22/07/2025

Introduction

At Vigyan Ashram, we work on making machines that help with traditional food processing. Right now, I’m working on fixing and improving the Ragi Roaster Machine. This machine is mainly used to roast flours and spices, especially ragi flour, which is an important ingredient for many healthy recipes.

Before the exhibition on the 29th and 30th, we took this machine back for maintenance to make sure it worked properly.

Problems We Found

When we checked the machine, we saw some problems:

- The electronic part that controls the motor wasn’t working well.

- The scraper (the part that stirs the flour) was not adjusted properly.

- Some parts of the machine had rust and needed cleaning and painting.

23/07/2025 To 25/07/2025

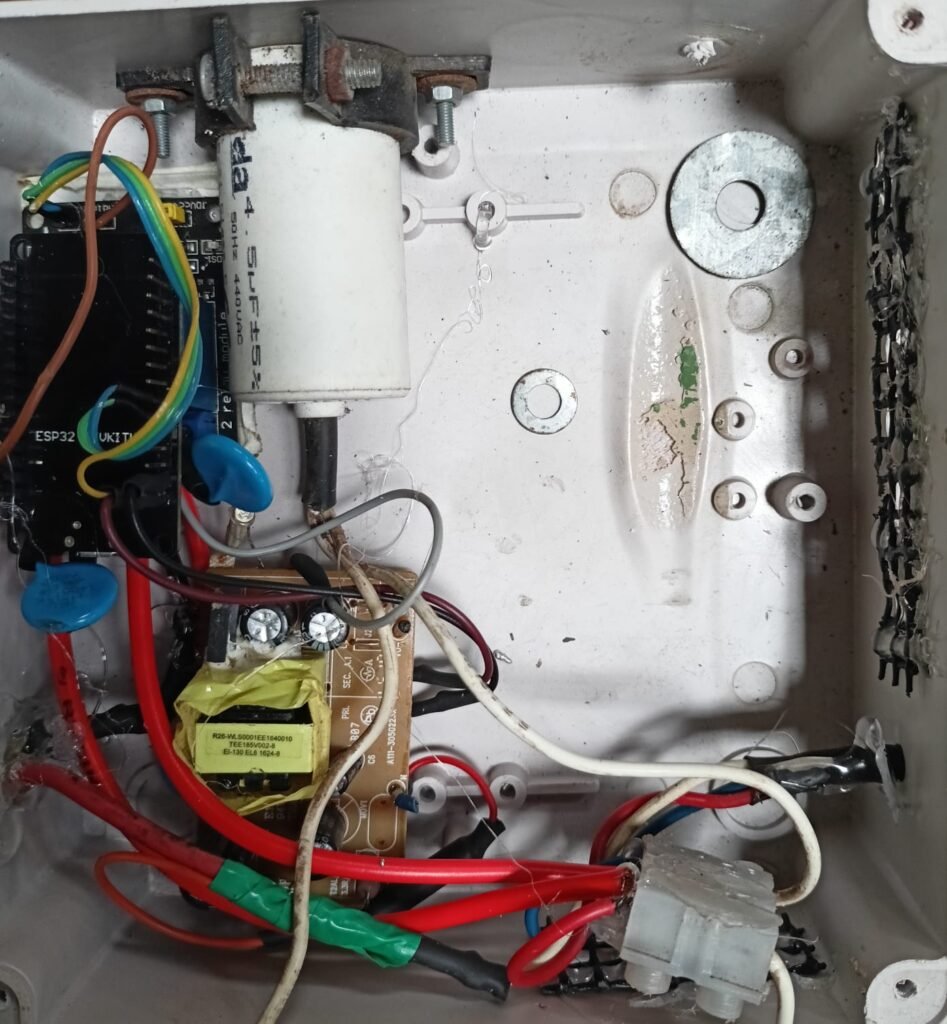

Step 1: Fixing the Electronics

We decided to build a new electronic system for the motor using an ESP32 microcontroller. This helped us control how the motor rotates better.The motor was programmed to turn clockwise twice, then stop for 10 seconds, and then turn anticlockwise once. This way, the flour roasts evenly.

This new setup worked well during the exhibition.

