One unit of composter is installed in Siddharth society, Aundh, Pune. Depending on the data or feedback from that we had to design a new unit of composter of big capacity.

For that purpose we worked with Mr. Soumitra Kulkarni sir in Nashik in their own manufacturing industry. Where, we supposed to get inputs from them for designing a new system.

At first Soumitra sir wants to go with existing design and test it.

But we have some alternatives for that system in my mind. But to prove that which one is good first we have to go with existing one.

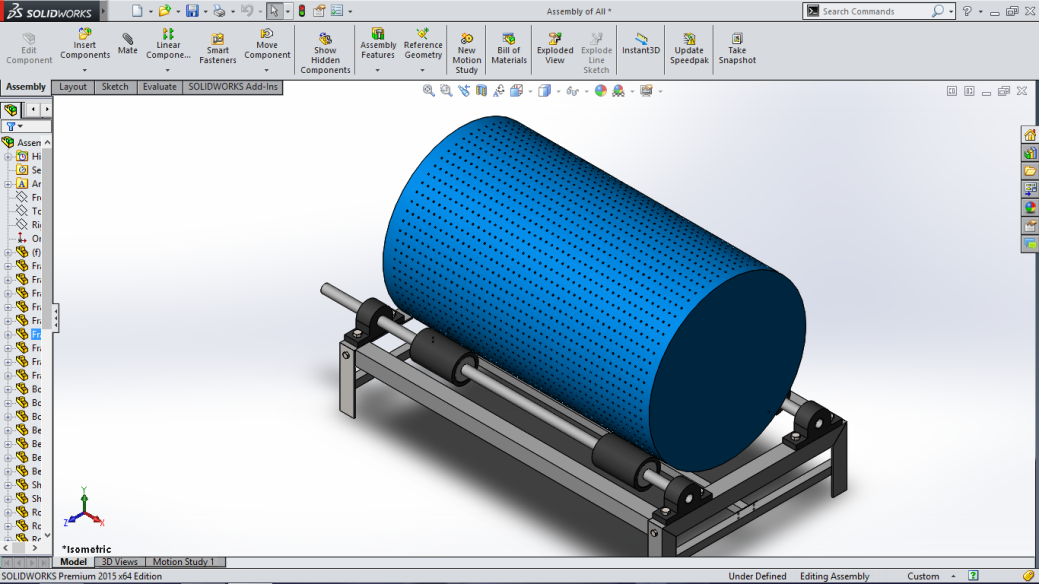

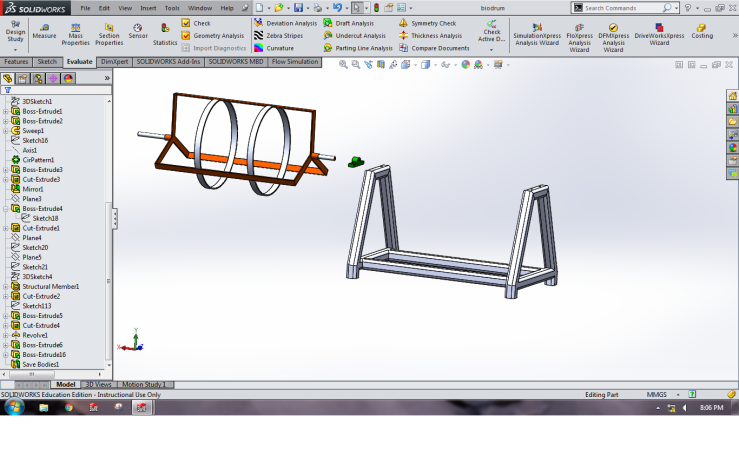

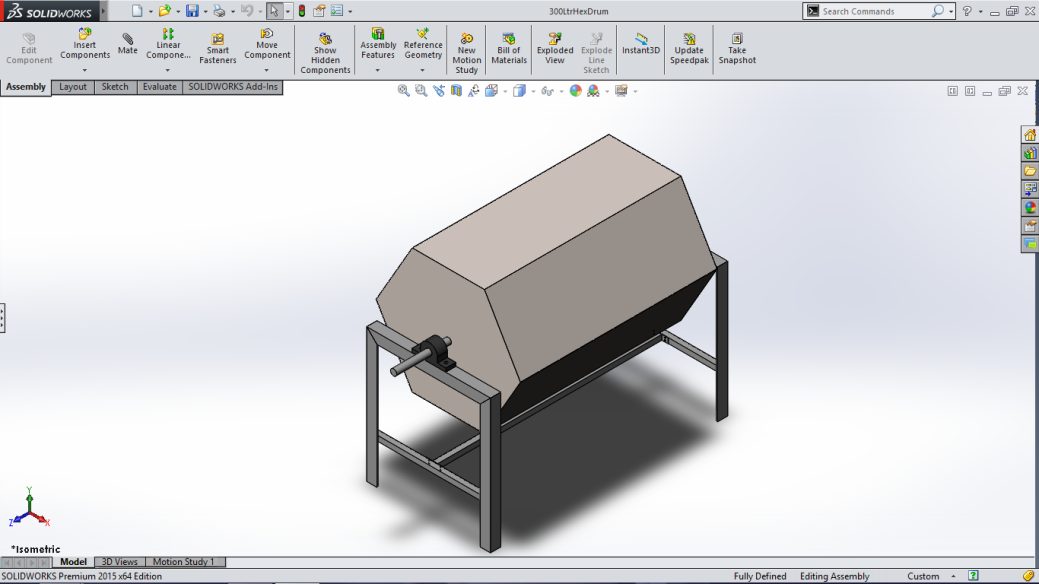

So we create 3D model on solid works, and made a Bill of Material (BOM).

While designing a new system we focused on three major areas:-

- Ease of transportation:-

In earlier system whole frame structure is welded, so it’s difficult to transport the unit. we designed a frame so that it can be easily dissembled and assembled.

For old system square tube is used for frame structure. Disadvantage of that is, it’s get rusted quickly. It is not a long life solution.

So we select L-channel for frame.

- Drum Rotating Mechanism-

It is one of most important parameter under consideration. Earlier system consists number of components on which drum rotates, like motor, gearbox & chain drive to rotate two solid MS shafts. On this shaft four nylon rollers are fitted. For firm grip between drum and roller rubber is fitted over nylon rubber.

As number of components more, manufacturing dependability on them and manufacturing cycle time is more. Production becomes lengthy process.

