A] Introduction

What is Khawa ?

Khawa is the concentrated whole milk product obtained in a open pan condensing of milk under atmospheric pressure.

- Khoa/Mawa/Khoya is a partial dehydrated whole milk product.

- It is prepared by the action of stirring and heating the milk continuously until it reaches semi-solid (doughy) consistency.

- Khawa is nothing but removal of the water (Evaporation) in the milk by the help of heating.

Differant names of Khawa-:

1]Khoa 2]Khoya 3]Mawa 4]Kova 5]Palghova

Sources of Milk for Khawa-:

Buffalo, Cow, and Goat.

Key words: SKMM (Solar Khawa Making Machine) , Steering , Khoa etc.

B] Problem Definition

- From literature study and market survey, I got some drawbacks in existing machines which has: a) They are heavy and large scale machines. b) Many machines motors operated only electricity. c)They have some limitations.

- Our organisation require a small scale khawa making machine (10-15 Lit) , which is not available in market as per our requirements.

- The same problem regarding small scale or low capacity machine has been occurred with some rural farmers.They do not pay money for existing machines.

- In rural area most of the time 8-10 hrs 3 Phase supply available from out of 24 hrs. So electricity limitations occurred in villages.

- As the my point of view there is no solar thermal khawa making machine exist in market , which is big opportunity for us.

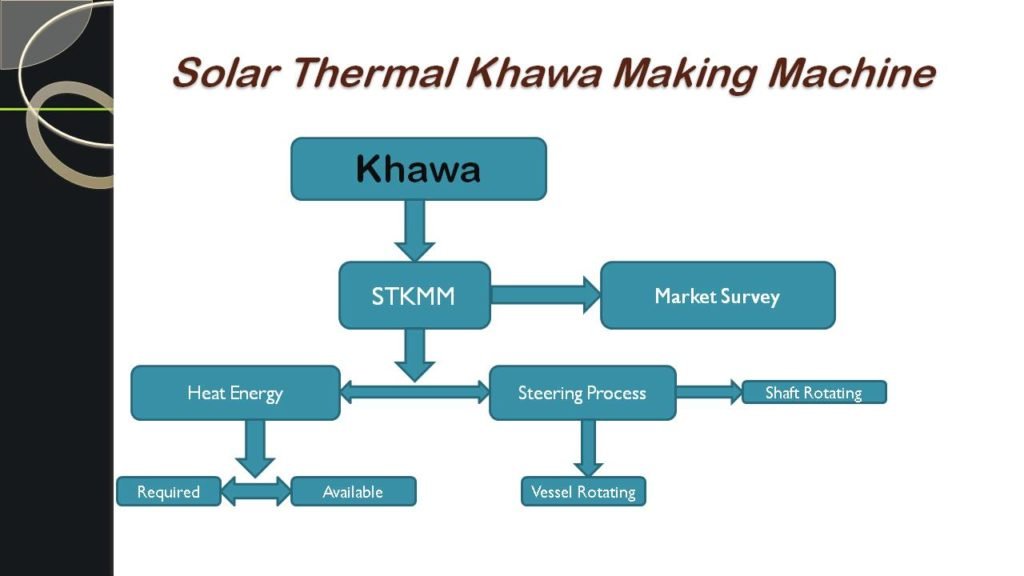

C] Our Mission / Objectives

- The main aim is make a Solar Khawa Machine which operated on scheffler.

- At the same time keep touch in Market Survey.

- Find out Heat Energy ( Available energy from scheffler and required energy for heat a milk.)

- Make Sterring Mechanism (Vessel rotating and Shaft rotating).

- Design the whole system.

D] Plan of Action

- Study the literature of existing Khwa making machine in market.

- Market survey and conduct feedback from manufacturer.

- List the availability of materials.

- Available energy (Heat) from scheffler and required energy for process.

- Take a trails on existing conditions and match with our requirements.

- Selection of proper Steering Mechanism .

- Sketch concept design and finalize from it.

- Make a system and take first trial.

Generally, To get 1 Kg Khawa we require 5 lit. (Fat 3-5) of cow and 4 Lit.(7-9) of buffalo milk.