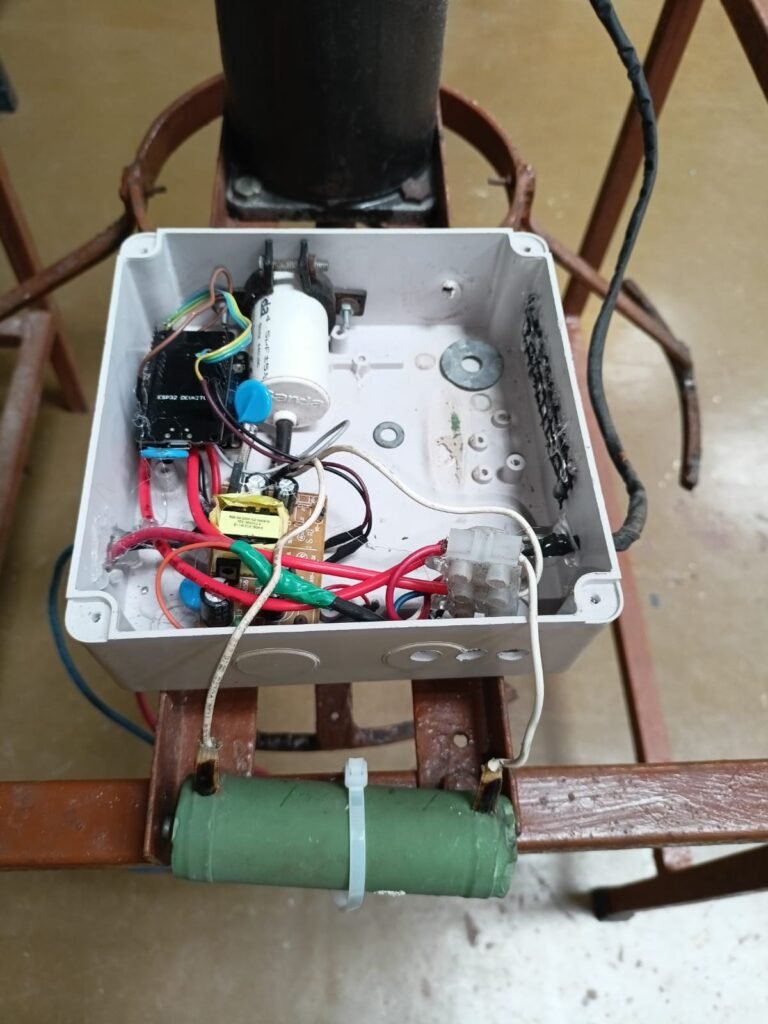

But after the exhibition, we noticed one resistor (a small electronic part) was getting very hot inside the machine’s box.To fix this, I moved the resistor outside the box so it could cool better in open air.

26/07/2025 to 28/07/2025

After fixing these issuses like electronic connection and and resister position we desided to take a actual trial .

Step 2: Testing with Ragi Flour and Scraper Issues

We tested the machine with 3 kg of ragi flour. We saw that because the amount of flour was small and there was some looseness (play) between the motor shaft and the scraper, flour was spilling out during the rotation changes.

I tried fixing this looseness by putting rubber around the motor shaft. It worked for a while but then the rubber tore and the problem came back.

