12/03/2025 – 14/03/2025

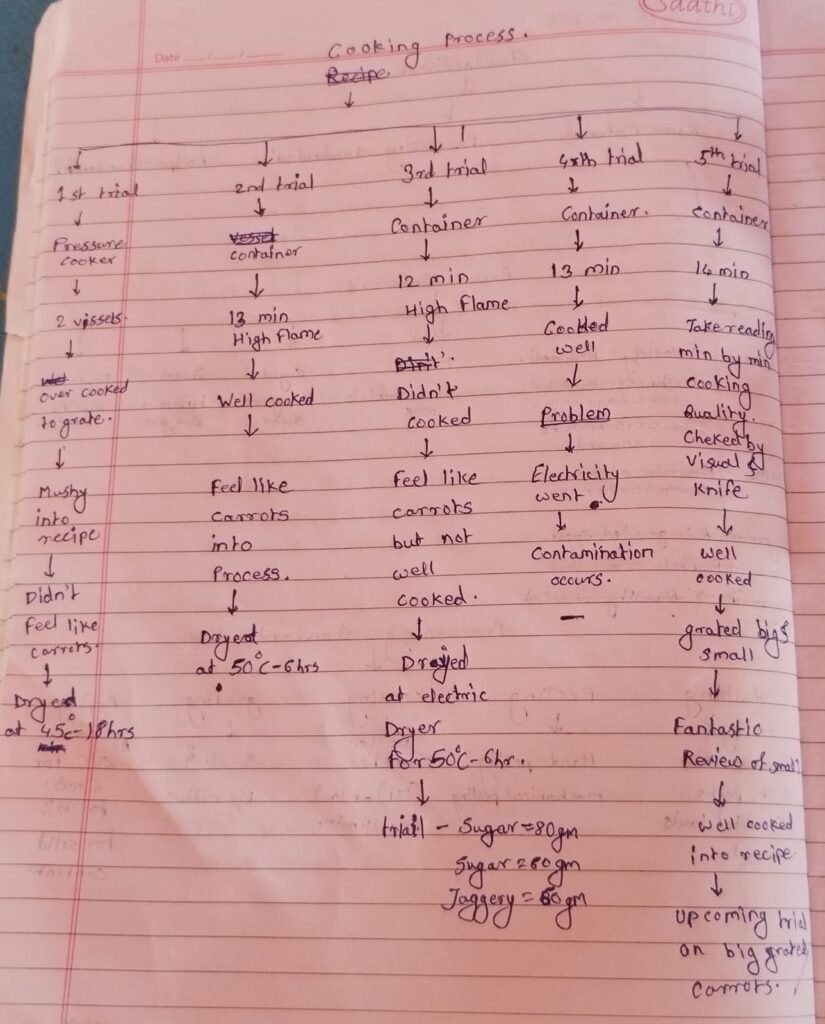

Instant Gajar Halwa Premix: My Journey at Vigyan Ashram

Introduction

Hi everyone! I’m excited to share my journey of working on an Instant Gajar Halwa Premix at Vigyan Ashram, Pabal. Under the guidance of Dixit Sir and for Tushar Kukreja Sir, I have been developing a convenient and tasty way to enjoy Gajar Halwa without the long preparation time. This project has been a fantastic learning experience, and I’d love to tell you all about it!

What is Instant Gajar Halwa Premix?

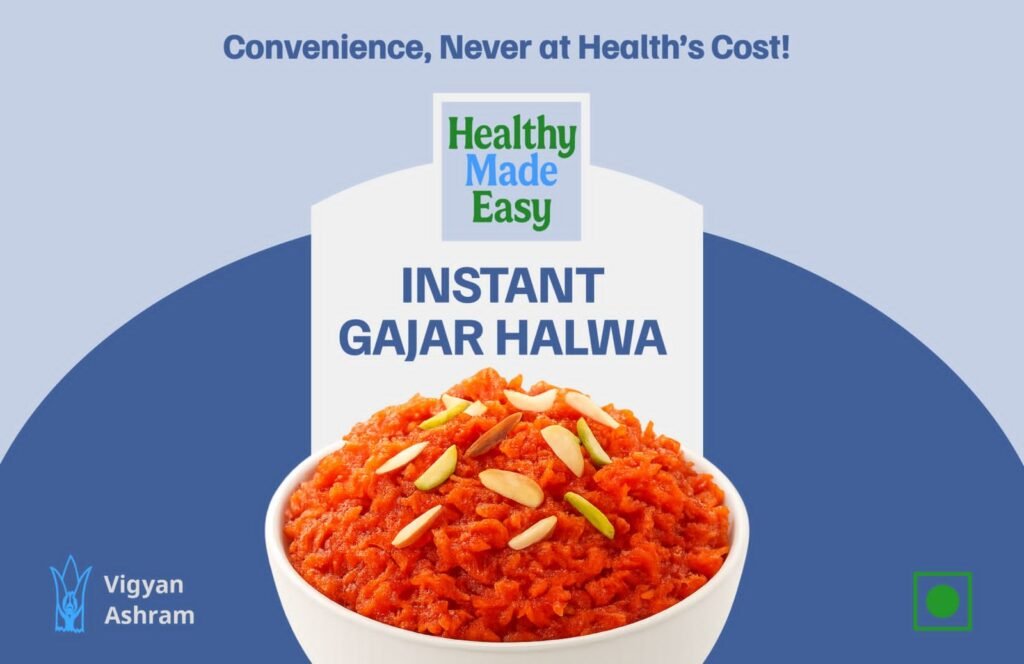

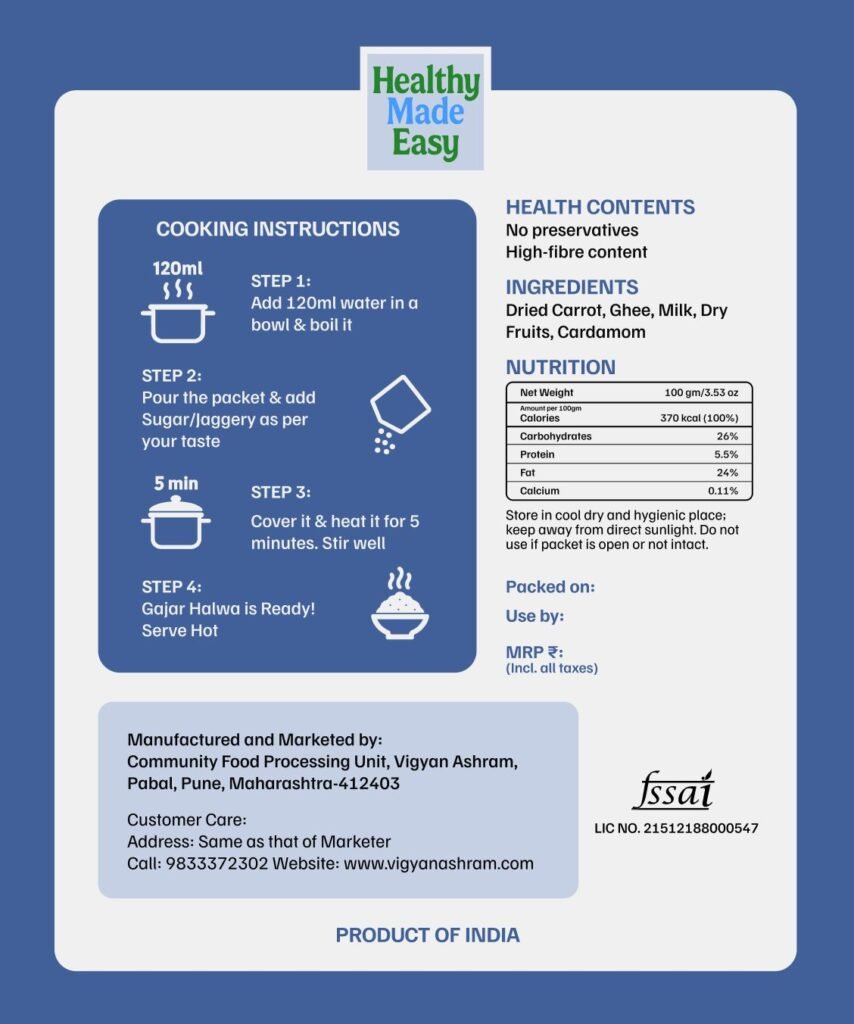

The Instant Gajar Halwa Premix is a ready-to-use mix that makes it super easy to prepare delicious Gajar Halwa in minutes. Just add milk or water, heat it up, and enjoy! The goal is to make this beloved dessert more accessible while keeping its authentic taste intact.

Why it is Important?

- Convenience: No more long hours of grating carrots and slow cooking.

- Long Shelf Life: It stays fresh for a long time without preservatives.

- Nutritional Value: Maintains the goodness of carrots, milk solids, and dry fruits.

- Market Demand: Instant and ready-to-eat foods are becoming increasingly popular, making this a promising idea.

Process & Challenges

Creating this premix wasn’t as easy as I first thought! Here’s what went into it:

- Ingredient Selection: Finding the best quality carrots, milk solids, sugar, and ghee.

- Drying & Processing: Testing different methods to dry the carrots while keeping their colour and nutrients.

- Taste & Texture Optimization: Balancing the flavours to get that rich, authentic taste.

- Shelf-Life Testing: Making sure the product stays fresh for a long time.

One of the biggest challenges was moisture control, as carrots have a lot of water content. I had to experiment with different drying techniques to keep the natural colour and flavour of the halwa intact.

Learnings & Experience

This project has taught me so much! I’ve gained hands-on experience in:

- Food processing and preservation methods.

- Nutritional analysis and ingredient selection.

- Problem-solving when dealing with real-world food production challenges.

- The importance of mentorship – a huge thanks to Dixit Sir and Tushar Kukreja Sir for their guidance!

Future Scope

I believe this premix has great potential beyond just personal use. It could be sold in:

- Ready-to-eat food segments.

- Grocery stores and online marketplaces.

- Export markets for Indian sweets.

There’s still room for improvement – I’d love to explore different flavours, a sugar-free version, and better packaging for extended shelf life.

Conclusion

Working on this project has been an exciting journey full of learning and innovation. It feels amazing to combine tradition with convenience, making Gajar Halwa more accessible in today’s fast-paced world. I’m looking forward to refining this product further and seeing where it goes!

These are the things that I focus on the most during practice .

17/03/2025

Raw Material inspection :-

Parameter:

1) Freshness – high in freshness – means that carrots is very fresh, clean, and in its best natural state—recently made, harvested, or prepared, and not stale or spoiled.

2) Size -Big in size – means that the carrots are larger than average—thicker, longer, or heavier compared to regular carrots.

3) Colour – carrots are, Red orange in colour, means the carrots has a eye-catching shade that is a mix of orange and red—like a deep sunset or a ripe tomato.

Standard :

1) Bright orange orange Red in colour – means the carrots has a eye-catching shade that is a mix of orange and red—like a deep sunset or a ripe tomato.

2) Firm in texture – means that carrots feels solid and slightly resistant when touched or pressed. It’s not too soft or squishy, nor is it hard like actual form —just nicely solid and holds its shape well.

3) Free from mould or rot – means that carrots (usually food or organic material) is clean, fresh, and not spoiled. It shows no signs of decay, fungus, or damage caused by bacteria or age

Control Method :

Go through visual inspection & Supplier quality check – Our ingredients pass a supplier quality check before reaching our production unit.

Pre – washing : ( Blanching )

Parameters :

- Dirt – Remove dirt , dust , mud – means cleaning the product (like carrots) to make sure it’s free from any unwanted natural particles that stick during harvesting or handling.

- Pesticides – Remove pests from it – Washing or treating the product to get rid of any harmful chemicals (pesticides) that may have been used during farming to kill pests.

Standards :

- Wash – wash into potable water or spray the water on to it.

