Introduction

The need for alternate energy source has been increased during last two decades due to concerns about environmental impacts of fossil fuels, their finite nature and their price. Biomass stands out as a potential solution due to its renewable nature and carbon neutral properties. Biomass utilization methods have evolved significantly over time, transitioning from traditional uses in cooking and heating to sophisticated technology driven process with its potential to reduce greenhouse gas emissions, promote waste management, mitigating climate change impacts and offering range of products from electricity to heat and biofuels and biochemicals. Biomass stands out as a sustainable energy source, promising a greener environment. alternative energies nowadays have to be more competitive than energy derived from fossil fuels. The amount of biomass used to provide industrial heat, power, and biofuels is continuously rising. Bioenergy is the main source of renewable energy in the world accounting to nearly 9.6% of total energy and 71.1% of total renewable energy.

Biomass is an important source of renewable energy because it is widely available, Carbon neutral, capable of providing firm energy and generating significant employment in rural areas. About 32 percent of total primary energy used in the country is still derived from biomass and more than 70 percent of the country’s population depends upon it for their energy needs. Biomass is most commonly used energy source of several small-scale industries and is used as a fuel source for independent power plants. Biomass materials used for power generation include sugarcane, bagasse, rice husk, straw, cotton, coconut shells, saw dust etc. As per MNRE assessment conducted between 2002-2004, available biomass estimated was about 500 million metric tonnes. The surplus biomass availability was estimated at about 120-150 MMT covering agricultural and forestry residues.

It is projected that by 2050, about 905 of the world’s population will reside in developing nations, underscoring the critical need for sustainable biomass processed in these regions. Upgrading biomass technologies for more efficient production and conversion stands as a potential direction for its use in these developing areas.

Bioenergy

Bioenergy is the main source of renewable energy in the world accounting to nearly 9.6% of total energy and 71.1% of total renewable energy. Biofuel is defined as “liquid, solid, or gaseous fuel produced by conversion of biomass such as bioethanol from sugar cane or corn, charcoal or woodchips, and biogas from anaerobic decomposition of wastes. Renewables make up 22% of total energy supply in India in 2019[3]. The renewable energy share in final energy consumption is 31%. Around 85% of renewable energy is from biomass. Bioenergy is increasingly receiving attention globally due to the advantages it offers over fossil forms of energy. However, there are certain issues related to the overall acceptability of bioenergy, as one of the major components of the energy mix, which continue to arise. These include the high cost of bioenergy production, unavailability of feedstocks, energy return on energy investment (EROI), GHG balance, water footprint, nutrient demand, competition for land, etc [4].

Pyrolysis

Among biomass-to-liquid fuel conversion techniques, pyrolysis of biomass appears to have large-scale production potential and could possibly displace liquid fossil fuels. Pyrolysis subjects biomass to temperatures of about 300–700o C in the absence of air to produce syngas, bio-oil and charcoal. The relative yield of syngas, bio-oil and charcoal can be controlled by varying the pyrolysis conditions.

