1. Initial Design, Development and Trials

Posted by AMOL KHAMKAR on 21 JUN 2018EDIT

Project Background –

Near Bhimashankar there is a village Taleghar in Khed Taluka of Pune District. The Shahid Rajguru Svayansevi Sanstha is making Ragi laddoo. To make the laddoo , they have to roast the ragi flour continuously . To roast the flour , there is so much manual power is required .

After taking all the trials on prototype with Intern we got results for 500 gm ragi flour. The mixing patterns we checked for Suji, Peanuts and Bhusa, It was good. This was assignment for me in which I helped and worked on the stirrer blade design and modifications.

With respect to above conclusions and discussions with Dixit sir we decided to develop stirrer system which can work for roasting Besan laddu flour and Ragi flour having capacity 2 kg.

Expected results and objectives –

- The capacity of the stirrer will be 2kg.

- It must be simple to handle by anyone in kitchen.

- Loading and unloading must be easy.

- Adjustable stand and Height.

- The mixing should be uniform.

- Detailed Design –

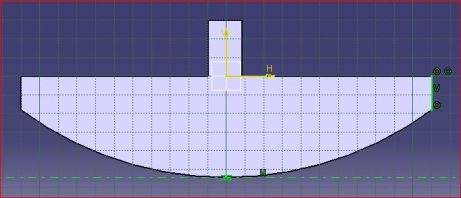

Vessel (Kadai) Details –

Fig. 1 Kadai Shape and dimensions

Radius of open end – 300 mm

Height from bottom to open end – 105 mm

Maximum capacity of kadai ( Ragi Flour ) – 2.5 kg

First Design Details –

By considering previous design of prototype the design procedure is classified as

- Motor selection

- Motor mounting frame

- Stand support bracket

- Stirrer design

- Motor Selection

Motor is the prime mover in this system. For selecting motor following are the factors important to consider.

- Required Torque

- Speed

- Torque Calculations –

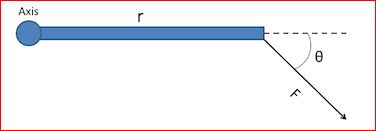

Torque is the twisting force that tends to cause rotation.

Mathematically Torque is,

T = F * r * sin(theta)

Where,

T = torque

F = linear force

r = distance measured from the axis of rotation to where the linear force is applied

theta = the angle between F and r

unit of torque is a Newton-meter (Nm).

– r has units of meters (m)

–F has units of Newtons (N)

Here, we need to stir 2 kg flour. While finding torque needed it is very important to find out /consider the load distribution. Here in our application the vessel is Kadai (Fig. 1), so the load is considered coming between 3 cm to 5cm area of the stirrer profile.

So we have,

r = 4 cm = 0.04 m

F = m * a = 2 * 9.8067 = 19.6133 N

Therefore,

T = r * F = 0.04 * 19.6133 = 0.784532 Nm

( 1 Nm = 10.197162129779 kg-cm )

So,

T = 0.784532 * 10.197162129779 = 7.999 kg-cm

This torque is calculated as the torque coming at the center of the stirrer and the stirrer shaft.

From above calculations it is clear that our required motor would have torque ranging from 7.999 kg-cm to 8.8 kg-cm to stir 2 kg material. The torque requirement may increase since the losses and self weight of stirrer and shaft are not considered.

- Speed Calculations –

From the observations taken from the trials of prototype we come to the conclusion that the speed of the motor should be i the range of 50 rpm to 60 rpm.

So, after considering above topics we finalize the AC synchronous motor with constant 60 rpm.

We buy of following configurations ;

AC SYNCHRONOUS MOTOR

∼ 240 V, 1 PH, 50 Hz, 100 mA MAX, 60 RPM

TORQUE – 3 Kg-cm.

Here now situation is change of loading capacity and come to 1 kg.

i.e. we can stir 1 kg flour with current design.