Peeling Method :

Type of peeling :

- Manual peeling (small scale) – use of vegetable peeler

- Mechanical peeling (large scale) – use of Abrasive peeling , use of steam peeling

Process Parameters :

- Peeling time – 30-60 sec in machine

- Blade condition – Sharp, clean, rust-free in manual peeling

Post peeling washing :

Objective – Remove the residual peel and debris .

Waste Management :

Peel utilization – Composting , animal feed or bio gas generation

Cooking process control :

Traditional cooking ( batch process)

- Cooking media – Potable water

- Temperature – 100 – 102 Degree cel ( maintain the temperature )

Water to carrot ratio :

- 1:1 ratio ( equal the wt. in kg or lit )

- PH maintained

Boiling Temperature and Time :

| Boiling Method | Temperature | Time | Purpose |

| Low heat simmering | 85-90 *C | 8-15 Min | Retains texture and nutrients |

| Full boil ( rolling boil ) | 90-100*C | 5-10 Min | Faster but too smooth |

| Steam boiling ( large scale ) | 121*C | 5-8 Min | Cooking with uniformly with less nutrient loss |

Key process checks :

- Uniformly cooking – Maintain the temperature

- Avoid overcooking – Over cooking carrots are became mushy / soften (trouble while slip)

- Drainage – Use immediate water draining to prevent water absorption after cooking .

Post – boiling process control :

- Cooling and draining – cool rapidly

- potable water to cool it to stop further cooking

- drain water

- moisture content at level 80% of it .

| Parameter | Acceptable range |

| Colour | Bright orange |

| Texture | Soft but not mushy |

| Moisture content | Below 70% after boiling |

| Microbial load | Within food safety limits ( 0.5 – 0.9 % ) |

18/03/2025

I conduct the 1st SET –

SET NO. -01 Step-by-Step Process

1. Preparing the Carrots

- First, I took fresh carrots and washed them in cold water to remove dirt and impurities.

- Then, I removed the excess parts and peeled them properly. (10% of overall wt.)

2. Cooking the Carrots

- The peeled carrots were placed in a pressure cooker and boiled for two whistles to ensure proper cooking.

3. Drying Process

- After cooking, I drained the water and sliced the carrots.

- The sliced carrots were placed on a 4 sq. ft. drying tray.

- Each tray contained 1200g of boiled carrots.

- The dryer was set at 40°C for 18 hours to remove moisture.

- After drying, the final weight of the carrots was only 10% of the original mass.

This is the SET NO. -01

Initial wt. – 2000 gm

Waste wt. = 271 gm

Final wt. – 1729 gm ,

Process of set -01 :-

Utensils / Container :-

Pressure cooker, hand peeler, 2 container, Knife, cloths, Grating / slip machine.

INGREDIENTS :-

- Carrots

FLOW CHART :-

Take a container

↓

Peel 2 kg of cleaned carrots and wash it

After peeling, 1729 g of carrot is left

Waste = 271 g

↓

Wash the peeled carrots with water again

↓

Put the carrots in a pressure cooker (1:1 ratio of water to carrot)

↓

Cook in the pressure cooker on low flame for 28 minutes

↓

Let the pressure cooker cool down

↓

Wash the carrots again and grate them

↓

Put the grated carrots in an electric dryer for 18 hours

↓

Only 10% of the carrot weight remains after drying

↓

The dried carrots are ready for packaging

Colour is not changed after drying.

Final wt. = Initial wt. – waste wt.

Final wt. = 2000gm -271gm

Final wt. = 1729gm

19/03/2025

Recipe Set No. 01:-

INGREDIENTS :-

- Dry carrot – 25 gm

- Ghee – 3 gm

- Dry Fruits – 5 gm

- Cardamom Powder – 3 gm

- Milk – 150 ml

- Sugar – 40 gm

Flow Chart :-

I Heat 3 ml Ghee in a Pan

↓

After that I Add all ingredient & Mix Well

↓

I Pour 300 ml Milk & Stir it all

↓

I mix all

↓

I Add 4 gm Dry Fruits

↓

I Add 1 gm Cardamom Powder

↓

I Cook all the ingredients for 12 Minutes on Low Flame

↓

Instant Gajar Halwa is Ready

↓

Serve Hot & Enjoy!

Observation :-

After the testing the recipe here are the observations i conduct ,

- The aroma and the flavour of the halwa is fabulous.

- Due to carrots are over cooked into the pressure cooker the halwa gets mushy and very soft .

- It doesn’t feels like carrots were eaten.

- overall instant gajar halwa was good in taste.

Reviews / Sensory Evaluation :-

DIXIT SIR :-

- Colour and appearance was good.

- Dryness and texture is uniform.

- Smooth and soft in texture.

- Aroma of ghee and cardamom powder is like extremely.

- Sweetness is like extremely.

- Solid milk (khova) is balanced properly.

- Overall acceptability was like extremely.

Kulkarni sir :-

- The color and appearance were appealing.

- The dryness and texture were consistent.

- It had a smooth and soft texture.

- The aroma of ghee and cardamom powder was highly noticeable.

- The sweetness was well-pronounced.

- The solid milk (khova) was well-balanced.

- The overall acceptability was excellent.

Abhijeet sir :-

- He is not satisfied with the gajar halwa.

- Texture is too smooth, Due to carrots are over cooked into the pressure cooker the halwa gets mushy and very soft.

- The moisture content is high.

- It doesn’t feels like carrots were eaten.

- The overall acceptability is like slightly.

Mahesh sir :-

- He is also confused about texture and taste.

- It’s very soft and mushy.

- Moisture content is also high.

- Texture is soft.

- Aroma of ghee and cardamom was good.

- Overall acceptability is good.

Pranit Kamble :-

- Sweetness is good.

- Satisfied with the texture , aroma , moisture content and taste.

- Overall acceptability was good.

Shivanjali :-

- The sweetness is good.

- The texture, aroma, moisture content, and taste are satisfactory.

- Overall, it is acceptable.

HEDONIC TEST / HEDONIC RATING :-

| Hedonic test | Rating |

| Dislike Extremely | 01 |

| Dislike very much | 02 |

| Dislike moderate | 03 |

| Dislike Slightly | 04 |

| Neither like nor dislike | 05 |

| like slightly | 06 |

| like moderately | 07 |

| like very much | 08 |

| like Extremely | 09 |

Sensory Evaluation / Hedonic Test :-

| PARAMETERS / | NAMES | RATING | ||

| TEST | DIXIT SIR | KULKARNI SIR | ABHIJEET SIR | MAHESH SIR |

| Texture | 8 | 8 | 5 | 6 |

| Dryness | 8 | 8 | 3 | 5 |

| Softness | 9 | 8 | 4 | 4 |

| Aroma | 9 | 9 | 4 | 8 |

| Sweetness | 9 | 9 | 5 | 7 |

| Colour ( Appearance) | 8 | 8 | 8 | 7 |

| Overall acceptability | 9 | 9 | 5 | 7 |

Learnings from My First Trial

- The drying process significantly reduces the weight of the carrots.

- Temperature and time play a crucial role in maintaining the quality.

- Further trials will help me improve the texture and colour of the dried carrots.

21/03/2025

I prepare the 2nd SET –

For 2nd trial Here i use carrots

Processing the Carrots

- Raw Material Preparation

- We started with 2000g of carrots.

- After peeling and cleaning, 269g of waste (about 13.45% of total weight) was recorded.

- This waste percentage helps in evaluating peeling efficiency and material utilization.

- Boiling Process

- A container was heated to 100°C, reaching the boiling point of water.

- The cleaned and chopped carrots were added and boiled for 13 minutes to achieve the desired softness.

- Following the Standard Process

- After boiling, we proceeded with the same steps as our previous trials, ensuring consistency in drying, grinding, and mixing with other ingredients for the premix.

Key Observations & Improvements

- Yield & Consistency: The final yield of the premix needs to be compared with previous batches to ensure uniform results.

- Texture & Colour: The boiling time and temperature affect the colour retention of carrots; maintaining a controlled process is crucial.u

- Waste Reduction: If waste percentage varies significantly across batches, adjustments in peeling and cutting methods can be explore

This is the SET NO. –02

- Final wt. = Initial wt. – waste wt.

- Final wt. = 2000gm -269gm

- Final wt. = 1731gm

Process of set -02 :-

Utensils / Container :-

Pressure cooker, hand peeler, 2 container, Knife, cloths, Grating / slip machine.

INGREDIENTS :-

Carrots .

STEP BY STEP :-

“I have carried out the following procedure.” :-

First i Weight the Carrots (2000 gm)

↓

I Remove Waste The waste weight is (269 gm)

↓

Place a container on the gas to Boil Carrots

↓

Carrots were boil for 13 Minutes at 100°C

↓

After that Cool the Carrots at Room Temperature

↓

After that all the carrots were grated in grate machine

↓

Spread Grated Carrots on Tray

↓

Dry Carrots at 55°C for 6 Hours

↓

Drying is done

↓

Ensure No Colour Change

↓

Dried Carrots Ready

Final wt. = Initial wt. – waste wt.

Final wt. = 2000gm -269gm

Final wt. = 1731gm

22/03/2025

“I have carried out the following procedure.” recipe set 02 :-

Recipe for Set No. – 02

INGREDIENTS :-

- Dry carrot – 25 gm

- Ghee – 4 gm

- Dry Fruits – 4 gm

- Cardamom Powder – 1.5 gm

- Milk – 150 ml

- Sugar – 40 gm

Flow Chart

I Heat 4 ml Ghee in a Pan

↓

After that I Add all ingredient & Mix Well

↓

I Pour 150ml Milk & Stir it all

↓

I mix all

↓

I Add 4 gm Dry Fruits

↓

I Add 1.5 gm Cardamom Powder

↓

I Cook all the ingredients for 12 Minutes on Low Flame

↓

Instant Gajar Halwa is Ready

Observation :-

After the testing the recipe here are the observations i conduct ,

- The aroma and the flavour of the halwa is fabulous.

- Due to carrots are over cooked into the pressure cooker the halwa gets mushy and very soft .

- It doesn’t feels like carrots were eaten.

- overall instant gajar halwa was good in taste.

Reviews / Sensory Evaluation :-

DIXIT SIR :-

- Colour and appearance was good.

- Dryness and texture is uniform.

- Smooth and soft in texture.

- Aroma of ghee and cardamom powder is like extremely.

- Sweetness is like extremely.

- Solid milk (khova) is balanced properly.

- Overall acceptability was like extremely.

Kulkarni sir :-

- The colour and appearance were appealing.

- The dryness and texture were consistent.

- It had a smooth and soft texture.

- The aroma of ghee and cardamom powder was highly noticeable.

- The sweetness was well-pronounced.

- The solid milk (khova) was well-balanced.

- The overall acceptability was excellent.

Abhijeet sir :-

- He is not satisfied with the gajar halwa.

- Texture is hard , Due to carrots are not cooked into the container the halwa gets hard to chew.

- The moisture content is high.

- It doesn’t feels like carrots were eaten.

- The overall acceptability is like slightly.

Pranit Kamble :-

- Sweetness is good.

- Satisfied with the texture , aroma , moisture content and taste.

- Overall acceptability was good.

Shubham sir :-

- The sweetness is good.

- The texture, aroma, moisture content, and taste are satisfactory.

- Overall, it is acceptable.

Mahesh sir :-

- He is also confused about texture and taste.

- It’s very soft and mushy.

- Moisture content is also high.

- Texture is soft.

- Aroma of ghee and cardamom was good.

- Overall acceptability is good.

They are the reviews that i conducts from the various peoples.

From that reviews these is the Hedonic Test Ratings

HEDONIC TEST / HEDONIC RATING :-

Sensory Evaluation / Hedonic Test :-

| PARAMETERS / | NAMES | RATING | ||

| TEST | DIXIT SIR | KULKARNI SIR | ABHIJEET SIR | MAHESH SIR |

| Texture | 8 | 8 | 5 | 6 |

| Dryness | 8 | 8 | 3 | 5 |

| Softness | 9 | 8 | 4 | 5 |

| Aroma | 9 | 9 | 4 | 8 |

| Sweetness | 9 | 9 | 5 | 6 |

| Colour ( Appearance) | 8 | 8 | 8 | 7 |

| Overall acceptability | 9 | 9 | 5 | 6 |

Learnings from My First Trial :-

Further trials will help me improve the texture and colour of the dried carrots. The drying process significantly reduces the weight of the carrots. Temperature and time play a crucial role in maintaining the quality.