Physical changes in Khoa with respect to cow and buffalo milk:

| Particulars | Cow | Buffalo |

| Color | Straw/pale-yellow, brown tinge | Whitish, brown tinge |

| Appearance | Moist surface | Slightly oily |

| Body | Slightly hard | Soft |

| Texture | Slightly sandy | Smooth, granular |

| Smell | Rich, nutty | Rich, nutty |

| Taste | Slightly salted | Slightly sweet |

| Suitability for sweets | Suitable | Highly suitable |

Methods for making Khwa:

A] Traditional Method

B] Improved Method

C] Continuous Method

D] Miscellaneous method

Market Survey of Khawa Making Machine:

Energy Calculations:

1] Available(Input) Heat energy at Scheffler = 10.01 KWh

2] Heat Energy Utilized By Scheffler = 1.28 KWh

3] Efficiency of Scheffler = 12.78 %

Energy Comparison for Heating and Steering :

Energy Calculations for Khawa making

(Comparison of energy required for stirring and heating operations)

1] Heat required for Khawa making –

- For making 6 Kg Khawa

Milk required = 24 Kg

Quantity of water to evaporate = 18 Kg

- Latent heat of evaporation for water =2260 Kj/Kg.

Energy required for evaporation of 18 Kg water = 2260 *18 = 40,680 KJ.

- Specific heat of 24 liters milk = 24 * 4.186 = 100.486 Kj

- Total heat required for making 6 Kg Khawa = Latent heat of evaporation + specific heat

= 40,680 + 100.486 = 40,780.486 Kj

Heat required to make 1 Kg khawa = 40,780.486/6 = 6796.74 Kj

2] Energy required for stirring –

Energy required for stirring 24 kg milk (6 Kg khawa) = 200 WHr(AC synchronus motor considered from previous experiments done of nachani roasting stirrer)

Total time required for stirring = 2 Hrs

Watt=Joule /Sec.

200 =J/(2*3600)

Energy required for stirrer = 1,44,0000 J = 1,440 Kj

Energy required for 1 hour stirring = 720 Kj

3] Available energy from scheffler-:

In the month of May 2020 available energy at scheffler =1.28 KWh = 1.28*3600 = 4608 KWs

Now,

Watt=Joule /Sec.

Available energy at schefflar in one hour = 4608 KJ

Hence, time required for making 6 Kg khawa = 40780.486 /4608 = 8.84 Hrs

Time required for making 1 Kg khawa using scheffler energy = 1.47 Hrs

Consider,duration of solar energy available = 6 Hours

Energy available from schefflar in a day = 4608 * 6 = 27648 Kj

Using schefflar 4 Kg khawa can be made in a day.

Conclusion –

By reviewing the above calculations it is easy to conclude that, energy required for heating is around 28 times more than energy required for stirring in khawa making operation.

With this data we can also conclude that use of Solar thermal energy from solar parabolic reflector/ collector will save more fuel (required as heat source e.g. wood, diesel, LPG, etc.) as compare with converting conventional khawa making machine stirrer to solar PV energy.

Automation of Scheffler

To rotate scheffler w.r.t. Sun motion automation was done by the help of my friend vipul.In that automation Scheffler is rotate after every 4 min. for 15 sec. and keep focal point in same point or place.The setup was already exist which was made by Yogasree mam in 2018. Vipul and me maintenance of it and necessary modification.