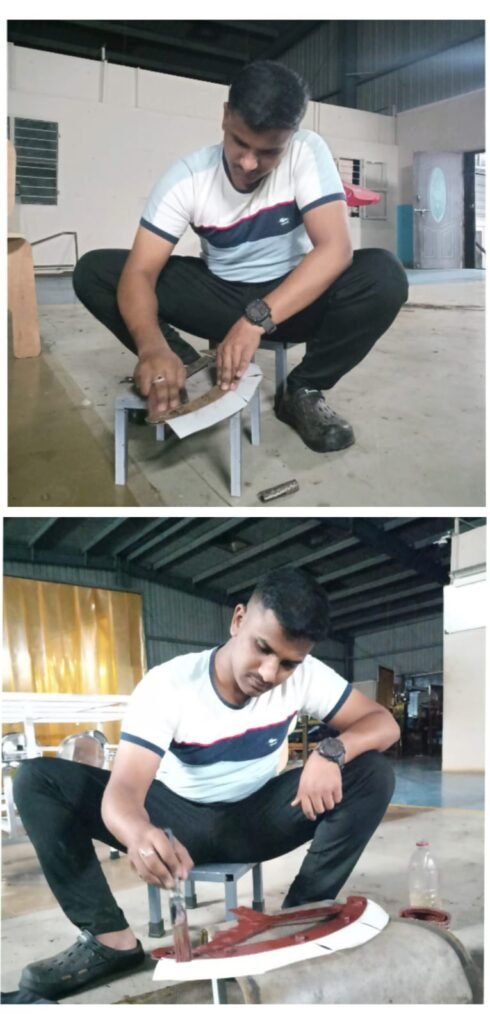

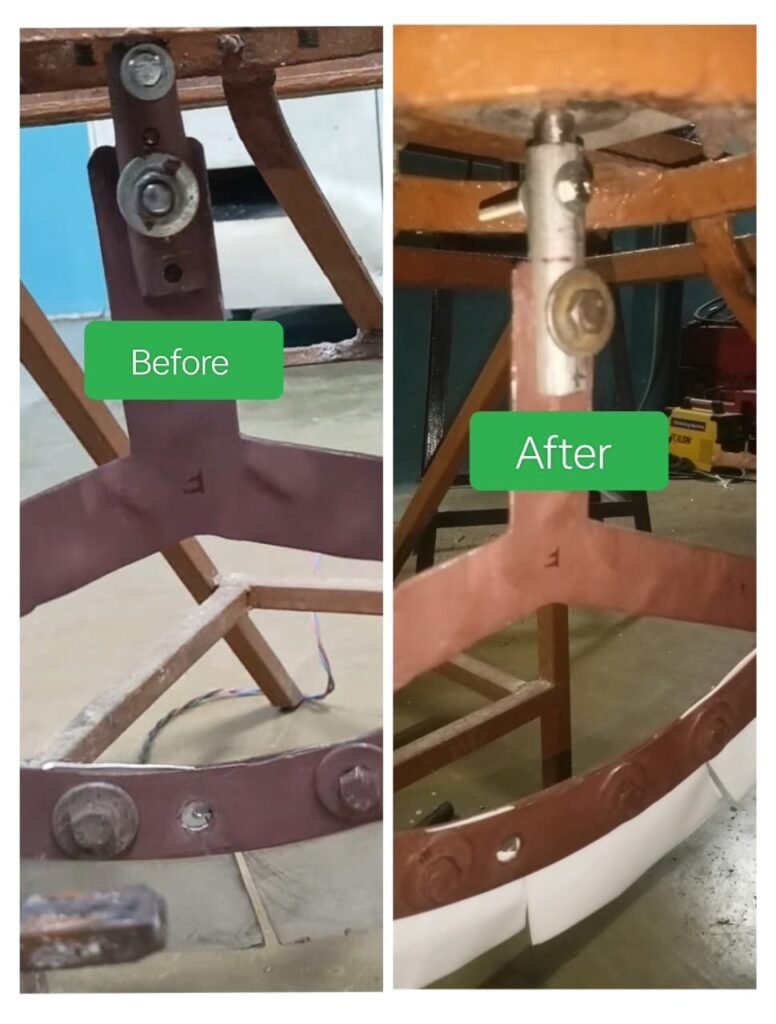

After these trial for exhibition we have to colour the scraper with removal of all rusted part on these scraper so for that I remove the scraper and rubed with polish paper and colour it with red-oxide .

01/08/2025

After exhibition I again work on these project to adjust the height of scraper so according requirement I mark the scraper and cut the parts according to requirement . For better performance and working efficiency and reduce the play in the scraper