23/03/2025

SET NO. -03

In the first trial, I made a fully cooked version of Gajar Halwa and then tried to dehydrate it. However, the texture and taste were not as expected after rehydration.

In the second trial, I focused on making a simpler and better formulation by dehydrating the individual ingredients separately (like carrots, khoya, etc.) and then mixing them. This gave a better result in terms of flavour and appearance.

Therefore, I selected the second trial method as the base for my final premix formulation.

Now, in the third trial, I am focusing on standardizing the ratios, improving taste, and testing shelf life. I am learning from each trial to improve the final product step by step.

Here i make a trial for process control :

- Initial carrot wt. – 5kg

- Waste – 700g

- Final wt. – 4300g

- Wt. after cooking – 4200g

- Boiling Water – 5lit

Process as it is follows :-

First i Weight the Carrots (2000 gm)

↓

I Remove Waste The waste weight is (269 gm)

↓

Place a container on the gas to Boil Carrots

↓

Carrots were boil for 13 Minutes at 100°C

↓

After that Cool the Carrots at Room Temperature

↓

After that all the carrots were grated in grate machine

↓

Spread Grated Carrots on Tray

↓

Dry Carrots at 55°C for 6 Hours

↓

Drying is done

↓

Ensure No Colour Change

↓

Dried Carrots Ready

Process controls for cooking :

Here is the readings of boiling water after adding the carrots:

| SR.NO | TIME (In minutes) | TEMPERATURE (In Degree Celsius) | TEXTURE |

| 1 | 1 | 96-99 | No change yet |

| 2 | 2 | 101 | Slight soft |

| 3 | 5 | 102 | Soft |

| 4 | 10-12 | 105 | Soft but not so mushy |

24/03/2025

Recipe for Set No. – 02:-01

INGREDIENTS :-

- Dry carrot – 25 gm

- Ghee – 4 gm

- Dry Fruits – 4 gm

- Cardamom Powder – 1gm

- Milk – 150 ml

- Sugar – 40 gm

Flow Chart

I Heat 4 ml Ghee in a Pan

↓

After that I Add all ingredient & Mix Well

↓

I Pour 150ml Milk & Stir it all

↓

I mix all

↓

I Add 4gm Dry Fruits

↓

I Add 1gm Cardamom Powder

↓

I Cook all the ingredients for 12 Minutes on Low Flame

↓

Instant Gajar Halwa is Ready

Observation :-

After the testing the recipe here are the observations i conduct ,

- The aroma and the flavour of the halwa is fabulous.

- Carrots are not cooked well.

- overall instant gajar halwa was good in taste.

- Proper sweeten in taste.

25/03/2025

Calculations of the heat required:

Specific Heat:

Q=MCΔT

Q=Heat energy (in joule or calory)

M= Mass of water(in kg)

C= Specific heat capacity of water (4.186J / g °C )

ΔT= Temperature change (in °C)

Here,

volume of water = 5lit

Density of water = 1kg / l , so mass = 5kg – 5000g

Temperature change (ΔT) = heating from 25°C to 100°C

ΔT = 100-25=75°C

Specific heat of water (C) = 4.186J / g °C

Q = (5000) × (4.186J / g °C ) × (75°C)

Q = 1570000 J OR 1.57 MJ (Mega joule)

LPG = 1.57MJ / 30MJ/KG

=0.0523kg

= 52.3gm

here we use commercial thats why the consumption of the LPG is twice

LPG per kg = 63Rs

=104.6× 0.063

=6.6 RS

here i calculate the specific heat we required in process is ”1.57MJ”

26/03/2025

After discussion with Dixit sir the product were parcel to Tushar Kukreja sir for tasting or review

3 packets of each SET NO 01 or 02 are parcel to Kukreja Sir to taste.

28/03/2025

I done the proper pre mix packet recipe of SET NO.-02

First i take a packet with mixed all ingredients

↓

Heat a pan on a low flame and add 8 ml of ghee.

↓

Add the entire packet of Instant Gajar Halwa Premix to the pan and stir gently.

↓

Pour in 300 ml of milk and mix well.

↓

Increase to medium flame and continue stirring for approximately 8 minutes.

↓

Allow the milk to evaporate completely, transforming it into khoya.

↓

Stir thoroughly for an additional 2 minutes to achieve the perfect consistency.

↓

Gajar Halwa Ready

Sensory Evaluation / Hedonic Test :-

| PARAMETERS / | NAMES | RATING | ||

| TEST | DIXIT SIR | KULKARNI SIR | ABHIJEET SIR | MAHESH SIR |

| Texture | 9 | 8 | 6 | 6 |

| Dryness | 9 | 8 | 6 | 5 |

| Softness | 9 | 8 | 4 | 5 |

| Aroma | 9 | 9 | 6 | 8 |

| Sweetness | 9 | 9 | 5 | 6 |

| Colour ( Appearance) | 9 | 8 | 8 | 7 |

| Overall acceptability | 9 | 9 | 5 | 6 |

29/03/2025

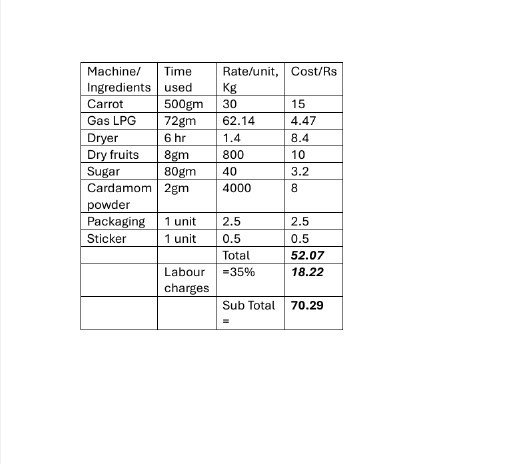

Here is the costing of 150g packet

31/03/2025 – 01/04/2025

The parcel reached Tushar Kukreja Sir today. They proceeded with testing the product and shared their feedback. According to their review, the sugar in the premix tends to caramelize, and the overall sugar content is on the higher side. They suggested using 60 grams of sugar per packet. Among the two samples provided, the first one was cooked perfectly, while the second one was not cooked consistently.

SET NO -01

Here are the pictures of the trail taken by the Tushar Kukreja Sir

Observations: (They process as it is i do for the recipe)

The sugar get caramelise,

The moisture contain is high,

Well cooked,

High content of the Sugar.

Observations: (They process as it is i do for the recipe) they do trail of this with put all the packets ingredient into direct to the milk

The sugar get caramelise,

The moisture contain is high,

Not properly cooked,

High content of the Sugar.

02/04/2025 – 05/04/2025

I have study the market, demand and other study.

This information i gather from online (website, social media)

The customer are attractive for this stuff,

Business study:-

For making the food business more successful in now day, here is the pillars of the food business

Food:-

- Convenience

- Health

- Nutraceutical

The crowd focus on this components. That’s why also we want to to focus on these components.

Convenience at Its Best:

No grating carrots. No boiling milk. No long cooking hours.

Just mix the premix with milk or hot water, stir for a few minutes, and your delicious halwa is ready! Whether you’re a student, a busy professional, or a sweet lover short on time—this is your perfect dessert solution.

Healthier Ingredients

We’ve carefully chosen every ingredient to make this halwa lighter and healthier:

- Sweetened with jaggery (or low sugar variants)

- Cooked in moderate desi ghee for that rich taste

- Made with real carrots and no artificial flavors

- Gluten-free and free from preservatives

Nutraceutical Boost

This isn’t just a sweet treat—it’s smart food!

We’ve added:

- Flaxseeds and dry fruits – rich in omega-3 and protein

- Vitamin A from carrots – for healthy skin and vision

Targeted customer:

1. Working Professionals & Busy Homemakers

- Needs: Quick dessert solutions with homemade taste.

- Why: They want to enjoy traditional sweets but don’t have time for long cooking processes.

2. Urban & Semi-Urban Consumers

- Needs: Ready-to-cook foods that taste authentic.

- Why: Often have higher disposable income and access to packaged food markets.

3. Students & Bachelors

- Needs: Easy-to-make comfort food.

- Why: They crave homemade sweets but may lack cooking skills or time.

4. NRIs / Indian Diaspora (people of Indian origin who reside outside of India, either temporarily or permanently)

- Needs: Traditional Indian flavour’s in a convenient form.

- Why: Gajar Halwa is a nostalgic dessert, and premix makes it accessible abroad.

5. Sweet Shop Owners / Food Businesses

- Needs: Consistent quality and time-saving dessert preparation.

- Why: They can use the premix to make bulk quantities quickly with minimal prep.

6. Tourists & Gift Buyers

- Needs: Authentic, ready-to-cook Indian food souvenirs.

- Why: Attractive packaging can appeal to gift buyers or those exploring Indian cuisine.

This type of customer will purchase our product.

Where do I sell the product:

Urban Supermarkets & Organic Stores:

- Why: Urban customers are looking for easy, healthy, and tasty options.

- Examples: D-Mart, Nature’s Basket, Big Bazaar, Organic India stores.

Online Platforms (E-commerce):

- Why: Perfect for reaching busy professionals, students, NRIs, and health-conscious buyers.

- Examples:

- Amazon, Flipkart, BigBasket – for mass reach.

- OneGreen, Qtrove, Satvic Movement Store – for health/natural product niche.

- Your own website using Shopify or Instamojo.

Specialty Food Stores / Sweet Shops

- Partner with sweet shops or halwai outlets to sell this as a ready-to-cook innovation.

- Pitch it as a festival special or a gift pack.

Airport Stores / Travel Retail

- Perfect for NRIs or tourists who want to take home a taste of India.

- Highlight long shelf life, no refrigeration, and easy preparation.

Local Exhibitions & Farmers’ Markets

- Especially useful for early feedback and building customer trust.

- Display live preparation demos to attract visitors.

Export Opportunities (NRIs & Indian Stores Abroad)

- Gajar Halwa is nostalgic and loved by Indians living abroad.

- Tie up with stores in USA, UK, UAE, Canada that stock Indian goods.

Who to Collaborate With

- Food influencers on Instagram/YouTube

- Cafes or food trucks for fusion dishes (e.g., Gajar Halwa shots or parfaits

- Nutritionists & health bloggers for product promotion

As this information i want to go on further days.

06/04/2025

I had a Review with the Prasad sir, Dixit sir, Abhijeet sir from that review i have edit my blog from that review i have clear to work on the gajar halwa cooking process standards in the upcoming further trail and days i have work on it, and done the costing of the dehydrated onion costing for Rudra and Rutika.

07/04/2025

I tried SET NO.04:-

Today i done the 4th trail

The process i done by before trails as it is, for cooking of the carrots.

I take a readings in between cooking, 1- 14 min readings of the Temp.

and observe the cooking steps of the carrots

Observation:

The carrots are cooked well for 14 min at 102°C,

I use the visual, touch and use knife to check the carrots are cooked or not,

The knife were pressed and if it is goes to the middle of the carrots very easily,

This is my observations for the cooking process.

| Time / Min | Temperature (°C) | Texture |

| 1 | 60 | No Change |

| 2 | 70 | No Change |

| 3 | 80 | No Change |

| 4 | 90 | No Change |

| 5 | 93 | No Change |

| 6 | 95.7 | No Change |

| 7 | 96 | Slightly soft from surface |

| 8 | 97 | Slightly soft from surface |

| 9 | 97.5 | Slightly soft from surface |

| 10 | 98 | Slightly soft from surface |

| 11 | 98.3 | Slightly soft from middle |

| 12 | 99 | Slightly soft from surface |

| 13 | 99.3 | All the parts are soft and well cooked |

| 14 | 102 | Cooked well |

Problem:

I put all the carrots into the electric dryer for drying, but after 2 hours, the electricity went off due to some issue. As a result, the dried carrots got contaminated due to moisture content.