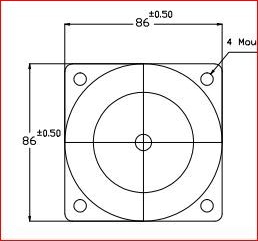

Motor Drawing –

2. Motor mounting frame

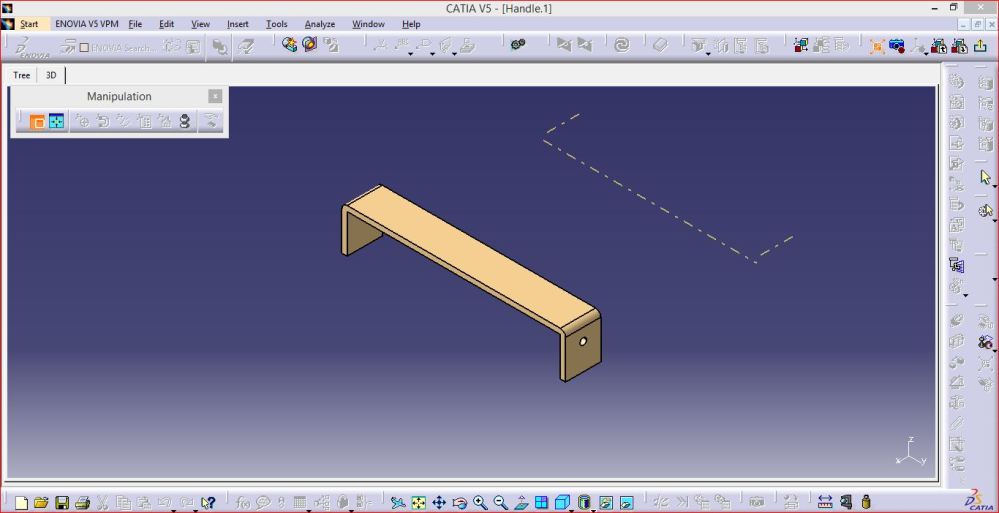

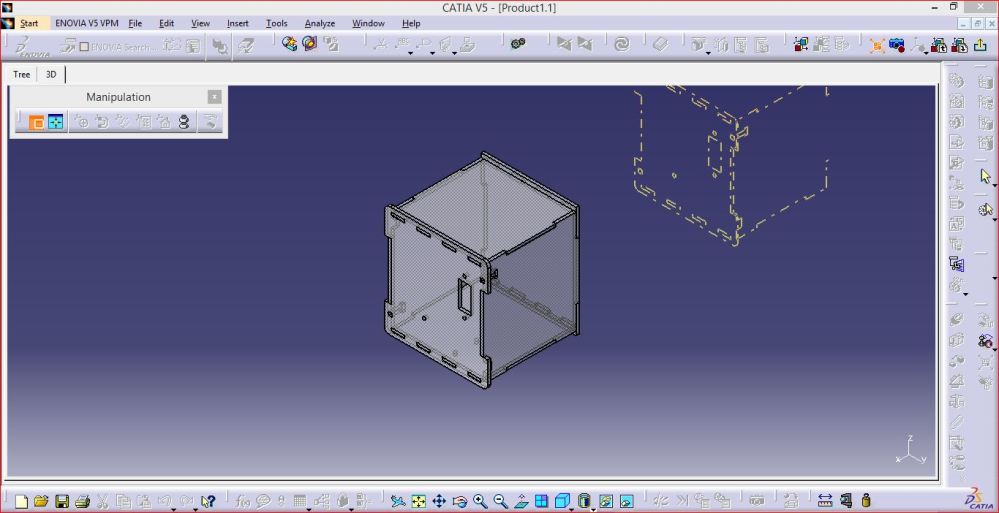

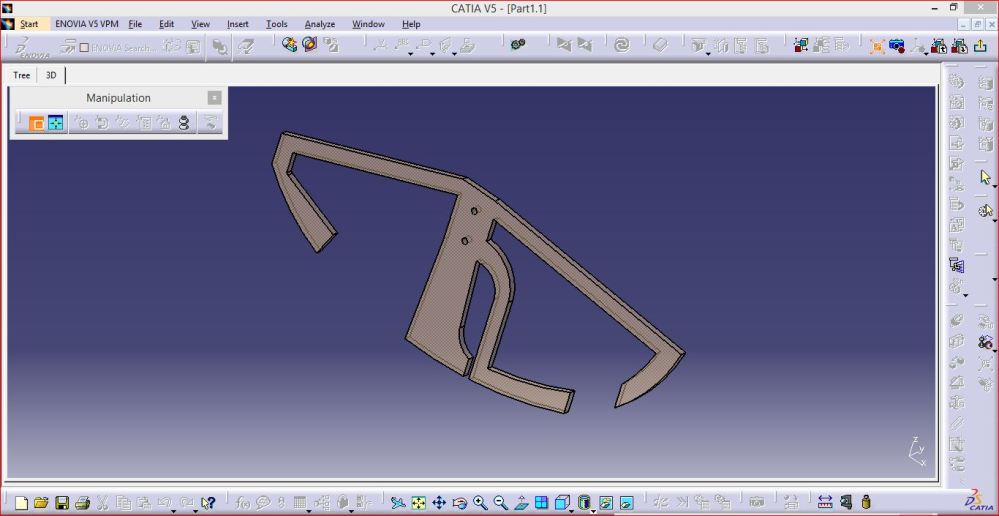

After getting all motor dimensions motor mounting frame is design as follow using CATIA V5 for CAD modelling.

Assembly of Motor and Mounting frame –

3. Stand support bracket –

To mount above assembly the mounting bracket is designed as follow

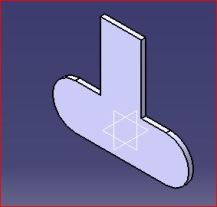

4. Stirrer Blade with Shaft

The assembly of stirrer blade with Shaft is shown below

The stirrer is designed with reference to the stirrer profile used in prototype model with modifications in shape and dimensions.

5. Assembly –

The full assembly is shown as follow

The Animated model in stages

Stage 1 –

Stage 1

Stage 2 –

After animating the assembly it is observed that the stirrer blade moves outside of the pan ( Kadhai), due to which the roasting material can stick and fall out of the pan.

So, this design is not approved to fabricate after discussing with Dixit Sir.

From this observation it is clear that if we move the stirrer vertically up and down then the above problem of falling the roasted material while unloading will not fall out.

Second Design Details –

From previous design it is clear that vertical movement of the stirrer is required while unloading the roast material.

- The motor is same as in first design

- Actual Motor

Motor mounting base Details

The motor shown below is Ac Synchronous Motor of 60 Rpm and 3 Kg-cm torque capacity and 240 Volt AC, 100 mA configuration.

- Motor Base Frame With locking mechanism

With the above dimensions of motor mounting base the frame and locking mechanism designed and fabricated as below

The locking mechanism is given so that while unloading the pan the motor assembly along with stirrer can locked at upper side.

The locking mechanism is shown below –

- Stand with motor base frame carrying structure and vertical sliding mechanism

While selecting the sliding mechanism different ideas come like use of linear bearing and guide rod, sliding rail, etc. Finally the mechanism is made with simple flat bar as shown following.

- Mounting Frame

The mounting frame is required to install the whole system on pan or kadhai.

