Introduction:

Chili is the fruit of plants from the genus Capsicum which are members of the nightshade family, Solanaceae. Chili peppers are widely used in many cuisines as a spice to add heat to dishes. The substances that give chili peppers their intensity when ingested or applied topically are capsaicin and related compounds known as capsaicinoids.

Chili peppers originated in Mexico. After the Columbian Exchange, many cultivars of chili pepper spread across the world, used for both food and traditional medicine. Chili with Kakronda, eaten in Uttar Pradesh.

Cultivars grown in North America and Europe are believed to all derive from Capsicum annuum, and have white, yellow, red or purple to black fruits. In 2016, the world production of raw green chili peppers was 34.5 million tonnes, with China producing half of the world total.

Origins

Pottery that tested positive for Capsicum sp. residues excavated at Chiapa de Corzo in southern Mexico dated from Middle to Late Preclassic periods (400 BCE to 300 CE)

Capsicum fruits have been a part of human diets since about 7,500 BC, and are one of the oldest cultivated crops in the Americas, as origins of cultivating chili peppers are traced to northeastern Mexico some 6,000 years ago. They were one of the first self-pollinating crops cultivated in Mexico, Central America, and parts of South America.

Peru is considered the country with the highest cultivated Capsicum diversity because it is a center of diversification where varieties of all five domesticates were introduced, grown, and consumed in pre-Columbian times. Bolivia is considered to be the country where the largest diversity of wild Capsicum peppers is consumed. Bolivian consumers distinguish two basic forms: ulupicas, species with small round fruits including C. eximium, C. cardenasii, C. eshbaughii, and C. caballeroi landraces; and arivivis with small elongated fruits including C. baccatum var. baccatum and C. chacoense varieties.

Distribution to Asia

The spread of chili peppers to Asia occurred through its introduction by Portuguese traders, who – aware of its trade value and resemblance to the spiciness of black pepper – promoted its commerce in the Asian spice trade routes. It was introduced in India by the Portuguese towards the end of the 15th century. In 21st century Asian cuisine, chili peppers are commonly used across diverse regions.

Production

| Green chili production – 2016 | |

|---|---|

| Country | (millions of tonnes) |

| China | 17.4 |

| Mexico | 2.7 |

| Turkey | 2.5 |

| European Union | 2.3 |

| Indonesia | 2.0 |

| Spain | 1.1 |

| United States | 0.9 |

| World | 34.5 |

| Source: FAOSTAT of the United Nations |

Worldwide in 2016, 34.5 million tonnes of green chili peppers and 3.9 million tonnes of dried chili peppers were produced. China was the world’s largest producer of green chilies, providing half of the global total. Global production of dried chili peppers was about one-ninth of fresh production, led by India with 36% of the world total.

Market study: parallel products

Inferences from the market study:

- Ergonomics issues

- Problem with usage

- High initial investment

- Loss of jobs

Objectives:

- To design and develop chili picker with considering human ergonomics.

- To design collecting system.

- To design conveying system.

- To test and modify the prototype.

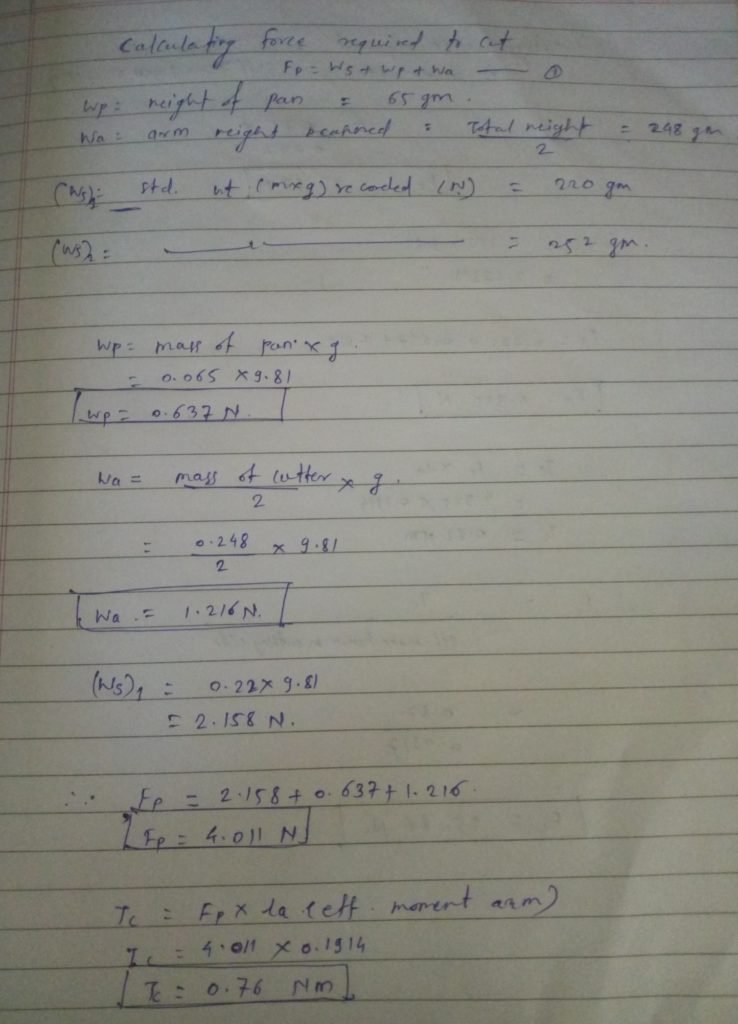

Experimental estimation of the force required to cut chili stalk:

