Need of project

In our on efforts to modify and maintain hydroponic fodder cultivation we faced to major issues described as follows

a) Fungal growth indicated by sticky maze gains and foul acidic smell.

b) The second issues is what is the right time of phase at which fodder is ready for use

This project driven now is aim to resolved both these issues in the sequence mentoned above i.e avoiding fungal growth would be the first target to achive

Objective

1.To remove fungus and mold infection from fodder.

a)Chemical

b) Biological

c) Mechanical

d) Chemical+Biological

2. To design experimental setup of fodder hydroponic.

Green fodder is essential to feed livestock. But due to the reduced availability of land and lack of water, It is become difficult to produce the required quantity of green fodder throughout the year. Also, the lack of quality fodder hampers the growth production, and Reproduction of livestock.

Basic procedure of fodder hydroponic

calculate total requirement of fodder in vigyan ashram

19/12/2022 to 25/12/2022

WORKDONE

Trial 1 How much water the seed absorbs up to a certain time

In this experimentation set up, the maize seeds were soaked into normal tap water.

Procedure

1.Take 20 gm of maize grains.

2. Add maize grain weight it with weighing balance.

3. Add 200 ml water in to maize grains.

4.Take weight of grains at one hour of interval up to constant readings were get.

| Water | |

| Time(hr) | Weight of sample(gm) |

| 0 | 20 |

| 1 | 32 |

| 2 | 33 |

| 3 | 33 |

| 4 | 34 |

| 5 | 32 |

Result– After 5 hours constant weight of seeds in tapwater is about 32 gm

Trial 2 How much salt water the seed absorbs up to a certain time

In this experimentation set up, the maize seeds were soaked into normal tap water and salt .

Procedure

1.Take 20 gm maize grains.

2. Add 200 ml water and 1 gram salt in to maize grains.

3. Take weight of grains at one hour of interval up to constant readings were get.

| Time | Weight of sample(gm) |

| 0 | 20 |

| 1 | 27 |

| 2 | 29 |

| 3 | 31 |

| 4 | 32 |

| 5 | 31 |

Result- After 4 hours constant weight of seeds in salt water is about 31 gm

TRIAL 3 Treatment to remove fungi 26/12/22 – 1/1/23

In this experiment using fungicide for maize grains

1. Take 500 gm of maize seeds and wash it with the help of water to clean the seed.

2. After cleaning of grains add 2 litters water and quantity of salt and Trichoderma at given below the table

| Sr.No | Sample | Quntity |

| 1 | Water | 2 liter |

| 2 | Water + Salt | 2lit +33 gm |

| 3 | Water + Trichoderma | 2 lit + 5 gm |

| 4 | Water + Tricoderma +Salt | 2 lit + 5 gm + 33 gm |

3. TPut grains for socking up to 12 hr

4.When seeds get soaked put into cotton bag for approximately 48 hours.

5. Sprouting seeds were placed into tray.

6.After one hour of interval give water manually that is 100 ml.

Loss on Dry 02/1/23 –9/1/23

To find out the dry matter of fodder for every vegetative stage the loss on dry method is used in which oven are used and for LOD approximately 48 hours get. From this LOD we can find out the water present in every growth stage of maize.

Methodology for Loss on Dry:

1.Take sample of maize fodder for every growth stage.

2.Weighning 5 gm of wet fodder.

3.placed into to oven at 105°c.

3.Take weight of sample one hour of interval till constant reading.

4.To find out loss on dry following formula use:

LOD =

Initial weight – final weight / final weight × 100

Day 4

| Sr.No | Dry seed | Water | Salt | Tricoderma | Tricoderma +Salt |

| 1 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 |

| 2 | 4.8 | 3.8 | 3.8 | 3.7 | 3.9 |

| 3 | 4.7 | 3.5 | 3.5 | 3.3 | 3.5 |

| 4 | 4.6 | 3.3 | 3.4 | 3.2 | 3.4 |

| 5 | 4.6 | 3.3 | 3.4 | 3.2 | 3.4 |

| LOD | 8% | 34% | 32% | 36% | 34% |

Day 6

| Sr.No | Water | Salt | Tricoderma | Tricoderma +Salt |

| 1 | 5.3 | 5.3 | 5.1 | 5.3 |

| 2 | 3.1 | 3.7 | 3.5 | 3.8 |

| 3 | 2.9 | 3.4 | 3.2 | 3.5 |

| 4 | 2.7 | 3.3 | 3.1 | 3.3 |

| 5 | 2.7 | 3.3 | 3.1 | 3.3 |

| LOD | 49% | 37% | 39% | 37% |

Day 8

| Sr.No | Water | Salt | Tricoderma | Tricoderma +Salt |

| 1 | 5.3 | 5.2 | 5.0 | 5.2 |

| 2 | 2.3 | 2.7 | 2.2 | 2.8 |

| 3 | 2.2 | 2.6 | 2.1 | 2.7 |

| 4 | 2.2 | 2.6 | 2.1 | 2.7 |

| LOD | 58% | 50% | 58% | 4.8% |

In this experiment there is highly growth in water and trichoderma treatment. We conclude that Fungus grows in all trays because of dust present in cotton bag(gonny)

Result

Gayatri- 6 Month Plan

Sr.No. | Month | Fodder (Microgreen) | |

| 1 | Feb | Biological and chemical trails, Mechanical Trails | Two week, M- 2 week |

| 2 | March | Best one replicate | Data collection |

| 3 | April | Trails | Design and fabrication trails |

| 4 | may | ||

| 5 | June | ||

| 6 | July |

TRIAL 4 How much water remains on the side of the soaking corn after watering

After discussion with dixit sir I calculated extract water around maize

1.taking small hole sieve

After socking maize seed, transfer it to small holes sieve then measure the weight before and after applying water

