DAY 1

– New Project: Repair e-cycle.

– Activities: Inspected and opened the e-cycle battery pack.

– Battery Check: Found that the battery was not charging and needed further inspection.

DAY 2

– Activities: Battery pack inspection.

– Battery Voltage Check: Checked the output voltage of the battery pack and identified issues with one series of cells.

– Battery Pack Opening: Opened the battery pack casing to inspect individual cells.

DAY 3

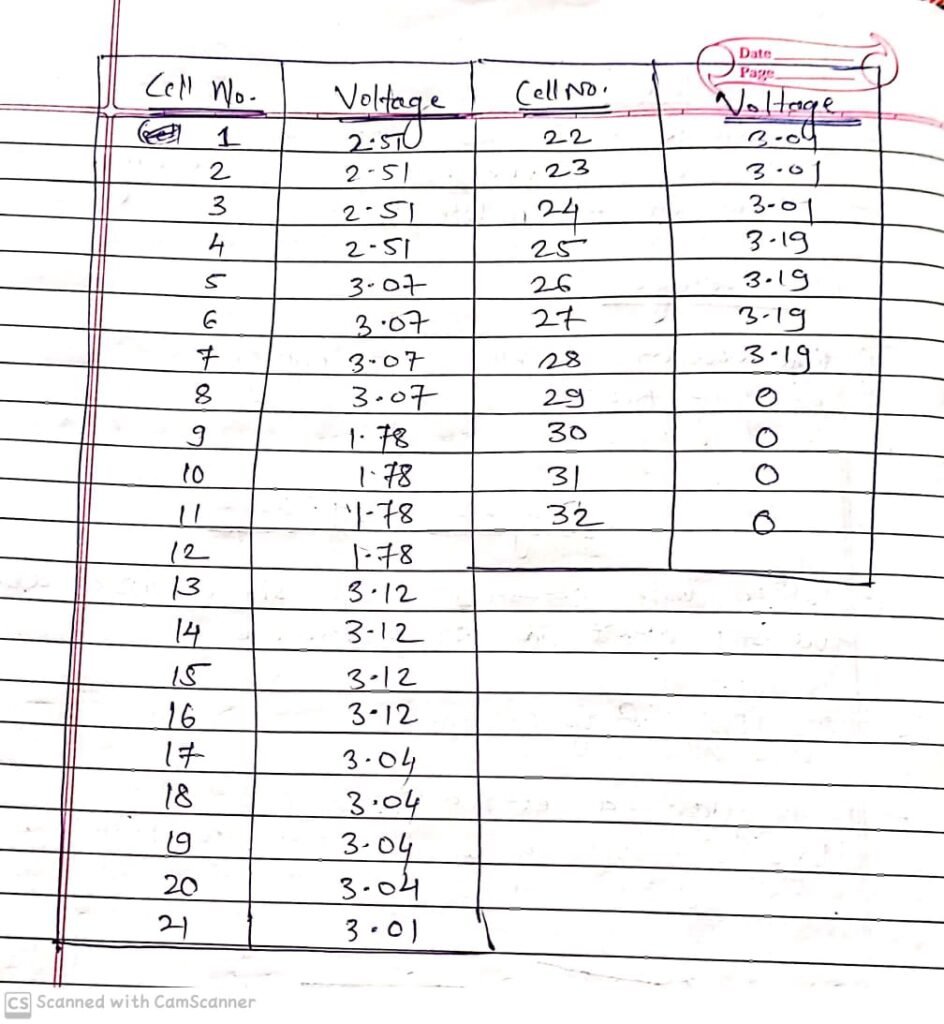

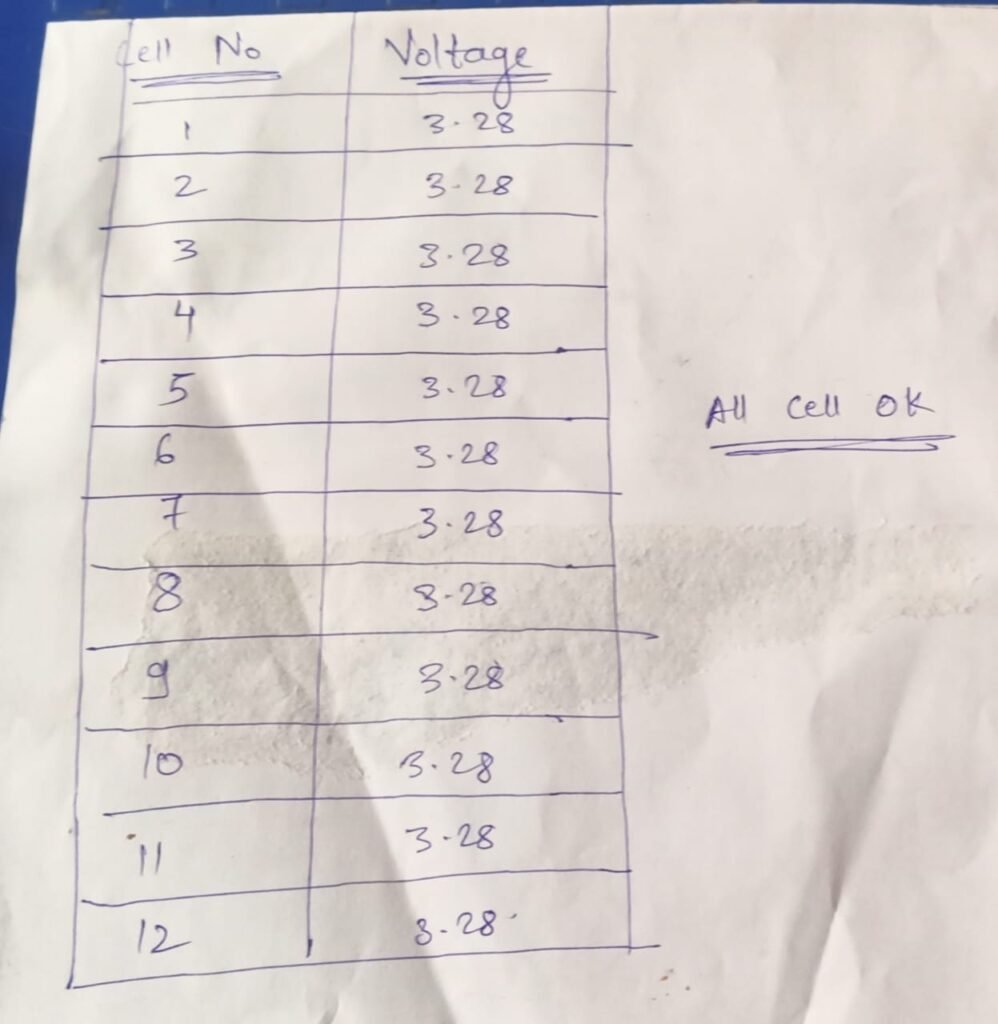

– Activities: Voltage inspection of individual cells.

– Cell Voltage Check: Checked the voltage of each cell in the battery pack, identifying one series with 0V output.