The force required to cut stalks of vegetable fruits is not readily available. Therefore it becomes necessary to determine the cutting force experimentally. The setup of the experiment consists of

- cutter

- pan

- std masses

- stalk samples

Setup:

- One arm of the cutter is fixed in a vice and another one is free to rotate about the joint of the cutter.

- Pan is suspended with the help of string tied to the free arm of the cutter.

- The pan serves the purpose of holding the mass loaded in steps until the stalk gets cut.

Procedure:

- Two samples are used to determine the cutting force.

- once the stalk is fed std masses are loaded in the pan step by step.

- The load at which the stalk gets cut into two is recorded.

- The above steps are repeated for each sample stalk.

- Force (Fp) obtained is at the point where the string is tied to the free arm of cutter and not the actual cutting force.

- Force (Fp) is the sum of weights of std mass in the pan, the weight of the pan, the weight of the free arm of cutter (approximately determined as the half of the cutter weight).

- In order to estimate the actual cutting force(Fc), the cutting torque (Tc) is to be calculated.

- Cutting torque is the torque applied by the cutter, weight system.

- Stalks that are to be cut are fed into a cutting portion of the cutter.

- It should be noted that arm weight and weight of pan are constant throughout the experiment.

- Cutter used in the experiment is weighted on the electronic weighing machine and arm weight is considered to be half of the weight of cutter.

- On the same weighing machine mass of pan is measured.

Calculation:

Experimental Setup:

Conclusion:

From the above calculation, we can conclude that the cutting force required to cut the chili stalk is 25.86 N.

Forces by fingers:

EMG (Electromyography) device used to measure the forces exerted by finger.

| Right hand | Left hand | |

| Thumb | 107.7 N | 109.5 N |

| Index finger | 56.7 N | 60.4 N |

Hand and finger strength:

- Male:- 50.90 – 97.02 N

- Female:- 35.20 – 64.84 N

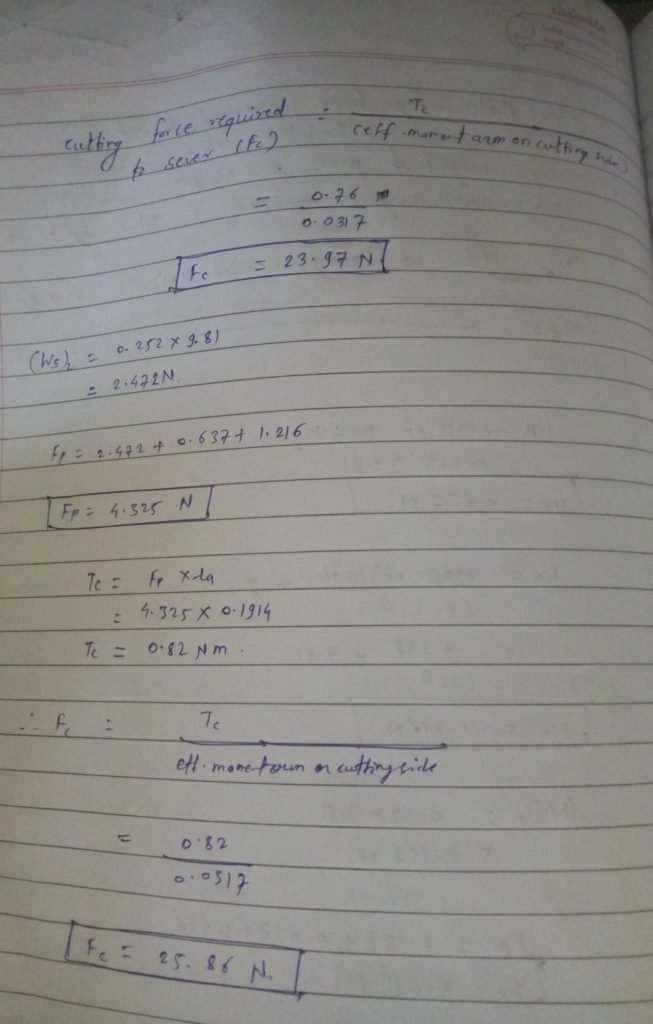

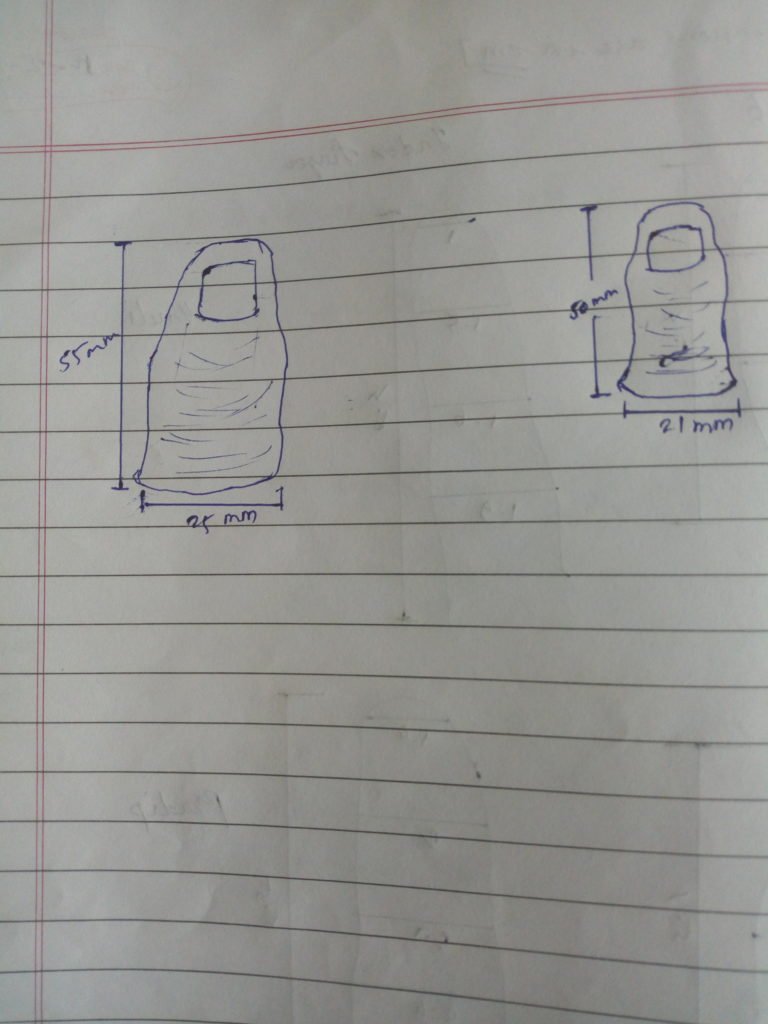

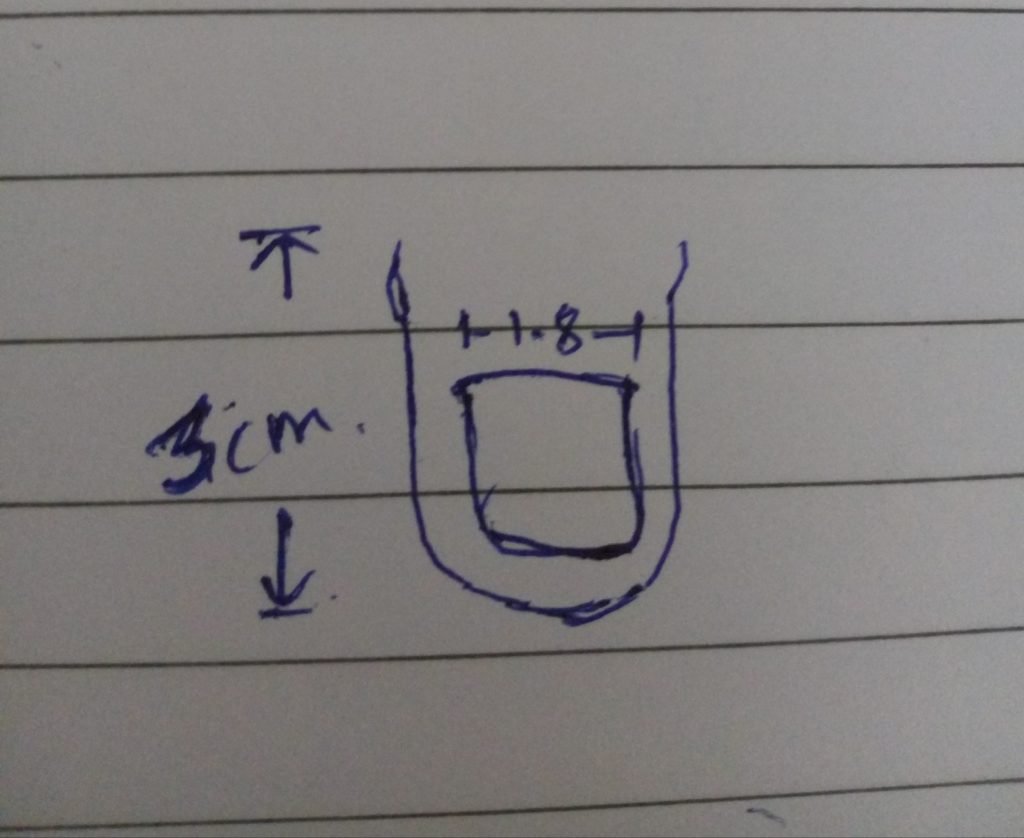

The average dimension of thumb and index finger:-

| Length (cm) | Width (cm) | Girth (cm) | |

| Thumb | 6 | 2.5-3 | 6-7 |

| Index finger | 9-15 | 1.6-2 | 6-6.5 |