Due to the power outage, the carrots didn’t dry properly and got spoiled because of the moisture, so I gave them to the chickens to eat.

08/04/2025

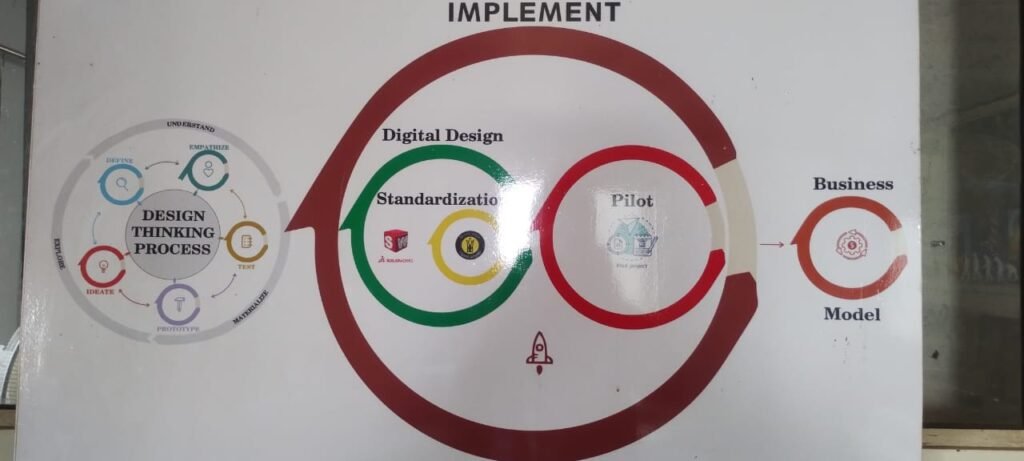

1. Empathize (Understand the Users)

Focus on who will use the premix and what their needs are.

- Target Users: Busy homemakers, working professionals, students, sweet shops, caterers, or anyone wanting traditional Gajar Halwa instantly.

- User Needs:

- Quick and easy preparation

- Authentic homemade taste

- Long shelf life

- No need to add many extra ingredients

- Affordable and hygienic

- Pain Points:

- Time-consuming to make halwa from scratch

- Seasonal availability of carrots

- Inconsistent taste

- Storage issues for fresh halwa

2. Define (Problem Statement)

Craft a clear problem statement based on the user’s needs.

“People love the taste of traditional Gajar Halwa but find it time-consuming and difficult to prepare, especially when carrots are not in season. There is a need for a ready-to-cook premix that delivers the same authentic flavor, texture, and aroma with minimal effort and a long shelf life.”

3. Ideate (Explore Solutions)

Brainstorm ideas that solve the defined problem.

- Use dehydrated grated carrots with ghee and khoya powder

- Add natural preservatives for shelf life (e.g. citric acid, vacuum sealing)

- Make it ready by just adding milk or water

- Offer in different packaging sizes (single-serve, family pack)

- Include jaggery or sugar variants for different preferences

- Use vacuum packing or nitrogen flushing to increase shelf life

- Add instructions in regional languages for rural users

4. Prototype (Build a Sample)

Create small-batch samples to bring the idea to life.

- Trial with different proportions of grated carrot, ghee, milk solids, sugar

- Experiment with dehydration techniques (solar dryer, hot air oven, etc.)

- Try packaging options: vacuum sealing, zip-lock pouches, etc.

- Label with branding, ingredients, cooking instructions

- Shelf-life testing under different conditions

5. Test (Get Feedback)

Test your prototype with real users and improve it based on feedback.

- Share with local users (staff, students, villagers, customers at Vigyan Ashram)

- Collect feedback on:

- Taste, texture, aroma

- Ease of preparation

- Packaging and instructions

- Shelf life and storage convenience

- Modify recipe or process based on what works best

I am at the first step of the my ‘Product Development’ Journey, Now i have to work on standardise and pilot the design of the product.

09/04/2025

Troubleshooting Dryer Issues:

At Vigyan Ashram, ensuring all equipment works smoothly is crucial for maintaining the quality of our food processing work. Recently, I encountered an issue with the dryer that was affecting our production process.

Initially, I observed that the dryer was not functioning properly. To identify the problem, I carried out a basic test and routine maintenance. Despite these efforts, the issue remained unresolved.

Upon closer inspection, I discovered that the root of the problem was the start button of the dryer. It was not functioning properly, which prevented the machine from starting or operating effectively. This small but critical fault was enough to halt the entire drying process.

I discussed the issue with Jadhav Sir to seek a possible solution. However, even after troubleshooting together, the dryer was still not working well. We tried different approaches, but the problem persisted.

This experience highlighted the importance of regular checks on not just the internal systems but also on basic controls like switches and buttons.

We are now exploring further repair options or replacements for the faulty start button to ensure the dryer can resume full functionality as soon as possible.

And parallelly i have done and help to the Akshay Nikam for doing solar dome dryer trail on onion.

11/04/2025

Tushar Kukreja Sir visited Vigyan Ashram to review and discuss the ongoing project details. His visit was an important opportunity for us to share our progress, challenges, and upcoming plans. We also discussed ways to improve efficiency and product quality in our current development projects. Overall, it was a learning experience that reinforced the value of teamwork, problem-solving, and expert guidance in practical work.

During this time, Tushar Kukreja Sir visited Vigyan Ashram to review and discuss our ongoing projects. His visit was a valuable opportunity to share our progress, discuss challenges, and gain feedback. The conversation helped us understand how to further improve our work and maintain quality in every step of the process.

Gajar Halwa Premix – New Trial Update

I also conducted another trial of the Instant Gajar Halwa Premix, repeating the method from my first trial with one key modification:

Sugar content was reduced from 40g to 30g.

This small change resulted in a well-balanced sweetness, and the overall taste and texture of the halwa turned out very nice. It’s exciting to see how small tweaks in formulation can improve the final product.

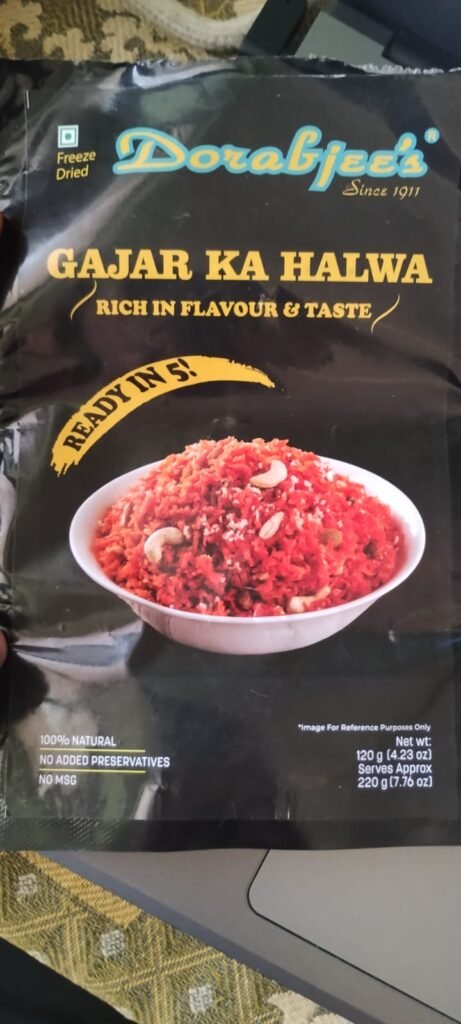

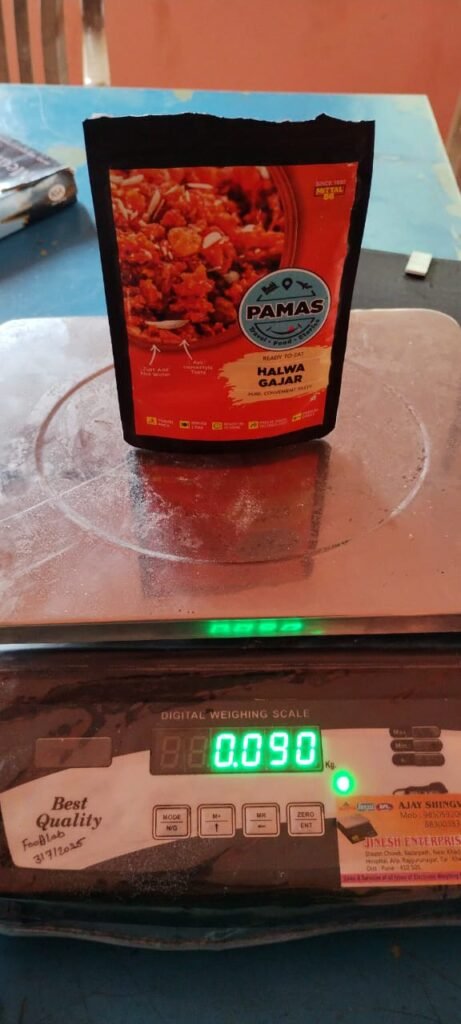

Comparison with Market Product

To evaluate our product better, I also tried the Ready-to-Eat Gajar Halwa from Dorabjee’s brand and compared it with our premix trial. This comparison helped me analyse differences in texture, flavour, sweetness, and aroma. While Dorabjee’s product is convenient and consistent, I found that our premix had a more traditional taste and fresher feel, especially with the reduced sugar.

I make this Dorabjee’s packet premix:-

Flow Chart:-

I Open the packet

↓

add 100ml boiled water into it

↓

after that i place it for 5 min and close the tin on it

↓

And the Dorabjee’s instant gajar halwa ready.

Sensory Evaluation / Hedonic Test :- For This two trail.

Vigyan Ashram trail:

Ours halwa have a high ghee

The texture was very good

The halwa looks like actual grated halwa

Taste was very good

Its looks like a Traditional Maharashtrian Halwa

Have dry fruits

| PARAMETERS / | NAMES | RATING | ||

| TEST | DIXIT SIR | KUKREJA SIR | ABHIJEET SIR | RANJEET SIR |

| Texture | 9 | 8 | 6 | 6 |

| Dryness | 9 | 8 | 6 | 5 |

| Softness | 9 | 8 | 4 | 5 |

| Aroma | 9 | 9 | 6 | 8 |

| Sweetness | 9 | 9 | 5 | 6 |

| Colour ( Appearance) | 9 | 8 | 8 | 7 |

| Overall acceptability | 9 | 9 | 5 | 6 |

Dorabjee’s trail:

Dorabjee’s halwa have a high ghee

The texture was not good

The halwa loose the water

Taste was not well

Its not looks like a Traditional Maharashtrian Halwa

Have no dry fruits

| PARAMETERS / | NAMES | RATING | ||

| TEST | DIXIT SIR | KUKREJA SIR | ABHIJEET SIR | RANJEET SIR |

| Texture | 7 | 5 | 4 | 5 |

| Dryness | 4 | 6 | 3 | 5 |

| Softness | 6 | 7 | 7 | 5 |

| Aroma | 4 | 7 | 5 | 6 |

| Sweetness | 9 | 9 | 8 | 6 |

| Colour ( Appearance) | 6 | 5 | 7 | 7 |

| Overall acceptability | 5 | 6 | 4 | 6 |

Difference between Dorabjee’s and Vigyan Ashram Instant Gajar Halwa:-

| Dorabjee’s Trial | Vigyan Ashram Trial |

| The texture was not good | The texture was very good |

| Dorabjee’s halwa have a high ghee | Ours halwa have a high ghee |

| The halwa loose the water | Our halwa was not |

| Have no dry fruits | Have dry fruits |

| Its not looks like a Traditional Maharashtrian Halwa | The halwa looks like actual grated halwa |

| In sweetness this was good | In sweetness this was fabulous |

| Colour was good but appearance was not good | Colour was good but appearance was good |

| Aroma of ghee was good | Aroma of ghee was like moderately |

| Overall acceptability was good | Overall acceptability was Like Moderately |

12/04/2025 – 13/04/2025

I tried SET NO.05:-

Initially, I explained the entire process of dehydrating carrots to Tushar Kukreja Sir, from start to finish, to help him understand the exact method I am following.