DAY 1

| Before weight | After weight |

| 100 | 100 |

| 144 | 140 |

| 150 | 147 |

| 146 | 142 |

| 149 | 146 |

Day 2

| Before weight | After weight |

| 100 | 100 |

| 162 | 159 |

| 163 | 162 |

| 164 | 162 |

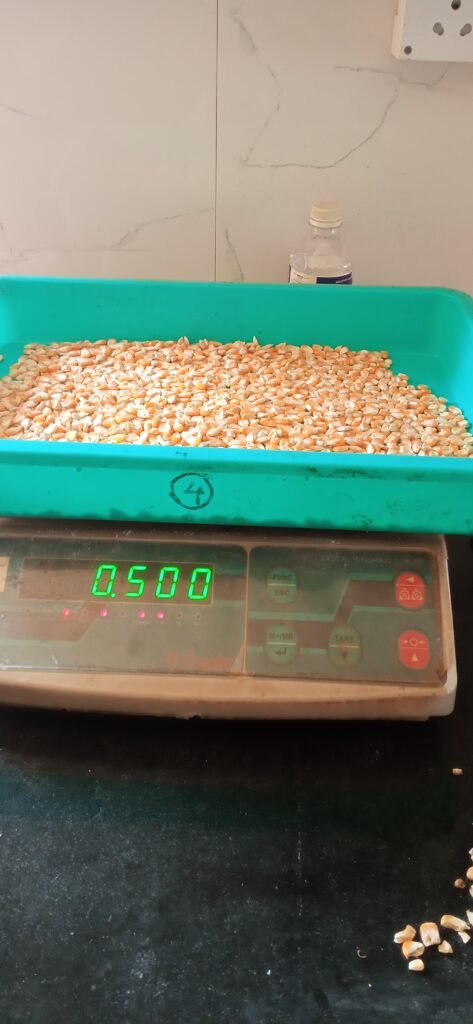

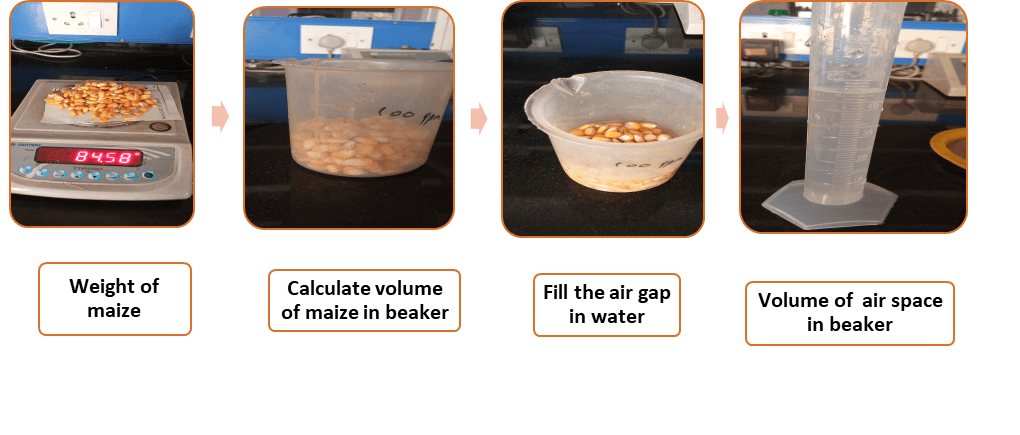

I calculate volume of maize after socking

- Weight of maize = 85gm

- Dimeter of beaker = 7 cm

- Height if maize in beaker = 2.5 cm

* Volume of maize in beaker = πr2h

= 3.14 * (3.5 )2 *2.5

= 96.16 cm3

*Air space in maize in beaker = 46 ml

After this observation i put one trayl back .

TRIAL 5 A trial was taken by shaking the sieve 16/1/23-23/1/23

S1= Slives in no shack

S2= slives in shack

S3 = slives in Tricoderma

Observation in trayal

S1= growth of maize is less than S2 but fugus is present.

S2= In S2 growth of maize is well , fungus is not present .

S3= In S3 growth of maize as compare S1 and S2 is good but fungus is present.

TRIAL 6

After discussion with dixit sir we decide taking trial in replication

SET 1 =Normal

SET 2 = Vibration

SET 3= sleeves

trial period is 8 day

conclusion in this trial

set 1 in this trial in normal trays growth of fodder is less because space between seeds is more so

set 2 in this vibration tray growth of fodder is more than set 1 same reason

Set 3 in sleeves growth of fodder is good than other set

After this trial we decide using small pore space buckets

Problem

Fungi increeased in the sieves because the bag used for socking may have grown fungi bacteria.

TRIAL 7 A trial was conducted by treating in a fine hole bucket

SET 1= Vibrate

SET 2 = Trichoderma

SET 3 = Tricoderma + vibrate

Conclusion in this trial

Result of this trial is Trichoderma and Trichoderma + vibrate is very good growth of fodder as compare to other two set

conclusion note on trials

In over all trials it will be understood that we can use trichoderma to prevent fugus growth and even if too much water remains between the seed fugus growth occurs ,for that we can give it a little shock after giving it water from a try with more holes it does not cause the growth of fugus bacteria.

After the trial, we discussed with Dixit sir about the mechanical system and it was decided that from the trials we have conducted ,there should not be to much water in the tray. what can we do for that if we can vibrate the trays, we can move the tray, after giving water, we decided to design the system accordingly. I calculated the fodder required for the cow in the Ashram but Dixit sir said that first let’s try to make a small system.then after ideation a system was finalized.