Thumb and Index finger measurement:-

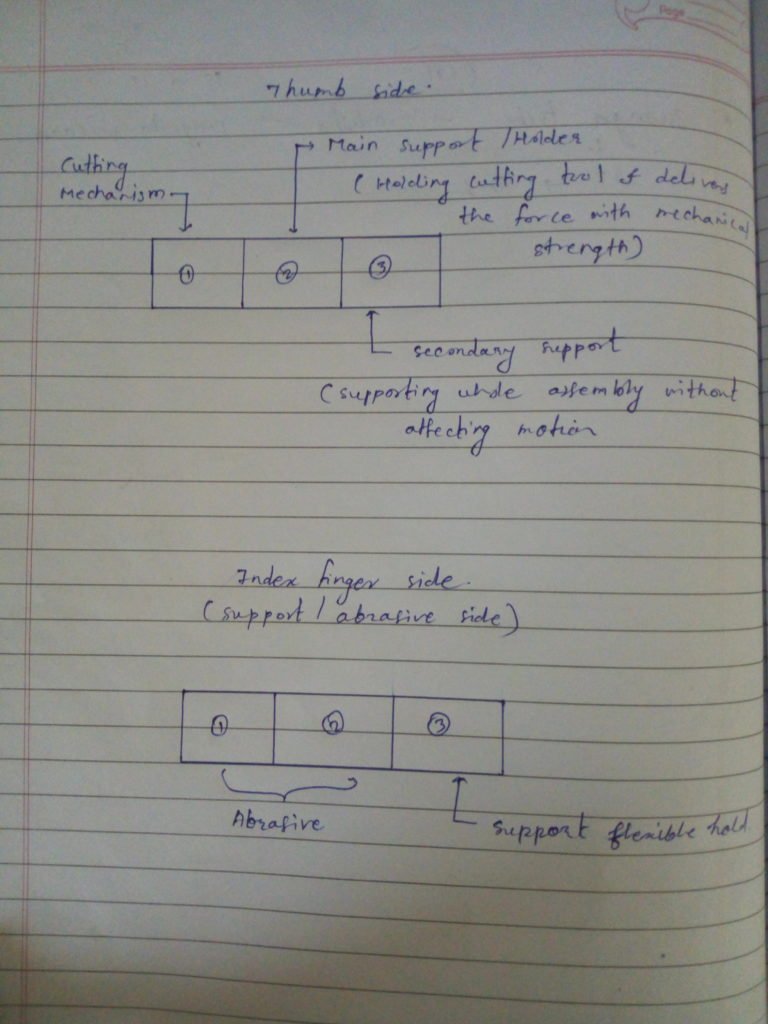

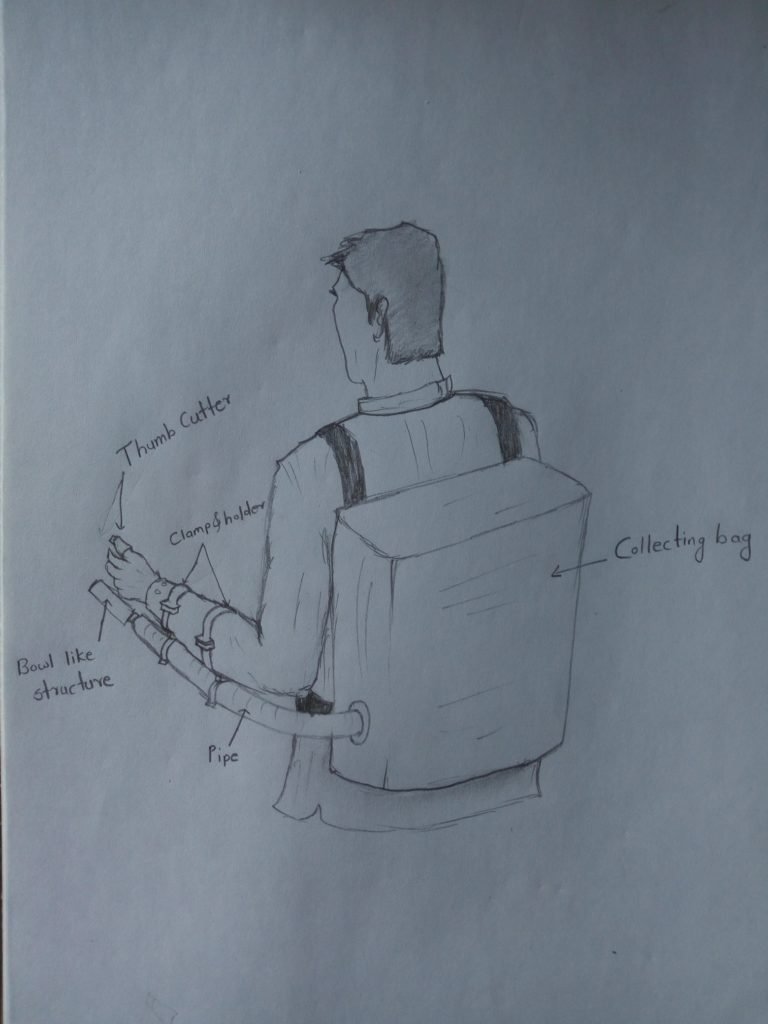

Sketches:-

Cut-resistant gloves made up of:-

- synthetic nylon fabric

- synthetic polyester fabric

- kevlar

- Dyneema

- metal weave or metal mesh

Block diagram:-

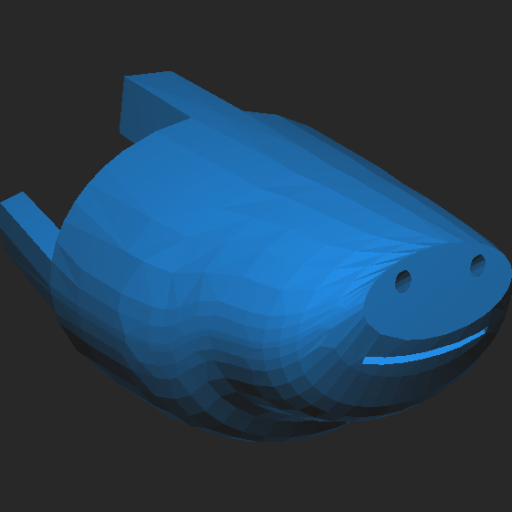