Step 3: Changing Scraper Material

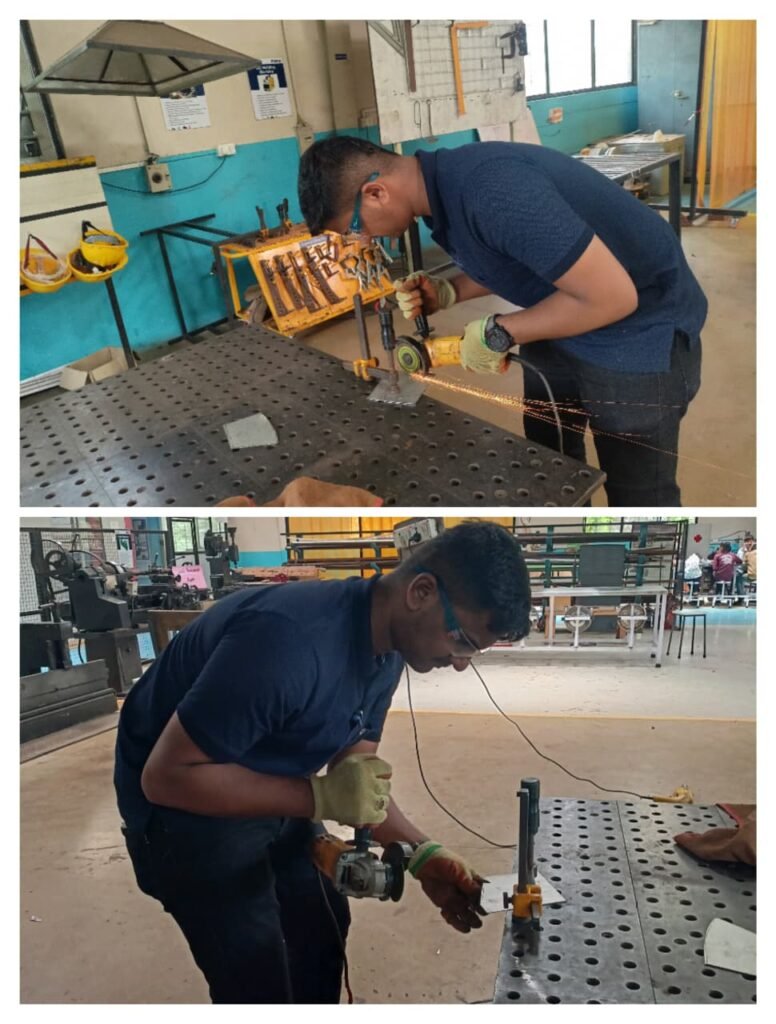

Following advice from Abhijit Sir, I replaced the scraper’s Teflon material with a stainless steel (SS) sheet of the same size.Because I think that due to single teflon the flour was spilling out during the rotation and I notised that the teflon was get bend and that is reason we desided to change the scraper material from teflon to SS sheet because these SS sheets are hard (not easily get bend)and having long life line then teflon. Then I cut SS sheet in same size of teflon making drills with the help of Akshay sir and again attach these scraper to the machine

I take a ramdom trials with these scraper having SS metal sheet but due to hard and non flexible material motor having some issues like carring load and the hard SS scraper scratched the roasting vessel (kadhae)

Then I desided to change the SS metal scraper from regular teflon meterial but these time I desided to increses the thickness of teflon material so for that I take another teflon material and attach these with previous one so one cut part of teflon consist two teflon pieces it make a scraper more effictive because the teflon not get bend during rotation and even spreading of flour is possible with that .But now I have to work on play issuse with scraper and motor shaft.Because it also affect the eficiency and losses .

02/08/2025 to 05/08/2025

Step 4: Finding a Permanent Solution for Looseness

I tried using tapes and threads to fix the looseness but these were temporary and didn’t last long.

So, I decided to change how the scraper attaches to the motor shaft.

I searched for a bar that fits tightly on the motor shaft to reduce the play completely.

06/082025 to 08/08/2025

Then I got a pipe which is fit to the motor shaft and it can help to reduce the play in motar shaft and scraper , after that I start to work on it . Firstly I take all reading on it like drill position and height of scraper attachment and after that with the help of Akshay sir I make a same part from these pipe like scraper attachment and we fit these to the motar shaft and we check that there is play occurs . But due to fit fitting the losses are negligible

After fitting these scraper adjustment we take another trial on these machine with groundnuts

During these trial the quantity of these trial – around 3 kg

Result of these trial is as follows

Losses occurs – very minute / negligible

Rosting – even with proper rotation

Trial with new adjustment – 01

11/08/2025

Final Trial with Suji in Kitchen

After completing all the setup and adjustments, I decided to test the machine in our Vigyan Ashram kitchen along with our staff mavshis (the ladies who prepare our daily meals).

This time, instead of ragi flour, we used 4 kg of suji , since it was required for the next day’s breakfast (upma).

The trial went well and the machine roasted the suji properly. It was a very practical test because the suji roasted in the machine was directly used in our kitchen, which gave us immediate feedback from the people who actually cook and serve the food.

This trial also showed that the machine can be useful not only for flour and masala roasting but also for regular kitchen needs like suji, making it a multipurpose food processing tool.

Results of Kitchen Trial with Suji

Quantity used for trial: 4 kg suji

Roasting quality: Even and good quality roasting throughout the batch

Time taken: 35 minutes for 4 kg

The trial showed that the machine is capable of roasting larger quantities evenly, and the roasted suji was directly used for preparing upma in our kitchen the next day.