Automation Box Arrangement

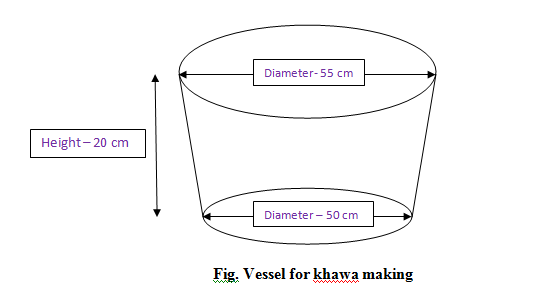

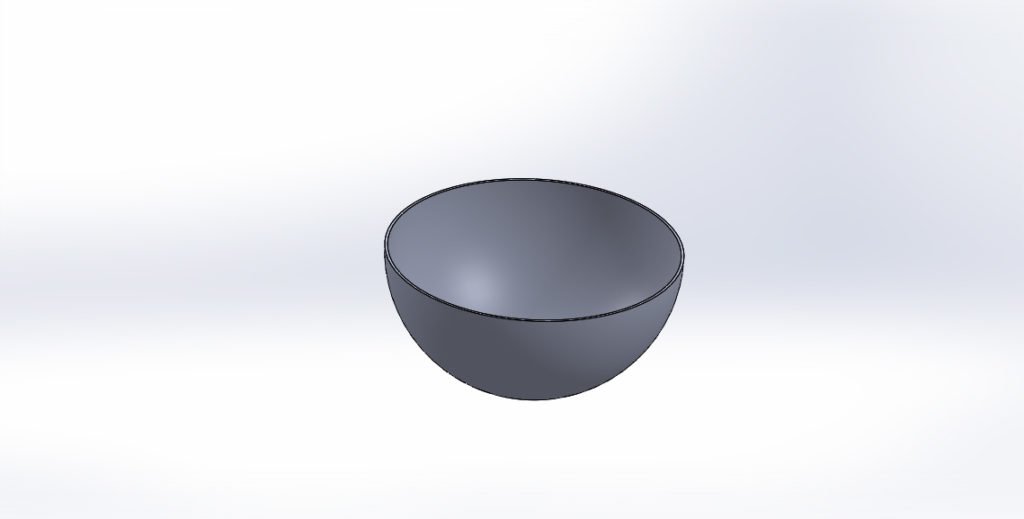

Vessel Design and Quotations

Vessel Design Calculations

Energy available at scheffler for 1 Hrs = 4608 Kj

Energy aviliable in a day from scheffler = 4608 * 6 = 27,648 Kj ………….. (10 am to 4 pm)

Energy required for make 1 Kg khawa = 6780 Kj

Milk required for make 1 Kg khawa = 4 Liters.

By using scheffler we can make per day khawa = 27648/6780 =4.01 Kg

Total milk required for making 4 Kg khawa = 4*4 =16 Liters

As per market survey , take 3 times bigger vessel to total milk volume.

Vessel required for khawa making = 16 *3 = 48 Liters

1] Energy aviliable per day = 27,648 Kj

2] Total Milk Required = 16 Liters

3] Produced Khawa Per Day = 4 Kg

4] Vessel Capacity required = 48 Liters

Volume of Scheffler Chulha : 3.14/4 *(55)2 * 23 = 54 .6 Liters

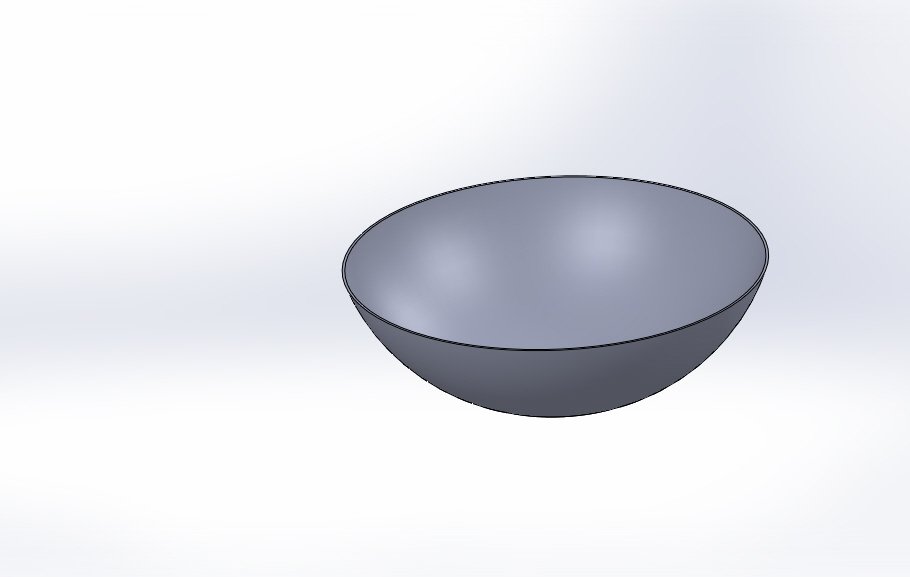

Selection of Vessel

After market survey and discussions we concluded that use khawa making vessel as a kadai which aviliable in vigyan asharam food lab.

The kadai dimensions as:

Volume-28 Liter, Material- Iron, Weight- 10 Kg , Thikness- 4 mm , Open Dimeter – 54.5 cm , Height- 21 cm.

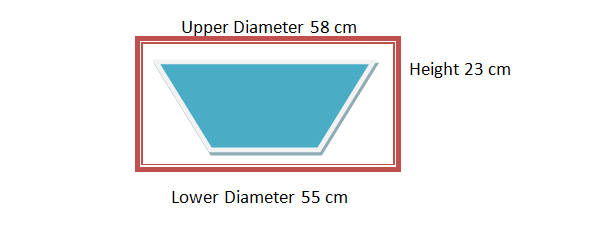

Kadai and Secondary reflector resting pan

The existing pan dimensions not appropriate for rest a kadai on it, so it could be modified as per kadai dimensions.