Ingredient: Carrots – 1400gm

Cooking Process (Latest Trial)

In previous trials, I used to peel the carrots before processing. However, in the current trial, I did not peel the carrots. Instead, after thoroughly washing them, I only removed the tail ends.

Drying:

The grated carrots were then placed in the dryer and dehydrated for 6 hours at 60°C

Boiling:

The unpeeled carrots were boiled for 14 minutes at 102°C.

Grating:

After boiling, the carrots were grated into two sizes:

Small size: 400 gm

Medium size: 850 gm

Waste (inedible or unusable parts): 150 gm

Drying:

The grated carrots were then placed in the dryer and dehydrated for 6 hours at 60°C

This is the big size grated carrots picture:

This is the small size grated carrots picture:

Tushar Sir and I conducted a trial on our premix using various ingredients, like using only sugar and including substituting sugar with jaggery.

With sugar:-

NOTE:

For this trial, I used previously dehydrated carrots in the recipe. This decision was made because the dehydration process takes approximately 6 hours, and Tushar Sir did not have enough time to wait for freshly dehydrated carrots during the trial. Hence, to proceed efficiently, I used carrots that were already dehydrated in an earlier batch.

INGREDIENTS:

- Dry carrot – 25gm

- Ghee – 5gm

- Dry Fruits – 5gm

- Cardamom Powder – 1gm

- Milk – 150ml

- Sugar – 30gm

Recipe as it is as first trial:

Here is the result of that:

With Jaggery:-

INGREDIENTS:

- Dry carrot – 25gm

- Ghee – 5gm

- Dry Fruits – 5gm

- Cardamom Powder – 1gm

- Milk – 150ml

- Jaggery – 30gm

Recipe as it is as first trial:

Here is the result of that:

Observation:

Review: between sugar, Jaggery.

| sugar | Jaggery |

| Sugar halwa is good in taste Appearance was good Texture was good sweetness is balanced cooked properly rehydrate well Moisture content was balance it doesn’t loose water The customer doesn’t interesting into consume sugar. | Jaggery halwa also good in taste Appearance was good Texture was good sweetness is balanced cooked properly rehydrate well Moisture content was balance it doesn’t loose water The customer interesting into consume Organic jaggery. |

The discussion start with Dixit sir, Ranjeet sir, Tushar kukreja sir on use the jaggery for substitute of sugar. Initially, the process involved drying and cooking the grated carrots directly in sweetened milk or plain milk. As a substitute for refined sugar, we experimented with natural sweeteners such as jaggery powder, raisins powder, dates powder, and other similar ingredients. After conducting multiple trials, we decided to modify the method.

14/04/2025

I tried SET NO.05 for recipe:-(Small grated carrots)

First i use the yesterday dried carrots,

Ingredients:

- Dry carrot – 38gm

- Ghee – 8ml

- Dry Fruits – 12gm

- Cardamom Powder – 2gm

- Milk – 230ml

- Jaggery – 45gm

Flow Chart:

I take a pan and heat it at lo flame for (30 sec)

↓

Add ghee into it (30sec)

↓

After that add all ingredients into it (Pre mix packet 105gm)

↓

After that mix it all well, the carrots are soften into the ghee and all the other ingredients mix well with each other properly

↓

adding the milk into it and mix well (2-3 min) (230ml milk)

↓

Additional Activity – I place tin on the pan for (4-10 min at high flame)

↓

After 10 min i remove the tin

↓

Mix it properly (at low flame for 10 to 12 min)

↓

The instant gajar halwa ready

Review:

Dixit Sir:

- The Carrots are well cooked.

- Sweetness was proper.

- Texture was like extremely.

- Appearance was good,

- Aroma & taste was like extremely.

- Overall acceptability was good like extremely.

Ranjeet sir:

- Colour is good Appearance is good.

- Well cooked.

- Moisture content was balanced.

- Aroma & taste is like extremely

- Neutral in sweetness.

- Overall acceptability was good / like extremely

Abhijeet sir:

- They are satisfy with cooking

- Appearance is like extremely

- Moisture content was balanced

- Aroma and taste is like extremely

- They say halwa smell like milk

- If the more sweeten the halwa the experience was more fantastic

- Overall acceptability is like extremely

Dixit sir and i have a discussion, As we discuss,

In the new trial, the process begins by grating the carrots and partially drying them to reduce their moisture content by approximately 50%. Once semi-dried, the carrots are cooked in ghee to enhance their flavour and richness. After this, milk is added and the mixture is allowed to soak and cook thoroughly. Finally, the product is further dried until only about 10% moisture remains, ensuring better shelf life and concentrated flavour.

15/04/2025

I had a discussion with Prasad Patil Sir about the review. He asked me to write my project summary.

I have written the entire project flow chart in the summary.

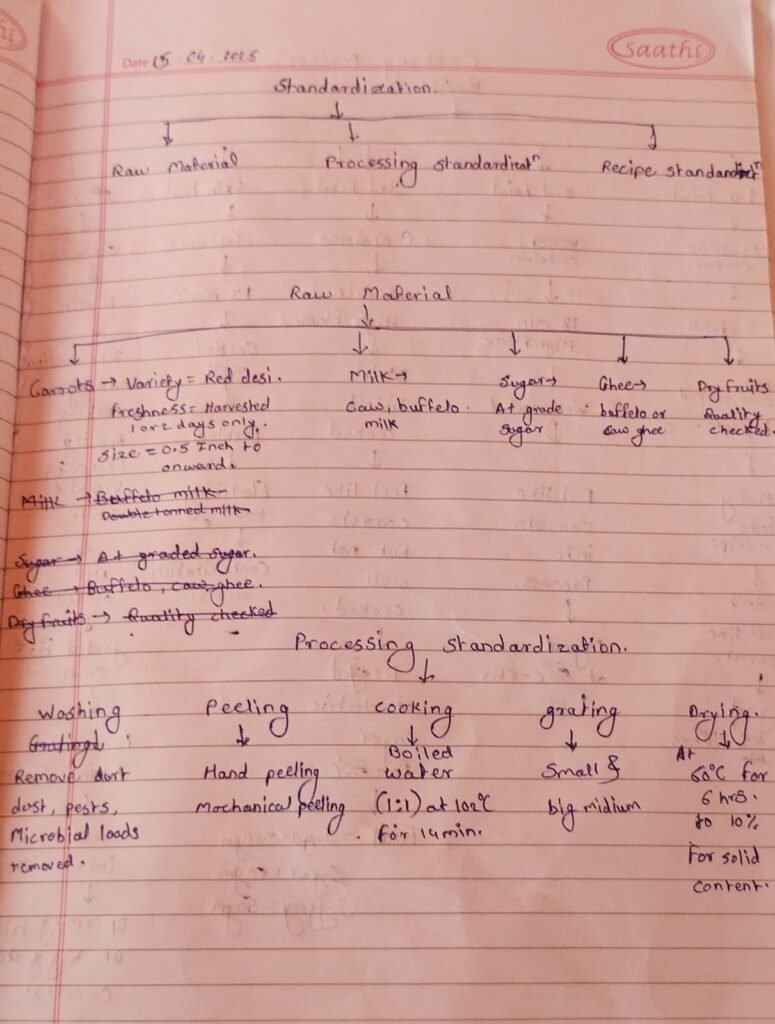

In this image i write the process of Raw Material standard, Processing Standard, Recipe Standard.

In this image i write the flow chart of my five trial, how i take trail and how i try it.

16/04/2025

Due to a shortage of red carrots in the market, they are not available for the trial.

There for i use the Orange carrots for trial

I had a discussion with Dixit sir on the recipe change of the Halwa were we change all the recipe further details are follow

I tried another set, but this set was totally changed

Carrots – 1870gm

Flow Chart-

First I shred the carrots

↓

wash the carrots

↓

After that I cook the carrots properly (18min at 102°C)(cooking were stoped by visual inspection)

↓

grate the carrots( waste is 170gm )

↓

place into electric dryer (at 55°C for 3hr)(1700gm)

↓

The dryer is not working properly, which is causing contamination in the grated carrots. The resistance of the Electric dryer is not working well.

17/04/2025-18/04/2025

I tried another set, and the procedure was completely changed after discussing it with Dixit Sir.

Carrots- 998.9gm

Flow Chart:-

First i take container

↓

After that i Add 998.9gm Orange carrots into it

↓

I add water ratio of 1:1 (Orange carrots 998.9 : Water 998.9)

↓

cooked for 19 min

↓

After that i i grate the carrots

↓

Placed to electric dryer to remove 50% moisture content for 3hr at 55°C(wt. 498gm)

↓

Heating all the carrots (498gm)into pan with ghee (16ml)

↓

And after that placed into electric dryer to remove the moisture below (20%)(wt. 198.2gm) at 55°C for 1hr

↓

As our proportion I add the milk (600), dry fruits(24gm), cardamom(4gm) and sugar(120gm) into dried carrots at(50°C) for 45 min

↓

After this all the mix goes to drying in electric dryer 9hr drying at 50°C

↓

After that remove from the tray the final wt is 338gm

↓

Premix Halwa was ready

25/04/2025

I tried now recipe:

Premix Packet – 120gm

Water – 100gm

Flow Chart:

First I take a packet(120gm)

↓

Boil the water in container (100gm)

↓

Add all the packet into boil water

↓

Mix it well in Low flame

↓

Close tin on the container

↓

Wait for 5min & mix it well

↓

Instant Gajar Halwa is ready

Reviews:-

| PARAMETERS / | NAMES | RATING | ||

| TEST | DIXIT SIR | PRANIT KAMBLE | ABHIJEET SIR | ADITYA |

| Texture | 7 | 6 | 6 | 5 |

| Dryness | 6 | 6 | 7 | 5 |

| Softness | 6 | 5 | 5 | 5 |

| Aroma | 8 | 7 | 7 | 6 |

| Sweetness | 9 | 7 | 7 | 6 |

| Colour ( Appearance) | 9 | 8 | 8 | 7 |

| Overall acceptability | 8 | 8 | 8 | 6 |

This is the hedonic rating of the candidates who have taste the Gajar Halwa Premix.

28/04/2025 – 29/04/2025

I does this trial to make Cooking process protocol

Flow Chart:-

I take 1752gm Orange carrots

↓

Wash all the carrots with water

↓

Steamed this carrots for (38min)

↓

Cooking process protocol

↓

Grate all the carrots & placed to electric dryer for 3hrs at 55°C

↓

After that heat a pan and with Ghee (21gm) high flame for 2min

↓

And placed into Electric dryer for 1.45hrs to remove moisture to 20% (at 55°C )(215gm)

↓

I add milk approximately 1050ml And sugar 210gm as our specification

↓

Placed for electric dryer for 30min at 50°C

↓

dried for 14 hrs (due to hydrogen bonding the sugar the water molecules are not separated and get trapped)

↓

Ready dried Instant Gajar Ka Halwa (558.3gm)

Cooking Process Protocol :

Before cooking:

I place the knife on the Raw carrot where carrot didn’t cut easily to middle core

| Weight of knife / gm | 330 | 330 |

| Diameter of carrot | 5.6 cm | 4.6cm |

| Result | cut 10% easily | cut 12% easily |

After cooking:

I place the knife on the cooked carrot where carrot easily cut to middle core:

| Weight of knife / gm | 330 | 330 |

| Diameter of carrot | 5.6 cm | 4.6cm |

| Result | cut 50% easily 2.3cm | cut 60% easily 2.76cm |

I make this prototype for cooking of carrot’s to standardise the process of cooking.