DAY 4

– Activities: Cell inspection and balancing.

– Connection Removal: Removed nickel strips and checked individual cell voltages.

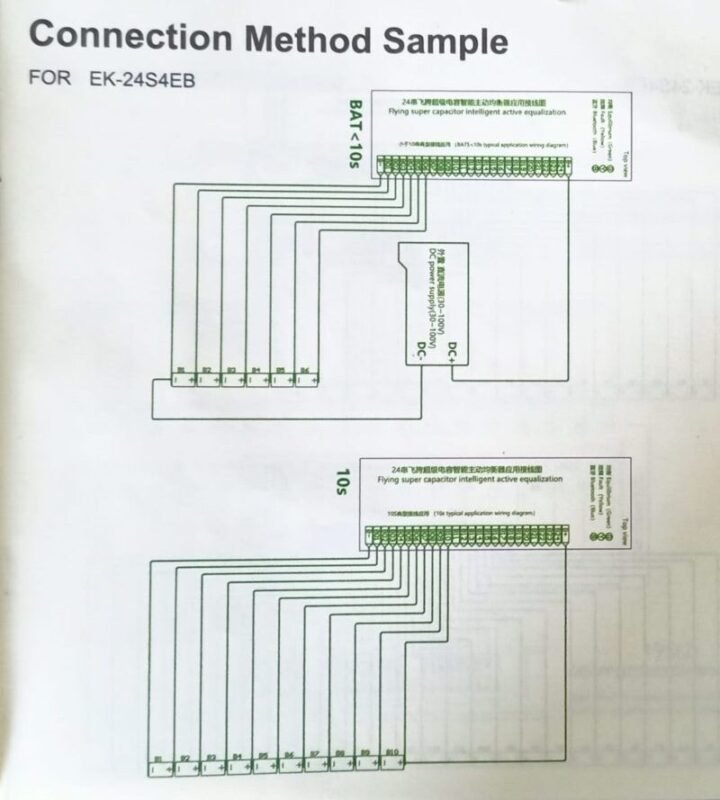

– Balancing Discussion: Discussed cell balancing with Vrushabh Sir and researched cell balancing units.

DAY 5

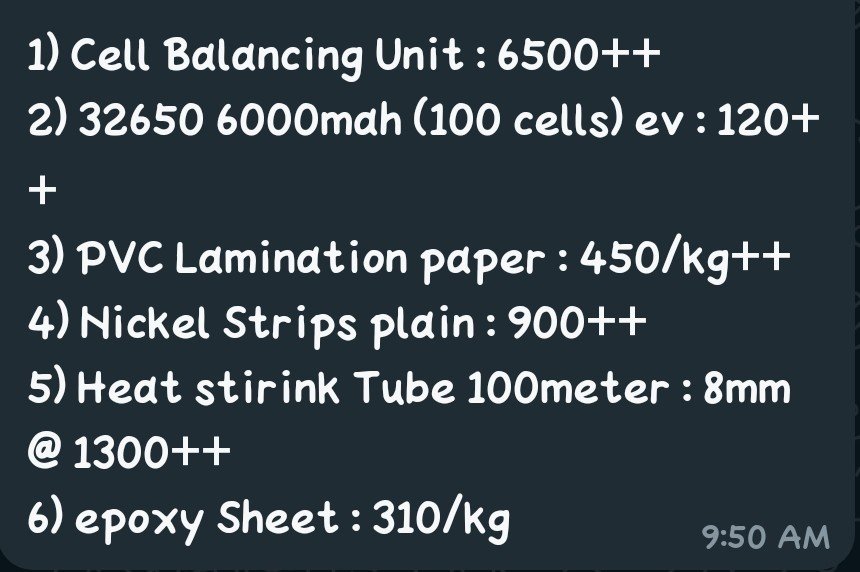

– Activities: Vendor research for cell balancing.

– Vendor Contact: Contacted local vendors for materials and cell balancing units.

– Specifications Study: Studied the specifications and costs of cell balancing units for the battery pack.

DAY 6

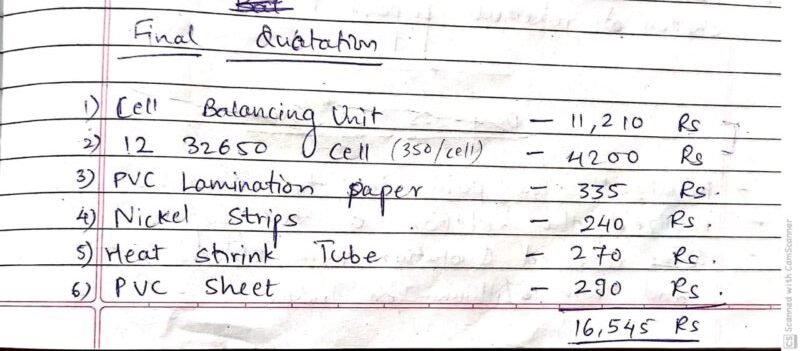

– Activities: Cost discussion and vendor finalization.