- Stirrer blade –

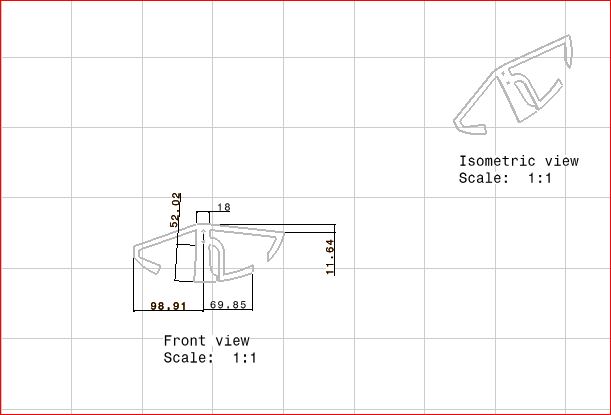

- Stirrer Blade Profile Design

2. Stirrer Blade mounting Support Design

Above stirrer blade components are designed in CATIA V5 and the .dxf file use to generate G-Codes to cut this profiles using CNC plasma cutter.

After cutting the profiles the complete assembly made as below ;

- Now complete assembly is made of all the above components

Date : 28.06.2018

For reversing of the direction of rotation switch installed in motor connection circuit.

Trial taken using current model made on Suji ( Rava )

This trial taken to check the following parameters

- Actual capacity of the roaster in Kilograms

- Mixing ability of the stirrer with the current blade profile

- To know possible modifications.

Trial Details :

- Quantity of Suji (Rawa) stirred – 410 gm.

From these trial it is found that the capacity of motor is too low.

It is important to install higher capacity torque motor to increase the capacity of the roaster.

With trial observations new motor of 10 kg.cm purchase and it is found that the previous connections to the motor was made wrong due to which motor was reversing automatically and fail to give its optimum output.

With the help of Avinash connections to motor made properly and trial taken with the old motor.

Trial Video check below,

Trial Details after modifications :

- Quantity of Suji (Rawa) Stirred – 960 gm.

From the trial it is observed that the resistance by the blade is more since it doesn’t have open space. To solve this problem the blade modified by cutting the central portion of blade and then the aluminium foil wrapped around the blade to perform scrapping of the roasting material from the bottom of pan to avoid burning of the material.

Trial taken after above modifications and it is observed that the resistance due to aluminium foil extension reduced the capacity of thee motor to stir the material to 700 gm.

Observations :

The aluminium foil starts wearing and its small particles get mixed into the suji.

Solution – The aluminium foil replaced using flexible food grade Teflon sheet as shown below.

The model is tested then for Rawa on 10th August, 2018 ;

Trial Readings –

- 300 gm Rawa roasted in 8 min on full flame gas burner successfully.

- 460 gm Rawa roasted in 14 min on full flame gas burner successfully.

Date – 11/08/2018

Visit to the Shahid Rajguru Svayansevi Sanstha, Taleghar at the place of the end user to show the trial of Nachani Roaster.

Trial taken using Ragi (Nachani) flour in Ghee and the observations are as follow,

- The formation of dough of flour in single block happen due to which the roasting not occur evenly.

- Center portion of the flour and ghee mixture remains un mixed properly.

With above observations and experience it is found that lot of modifications are necessary in the blade profile and trial must be taken on Ragi flour in gee.

At Taleghar the process of making the mixture and stages of addding the flour in ghee get known from Mr Sunil and Mr Ashok Joshi and also we discuss in brief about the current model , also I got some useful suggestions from them as there feedback.

With the trial experience at Taleghar I started working on modification of blade profile and 1st modification done as below ;

By taking trial using above modified blade profile I come to know that 20 % results are improved and new profile designed and cut using CNC PLASMA Cutting machine.

With this 3rd design trial the results are good for mixing but need to modify it. So the 4th modified blade profile made as following ;

In this profile the blade has given proper angles due to which the scrapping and pressing action happened and proper mixing of the Ragi flour in ghee done. Only a new problem found with this modified blade design is the small block at the central portion is properly mixing. For this final modification in the blade profile done and installed alongwith teflon sheet scrappers at the end and trial taken using 350gm Ragi flour and 150gm Ghee. The video of trial is as below.

This is final successful trial of the Nachani (Ragi) flour roaster.