02/05/2025

I take a trial on recipe of this well cooked carrots

Ingredient:

Dried processed carrot – 120gm

Water – 120ml

Flow Chart :-

Take a container add 120ml water to it

↓

boil the water

↓

Add 120gm processed carrots into boiling water

↓

Mix well for 30 sec and place tin on the container (low flame)

↓

After 5 min the Instant Gajar Ka Halwa Ready

Discussion with prasad sir were i have to detailed study & do all over information about Raw material selection, variety, size, length, Price, & all the other aspect to obtain and standard the strength of the material.

| PARAMETERS / | NAMES | RATING | ||

| TEST | DIXIT SIR | PRANIT KAMBLE | ABHIJEET SIR | ADITYA |

| Texture | 9 | 8 | 8 | 9 |

| Dryness | 8 | 8 | 8 | 9 |

| Softness | 9 | 7 | 8 | 9 |

| Aroma | 8 | 9 | 8 | 9 |

| Sweetness | 9 | 9 | 8 | 9 |

| Colour ( Appearance) | 9 | 8 | 8 | 9 |

| Overall acceptability | 8 | 8 | 8 | 9 |

The review of the Abhijeet sir is not good for previous trial, but for this trail they are satisfied.

This is the hedonic rating of the candidates who have taste the Gajar Halwa Premix.

04/05/2025

I had a revie on the my Blog were

1)Talk with Tushar sir about Market trial.

2)Check a Red Carrot availability for trail.

3)Make a packet and send to Tushar sir closed ones for the detailed review on our trial.

4)Take a trial on Beetroot and mix beetroot and carrot. (20% : 80%)

5)Calculate the costing. ( To insure different Cost Cutting Method )

6)From that market trial we adjust the our SOP.

7)Take trial with sugar and also without sugar.

06/05/2025

i have make a trial Final wt. of the sample is 558.3gm but this costing for 120gm trial.

I have to make a cost cutting,

Raw Material:-

| Carrot | Sugar | Dry fruits | Milk | Ghee | Cardamon |

| 250gm/10rs | 30gm/1.2rs | 5gm/4rs | 150gm/10rs | 5gm/4rs | 1.5gm/6rs |

| ∑ = 35.2rs | |||||

| 28.4% | 3.4% | 11.36% | 28.4% | 11.36% | 17.04% |

Processing Cost:-

| Depreciation | Cost | Labour | Gas | Dryer Electricity |

| Water | 0.40rs | Ex:- 8hr= 320rs | Duration = 40min | |

| Kadhai | 0.20rs | Ie. 2hr= 80rs | Rate = 850/14kg | |

| Gas stow | 0.36rs | 560gm:80rs | Use =1hr/90gm | |

| Tray | 0.14rs | 120:17.14rs | Price= 3.64rs | |

| Container | 0.06rs | |||

| Electrical Dryer | 1rs | |||

| ∑ = 2.16rs | ∑ = 17.14rs | ∑ = 3.64rs | ||

| ∑ = 22.94rs | ||||

| 9.41% | 74.71% | 15.86% |

Packaging Cost :-

| Sticker | Pouch | |

| 0.50rs | 1.25rs | |

| ∑ = 1.75rs | ||

| 28.57% | 71.43% |

∑ Of Raw Material Cost :- 35.2rs = 58.82%

∑ of Processing Cost :- 22.94rs = 38.33%

∑ of Packaging Cost :- 1.7rs = 2.84%

Cost Per 120gm Packet = 59.84rs

07/05/2025 ,09/05/2025, and 10/05/2025

Make a market trail with discussed with Dixit sir and Tushar sir.

Ingredient :-

Carrot-1873gm

waste-190gm

Sugar-200gm

Dry fruits- 26gm

Cardamon-6.5gm

Milk- 1003ml

Ghee- 33.66gm

Flow Chart:-

I take 1683gm Orange carrots

↓

Wash all the carrots with water

↓

Steamed this carrots for (37min)

↓

Cooking process protocol

↓

Grate all the carrots & placed to electric dryer for 1hrs at 60°C

↓

After that heat a pan and with Ghee (33.66gm) high flame for 2min

↓

And placed into Electric dryer for 1.45hrs to remove moisture to 20% (at 55°C )

↓

I add milk approximately 1003ml And sugar 200gm as our specification

↓

Placed for electric dryer for 30min at 50°C

↓

After that due to electric dryer not working i put it into Flat dryer (44°C )(4hrs)(Final wt.346.6gm)

↓

Cooking Protocol:- 01

- 60gm knife :-

Raw Carrot

Throw the knife with 15cm,30cm with respect to gravity

| Distance | A1 | A2 |

| 15cm | 0.9cm | 0.8cm |

| 30cm | 1.8cm | 1.6cm |

| Diameter of carrot | 3.6cm | 4.6cm |

Cooked carrot

Throw the knife with 15cm,30cm with respect to gravity

| Distance | A1 | A2 |

| 15cm | 1.8cm | 1.7cm |

| 30cm | 3.3cm | 3.4cm |

| Diameter of carrot | 3.6cm | 4.6cm |

Cooking Protocol:- 02

2 . 165gm Knife

Raw Carrot

I place the knife on the Raw carrot where carrot didn’t cut easily to middle core

| Weight of knife / gm | 330 | 330 |

| Diameter of carrot | 3.6 cm | 4.6cm |

| Result | cut 11% easily(0.4cm) | cut 8.6% easily(0.4) |

After cooking:

I place the knife on the cooked carrot where carrot easily cut to middle core:

| Weight of knife / gm | 330 | 330 |

| Diameter of carrot | 3.6 cm | 4.6cm |

| Result | cut 52.77% easily 1.9cm | cut 72.22% easily 2.6cm |

This are my two type to set a Cooking Protocol

11/05/202 –12/05/2025

I discuss with Dixit sir

Today I make a slice of carrot by discuss with Dixit Sir For experiment prepose

I take 250gm Orange carrots

↓

Wash all the carrots with water

↓

Steamed this carrots for (37min)

↓

Cooking process protocol

↓

Slice all the carrots (3.3mm) & placed to Flat bed dryer for 6hrs at 45°C

↓

I add milk approximately 150ml as our specification

↓

Placed for Flat bed dryer for 12hrs at 45°C

14/05/2025

“Today, we had a guest (Bajaj industries owner) visit Vigyan Ashram. I spent most of my time in the Food Lab preparing for the visit, and we also welcomed a new DBRT student to our Food Lab team.

15/05/2025

I Make a packets of Instant Gajar Halwa Premix Pouches.

With sugar – 8 Pouches

Without sugar – 8 Pouches

Each of this Pouches are weighted 50gm only

I spent most of my time in the Food Lab preparing for the visit, and we also welcomed a new DBRT student to our Food Lab team.

16/05/2025

Today i take a sliced carrot grinding for the trial

17/05/2025

I make a sticker for the market trial with the help of Ravindranath Chadwik.

18/05/2025

Make a halwa of Sliced carrots

Sample without sugar = 34gm

Sugar = 30gm

Cardamon = 1gm

Boiled water = 40ml

Flow chart:-

Take a container add 40ml water to it

↓

boil the water

↓

Add processed carrots (34gm), Sugar (30gm), Cardamon (1gm) into boiling water

↓

Mix well for 30 sec and place tin on the container (low flame) for 5min

↓

After 5 min the Instant Gajar Ka Halwa Ready

Observation:-

The sliced carrots are not able to grate properly

Then i grinding it, After grinding

- Powder – 20%

- Granule – 80%

This sliced carrots are not rehydrate well.

Conclusion:-

We have to enhance the grinding particles

We have to use Multiple fruit processors.

19/05/2025

Make a Project Note on the Instant Gajar Halwa.

And cooking Standard protocol

And also make a print out of the all the stickers in stick on the all pouches of market trial with and without sugar pauches.

20/05/2025

Parcel the all Pouches to the Tushar Kukreja sir, with and without sugar (8-8)

24/05/2025

I planned to start mass production of the Instant Gajar Halwa, but due to a malfunctioning dryer and the lack of sufficient sunlight during the rainy season, I was unable to use the flatbed dryer. As a result, the drying process was delayed.

Carrot availability was also checked, but it tends to be poor during the rainy season when the demand is high.

27/05/2025

The package has reached to Tushar Kukreja Sir for market trial.

31/05/2025

Buy 10kg Carrot at rate of 35rs in the market.

01/06/2025–04/06/2025

Take a trial on the carrots

I take 5kg Orange carrots

↓

Wash all the carrots with water

↓

Steamed this carrots for (37min)

↓

Cooking process protocol

↓

Grate all the carrots & placed to flat bed dryer for 3hrs at 45°C

↓

After that heat a pan and with Ghee (70gm) high flame for 2min

↓

And placed into flat bed dryer for 3hrs to remove moisture to 20% (at 44°C )

↓

I add milk-1750ml, raisins-41gm, Cardamon-17gm & Dry fruits- 82gm approximately soaked for 45min

↓

Placed for flat bed dryer for 3hrs at 45°C

↓

After that Placed into electric dryer 3hrs for final drying.

↓

After all the process we add sugar pouches

↓

Ready the mix Instant Gajar Ka Halwa

Make a pouches of all this ingredients with 120gm respectively.(8pouches were made up from 1050gm pre mix and remaining 85gm were forwarded for trial of the recipe)

07/06/2025

Take trail on the 85gm of premix of the Gajar Ka Halwa

Take a container add 100ml water to it

↓

boil the water

↓

Add premix pouches (85gm) into boiling water

↓

Mix well for 30 sec and place tin on the container (low flame) for 5min

↓

After 5 min the Instant Gajar Ka Halwa Ready(160gm)

Observation:-

- Texture was good.

- Aroma was good.

- Due to raisins it taste bitter

- Sweetness was good

- The pungent smell occurs because of milk and all ingredients are placed for slow drying into flat bed dryer.

Conclusion:-

- Use Electric dryer for drying, after adding all ingredients.

06/06/2025

Another mass trail NO.- 01 7.5kg of carrot,

I take 7.5kg Orange carrots

↓

Wash all the carrots with water

↓

Steamed this carrots for (47min)

↓

Cooking process protocol

↓

Grate all the carrots & placed to flat bed dryer for 3hrs at 45°C

↓

After that heat a pan and with Ghee (148.2gm) high flame for 2min

↓

And placed into flat bed dryer for 3hrs to remove moisture to 20% (at 44°C )

↓

I add milk-4446 ml, Cardamon-29gm & Dry fruits- 148.2gm approximately soaked for 45min

↓

Placed for flat bed dryer for 3hrs at 45°C

↓

After that Placed into electric dryer 3hrs for final drying.

↓

After all the process we add sugar-444.6gm in all pouches

↓

Ready the mix Instant Gajar Ka Halwa

14/06/2025

Calibrate the dryer to check the on off time of the Electric dryer for archiving 55°C temperature.

| Temperature (°C) | Duration / Time (min) |

| 33 | 0 |

| 36 | 1 |

| 38 | 2 |

| 42 | 3 |

| 44 | 4 |

| 46 | 5 |

| 48 | 6 |

| 50 | 7 |

| 51 | 8 |

| 53 | 9 |

| 54 | 10 |

| 55 | 11 |

| 55 | 12 |

| 54 | 13 |

| 55 | 14 |

After 12min the heater was off and the temperature change to 54 then heater start and temperature goes to 55°C

And the remining process continuous for 1min on off for rest of hrs.