Prototype 1

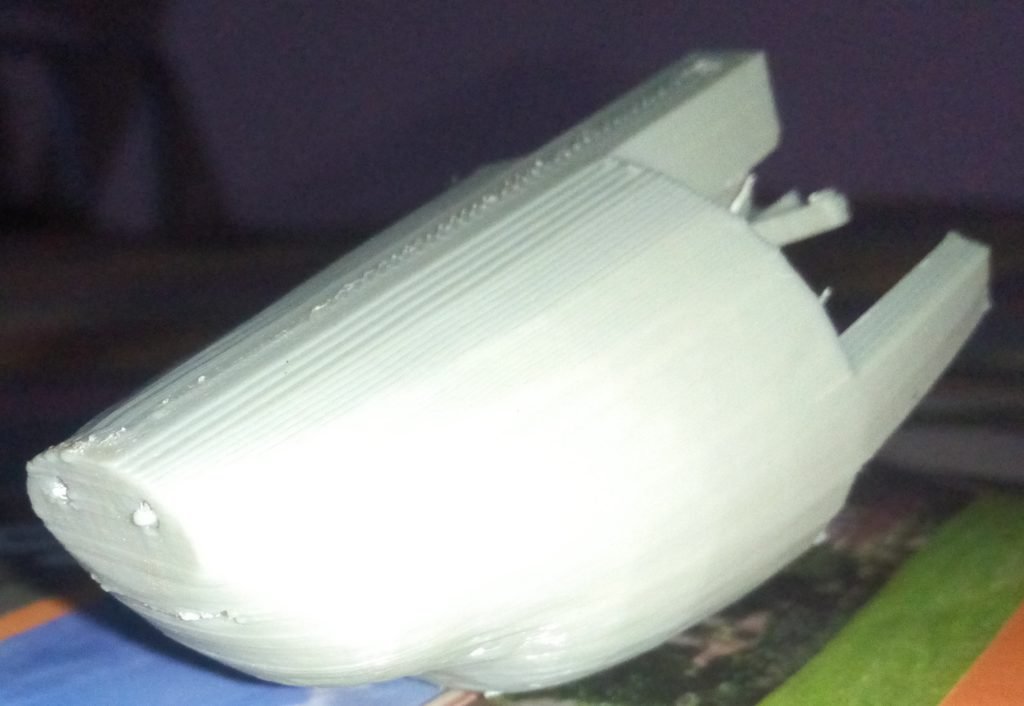

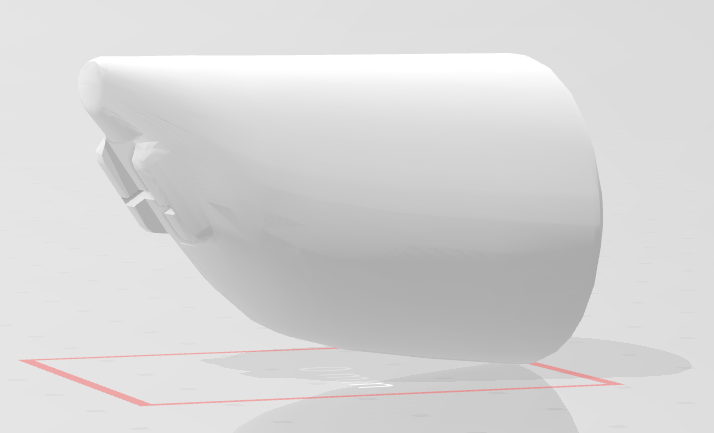

From the information that I had gathered, we reached the conclusion that we should make the prototype first and test it, hence Amol sir and I decided to 3-D print the object. For that, we made a design in CATIA software.