Learning and use of Arduino

For auto reversing of motor the dual relay module with Arduino Leonardo is installed. I started to understand the basics of Arduino connections and coding with the help of Avinash who is working with me as Research Fellow.

With the help of Arduino the auto reversing of motor is done in which motor runs in clockwise direction for 10 seconds and anticlockwise for next 10 seconds.

Arduino Code For Auto-Reversing of Motor –

int in1 = 2;

int in2 = 3;

void setup() {

}

void loop() {

pinMode(in1, OUTPUT);

digitalWrite(in1, HIGH);

pinMode(in2, OUTPUT);

digitalWrite(in2, LOW);

delay(7000);

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

delay(7000);

}

Motor Troubleshooting

Before the final trial of Nachani Roaster the motor stops running. To know what happened with motor I checked all connections of motor. But all the connections were looking right. Then I dismantle the motor and checked the connections inside the motor, I found blue color wire was burnt. So, I repaired it and assembled the motor and the final trial taken.

From this I physically checked and troubleshooted the motor 1st time.

Final Trial at Taleghar

Date – 22 September 2018.

Trial of Nachani Roaster taken at Falode, Taleghar using 450 gm of Nachani flour and ghee. Roasting done was very good. The handling of machine done completely by the people who work there, all of them satisfied with the results and functionality of machine. Following are the images taken during trial.

2. Design Details With Modifications

Posted by AMOL KHAMKAR on 27 OCT 2018EDIT

Modifications For increasing Capacity :

- Installation of High capacity Motor-

To increase capacity of current nachani roaster, Following are the specifications of AC Synchronous Motor that is to be use.