– Cost Discussion: Discussed the cost of cell balancing units with Dixit Sir.

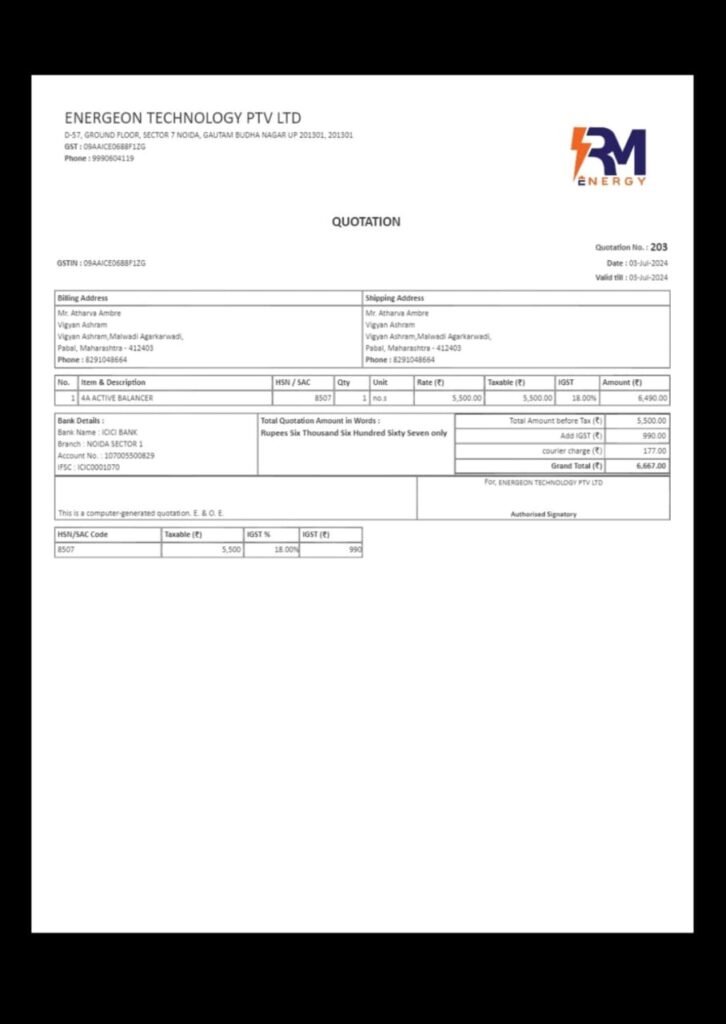

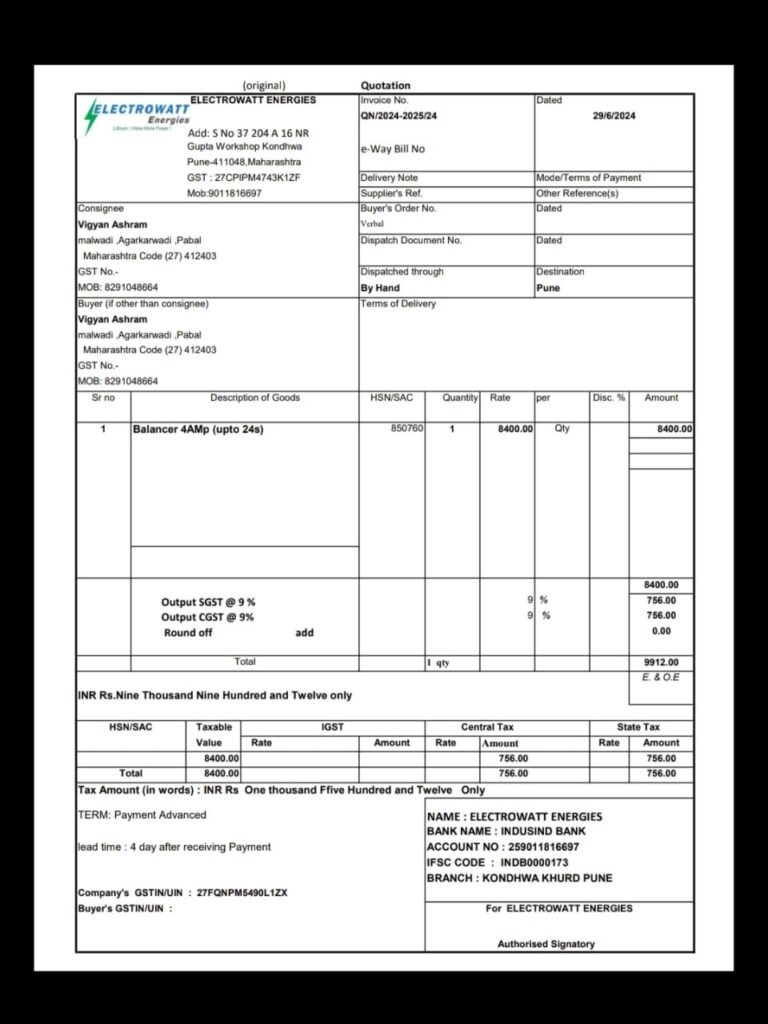

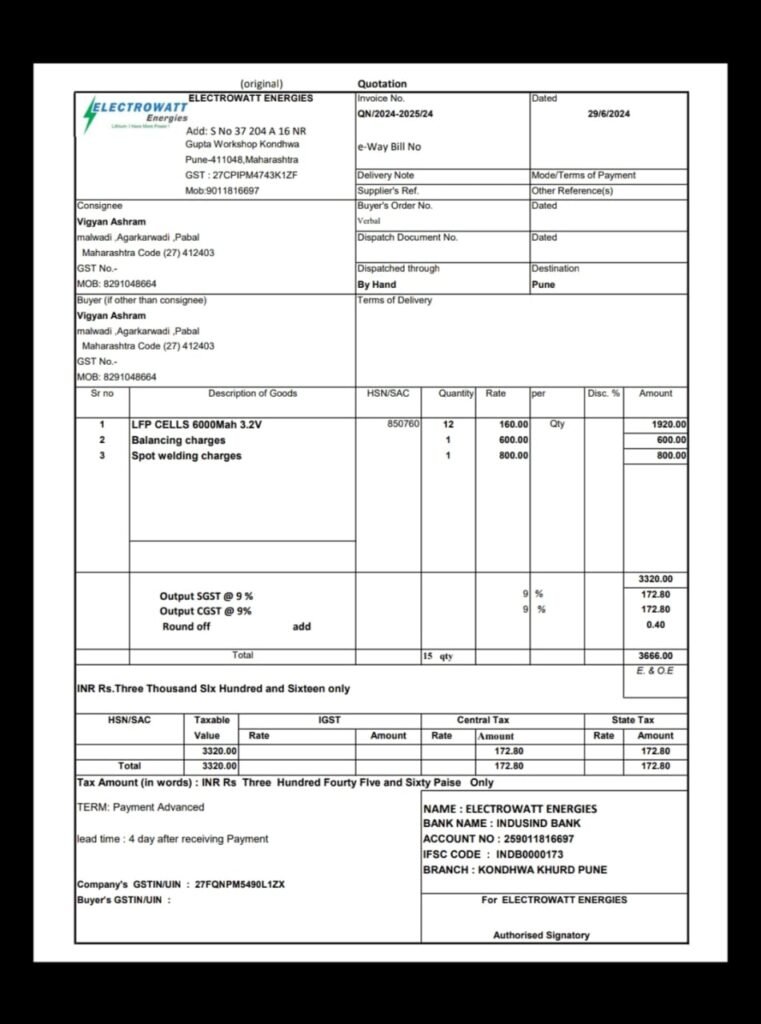

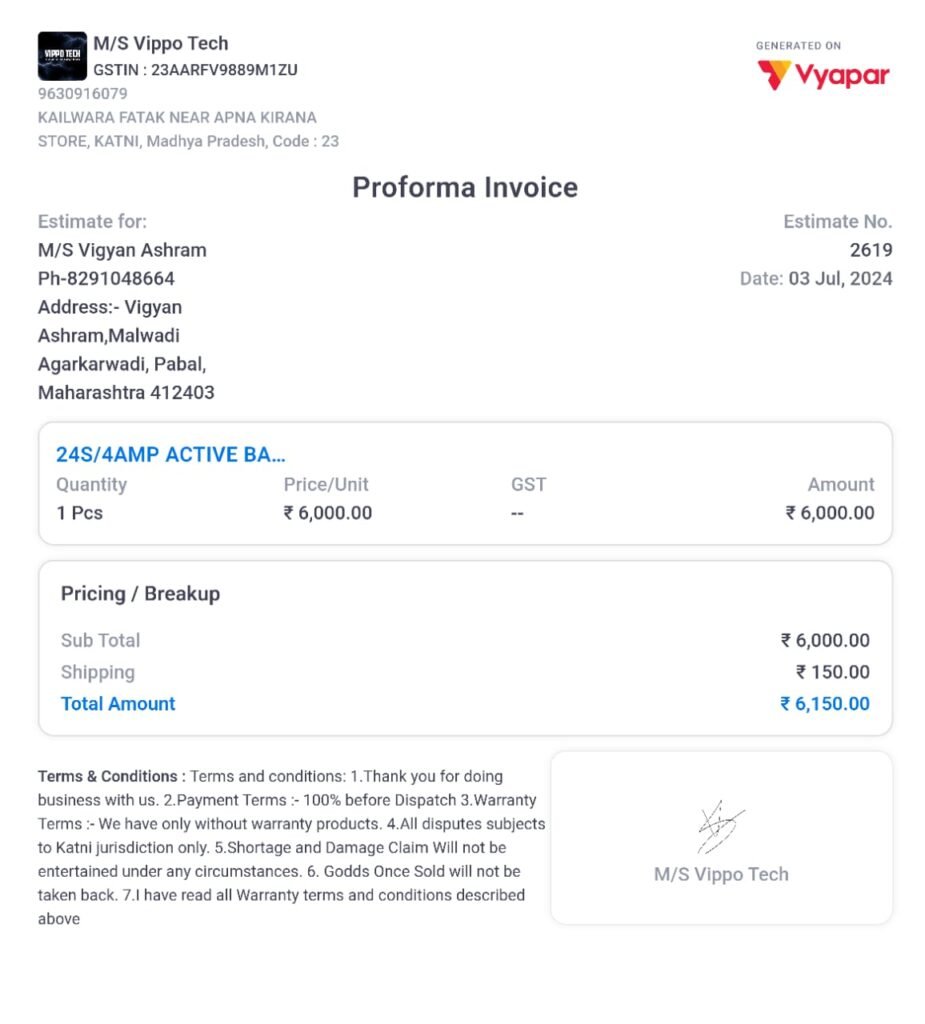

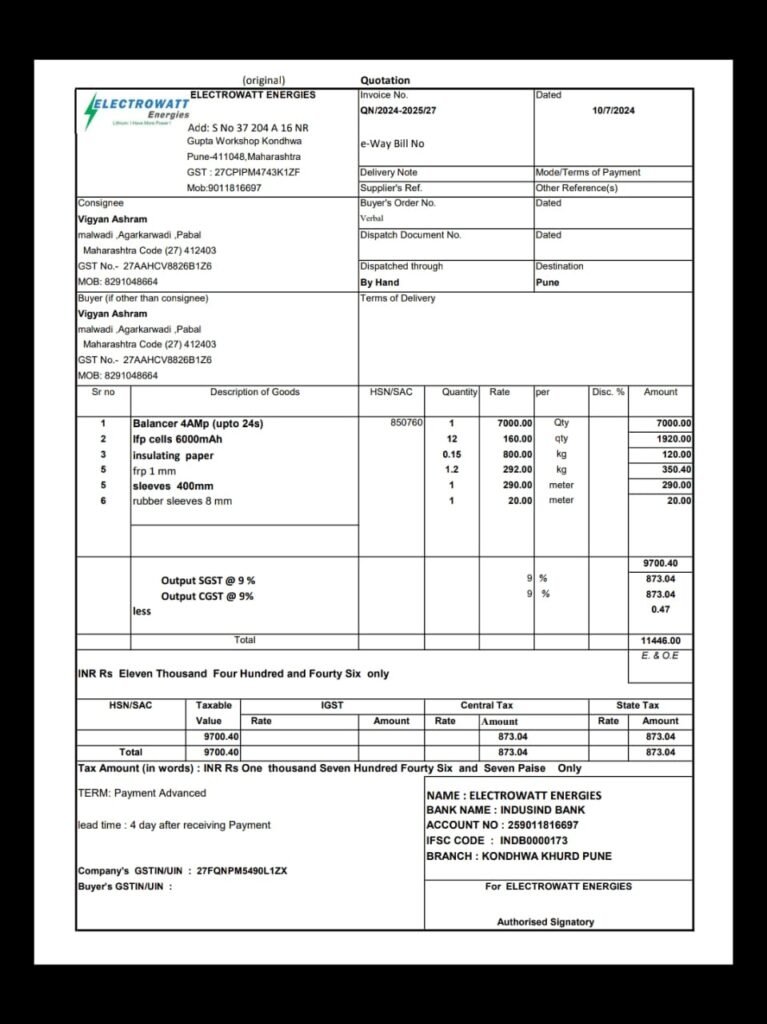

– Vendor Quotation: Obtained and finalized quotations from Electrowatt and Lithium-Ion India, RM Energy and Vippo Tech.