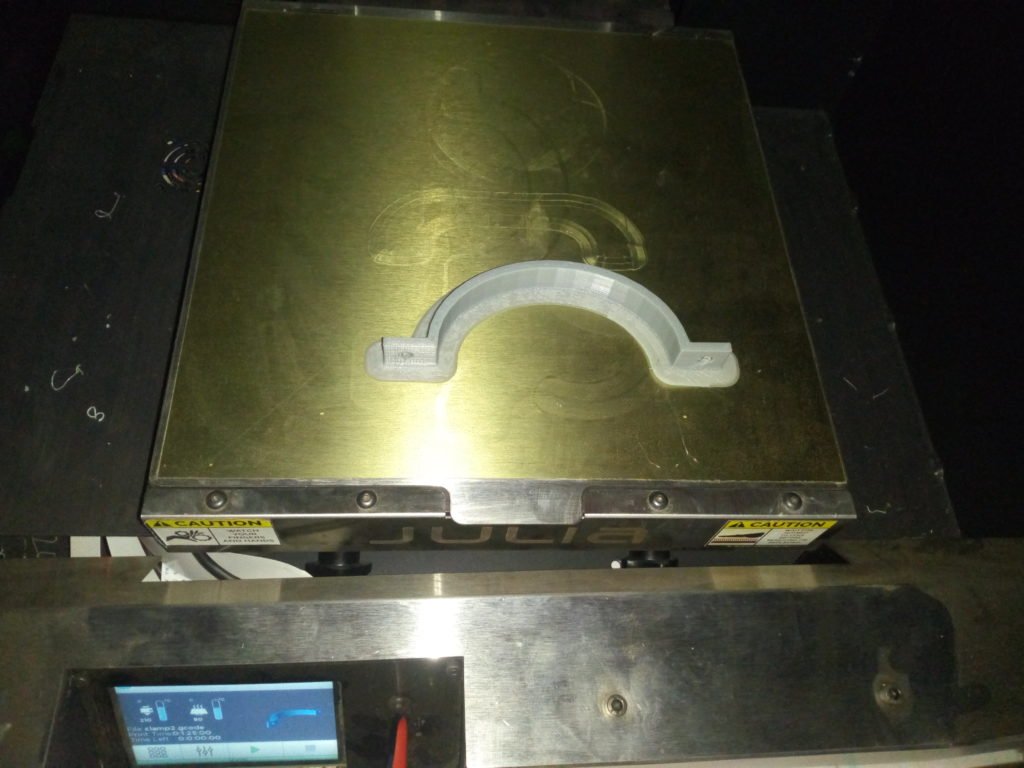

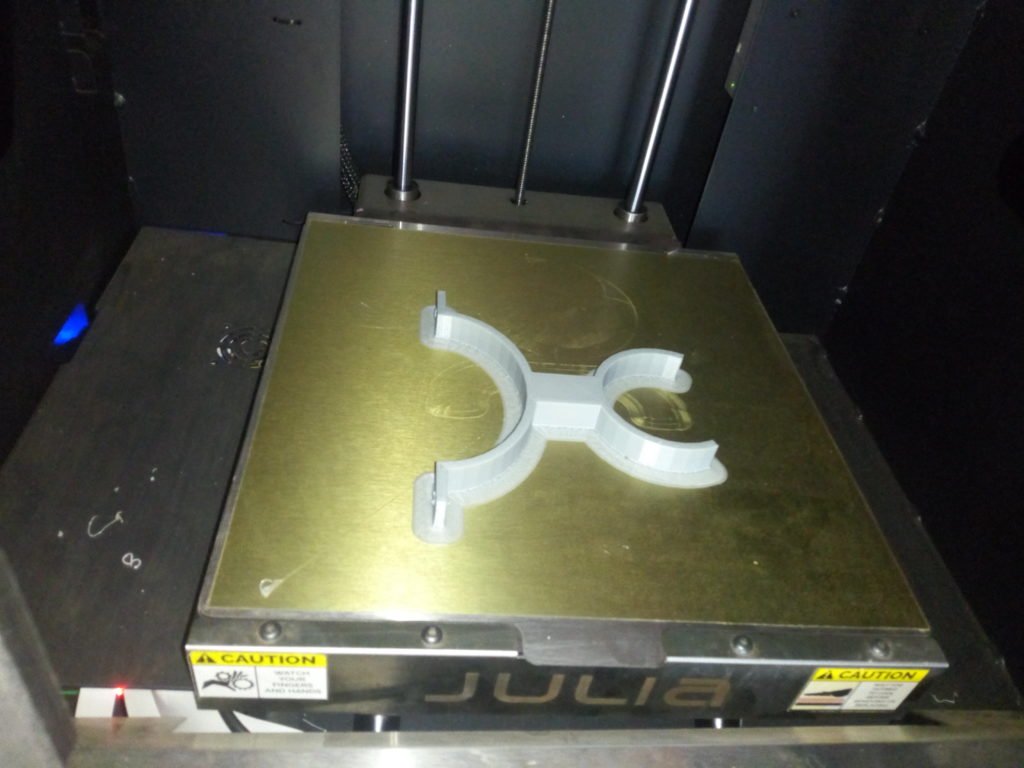

3-D Printing:-

The 3D printing process builds a three-dimensional object from a computer-aided design (CAD) model, usually by successively adding material layer by layer, which is why it is also called additive manufacturing, unlike conventional machining, casting and forging processes, where material is removed from a stock item (subtractive manufacturing) or poured into a mold and shaped by means of dies, presses, and hammers.

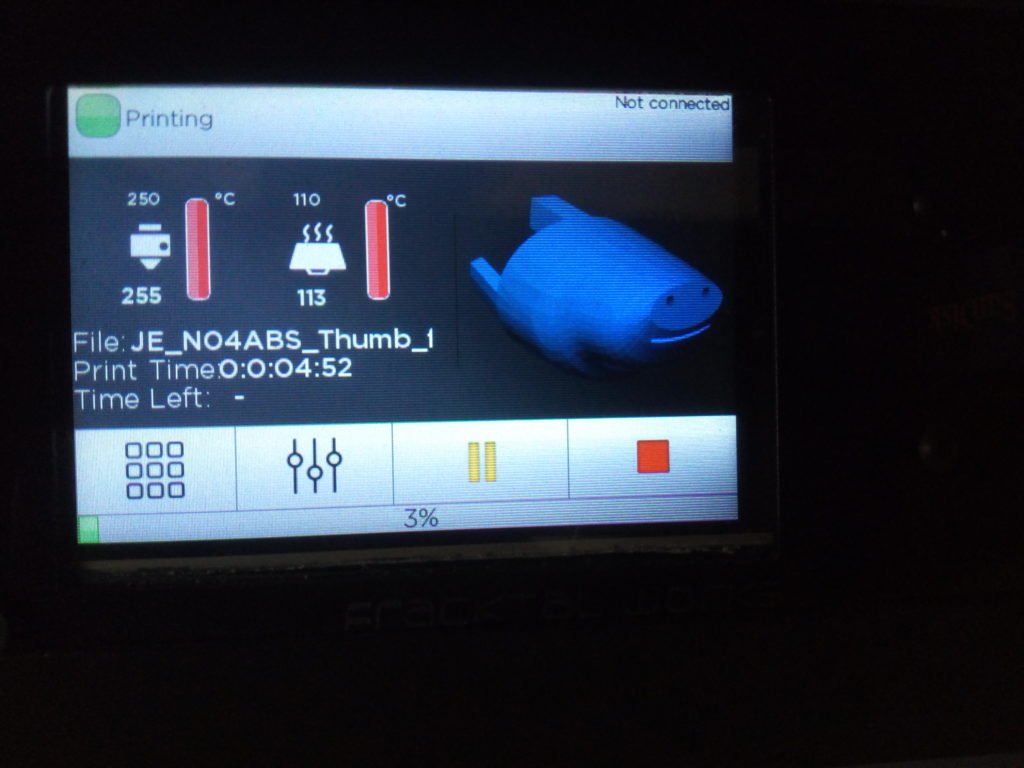

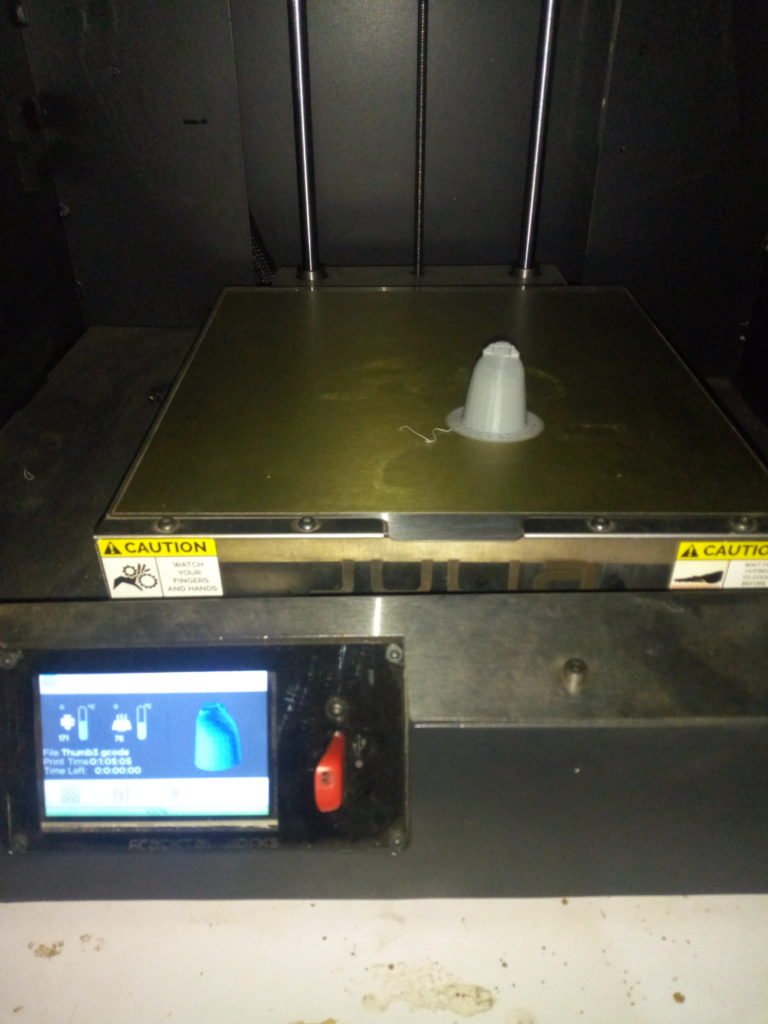

It is not feasible to cast the blade in rubber that’s why we chose the option of 3-D printing. The material used for making the prototype was ABS(Acrylonitrile Butadiene Styrene). The temperature of bed was set at 74 0c and that of the nozzle was 215 0c. The display of printer looks like-

Process of printing:-

Prototype after printing:-

Testing:-

Problems in 1st prototype

- thickness is more

- heaviness

- not fit in thumb

- not easy to operable

suggestions

- It should fit in everyones thumb

- reduce thickness

- design should be more flexible

- It should be operable

Prototype 2

3-D Printing:-

Testing:-

As per the suggestions by the DIC members and others the second prototype was designed, here are some problems we faced at second prototype

Problems in 2nd prototype

- thickness became very low

- blade cant inserted because of low thickness

- wrong blade positions

Suggestions

- slightly increase in thickness

- blade material should be stainless steel

- blade position should be slight upper

Third prototype:-

3-D Printing:-

Testing:-

With the third prototype we had observed that cutting the stalk of the chili was easy and operable. All the problems in the 2nd prototype eliminated here. It was fit in thumb easily, blade position also correct. Hence we decided to carry out experiment with third prototype.

Testing with collecting mechanism

The material we selected was a PVC pipe to convey the chilies to the collecting bag. The chilies can easily travel through the pipe hence we decided to test with the pipe. Though this was not our last material but it was easily available at that time thats why we run with pipe.

Collection Mechanism:-

- Cutting mechanism was then finalized by discussing with Amol sir. Now its time to collect those chilies which are cut.

- Our main objective was to reduce the cycle time required to pick and collect the chilies.

