The result of our work

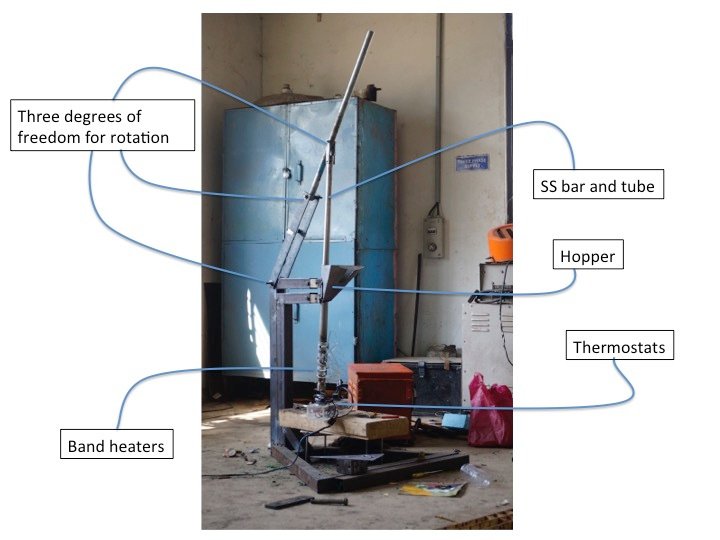

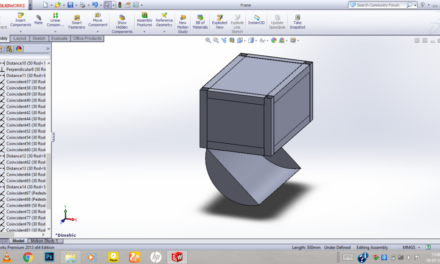

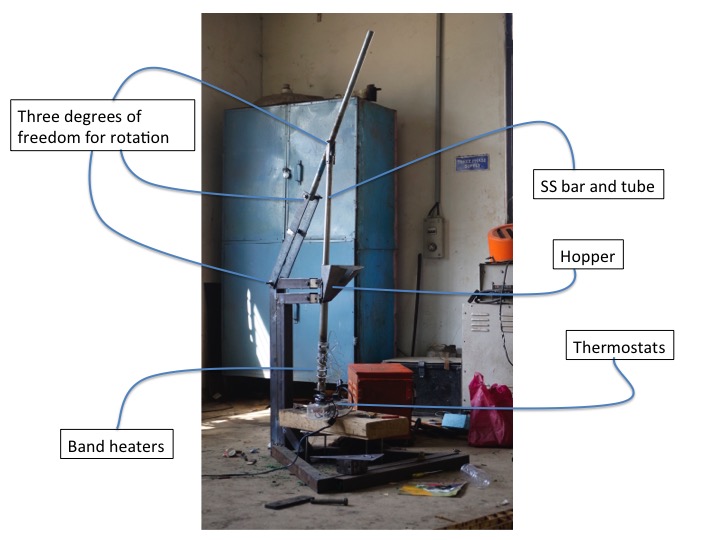

fter long discussions of different machine hacks we could do, and where we wanted to go with the whole plastic recycling project, we concluded that the first thing we should work on was replicating the design that Dave laid out. Here is the result of that work.

Some lines of credits:

A lot of the design problems I came across were discussed with LPJ and Subir. Special thanks to Subir for welding the tube onto the frame and for setting me up using Solidworks and Fastcam for the plasma cutter. Thanks to Vinayak for welding most of the frame together and the hopper onto the tube. Credits to Suvarna for working through the electronic part connecting the two thermostats to the band heaters. Thanks also go to Aditya for cutting some tubes, Shubham for fixing the bending problem (the tube bended after we welded the connectors on), Swami, Vishwas, Suyog, Suhas, Arundhati, Dipali, Ravi, Adesh, countless others who helped every step along the way. And of course, to Supriya for the two hour discussion that helped set up a great brainstorming session with our mentors Yogesh and Arun.

I’m a little disappointed I couldn’t follow through, but at least we got to melt some plastic. At the end of my work, the nozzle wasn’t effectively extruding all the plastic, and the bar also got expanded from being left with the band heaters for a while. We had to lathe the bar, think about a stop to prevent pellets from falling out, a way to extrude most effectively into a mold, the objects to make, the designs of the mold, and eventually make the process robust. Best of luck to Anirut and Suvarna!