DAY 7

– Activities: Travelled to Pune Market

– Visited Pune market for purchasing components but found limited availability.

DAY 8

– Activities: Online research of components.

– Searched for components online and decided to purchase them online.

DAY 10

– Placed an order for cell balancing units and all other components.

DAY 11

– Followed up on orders.

DAY 12

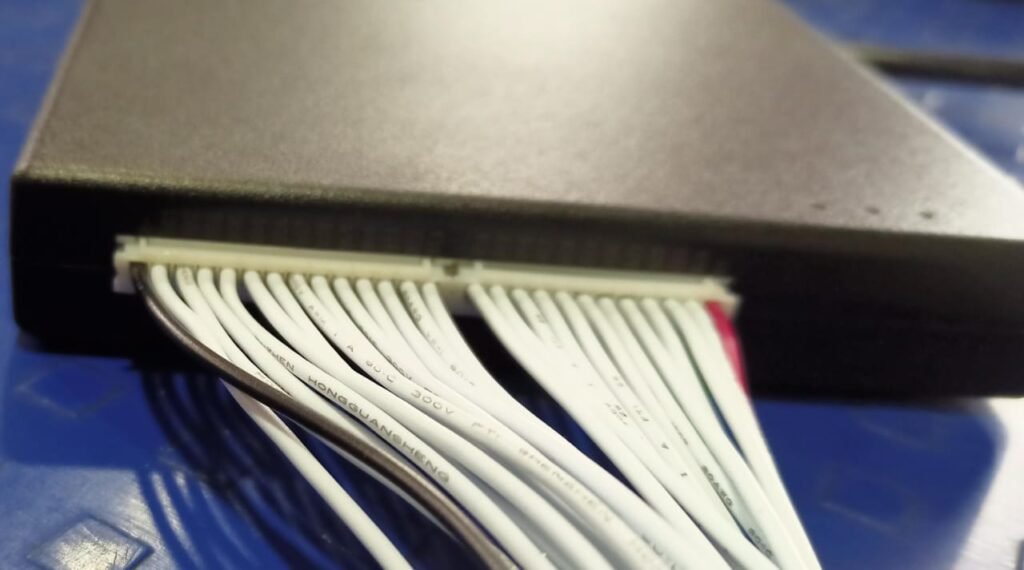

– Delivered equipment to Vigyan Ashram Pune Centre through Porter.

– Checked the voltage of the arrived cells.

DAY 13

– Cut FRP sheets ( (15cmx30cm) (Quantity:2) (8cmx30cm) (Quantity:2)

(15cmx8cm) (Quantity:2) ) and PVC paper to required dimensions (15cmx30cm) (Quantity:2)

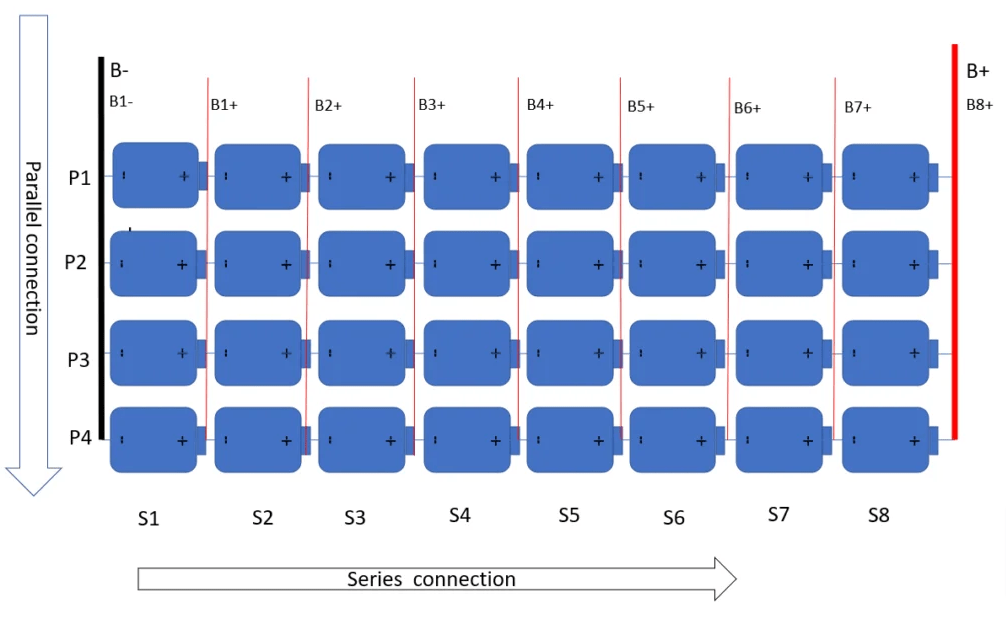

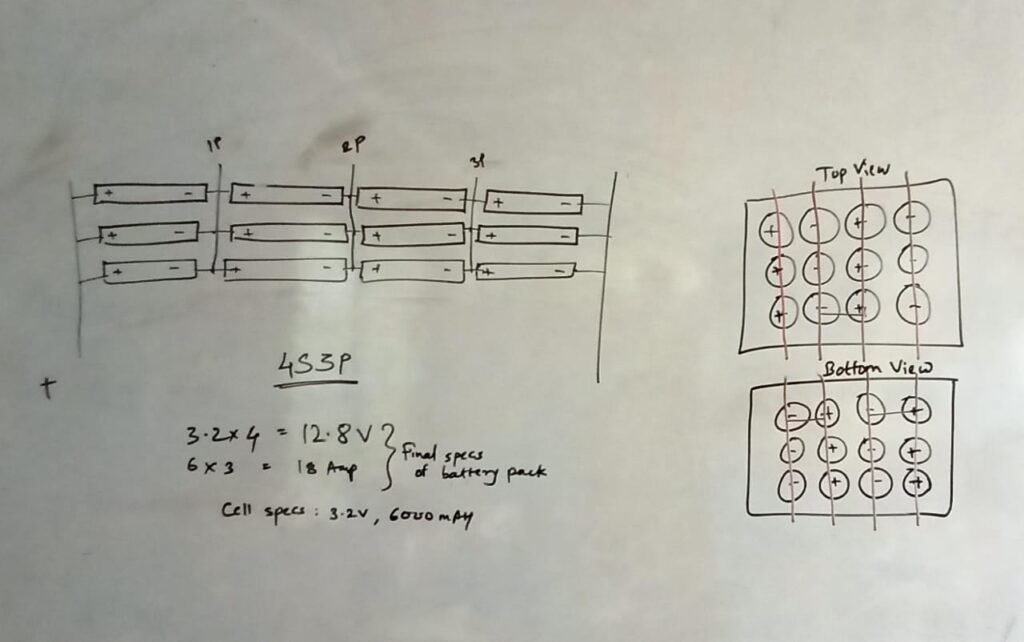

– Understood parallel and series connections.

DAY 14

-Created a random 4S3P battery pack for understanding connections.

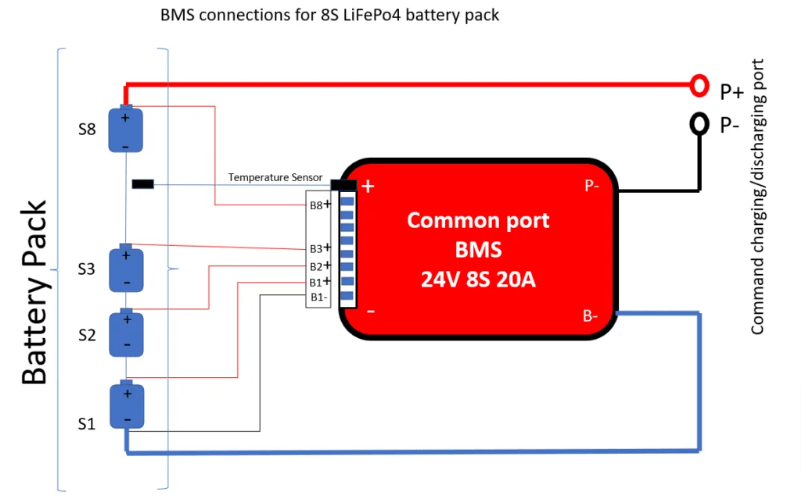

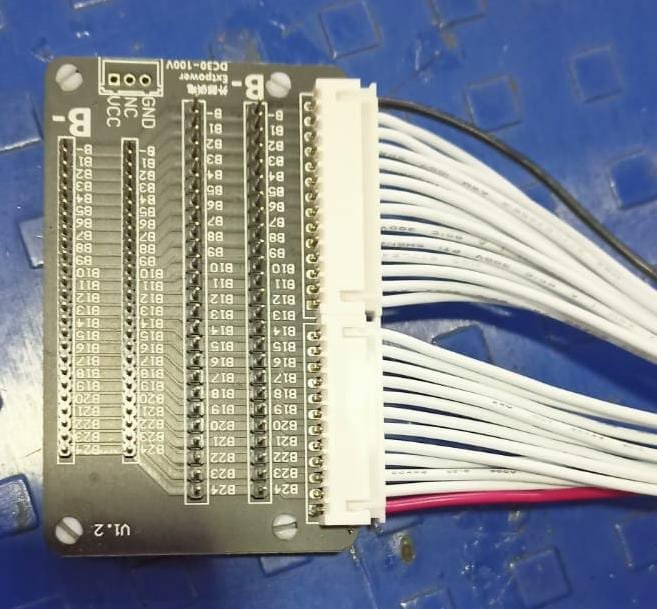

– Understood BMS and cell balancing unit connections.

DAY 15

– Conducted theoretical calculations for range

– Learned how to calculate the range of an e-cycle in real-world tests for a given battery pack.

DAY 16

– Travelled to Electro watt in Pune.