- Hence when the chilies got cut they will fall on bowl like structure which is fitted on the pipe collection system with the help of clamp and holder mechanism.

- The chilies will travel through this pipe and get collected into the bag which is on the back of the worker or anyone who want to collect the chilies. Overall system sketch is shown below.

Ideation of Collection system:-

When i was assigned to this project i considered in my mind that i had to make a harvester for chili picking and i am unable to think in proper way. Then some discussion with members at Vigyan Ashram I got the direction for how to start the project thinking. I have to consider the small things that I prefer to ignore earlier. I got the idea of collection system due to our main objective which to reduce the cycle time required to collect the chilies. Normal picking required picking, holding the chilies in hand and then put in the box. To reduce such tasks me and Amol sir decided to focus only on cutting mechanism. In the whole process the only operation is to cut the chilies there is no need to hold and put them in box. Hence we arrived at conclusion that the main problem was to cut the chilies and hold them in hand, hence we decided to reduce time by mechanism explained above. The following photos shows that how with the basic ideas we start.

With the above experiment we decided to use the PVC pipe for collecting the chilies or it act as medium of travel (path of travel) for chilies. And for holding the pipe we must have something that holds the pipe inline with the hand position. Hence we decided to 3-D print the clamp and holder.

Clamp and Holder 3-D printing:-

Process of printing:-

Conclusion:-

From the above study we can say that the time required for the picking and collecting the chili pepper will be surely reduced as compared to the traditional method.

The proposed equipment which consists of cutting mechanism i.e. thumb cutter for chili cutting and conveying system (PVC pipe with clamp and holder) and collecting bag will helpful for picking chilies in less time which ensures the timeliness of operation.