Introduction- For dehydration of food material

Objective-

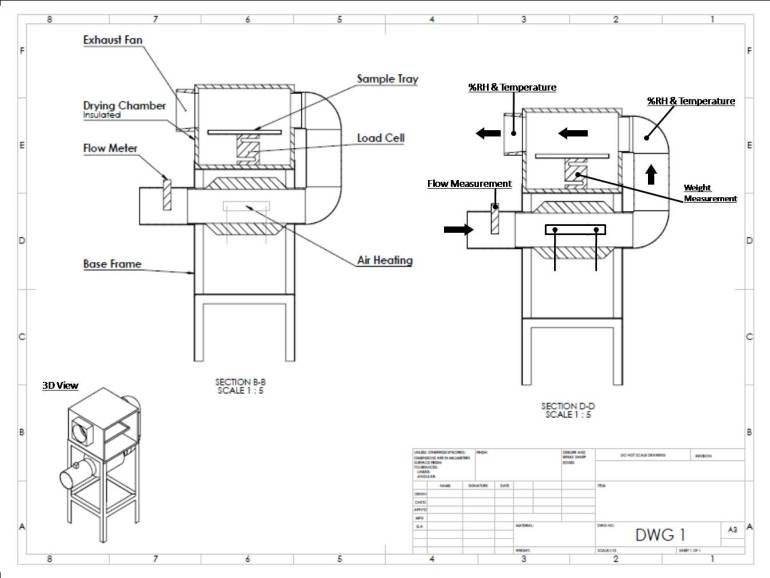

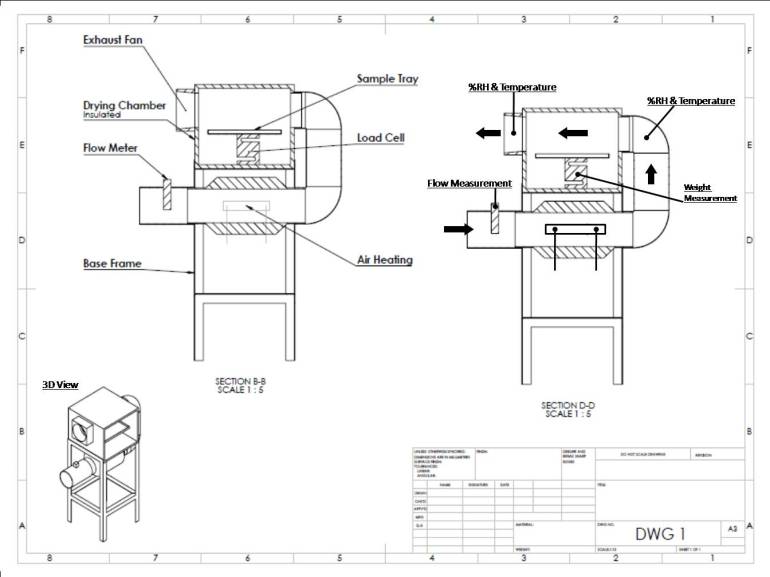

1. To design drying chamber

2. To design air humidity control system

3. To design air temperature control system

4. Data logging and data interpretation

Design of project-

Programme for load cell-HX711 PROGRAMME

Connections for arduino-

load cell- 4,5 (DT-4,SCK-5)

GND(GREY)- ground

VCC(RED)- 5v

Then I started to collect data on various food materials in the following format-

Data collection-

After that, we observed that –

1. There was a lot of fluctuations in readings so the interval was changed to 1 minute.

2. load cell readings were correct upto 2 to 3 hour after which readings were not proper.

3.Method of data collection was not appropriate i was generating data on initial moisture content on short span so the resulted graphs was not indicating the entire rate of drying of material so we decided to take readings on different moisture levels such as 90% 80% 70% 60% 50% 40% 30% 20%.

so after which the generated graphs were as follow-

So after observing the above data, I took reading at a constant temp of 50 degree Celsius so data was as follow-

so even the data obtained was good but still there was lot noise in reading so while calibrating i got to clearly know that the noise was mainly due to vibrations of fan so after discussing this problem with Dixit sir and Yogashree Didi we decided to connect relay to the fan so which will stop at the time of reading so that vibrations will not affect the reading so, later on, i connect the single module relay to the fan under the guidance of yogashree didi and shrikant.

so reading on azolla after relay –

Flow-high flow

Temprature-29 degree Celsius

Sample-onion

So this readings were on high flow and also there was not proper control on temperature so reading were on ambient temperature so we tend to design a control panel so we can control temperature and speed of fan so data after all this arrangement for interval of 5 minutes 25 seconds

Connections for relay-

GND- GROUND

IN – 8

VCC- 5V

the final programme for relay-

Final Trials-

- Product-onion

Temperature- 28 degree Celsius (low temperature)

Air flow- low flow (0.4m3/min)

- Product- onion

Temperature- 50 degree Celsius (high temperature)

Air flow– low flow (0.4m3/min)

- Product- onion

- Temperature- 27 degree Celsius

- Airflow– high flow (1.2m3/min)

observations-

readings are now proper without any noise