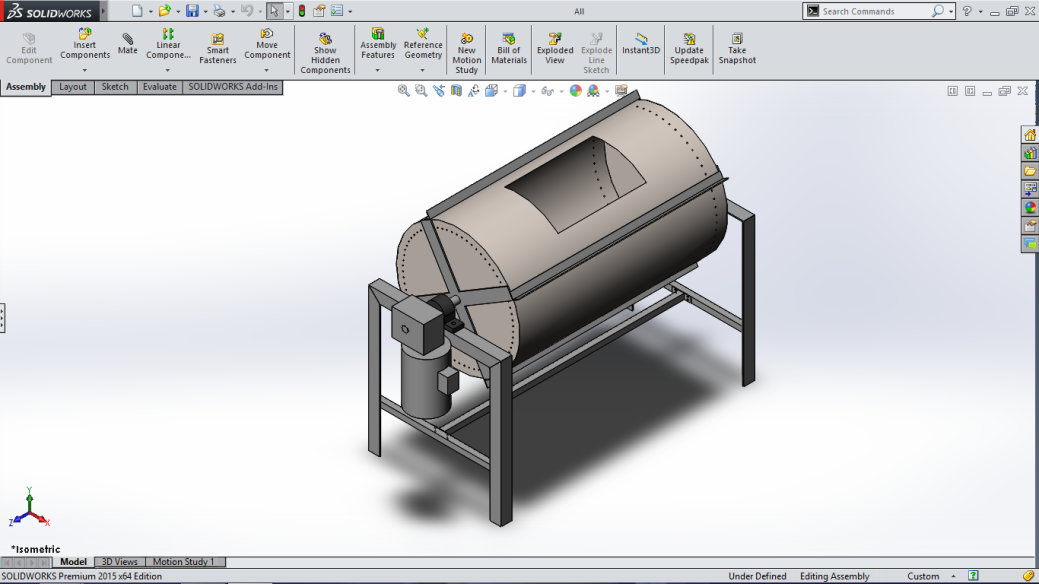

To avoid that we referred an arrangement like drum is fixed on single shaft and to rotate that shaft mechanism can be used like direct coupling of motor and gearbox to drum shaft or chain and sprocket to connect gearbox shaft and drum shaft. So that there should be less no of components so complexity gets reduced and manufacturing gets also easy and low cycle time.

- Motor selection:-

Existing unit runs by 1 hp motor. So proper selection of motor need to be done.

we were expecting inputs in these calculations from employees from Nashik but disappointed.

3D models that we made:-

- Old drum:-

While creating this model we had done some modifications in frame as using fasteners so that it can be easily dissembled and assembled. But after discussion with Yogesh sir(Nashik) , this arrangement is not suitable for long term application concluded.

Also made a BOM for ease of comparision.

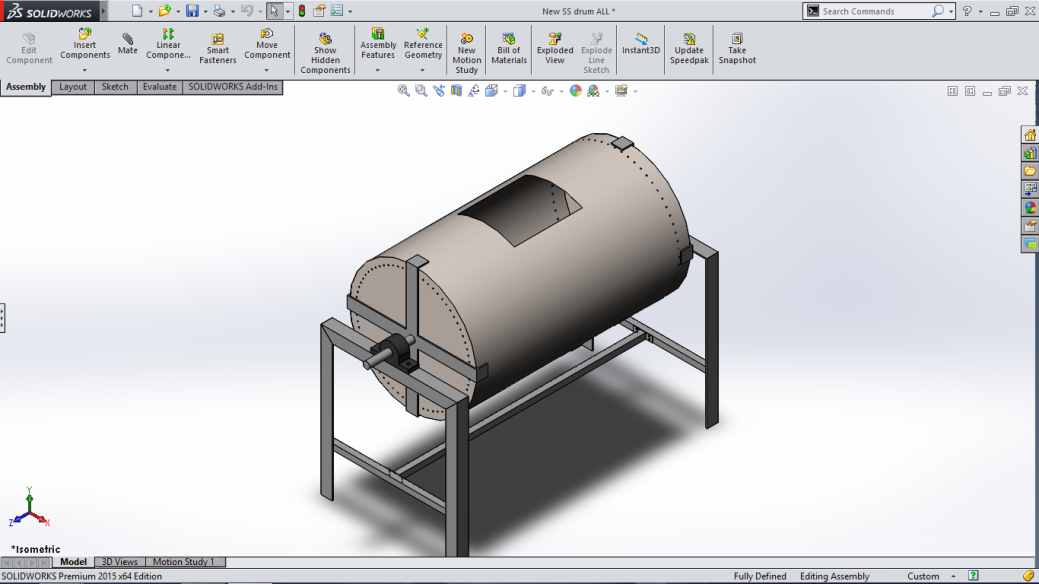

2. Design for Metal Cylindrical Drum:-

This system is designed for metal drum. It’s appropriate height, length, width etc is fixed and design.

BOM is made for both M.S. drum and S.S. Drum.

- Design for plastic Drum:

- Design for Hexagonal Drum 300 Ltr

After all this process Soumitra sir gave us A mixer drum with motor and gear arrangement.

We all agree to use it as composter because its economical but problem was its worm shaft from gearbox is missing.

We approach to a gear manufacturer he promised to give it within 4 days. But he did not follow his words and wasted our 5 days.

Then we approached to another gear manufacturer who original manufacturer of this mixer drum.

While gear is manufacturing we made perforation on drum to 3% open area.

These are all designs we are having, we all are finally come to conclusion that lets fabricate Model No. 1, and we start it fabricating. The belows images and vedio shows actual field working of Big Composting Drum: