19 Sept 2025

Trial on Protein bar with Aditya Joshi for solving binding issue by using ragi flour (उकड काढून) & fermented wheat starch and Ghee (mohan)

17 oct 2025

Protein ball trial

- Less FOS & jaggery with roasting the ground flour.

Anarasa Pith production

Shankar Pali production

19 OCT 2025

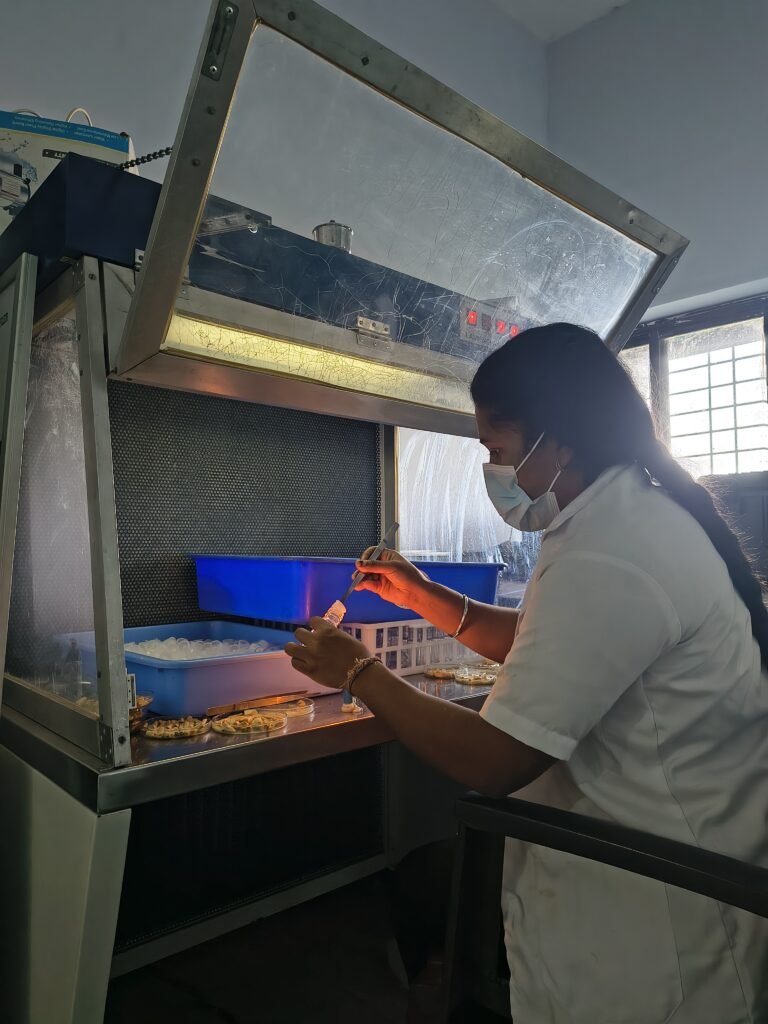

H2 S kit preparation in Soil Lab for completing order of 1500 bottles

Total bottles on 19 OCT = 900

24 OCT 2025

Preparation for Dudhi Halwa premix Trial

Washed & grated the bottle gourds.

Weight of sorted & waste material taken.

25 OCT 2025

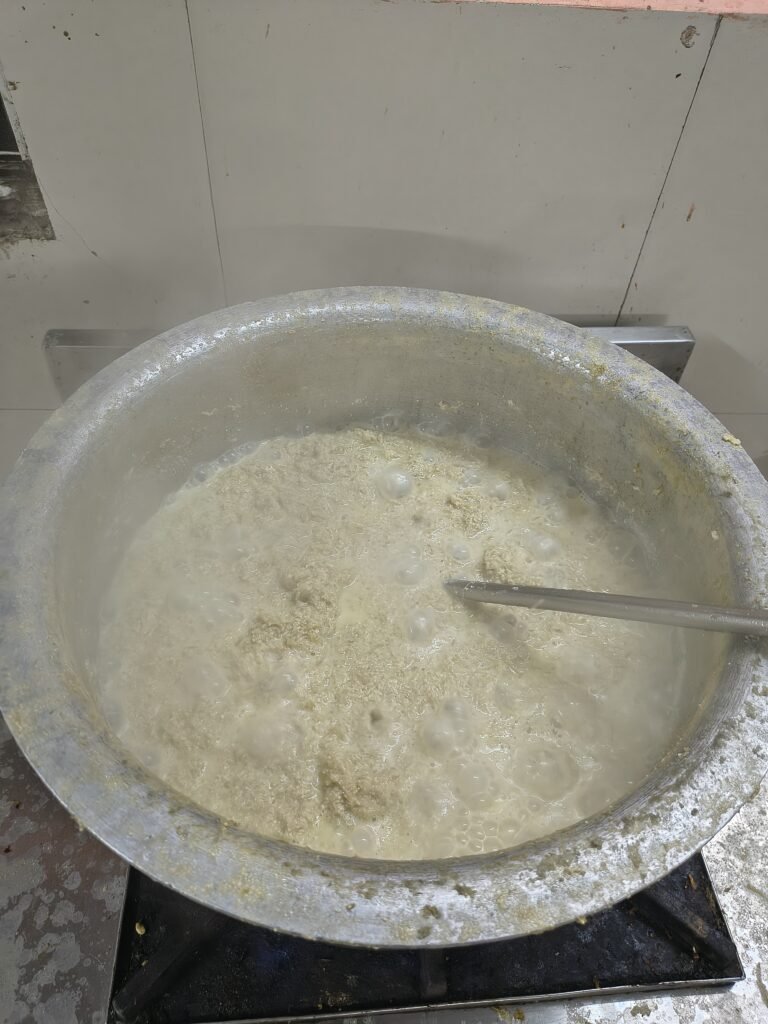

Dudhi Halwa Trial 1st

Trial carried out with 1:1 and 1:1.5 proportion of Grated bottle & Milk.

Material

A) Proportion 1:1

500 gm grated bottle gourd ( water is squashed with hands)

Half ltr milk

20 gm ghee

0.5 gm cardamom powder

B) proportion 1:1.5

1 kg grated bottle gourd ( water is squashed with hands)

1.5 ltr milk

40 gm ghee

1 gm cardamom powder

procedure.

step 1= Add a ghee in pan melt it and then add grated bottle gourd and cook until the dudhi get cooked properly.

step 2= Then add milk and cook until the semi viscose mixture is obtain and milk get absorbed properly with stirring continuously.

step 3= Turn of the gas and keep the mixture for cooling for a while and after 5 mins add cardamom powder and mix properly.

step 4= Take the weight of mixture after cooling.

Step 5= Grease the drying tray with ghee ( don’t apply too much ghee) and spread the halwa mixture on tray evenly ( spread thin layer)

Step 6 = put for drying in electric tray dryer.

•Temperature= 48° C

• Bottle gourd was properly riped and some often started seed hardning.

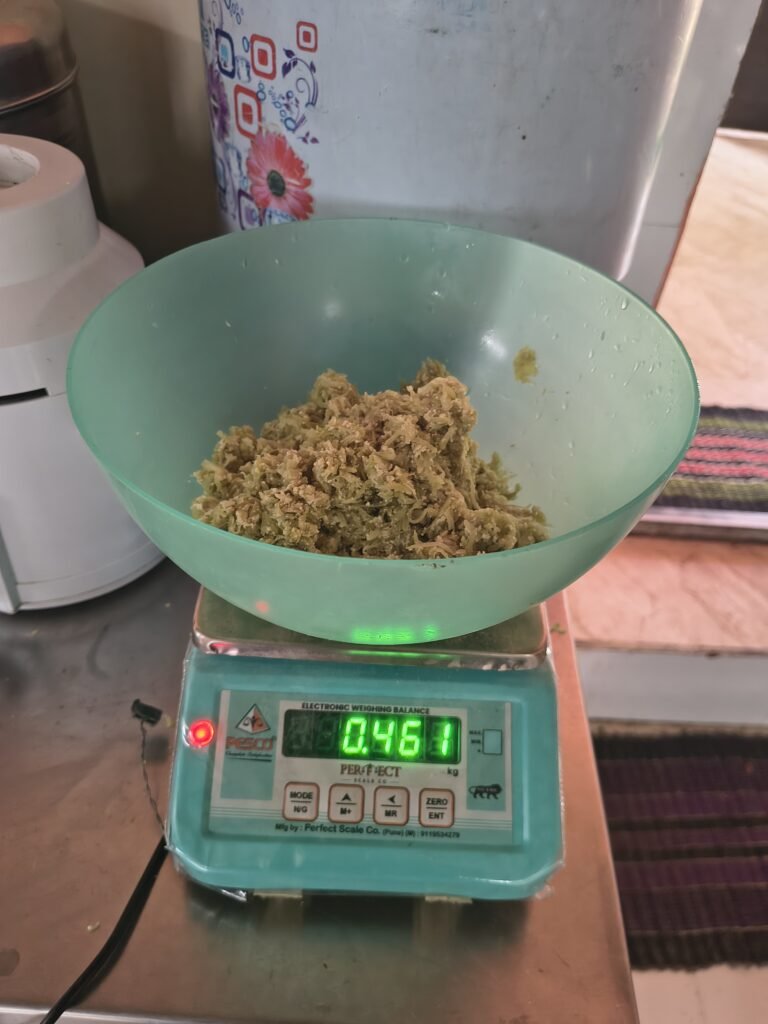

A) wt after cooking 471 gm

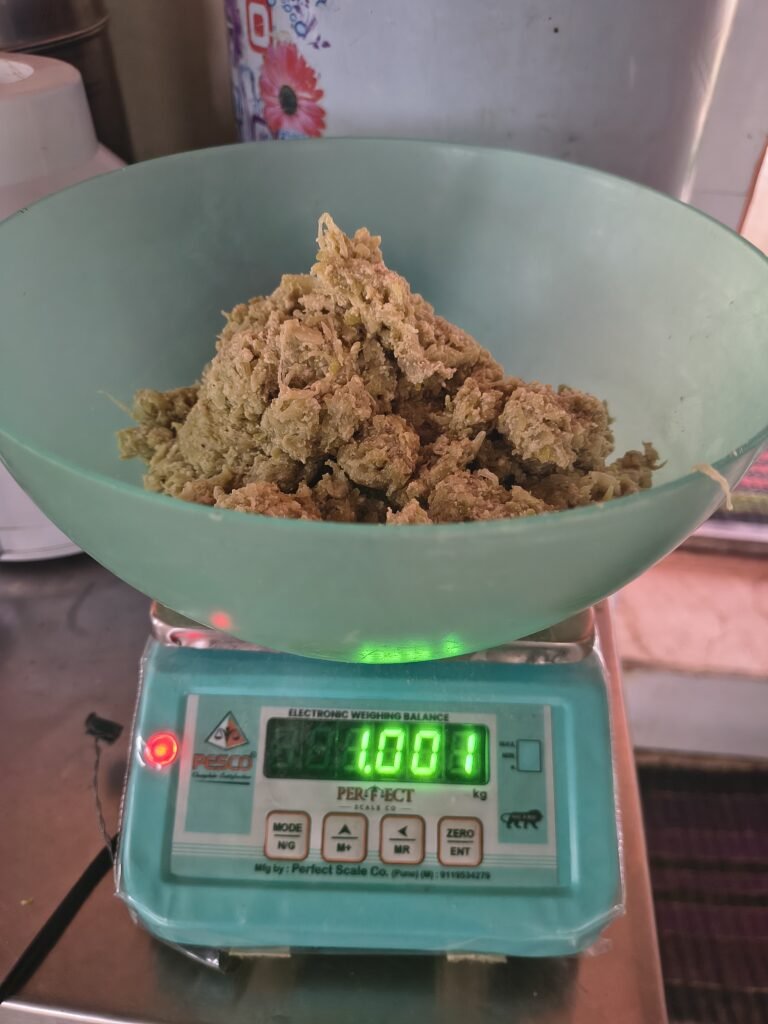

B) wt after cooking 1001 gm

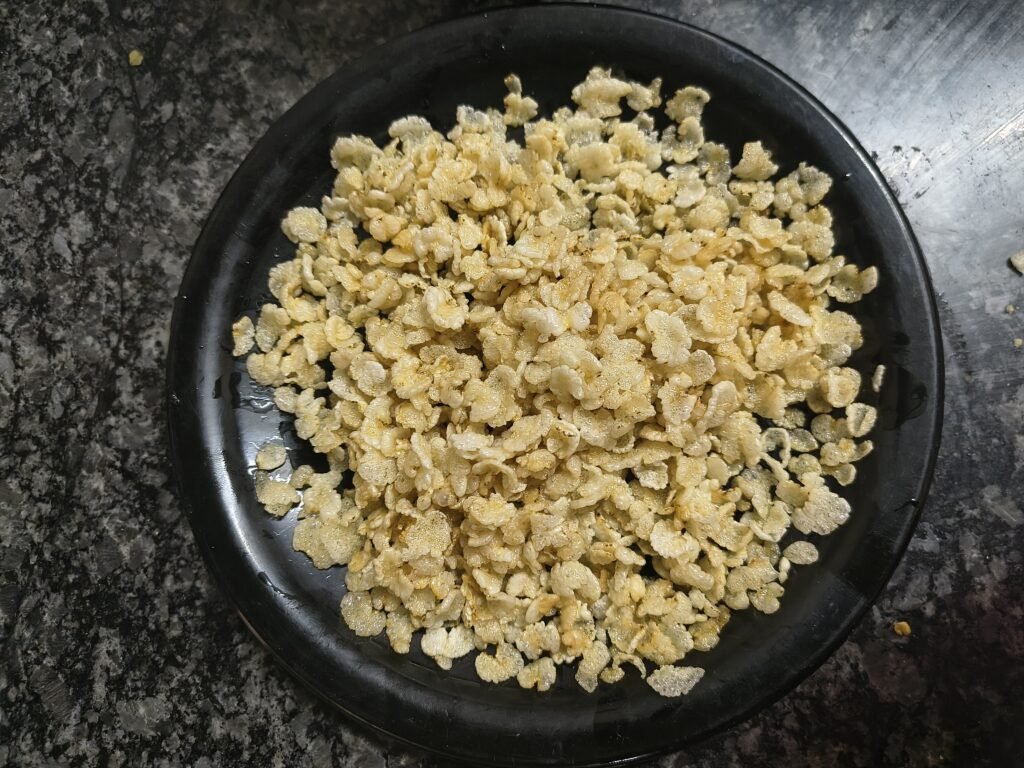

*Millets Flakes machine

Jowar flakes trial with Sujay Desai

27 OCT 2025

*Removed the dried dudhi halwa from dryer

Taken the weight

A) wt after drying =108 gm

LOD = 461-108/461 × 100 = 76.57 %

B) wt after drying = 282 gm

LOD = 1001 – 282 /1001 x 100= 71.82 %

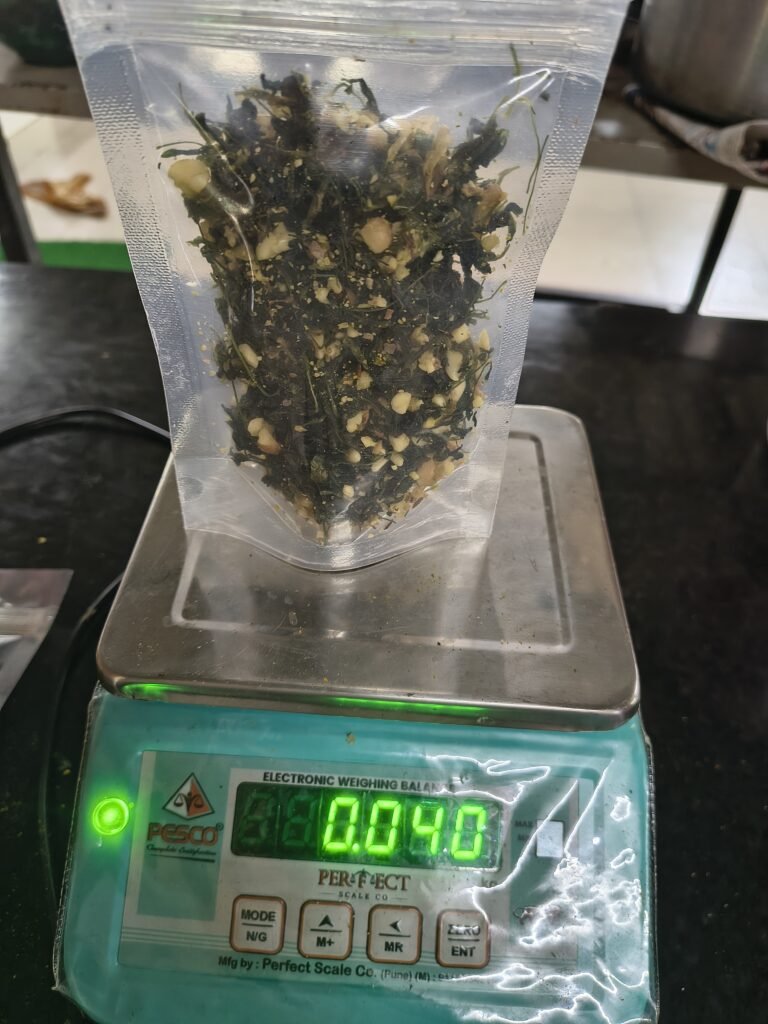

*Methi bhaji premix , palak bhaji premix , aluchi bhaji premix

Dehydration of various Bhaji for making its premix.

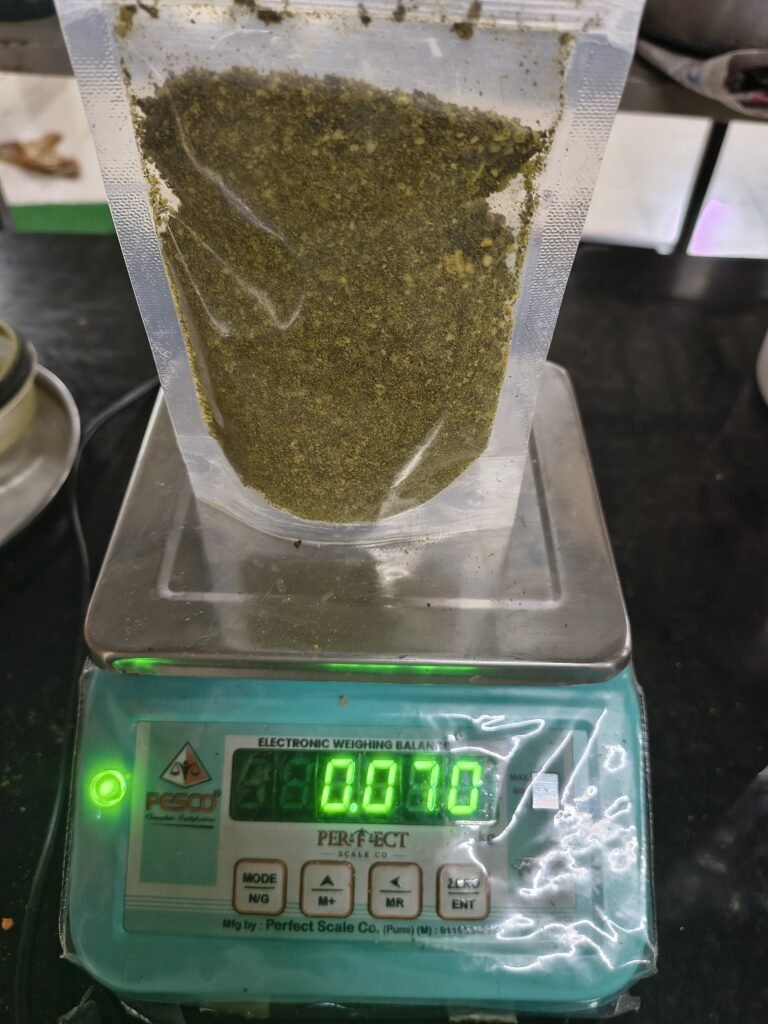

Moringa Leaves Drying for making chutney and powder

28 OCT 2025

Moringa Leaves Chuterny

Ingredients:

Dried moringa Leaves

Coriander seeds

sesame seeds

Groundnut seeds

Cumin seeds, Ajawain

Red chilli Powder

Garlic powder

Salt , Turmeric

Chat masala

Procedure

- Dry roast the all seeds in a pan on medium flame.

- Then add turmeric powder, garlic powder, chilli powder, chat masala and turn off the flame.

- Remove the mixture in mixer jar cool it and grind it finely then crush the dried moringa leaves and add it in mixer jar add salt as per taste grind again at pulse mode.

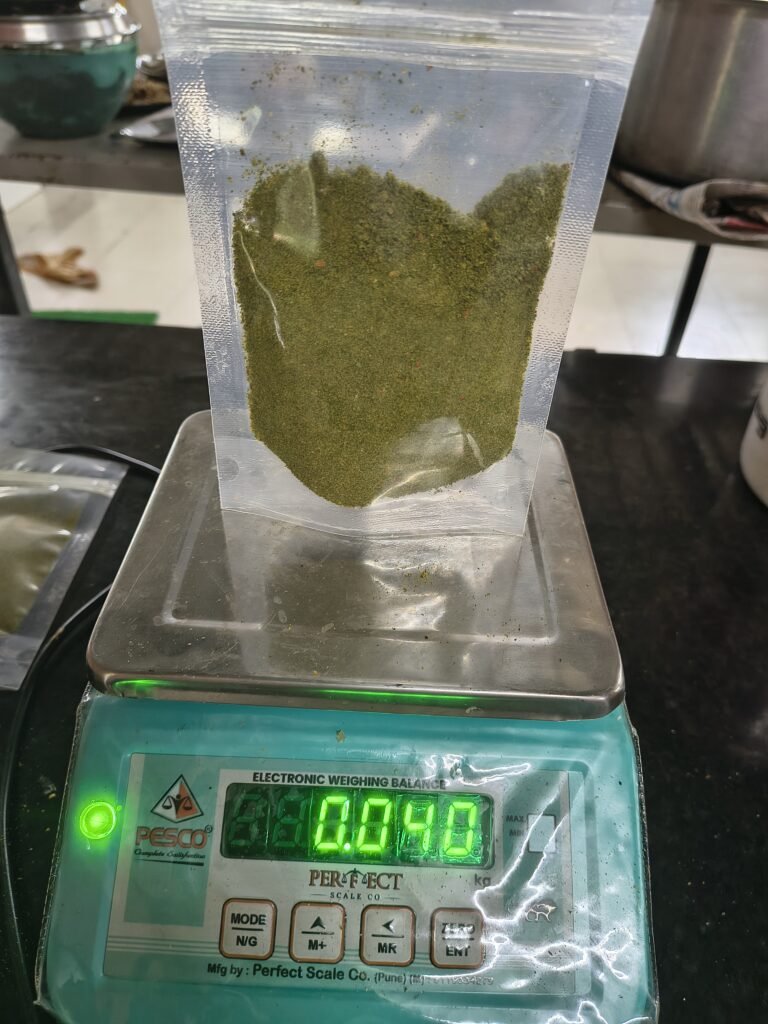

- Moringa Chutney is ready, spread the chutney on plate ,cool it at room temperature and fill in air tight container or pouches

29 OCT 2025

Dudhi Halwa bulk production for Tushar Kukreja sir.

SOP

SOP for instant Dudhi Halwa premix

Ingredients:Dudhi (bottle gourd), grated,Ghee,Milk ,Cardamom powder Preparation.

Steps:

Dudhi Preparation:Wash, peel, and grate the dudhi.Manually squeeze the grated dudhi to remove excess water.

Cooking Dudhi:Heat ghee in a pan until melted.Add the grated dudhi and cook on medium heat until it is properly cooked and softened, stirring often. This removes raw flavor and moisture.

Adding Milk:Add milk (or reconstituted milk if using milk powder) to the cooked dudhi.Cook the mixture further, stirring frequently, until the milk is absorbed and the mixture thickens.

Adding Cardamom:Add cardamom powder during the final stages of cooking for flavor.

Drying :To make a premix, spread the cooked dudhi-milk mixture thinly and dehydrate until dry. Temperature 48°C.

Weight After cooking = 6,302 kg

30 OCT 2025

Removed the dried premix from Dryer

Weight taken and packaging done.

Wt after cooking =6.302 kg

Wt after drying = 1.520 kg

LOD = 6.302- 1.520/ 6.302 x 100= 75.88 %

2 NOV 2025

Bhaji premix packaging for Kulkarni sir

viz: Mataki bhaji premix, methi bhaji premix, Moringa Chutney premix , Aluchi bhaji premix.

Wheat khir & shira premix packaging

Wheat khir premix = 1.5 kg

shira premix = 300 gm

4 NOV 2025

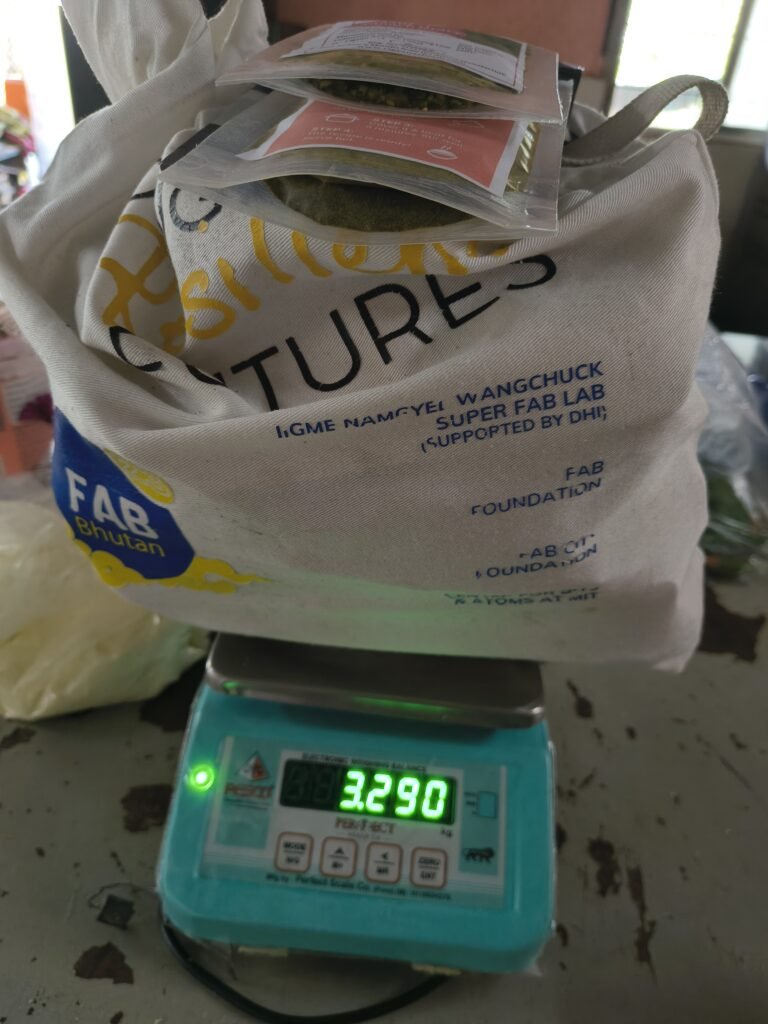

Dehydrated Products Handover to Kulkarni Sir.

Total weight – 3290 gm

Kavath jam Production from DBRT students.

6 NOV 2025

IBT vocational training to Gujrat Teachers Team.

Products Cover in training are कवठ jam, Nankatai, Khari, Moringa Chikki, Peanut chikki, Apple Jam,etc

H2S kit and water testing training.

10 NOV 2025

Medicinal plant part arrived at Food lab for Drying.

Weight taken of Herbs.

Total 8 Herbs are as below :

- Amarkand- 9790 gm

- Safed kuda- 6300 gm

- Kala kuda- 20100 gm

- Shatavari- 6 kg

- Safed Shatavari- 8500 gm

- Gulvel- 5124 gm

- Bibla Saal- 28 kg

- Jangali Adrak- 5116 gm

12 NOV 2025

कवठ jam Production from DBRT students

Ingredients

- Kavath pulp-1760 gm

- Jaggery- 700 gm

- Ghee- 52.8 gm

Wt after cooking = 2.1 kg

Procedure-

- Add a ghee in a pan melt it and then add chopped jaggery and melt it properly note that no lumps should remained.

- Then add kavath pulp in syrup and mix it well by stirring continuously.

- Cook on low flame with stirring turn off the gas when mixture get thicken and starts to leave the sides and bottom of pan.

- Cool it down and then pack in air tight container.

*LOD of Amarkand, kala kuda,safed kuda,shatavari, safed Shatavari is done are as below:

- Amarkand- 84.2%

- safed kuda- 16.5%

- Kala kuda- 59.4%

- shatavari- 58%

- Safed Shatavari- 71.9%

14 NOV 2025

Amarkand Preparation For Drying

Slicing by machine and manually done.

And putted for Drying in Electric tray dryer.

Temperature=58°C

LOD for remaining herbs is done.

LOD:

- Gulvel- 24.5%

- Jangali Adrak- 65.5%

- Bibla Saal- 38.9%

15 NOV 2025

Frying Trial on Jowar flakes made in Tha Multigrain flakes machine.

16 NOV 2025

17 NOV 2025

- Jyosta Mam carried the Spinach leaves to food lab for drying.

Spinach leaves putted for drying

Wt before Drying=

Wt after Drying =

2.Amarkand powder

Dried Amarkand slices removed from Dryer and Powdered in Mixer grinder.

Wt of powder =1117 gm

18 NOV 2025

19 NOV 2025

20 NOV 2025

Flakes machine trial on Jowar flakes

wt of dry jowar = 500 gm

Treatment given= soaked for 6 hrs and then hot water treatment at 95°C for 10 mins

Then Dried upto 26% moisture content to 500 gm

i.e. 630 gm

Wt of expected or ideal flakes= 172 gm

i.e. 34.6 %

24 NOV 2025

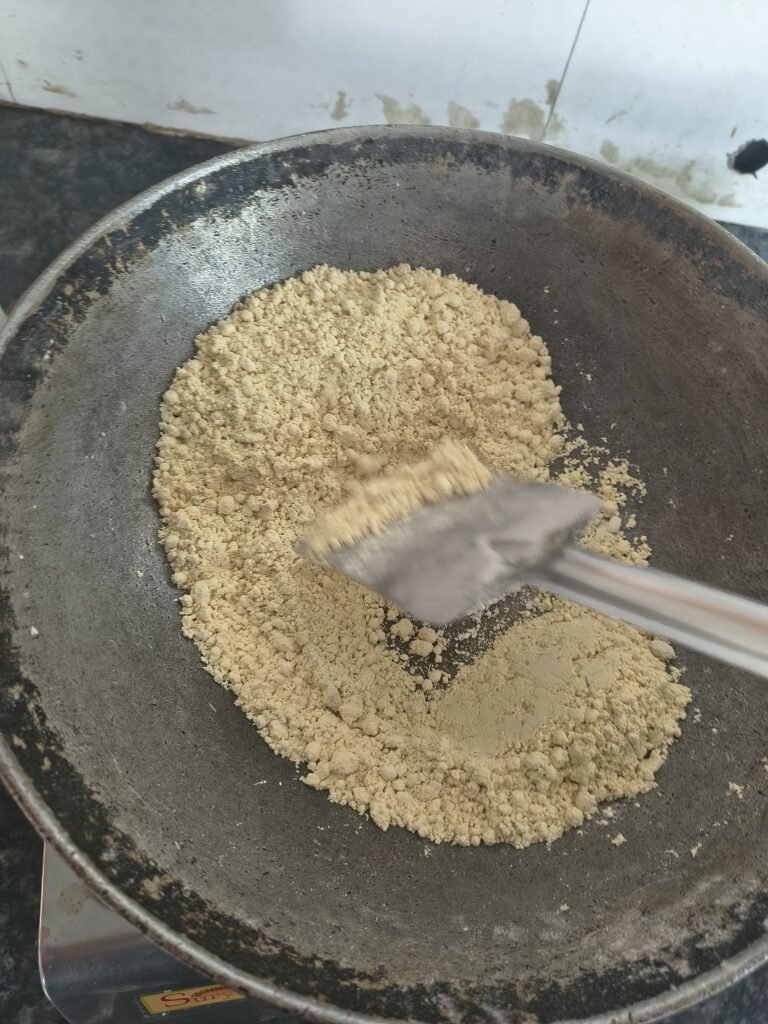

Nachani Ladu trial

Ingredients-

- Nachani pith-350 gm

- Besan pith-150 gm

- Jaggery- 300 gm

- Ghee- 200 gm

- Cardamon powder-1 gm

- Kaju,Badam – 10 gm

Procedure-

Roast the both flours separately until they changes their colour and start releasing aroma.

Add the ghee in another pan melt it and heat up to it start vapourises turn off the flame.

Now add roasted flours and mix them well with ghee and then add chopped jaggery or jaggery powder mix the whole and turn on the flame and cook for 5-7 mins until jaggery melts well and mixture get required consistency to make Ladu.

Turn off the flame pour the mixture in flat dish and allow it to cool lightly then start making laddu by greasing the hands with ghee.

Wt of product= 1 kg

27 NOV 2025

Moringa Chikki Production

40 boxes delivered to Agro rangers.

28 NOV 2025

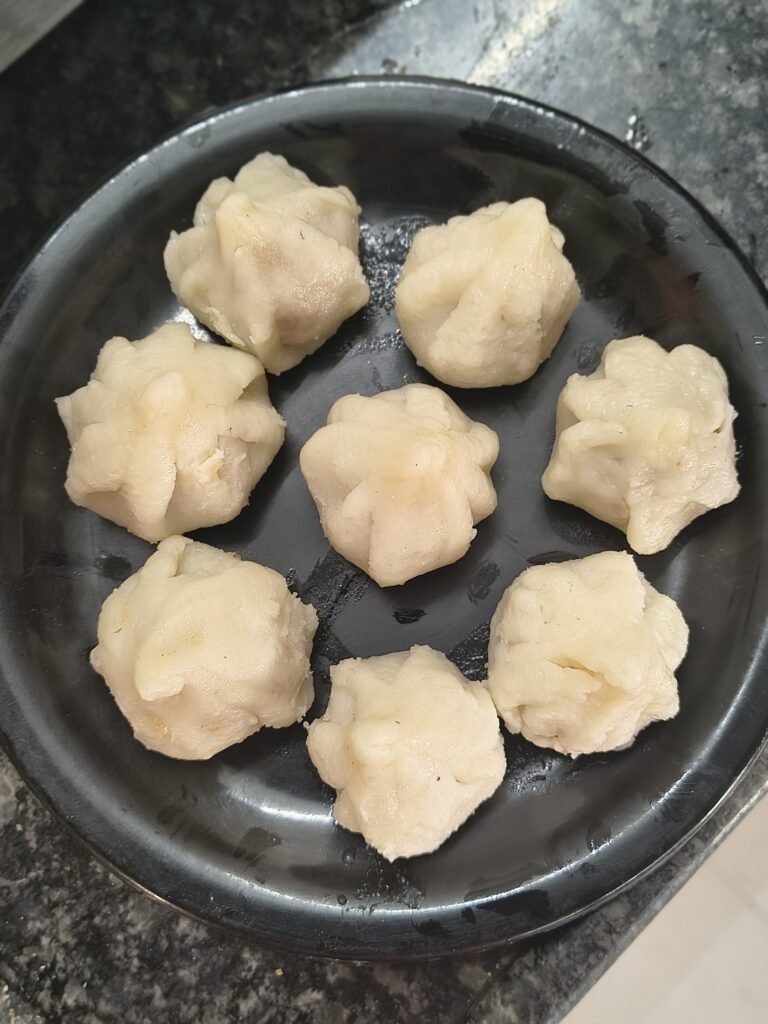

उकडीचे मोदक

Trained DBRT students to make Ukadiche Modak.

Saran ingredient

- Grated coconut- 100 gm

- Jaggery -50 gm

- cardamom powder – 2 pinch

- Ghee – 10 gm

procedure

Heat the pan add ghee in it and then add grated coconut,cook it for 5 mins & then add jaggery mix it all well and cook until the jaggery melts well and starts absorbed by coconut.Then turn off the flame immediately.

Ukad ingredients

- Rice flour -250 gm

- Salt – 1 gm

- water – 200 ml

- ghee – 1/2 tspoon

Procedure

Heat the water in a vessel and add ghee, salt to it after 1st boil add rice flour to it and store well on medium flame, make sure no lumps should remained.Then low the flame and place cap on vessel & allow it to steam for 7-8 mins. Make sure that stuff won’t get burnt at bottom. Then turn off the flame and keep it for another 4-5 mins.

Modak stuffing

After 5 mins remove the rice dough in a place and knead it well with ghee greased hand or bowl.

Then immediately starts the Modak stuffing by making the thin flat round shape of rice dough and then filling it with coconut stuff and then closing it by giving Modak shape.

3 NOV 2025

Data of Herbs Drying

| Herb name | Wt before Drying (Kg) | Wt after Drying (Kg) | Wt of powder (Kg) | LOD % |

| 1)Amarakand | 9.790 | 1.271 | 1.177 | 84.2% |

| 2)Gulvel | 5.124 | 4.493 | 3.542 | 24.5% |

| 3)Jangali adrak | 4.722 | 2.420 | 1.733 | 65.5% |

| 4)Safed kuda | 6.395 | 5.685 | 5.330 | 16.5% |

| 5)Kala kuda | 25.100 | 8.598 | 7.800 | 59.4% |

| 6)Bibla saal | 29.050 | 17.323 | 16.651 | 38.9% |

| 7) Shatavari | 6.053 | 1.540 | 1.149 | 58% |

| 8)pandhari shatavri | 8.504 | 2.144 | 1.838 | 71.9% |

| Total | 94.738 | 44.474 | 39.215 | – |

COSTING for Dehydration of Medicinal plant parts.

| Sr.No. | Specific | Used for | Rate | Cost |

| 1. | Solar Dome dryer | 7 days (4 units/day) | 28 Rs/Day | 392 Rs |

| 2. | Electric Dryer | 7 Days (14 hrs/day) (1.33 unit / hr) | 260 Rs/Day | 1824 Rs |

| 3. | Chaff cutter | 2 hrs (6 unit) | 14 Rs/ Unit | 84 Rs |

| 4. | Powder making Cost | 42 kg material | 50 Rs/kg | 2100 Rs |

| 5. | Mixer & Slicer cost | 2 hrs (2 units) | 14 Rs/kg | 28 Rs |

| 6. | packing bags | 16 bags | 5 Rs/bag | 80 Rs |

| 7. | Petrol | Dhamari trips | 104 Rs/ltr | 600 Rs |

| Total | 5108 Rs | |||

| 8. | Labour Charges | 25 % of Total | – | 1277 Rs |

| Total | 6385 Rs |

Cost Per 1 kg is 163 Rs.

Above is the Costing data for Dehydration and powder making of Amarkand, kala kuda, safed kuda, Shatavari, pandhari shatavri, Bibla saal, Jangli Adrak,Gulvel.