Old Base Daimeter = 55 cm Kadai Dimeter = 54.5 cm

New / Modified Dimeter = 58 cm

Operations Done on Pan:

i) Grinding ii) Cutting iii) Welding

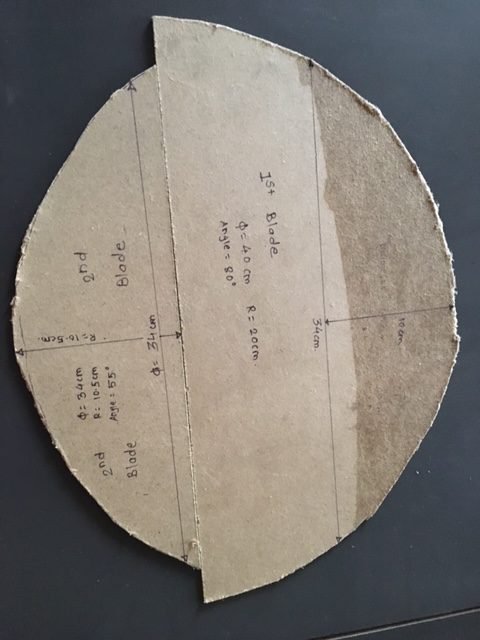

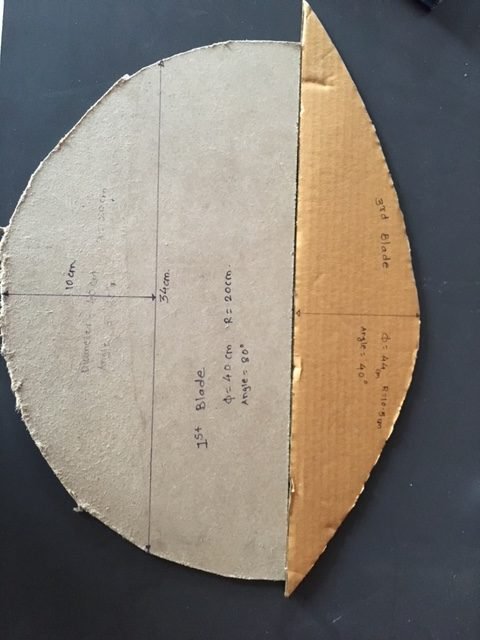

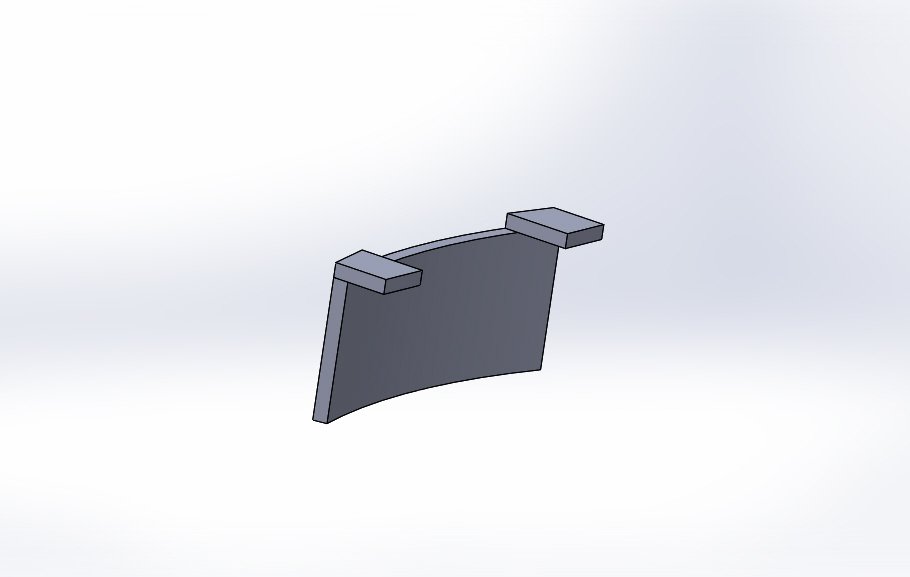

Stirrer Design

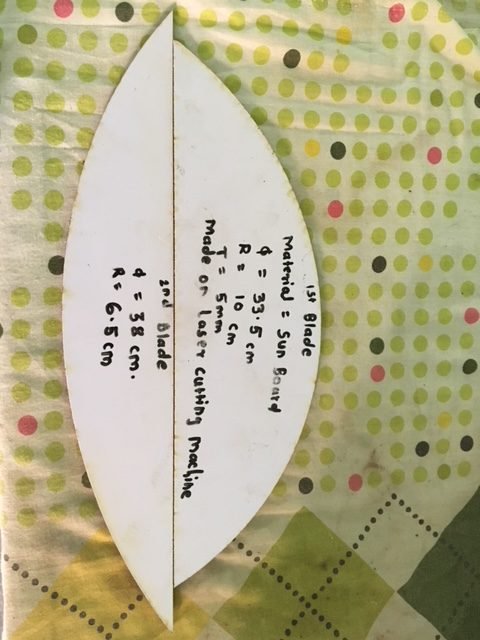

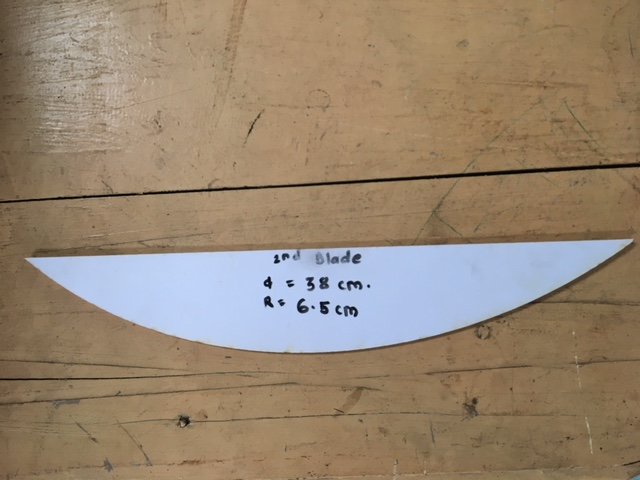

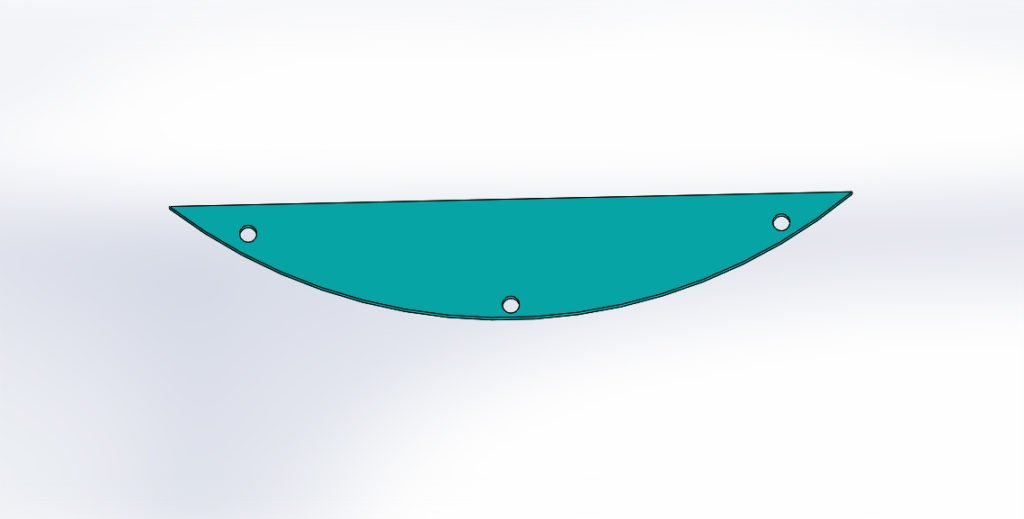

The stirrer blade profile selection is primary goal in stirrer design.From discussion with Dr. Dixit Sir and Mr. Amol Sir we decided the blade profile is such taht which cover maximum bottom surface contact with kadai.

For select proper blade profile I try many blades as:

After getting some matching blade profile I made it on Laser Cutting Machine which is aviliable in vigyan ashram FAb LAB. Another purpose of making this blade on laser cutting machine because if blade made by hand cutting its profile inaccurate or vary the dimensions.

Motor Selection

In vigyan ashram workshop I got a motor which is suitable for our Stirrer.

Specification of Motor:

Reversible Synchrnous Motor

Torque- 45 Kg-cm , N- 60 RPM , Frequancy- 50 Hz , Electric Supply- AC, Voltage- 240 V .