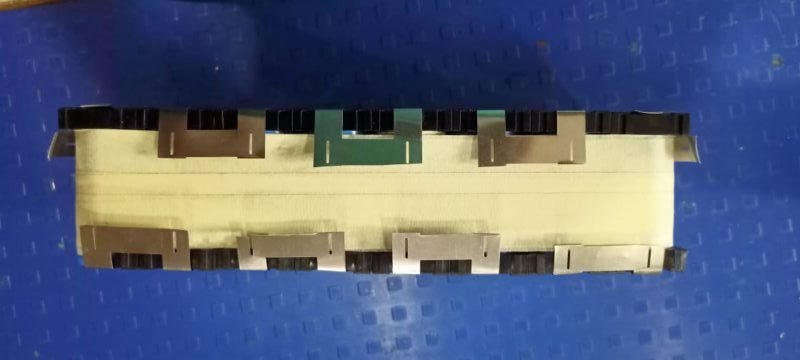

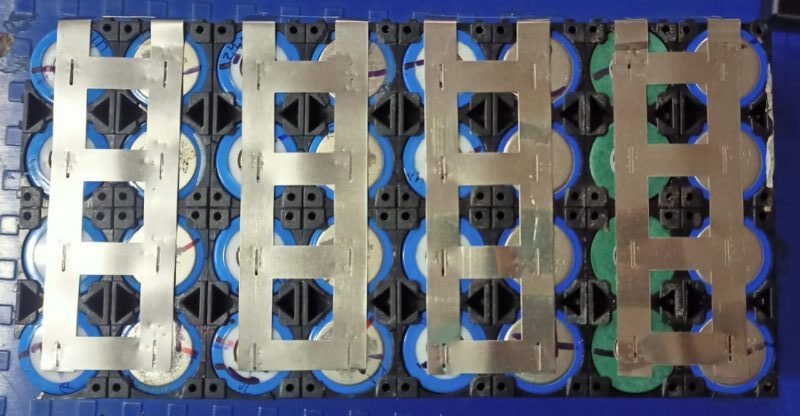

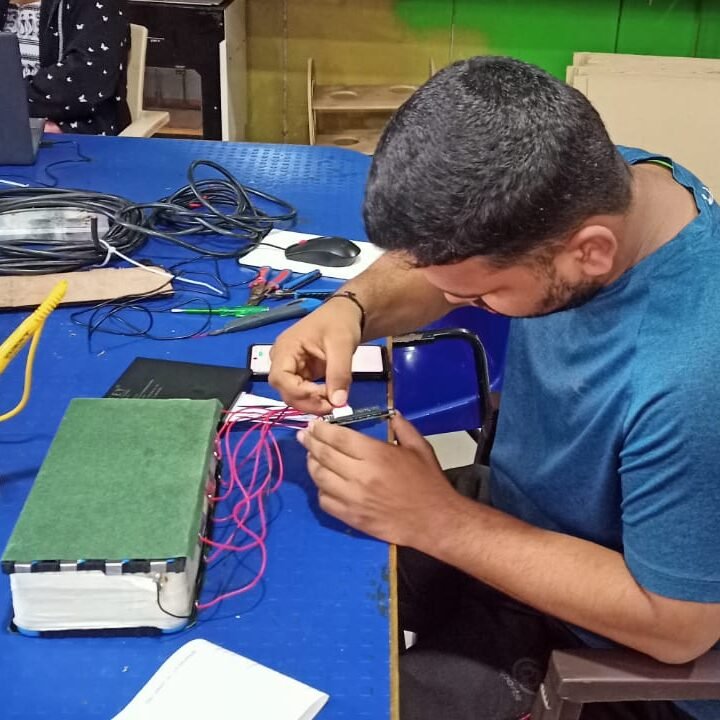

– Worked with the Electro watt team to finalize the connections for the battery pack using spot welding machine.

– First performed grinding operation to avoid formation of air bubbles while making connections.

– Ensured all connections were secure and properly configured.

– Outcome: Successfully completed the battery connections, ensuring they were ready for further testing and integration

DAY 18

– Checked the functionality of the Battery Management System (BMS).

– Connected the BMS and checked the output voltage, which showed 11.4V instead of the expected 24V.

– Rechecked the pre-existing BMS attached to the cycle, which showed 0V.

– Drafted a quotation to purchase new BMS units to replace the faulty ones.

DAY 19

– Consulted with Vrushabh Sir regarding the possibility of cell imbalance affecting the BMS output.

