of baling machine prototype we found that the old structure of baling machine is unbalaced and the axis of gear mechanism is not proper, because of that the gears are not aligned properly. So we decided to manufracture a new structure with the available material.

New Structure

Fabrication

Design of Roller Guide for Rack and Quater pins for shaft:

12 Aug 2021

Roller Guide

Quater Pin

Updated Design :

Prototype :

Ready to take trials………..

Trial 3 :

25 Aug 2021

The details about 1 st two trials are posted by Mr. Sanket Valse.

blog link :

http://vadic.vigyanashram.blog/belling-machine/

To observe the leakages and calculate compression ratio at maximum plastic carrying capacity.

Plastic Poured = 600 gm

Initial volume of plastic (before press): 20*21*21 = 8820 cm3

before soaking it into hot water , we got only 2 cm compression.

Then plastic pored into 91 °C hot water and let it to be soften for 5 minutes then transferred to our baling machine. On applying pressure the soften plastic compressed by 10 cm.

The final volume after baling:

10*21*21 = 4410 cm3

Total reduction in volume: 8820-4410 = 4410 cm3

therefore 50% reduction in volume.

Initial density of 600 gm plastic: Cold press:

rho= m/v = 600/8820 = 0.068 gm/ cm3

Final density hot press:

rho= m/v = 600/ 4410 = 0.1360 gm/ cm3

the compression ratio is 1:2

Conclusion :

After this trial we found one leakage at bottom plate because of bellow. The bellow was not designed as per our requirements whatever the bellow available in the market we have used that. So We have to design a bellow which occupy less space in baling machine so we get more volume to insert plastic in it. And the bellow should expand and compress with the plunger.