After some discussions we decided that replacement of some arrangements / resources as:

- 28 liter kadai replaced by 18 liter

- Solar energy reflector schefflar replaced by prince-40 (Prince -40 is the small parabolic reflector as comparired to scheffar)

The next plan of action was:–

- Take 18 liter kadai from food lab and measure its all dimensions

- Make CAD drawing of Kadai , Motor mounting stand , Stand mounting curve plates.

- Fabrication of motor mounting stand.

- Purchase material required for stirrer and shaft (Taflon Scrapper, lovejoy coupling, Extra lentgh shaft etc.)

- Fabrication of stirrer shaft with cad drawing.

- Design and fabrication of stirrer blade.

- Conduct 1st trial.

Dimensions of 18 liter kadai –

– Capacity – 18 liter

–Material- Iron

–Open Diameter and height-510 mm & 170 mm

–Weight and thickness – 7.86 kg & 3 mm

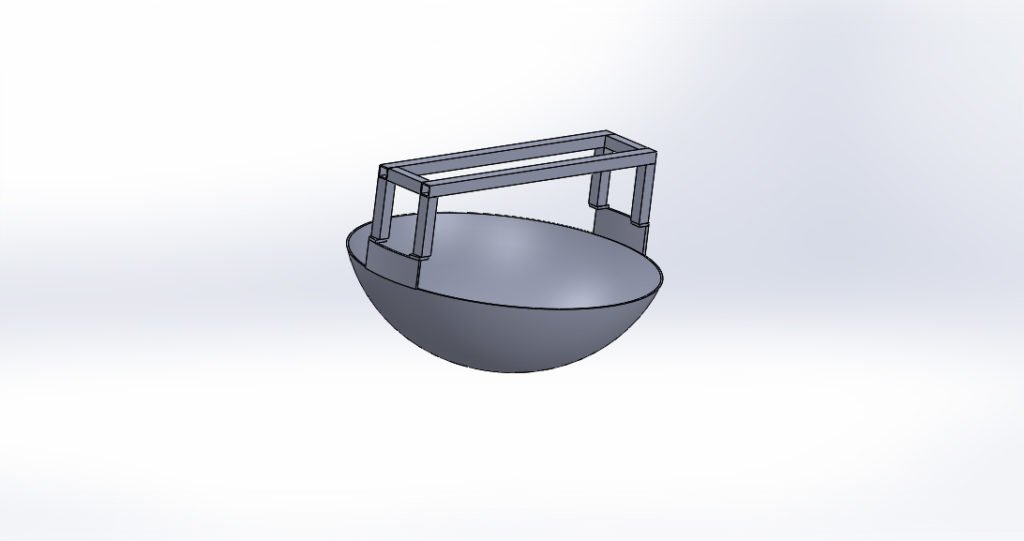

Conceptual cad drawing of kadai and motor mountaing stand:

Fabrication of motor mounting stand:

Before the start actual fabrication, Amol sir guided me how to take dimensions of stand as per kadai and finally we take dimensions as:

Length- 495.4 mm , Width- 100 mm , Height-238 mm Material- MS Square tube (20*20 mm and thickness- 2 mm )

At the time of welding is very difficult because of my less experience and thickness of tube is very less then I was taken a help of my friend Ghnysham which is very experienced person in welding.

For mounting of motor stand on kadai was not easy because kadai top part is curve.This difficulty solved by use curved plates at the bottom of stand.

Dimensions of curve plate:

Length-120 mm , Width/Thickness- 5 mm , Height- 48 mm , Material- Iron

On the 27 June 2020 Amol sir and me purchased the material from Bhosari MIDC which was required for next plan of actions. Materials as:

- Stirrer shaft of 16 mm diameter and length is 3 foot.

- Lovejoy coupling of 30 mm diameter.

- Taflon sheet for stirrer blade.

Motor stand resting on kadai

After completion of motor resting stand the main challenging task was how to rest it on kadai and remove easily at the time of collection of Khawa.

We search and think on many options then finally got a idea –

- Make hinge type joint at one end of stand and wing nut at other end.

- It is easy to remove / separate from kadai .

- The stability point of view it is better option than other.

- Material easily available for that joint.

- Aesthetically looking good.

How to make both joints-:

L- angle Specifications-: Length- 100 mm , Size- 25*25 mm , Thickness- 2 mm

Bush Specifications-: Length- 27 mm(Corner -2) ,Length- 37 mm (Center-1) I.D- , O.D- Thickness- mm