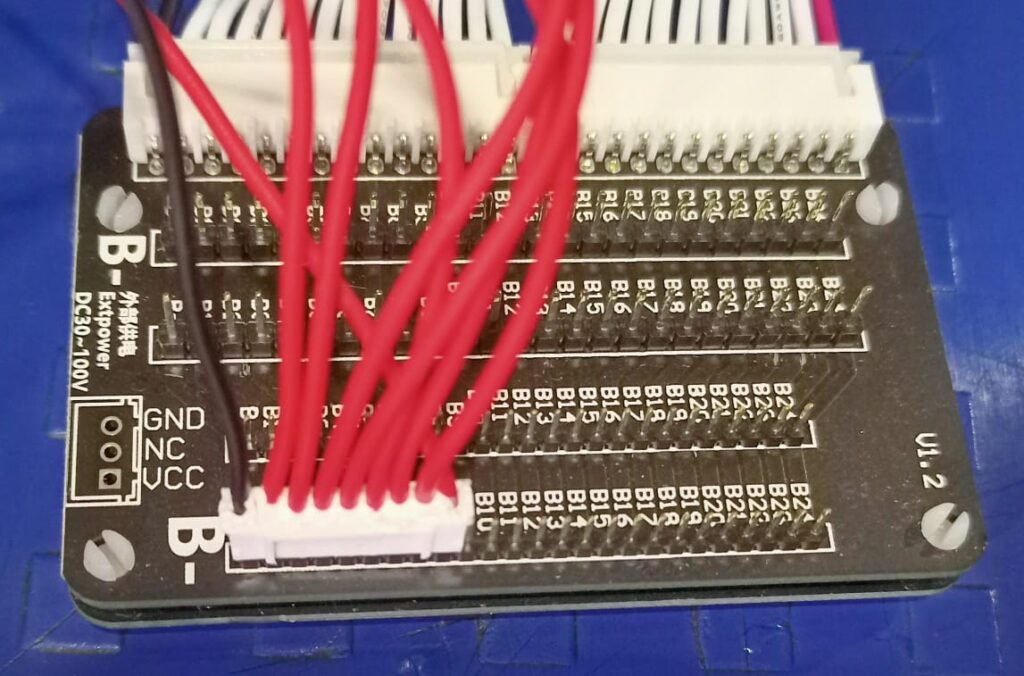

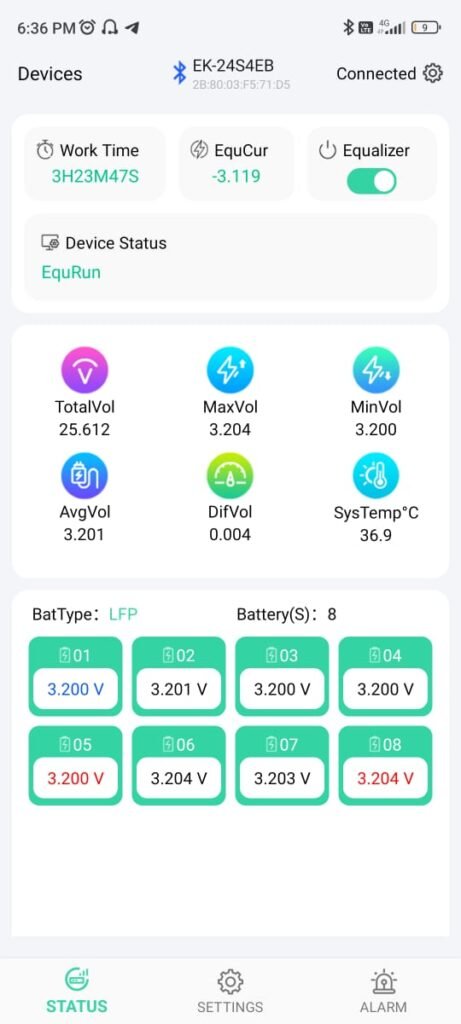

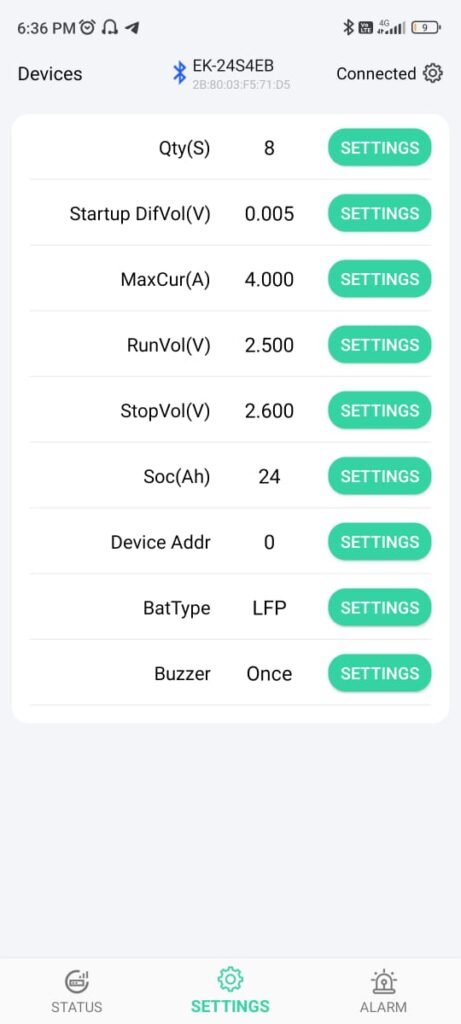

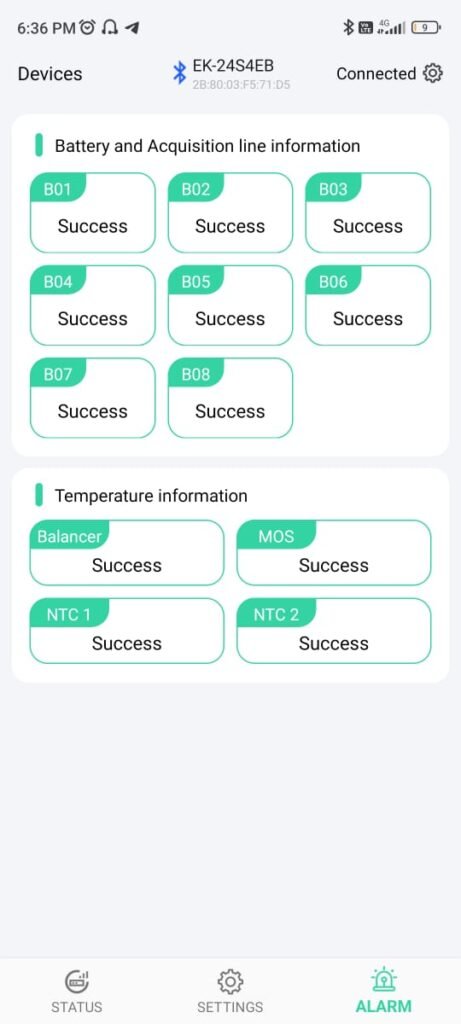

– Connected the battery pack to a balancing machine to balance the cells.

– Monitored the balancing process to ensure all cells reached the required voltage levels.

– Outcome: Completed the cell balancing process, which was a crucial step before testing the BMS again.

DAY 20

– Reconnected the balanced battery pack to the BMS.

– Tested the output voltage, which still did not show the required 24V.

– Concluded that the BMS was faulty.

– Drafted a two new quotation for the approximate cost to purchase new BMS units and submitted it to Dixit Sir for approval.

Future Work on Battery Pack Project

Based on the progress and findings during the internship, several tasks remain to ensure the successful completion and operational efficiency of the battery pack project. The primary step involves purchasing new Battery Management Systems (BMS) to replace the faulty units identified during testing. Once the new BMS units are acquired, the next step will be to make appropriate connections between the BMS and the battery cells, ensuring proper voltage regulation and monitoring. Following the BMS installation, the battery pack will need to be reassembled, paying careful attention to secure all components and connections.Subsequently, the connections to the controller must be checked and verified to ensure seamless communication between the battery pack and the vehicle’s control system. Additionally, the charging connections will need to be thoroughly inspected and tested to confirm that the battery pack charges correctly and efficiently. These future tasks are crucial to ensure the battery pack’s reliability and performance, ultimately contributing to the overall success of the e-cycle and e-rickshaw projects.