15/06/2025

Raw Material Costing :-(7.5kg Raw carrot )

Raw Material:-

| Carrot | Sugar | Dry fruits | Milk | Ghee | Cardamon |

| 262.5 rs | – | 118rs | 135rs | 118rs | 116rs |

| ∑ = 749.5rs | |||||

| 35% | – | 15.70% | 18% | 15.70% | 15.47% |

Processing Cost:-

| Depreciation | Cost | Labour | Gas | Dryer Electricity |

| Water | 0.20rs | Ex:- 8hr= 320rs | Duration = 40min | duration electric dryer on use 9hrs |

| Kadhai | 0.20rs | Ie. 2hr= 80rs | Rate = 850/14kg | electricity consumption time 4hrs |

| Gas stow | 0.20s | Use =1hr/90gm | 1 unit per 1hr | |

| Tray | 0.06rs | Price= 4.12rs | 1 unit-10rs | |

| Container | 0.06rs | 4 unit-40rs | ||

| Electrical Dryer | 1rs | |||

| ∑ = 2.16rs | ∑ =80rs | ∑ = 4.12rs | ∑ = 40rs | |

| ∑ = 125.84rs | ||||

| 1.37% | 63.56% | 3.27% | 31.78% |

Packaging Cost :-

| Sticker | Pouch | |

| 1rs for 1 sticker we use 17 sticker 17rs | 1.5rs for 1 sticker we use 17 sticker 25.5rs | |

| ∑ = 42.5rs | ||

| 40% | 60% |

∑ Of Raw Material Cost :- 749.5rs = 81.66%

∑ of Processing Cost :- 125.84rs = 13.71%

∑ of Packaging Cost :- 42.5= 4.63%

Cost per 1 single pouch is 54rs.

17/06/2025–18/06/2025–20/06/2025

In the discussion we were discuss to make a 50 kg Raw carrot processing.

Mass production NO-02

Gajar – 9.740kg

I take 9.740kg Orange carrots

↓

Wash all the carrots with water

↓

Steamed this carrots for (46min)

↓

Cooking process protocol

↓

Grate all the carrots & placed to flat bed dryer for 3hrs at 45°C

↓

After that heat a pan and with Ghee (240gm) high flame for 4min

↓

And placed into Electric dryer for 3hrs to remove moisture to 20% (at 44°C )

↓

I add milk-6000 ml, Cardamon-40gm & Dry fruits- 160gm approximately soaked for 45min

↓

Placed for Electric dryer for 3hrs at 55°C

↓

After that Placed into electric dryer 3hrs for final drying.

↓

After all the process we add sugar-444.6gm in all pouches

↓

Ready the mix Instant Gajar Ka Halwa

Observation:-

We get 27 pouches from the 10kg of carrot (Pouch size- 100gm)

20/06/2025

Recipe on NO-01–

Premix packet – 20 gm

Boil water – 20ml

sugar – 5gm

Open the packet

↓

Boil the water

↓

add all into the water

↓

Mix well with spatula

↓

5 min tin on the container

↓

mix slow

↓

ready Instant Gajar Halwa

Observation:-

- The aroma was very good

- Taste was nice

- Colour is good

- Milk was slightly smell pungent

20/06/2025 – 21/06/2025 – 23/06/2025

Mass production NO-03

Gajar – 9.740kg

I take 9.598kg Orange carrots

↓

Wash all the carrots with water

↓

Steamed this carrots for (46min)

↓

Cooking process protocol

↓

Grate all the carrots & placed in electric dryer for 3hrs at 55°C

↓

I add milk-3000 ml, Cardamon-20gm approximately soaked for 45min

↓

Placed for Electric dryer for 3hrs at 55°C

↓

After that Placed into electric dryer 3hrs for final drying.

↓

Ready the mix Instant Gajar Ka Halwa

Recipe:-

Premix packet – 50gm

Boil water – 60ml

sugar – 15gm

Open the packet

↓

Boil the water

↓

add all into the water

↓

Mix well with spatula

↓

5 min tin on the container

↓

mix slow

↓

ready Instant Gajar Halwa

Observation:-

Due to Electric dryer problem Batch get contaminated.

Make a recipe on it it smell pungent and bitter in taste

Also take a trial on the beet root and gajar mix Instant Gajar Halwa for Inhance colour and texture of the halwa.

I take 2kg Orange carrots & beet root 500gm (4:1)

↓

Wash all the all with water

↓

Beet are peeled after peeling wt is 400gm appox.

↓

Steamed all for (46min)

↓

Cooking process protocol

↓

Grate all & placed in electric dryer for 3hrs at 55°C

↓

I add milk-900 ml, Cardamon-6gm approximately soaked for 45min

↓

Placed for Electric dryer for 3hrs at 55°C

↓

After that Placed into electric dryer 3hrs for final drying.

↓

Ready the mix Instant Gajar Ka Halwa

Recipe:-

Carrot and beet Premix packet – 70gm

Boil water – 80ml

sugar – 15gm

Open the packet

↓

Boil the water

↓

add all into the water

↓

Mix well with spatula

↓

5 min tin on the container

↓

mix slow

↓

ready Instant Gajar Halwa

Observation / conclusion:-

- Colour is inhanced

- Texture was good

- The smell of beet root is slightly pungent, we worked on upcoming days.

27/06/2025 – 28/06/2025 – 30/06/2025– 01/07/2025

Take another mass trial-

Mass trial –NO-04

I take 15kg Orange carrots

↓

Wash all the carrots with water

↓

Steamed this carrots for (46min)

↓

Cooking process protocol

↓

Grate all the carrots & placed to flat bed dryer for 3hrs at 45°C

↓

After that heat a pan and with Ghee (240gm) high flame for 4min

↓

And placed into Electric dryer for 3hrs to remove moisture to 20% (at 44°C )

↓

I add milk-9000 ml, Cardamon-40gm & Dry fruits- 200gm approximately soaked for 45min

↓

Placed for Electric dryer for 3hrs at 55°C

↓

After that Placed into electric dryer 3hrs for final drying.

↓

Ready the mix Instant Gajar Ka Halwa

Observation:-

We get 27pouches from the 10kg of carrot (Pouch size- 100gm)

And also have a 17 pouches from past they also packed Total Pouches 44.

I get 3 pouches of it to my home for feedback it was awesome feed back from my peoples.

Also we work on the louki halwa premix Sujay Desai is working on it we will guide to him for the SOP.

Costing:-

I have completed the costing of the materials used in the food lab from the day I joined Vigyan Ashram till now, which amounts to approximately ₹5,989.

06/07/2025-10/07/2025

Take another mass trial-

Mass trial –NO-05

Ingredients:-

Carrot-20kg

Elaichi-72gm

Milk-9.5lit

Dry fruits-350gm

Ghee-350gm

Flow Chart:-

I take 20kg Orange carrots

↓

Wash all the carrots with water

↓

Steamed this carrots for (46min)

↓

Cooking process protocol

↓

Grate all the carrots & placed to Electric dryer for 4.5hrs at 55°C

↓

I add milk-9500 ml, Cardamon-72gm,Ghee-350 approximately soaked for 45min

↓

Placed for Electric dryer for 5hrs at 55°C

And all Dough is saperate each other

↓

After that Placed into electric dryer 5hrs for final drying.

↓

Ready the mix Instant Gajar Ka Halwa

↓

Mix crushed Dry fruits- 3500gm into premix pouches(35)

LOD Calculations:-(of carrot)

=Initial Wt.-Final Wt./Initial Wt.*100

=28.88-3.54/28.88*100

=87.75%

Solid Content – 12.25%

16/07/2025

Take another mass trial-

Mass trial –NO-06

Ingredients:-

Carrot-40kg

Elaichi-160gm

Milk-32lit

Dry fruits-856gm

Ghee-856gm

Flow Chart:-

I take 40kg Orange carrots

↓

Wash all the carrots with water

↓

I make 2 batch 20:20kg each, Steamed this carrots for (60min) each.

↓

Cooking process protocol

↓

Grate all the carrots & dryed it into Heat Pump dryer for 15hrs at 55°C (the dry Carrot is around 5.350gm from 40kg Carrot)

↓

I take around 3.850kg dry carrot for final process & the remaining 1.5kg is for inventry

↓

I add milk-, Cardamon-160gm,Ghee-856gm approximately soaked for 45min

↓

Placed for Electric dryer for 6hrs at 55°C

And all Dough is saperate each other

↓

After that Placed into electric dryer 6hrs for final drying.

↓

Ready the mix Instant Gajar Ka Halwa (6.7kg)(LOD is 64.13%)

↓

Mix crushed Dry fruits- 856gm into premix pouches(73)

18/07/2025

I discuss with Dixit Sir about the Dhamari trial,

Here is the summerry

https://1drv.ms/w/c/940cc8cbca3238c2/ETw1xb26zupMql4yGvU3EUIBCbrAXGdF93O1w9U5cZJX5g?e=sf8xBf

22/07/2025

We are busy and working on the 29th &30th Exhibition Program

Make a video on this Project

23/07/2025 – 28/07/2025

Juven make a Label design from i sent the information

Take a trail to observe the after serving wt. of the 1pouch

29/07/2025

On this Day I convey my information about various Machine to the Visitors

30/07/2025

We label the product with sugar & without sugar on the pouches

We sell the 72 pouches to 27 customer

I am happy to get knowledge information from Mr.& Miss. Kukreja

Were we make sample for visitors for feedback

06/08/2025

Then make a market Instant Gajar Halwa Premix @PAMAS

Flow Chart:-

Boil 150ml water

↓

Open the pouch & Add into boil water stire well

↓

wait for 15 min

↓

And the Instant Halwa Ready

Observation:-

- The carrots are uncooked.

- When we open the packet the pungent smell is come from packet.

- Serving wt. is not propreate as they say.

- It is not taste like Halwa.

10/08/2025

In the 30th Exhibition we sell our product then we get a feedback of the customer

Here is the feedback file

05/08/2025-10/08/2025

Work on Beetroot Halwa

Flow Chart:-

Take 1kg of Beetroot

↓

Peel it (waste is around 10%)

↓

Add 900ml water into cantainer & add peeled beetroot into water boil for 20min

↓

After that i grate it all

↓

Place into electric dryer for 5hrs at 52degree cel

↓

Dry beetroot ready

Here we ready the dry beetroot.

Make Beetroot Halwa:-

Carrot-90gm

Beetroot-10gm

Ghee-16ml

Dry fruits-16gm

Elaichi-2gm

Milk-600ml

Flow Chart:-

Take a Dry Carrot & Dry Beetroot

↓

Add Basundi milk into it soaked for30min

↓

add all the ingredient

↓

Make a dough and spread into dryer trays dry it for 55degree cel for 6hrs

↓

Ready Premix Beetroot Carrot Halwa(LOD is 64.13%)(Final wt. is 198gm)

Make a recipe from that:-

Boil the water

↓

add all into the water

↓

Mix well with spatula

↓

5 min tin on the container

↓

Mix slow

↓

Ready Instant Beetroot Gajar Halwa

Observation:-

- We have to set cooking protocol for the beetroot.

- Overall taste was good

- Apearance is also good

12/08/2025

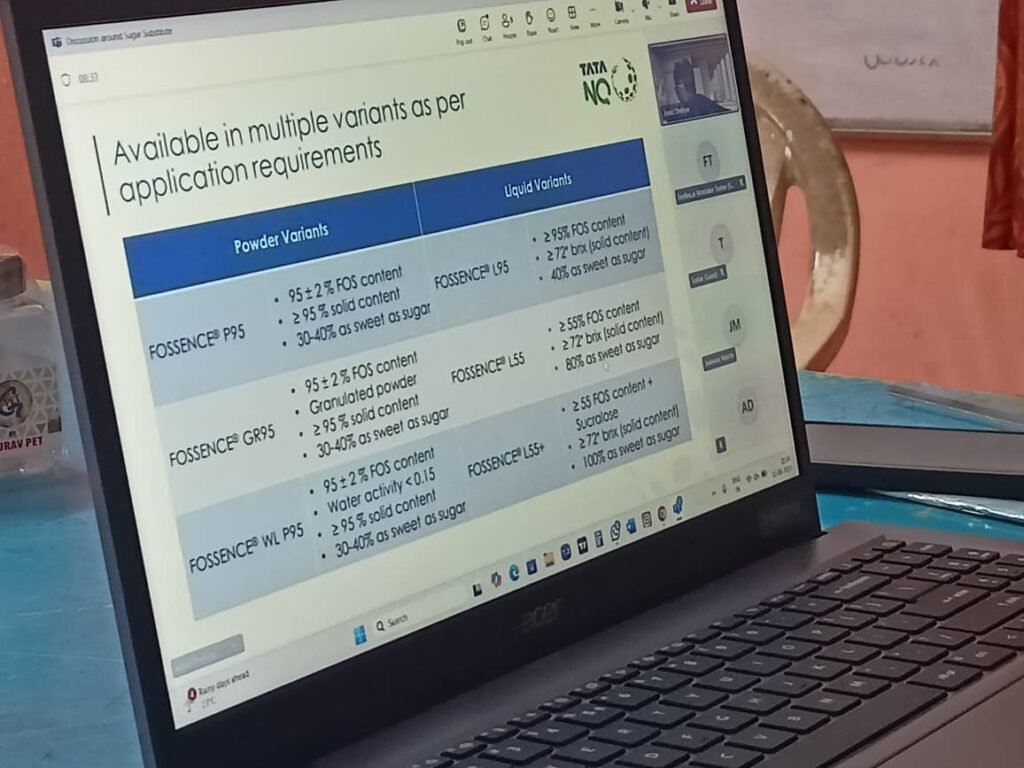

We atend the FOS(olego fructoes) Discussion with Mr.Ankit Dhelriya (ICT Mumbai gradute, Chemical Engineer)

Now, He work in Tata Chemical &The Tata Chemical industry produce FOS.

FOS is the substitute of the Sugar & Jaggery

They send the sample to us in upcoming days.

I had a call with Tushar sir about that they sayi will get info & reach you.

The Package is dispatched on 22/08/2025

This it the chart of the FOS that they make InIndustry

| Powder | FOS Content | Fibre Content | Sweetness | |

| FOSSENCE P95Short Chain FOS | 95% | 90.25% | 30-40% | |

| FOSSENCE GR95Granulated Short Chain FOS | 95% | 90.25% | 30-40% | |

| Liquid | FOSSENCE L95Short Chain FOS | 95% | 74% | 40-45% |

| FOSSENCE L55Sweet Tasting Short Chain FOS | 55% | 43% | 60-70% | |

| FOSSENCE L55+Short Chain FOS, matching sweetness of Sugar | 55% | 43% | 100% |

13/08/2025 – 23/08/2025

Detail Presentation of the Project

20/08/2025-24/08/2025

We have dry cooked carrot in inventory. I have completed the Phase 02 process on it.

Flow Chart:-

The remaining 1.5kg is from inventry

↓

I add milk, Cardamon,Ghee approximately soaked for 45min

↓

Placed for Electric dryer for 6hrs at 55°C

And all Dough is saperate each other

↓

Ready the mix Instant Gajar Ka Halwa (3.5kg)(LOD is 64.13%)

↓

Mix crushed Dry fruits into premix pouches(35)

25/08/2025

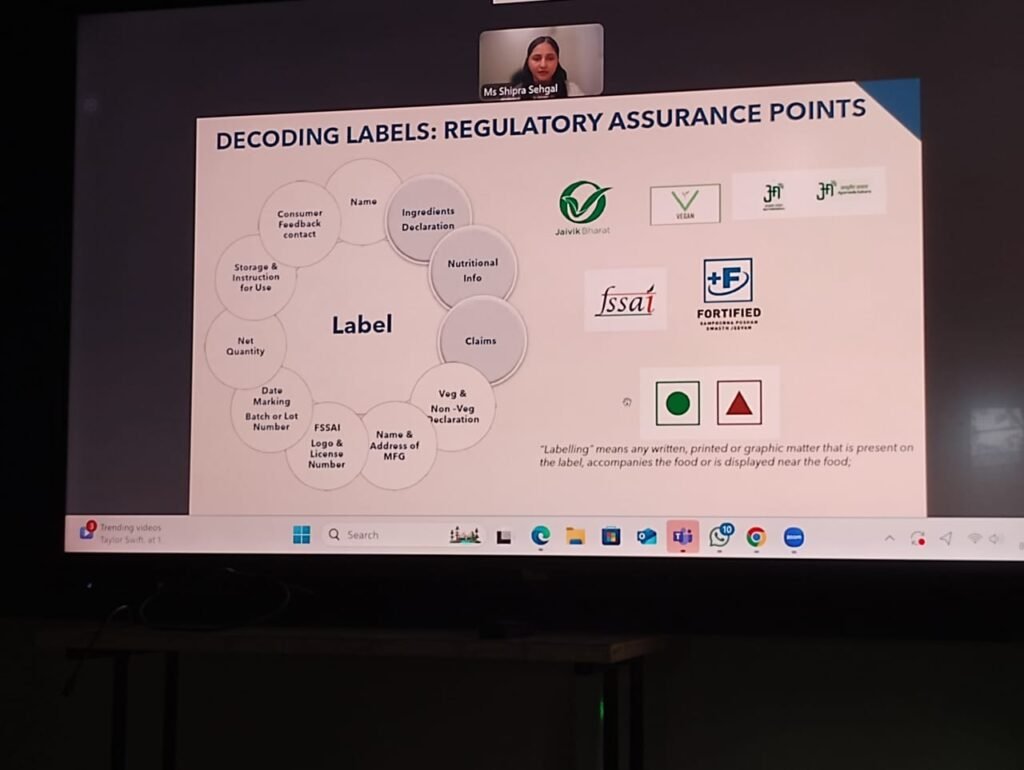

I attended a conference on sweet products where Sweet Monk sugar was used as a sugar substitute. Various mentors gave their presentations on sugar substitutes.

11/09/2025

FOS samples reached Vigyan Ashram, and I had a discussion with Dixit Sir about what we need to do with them. He suggested replacing 10% of sugar with FOS, and I have made the change.

Then i take a trial on it 1) with whole sugar and 2)FOS 10% and sugar 90% composition for comparison

Boil the water

↓

add all into the water

↓

Mix well with spatula(add FOS & sugar)

↓

5 min tin on the container

↓

Mix slow

↓

Ready Instant Beetroot Gajar Halwa

- With whole sugar

2)FOS sugar composition

Observation:- (FOS)

The aroma was very good.

The taste was pleasant.

The colour was appealing.

Sweetness is slightly low

12/09/2025-14/09/2025

I had a discussion with Tushar Sir about drying technologies to compare our halwa dried in various dryers such as heat pump, electric dryer, and freeze dryer. We also planned to prepare Gajar Halwa in the traditional homemade style, then dry it in the electric dryer, rehydrate it, and record the observations.

Take a trial on traditional homemade style gajar ka halwa

Flow Chart:-

Take 500gm raw carrot

↓

Washing

↓

Grating(0.4cm)(waste 40gm)

↓

Boil in Milk (1:1 ratio)1hrs

↓

Addition of ingredients (Elaichi-2gm, Ghee-10gm)

↓

Ready homemade Gajar ka halwa (500gm)

↓

Place into electris dryer for 6hrs (45 degree cel)

↓

Final product after drying 110gm (LOD-75.52%)

Recipe Flow Chart:-

Dry Traditional Halwa 50gm

↓

Boiled Water (100ml)

↓

Rehydration for 10min

↓

Ready Traditional Halwa

Observation:-

Appearance: Orange-brown, close to original but slightly darker.

Texture: Carrot strands reappear but softer; slightly mushier than fresh.

Aroma: Aroma comes back but weaker compared to fresh halwa.

Taste: Sweetness returns, but ghee flavor reduced; overall slightly bland compared to original.

Mouthfeel: Moist and edible, but lacks the fresh richness; a little watery if excess water is added.

16/09/2025-19/09/2025

Our SOP & this Traditional trial We Name A & B

I take a Comaparison trial Between A&B,

For this i take a trial B–

Take 1000gm raw carrot

↓

Washing

↓

Grating(0.4cm)(waste 40gm)

↓

Boil in Milk (1:1 ratio)1hrs

↓

Addition of ingredients (Elaichi-4gm, Ghee-20gm)

↓

Ready homemade Gajar ka halwa (1000gm)

↓

Place into electris dryer for 6hrs (45 degree cel)

↓

Final product after drying 220gm (LOD-75.52%)

& I have a premix packet of Instant Gajar Halwa Trial-A

Boil the water(150ml)

↓

add all premix into the water

↓

Mix well with spatula(add sugar 30gm)

↓

5 min tin on the container

↓

Mix slow

↓

Ready Instant Gajar Halwa

Observation:-

Comparison Observation Table

| Parameter | Traditional Homemade Halwa (Rehydrated) “A” | SOP Halwa (Rehydrated) “B” |

|---|---|---|

| Appearance | Orange-brown, slightly darker than fresh; uneven carrot strands visible | Bright uniform orange-brown; more consistent appearance |

| Texture | Soft but slightly mushy; some fibrous carrot strands remain | Smooth, uniform texture; better binding due to standardized process |

| Aroma | Mild carrot & ghee aroma; weaker than fresh | Stronger aroma retention; balanced smell of carrot, ghee & cardamom |

| Taste | Sweetness uneven, ghee flavor reduced; slightly bland | Balanced sweetness; ghee & carrot flavor well-retained; closer to fresh halwa |

| Mouthfeel | Watery if excess water added; less richness | Moist, rich, with better mouth-coating effect; feels fresher |

| Shelf-life Stability (after drying) | Less stable, risk of spoilage due to uneven drying | More stable due to SOP-controlled drying & standard ingredients |

| Overall Acceptability | Acceptable but not very close to fresh halwa | Higher acceptability; closer to fresh halwa in taste, texture & aroma |

Next Step:-

Make a fresh trail A&B and parcel to Tushar Kukreja Sir For Onservation of it.

20/09/2025-25/09/2025

As we decided, I made Trial A & B (1.5 kg each, respectively).

I made a trial and dispatched it by courier to Tushar Kukreja: 2 pouches of 100 g each.

Sample were reach to Tushar Sir on 25/09/2025

Trial A – SOP Method

- Process Used: Followed the standardized SOP for Instant Gajar Halwa Premix preparation.

- Appearance: Uniform orange color; slightly lighter after drying.

- Texture (After Rehydration): Smooth, semi-moist, easy to mix with hot milk.

- Aroma: Balanced aroma of ghee and cardamom retained after rehydration.

- Taste: Mildly sweet, authentic halwa flavor achieved.

- Rehydration Time: 4–5 minutes with hot milk.

- Shelf Stability: Stable at room temperature; no moisture or lumping observed after 3 days.

- Remarks: Overall product quality good; slight increase in ghee could enhance richness.

Trial B – Traditional Method

- Remarks: Excellent traditional taste; however, SOP method offers better consistency and handling.

- Process Used: Prepared halwa using traditional home-style method and dehydrated.

- Appearance: Slightly darker orange color due to extended cooking time.

- Texture (After Rehydration): Softer and more oily texture compared to SOP batch.

- Aroma: Strong ghee and roasted carrot aroma noticeable.

- Taste: Rich, traditional halwa taste with deeper caramelized notes.

- Rehydration Time: 5–6 minutes with hot milk.

- Shelf Stability: Minor stickiness observed after 3 days; may require lower drying temperature.

We prefer Type B process.

04/10/2025-14/10/2025

We have here Drying tranning by EDP & DIC,

For that we take a another trial on Resistive dryer & Heat Pump Dryer at Dhamari.

I take 40kg Orange carrots

↓

Wash all the carrots with water

↓

I make 2 batch 20:20kg each, Steamed this carrots for (60min) each.

↓

Cooking process protocol

↓

Grate all the carrots & dryed it into Heat Pump dryer for 15hrs at 55°C (the dry Carrot is around 3.834gm from 40kg Carrot)

↓

I take around 3.834kg dry carrot for final process

↓

I add milk-, Cardamon-80gm,Ghee-856gm approximately soaked for 45min

↓

Placed for Electric dryer for 6hrs at 55°C

And all Dough is saperate each other

↓

After that Placed into electric dryer 6hrs for final drying.

↓

Ready the mix Instant Gajar Ka Halwa (5.2kg)(LOD is 64.13%)

↓

Mix crushed Dry fruits- 856gm into premix pouches(50)

11/10/2025

On 11th October, I will be participating in an exhibition to pilot-run the Instant Gajar Halwa Premix project and collect feedback from visitors.(In Light house Yeravda)

16/10/2025