Normally cement bags are designed one above other. workers load and unload the bags are manual. they used hooks to pull the bag on the roller. the process is very laborious. the idea is to make a simple device which can help to pull or put the bag on the conveyor. generally, at the time of loading and unloading of cement bag due to hooks used by workers, bags got holes and causes loss of approx, up to 4 kg of cement. the device made will reduce this wastage of cement and human efforts.

Manual stacking og cement bag in the were house is laborious and inefficient when loading and unloading time worker used to hooks cases around 4 kg of cement was wasted . it is tedious work which is lead to helth hazards, fine dust is the breading problems of worker , therefore ,a cost effective device is needed to lead and cement bags on to conveyor.

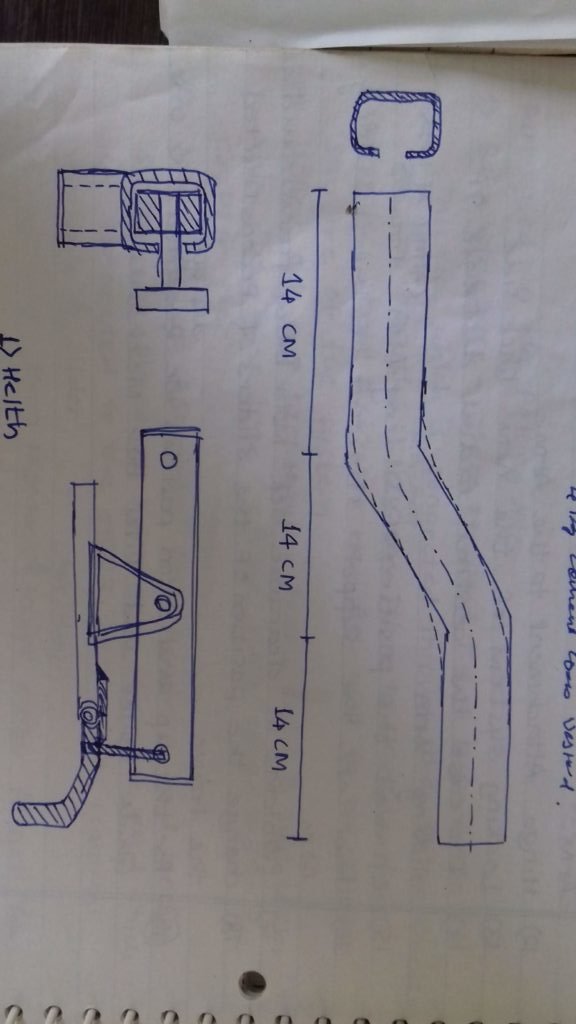

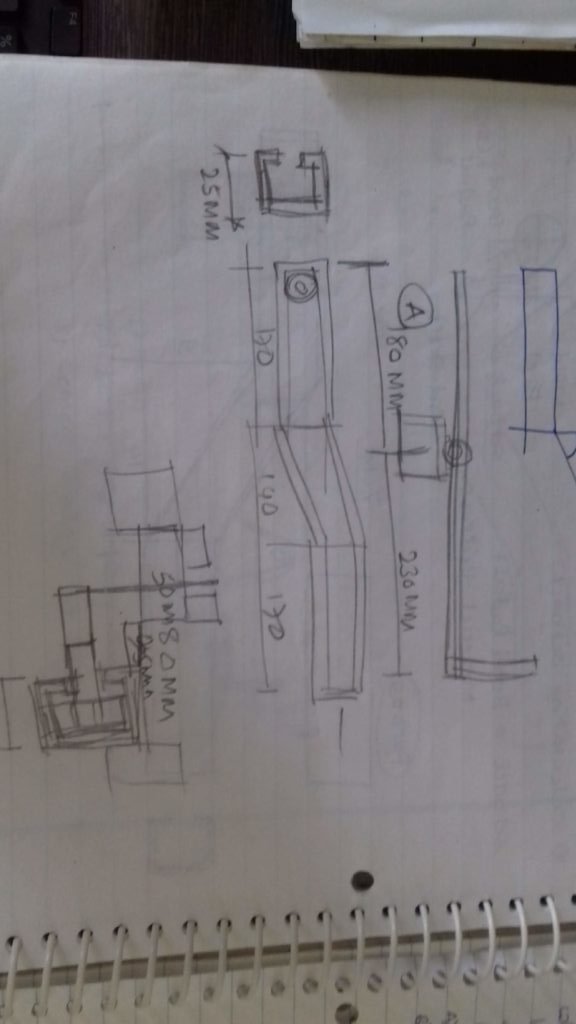

- a mechanical arm is design to pull the cement bag and put it on the roller .the arm will be operated by electric motor .

- for up and down movement is made possible which willl help in stacking bags at hight or pulling them from top of the stack.

- the surface of the jaw will be soft in texture to avoied tearing of bags.

- the machine is designed torach 14 bags approximately 6 feet hight.

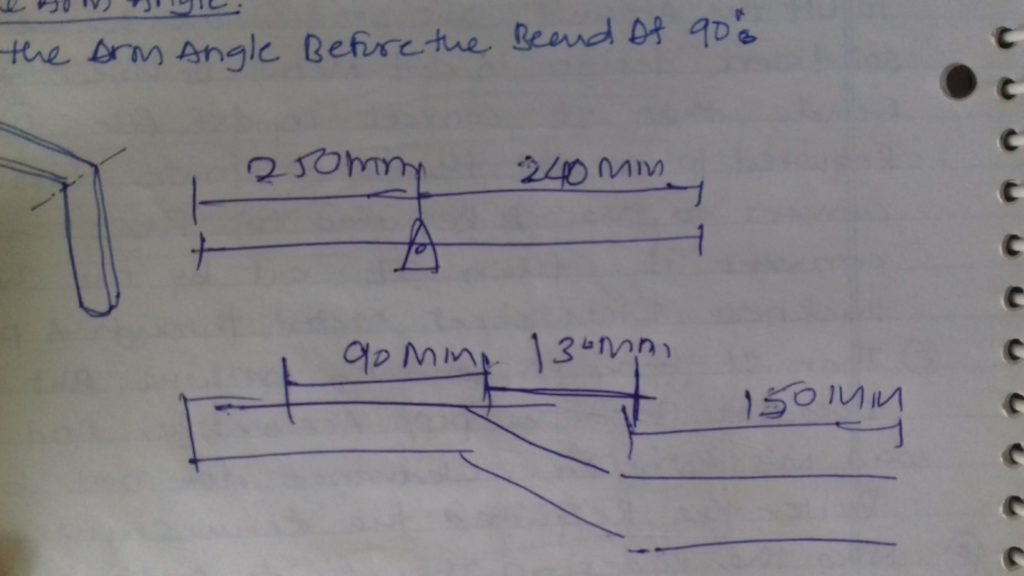

LEVER ARM MOTION UP AND DOWN :

The main problem of the arm is it was requierd change th movement of the front portion. that is requied to pull the cement bag in proper way .as per last development we cut the arm and joint in ways hinge and movement. now we requierd a contraied motoin of hte arm in he position up down as per the shape of the cement bag.

DESIGN AND DEVELOPMENT :