𝐵𝑖𝑜𝑚𝑎𝑠𝑠 → 𝐻2 + 𝐶𝑂 + 𝐶𝑂2 + 𝐶𝐻4 + 𝐻2𝑂 + 𝑇𝑎𝑟 + 𝐶ℎ𝑎𝑟

Research Objectives

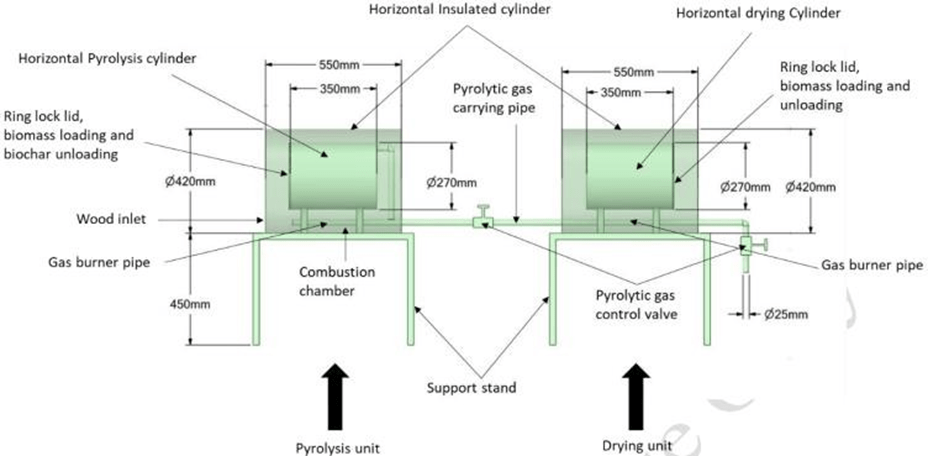

This research aims to develop a small-scale setup for Biochar production using pyrolysis process. This research also aims to maximize biochar production and increase overall energy efficiency of the process. The auto-pyrolysis setup has 2 horizontal cylinders in which biomass is fed, initially energy is provided to one cylinder, as the gases start to release, they are rerouted below the cylinder and ignited. Due to this, external requirement of energy is eliminated and efficiency increases.

Other than this, aim of this research to develop such a setup that is easy to handle and can be used by everyone with or without technical background.

Material and methods

Apart from a conventional pyrolysis setup, this setup consists of two units, one for pyrolysis of biomass and the other one for drying of biomass feedstock. Initially both the units are filled with biomass. Ignition is provided to the pyrolysis unit to initiate the reaction. After some time, moisture escapes using the vent provided. As the pyrolysis proceeds, pyrolytic gases start to form, which are redirected using a recirculation pipe provided. This pipe joins both the units, a valve is installed to adjust the gas flowrate. Initially the valve is kept off and all the gas is directed towards the pyrolysis unit and is ignited to provide heat for further process.

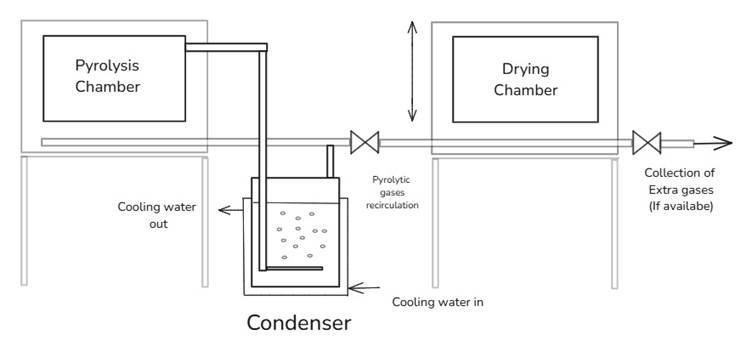

After some time, it is able to visualize that there is some extra amount of gas which is not required to burn for pyrolysis. These extra gases are directed to drying unit by turning valve on to be used for drying of biomass feedstock. The advantage of recirculating the pyrolytic gases is that there is no need to provide an external heat source to carry out the whole process apart from the heat provided to initiate pyrolysis. The implementation of this preheating and drying unit offers a two-fold benefit: it not only utilizes the previously wasted gases but also contributes to an increase in biochar yield.

Condenser installation

During the total process pyrolytic vapours are released, these vapours contain condensable and non-condensable part. Non- condensable vapours include majorly synthesis gas which flow smoothly through pipes to the nozzles where the are ignited to continue pyrolysis.

Condensable vapours contain a small part of moisture and a large chunk of bio-oil vapours. These vapours are acidic and corrosive in nature which causes degradation of material. If these vapours condense in the pipes they clog the pipes, elbows, valves as bio-oil is very crude and viscous thus blocking the flow for next batch.

To resolve this issue, a direct contact condenser is installed to condense bio-oil vapours so it will not cause any problem to the setup and the Process

Figure 1 Auto pyrolysis setup

Figure 2 Modified Auto pyrolysis setup