Motor Details –

Torque – 10 Kg-cm

1 PH, 60 Watts, 240 V AC, 50 Hz, 250 mA

Trial Details after motor installation –

Materials –

- Besan Flour – 750 gm

- Ghee – 300 gm

Total Weight – 1050 gm

Observations –

- Trial completed successfully

- Motor run without stalling

- Even roasting occur without charring

Nachani Roaster CAD Designs With Details –

Final Assembly

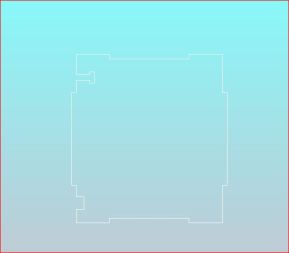

- Motor Frame

2. Motor

3. Handle

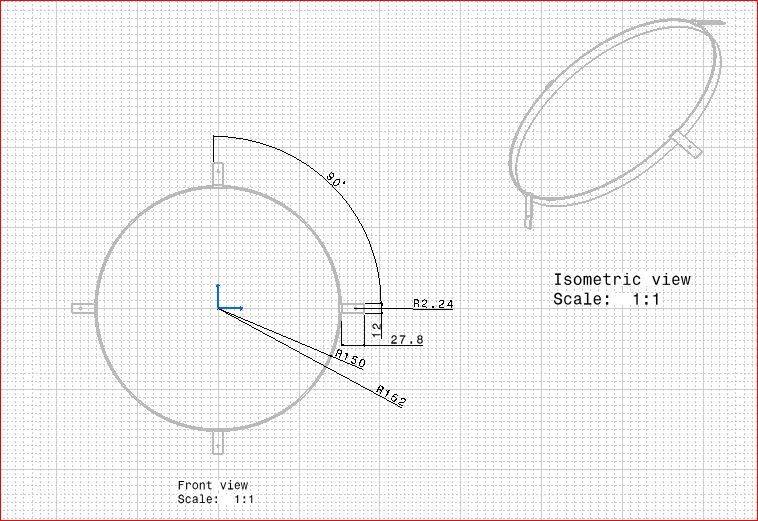

4. Mounting Ring

5. Stand Rod

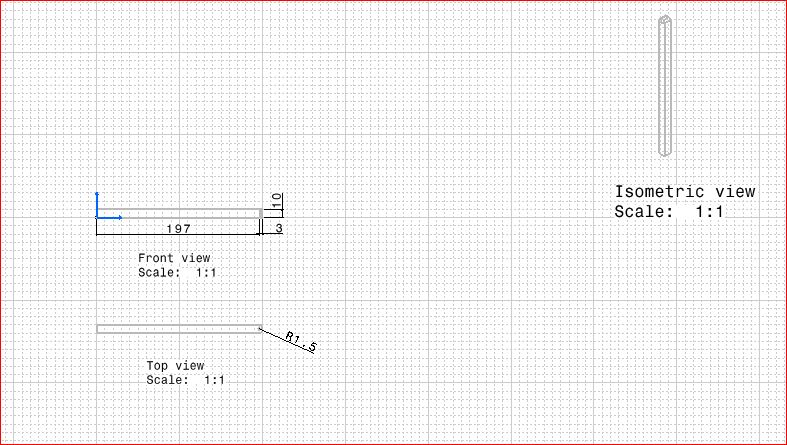

6. Stirrer Shaft

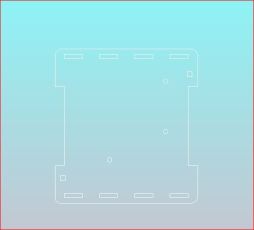

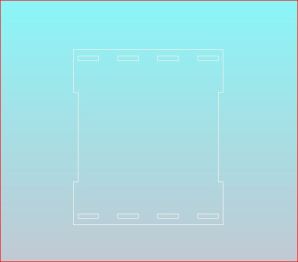

7. Electronics Controls Box

Electronics controls having following components

- Arduino Leo Nardo

- Dual Relay Module

- Resistor

- Capacitor

- 12 V DC power Supply

- On- Off Switch

The box is made of Acrylic and cut using LASER Cutting machine in Fablab.

8. Stirrer Blade

Following is the final design of Stirrer blade cut using CNC Plasma Cutting Machine.

Bill of Materials –

| Sr. No. | Description | Material/Details | No. of Units | Material Quantity |

| 1 | AC Synchronous motor | 10 Kg.cm torque | 1 | 1 |

| 2 | Stirrer shaft | EN8 polish bar | 1 | 45 cm |

| 3 | Stirrer blade | MS CRCA 1.5 mm | 1 | 1 sq. ft. |

| 4 | Allen bolt | M4* 25 mm | 4 | 4 |

| 5 | Motor mounting frame | L angle 25*25*2 mm | 4 | 60 cm |

| 6 | Stand | Square bar 10*10 mm | 4 | 180 cm |

| 7 | Vessel mounting ring | Flat plate 10*2 mm | 1 | 210 cm |

| 8 | Nut and bolts | M8* 25mm | 4 | 4 |

| 9 | Nut and bolts | M6* 25mm | 12 | 12 |

| 10 | Arduino Leonardo/Uno | – | 1 | 1 |

| 11 | Dual relay module | – | 1 | 1 |

| 12 | On/off switch | – | 1 | 1 |

| 13 | Two pole switch | – | 1 | 1 |

| 14 | Panel box | 150*100*50 mm | 1 | 1 |

Nachani Roaster Technology Dissemination

As the requirement or problem statement was actually raised by SHG Shahid Rajguru Svayansevi Sanstha at village Falode, Taleghar the proof of concept and 1st prototype was tested successfully. The successful demonstration given to the above organization. The solution developed was appropriate as per there requirement, so they have given order of development of 5 kg batch size roaster machine. The machine was developed and deployed to Shahid Rajguru Svayansevi Sanstha Falode.

With using the roasting machine they are able to fulfill the production requirements 3 times more than that of done manually. So, there productivity is increased by 3 times also safety for women at workplace increased. The manual efforts for the operation reduced.

The roasting machine deployed is shown below.

Reach us for simillar requirements if any…….

Thank You