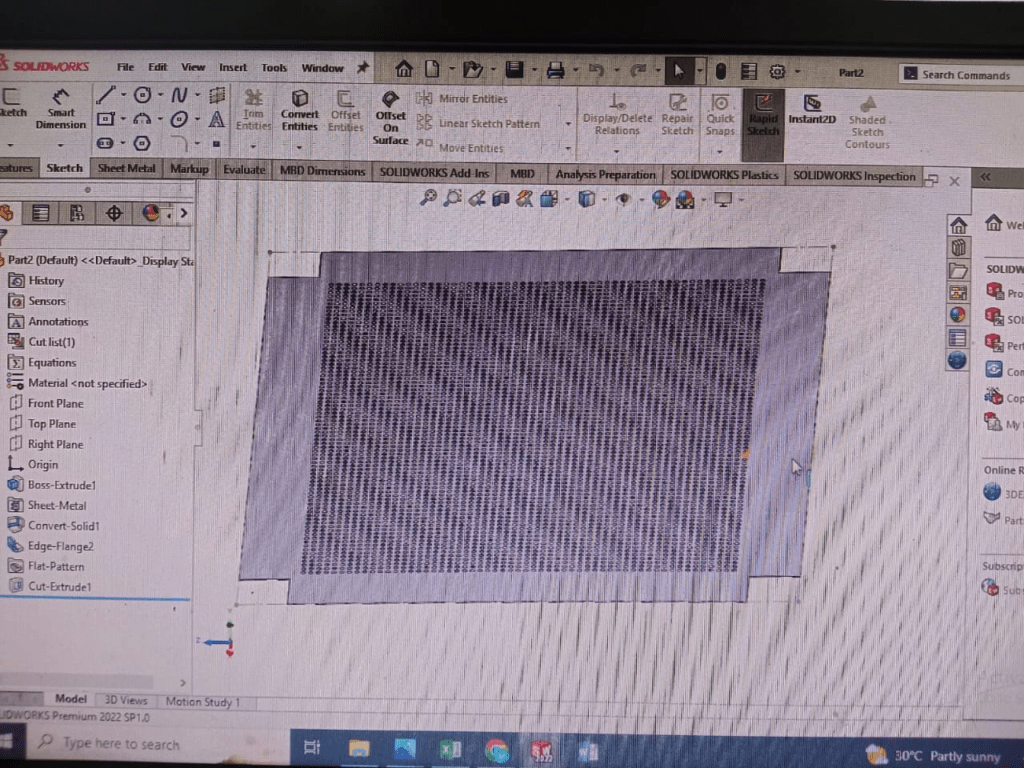

Design of system

Drawing design in solid work

Stand

2. Tray

3. plate

4.Nut

Design of system

Bill of material

| SR.NO | Material | Quantity | Rate | Price |

| 1 | Punchmesh sheet | 16 ft | 8*4 ft=2500 | 1250 |

| 2 | Square tube | 16ft | 20ft=600 | 480 |

| 3 | Nut bolt | 20(2in 6mm) | 5 | 100 |

| 4 | Flat pati | 9ft | 150 | |

| TOTAL | 1980 |

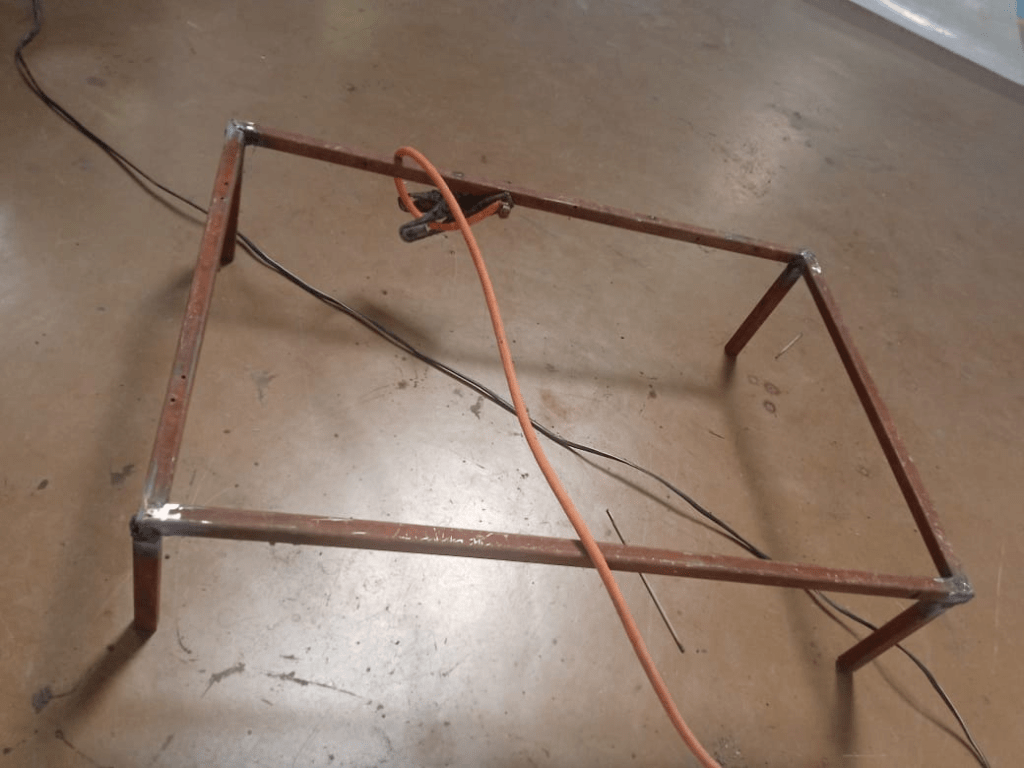

System fabrication

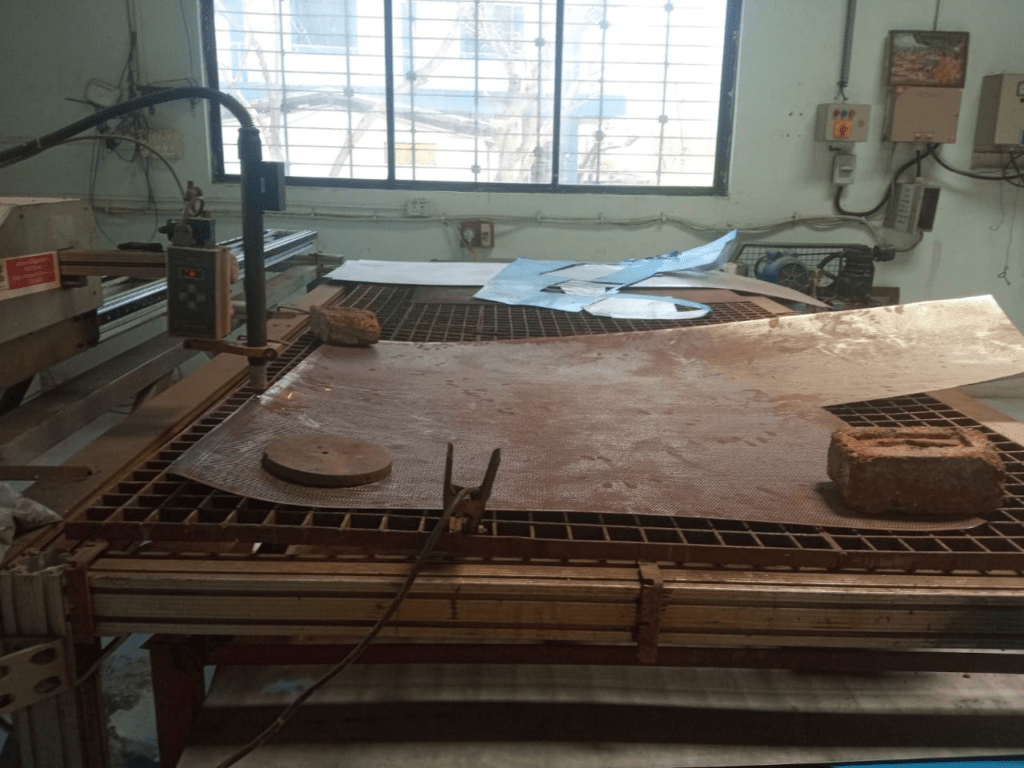

After system design and bill of material, square tube and flat pati are cut to dimension on cutter.Then it was welded by welding machine.Punchmesh sheet cut on plasma cutter,after that it was made into a tray by spot welding

Fig Name- welding

Trials in system

First Trial

After preparing the system, the motor was selected for it, but because the rpm of the motor was high, the system was not working.After that, the system will be worked manually and a trial will be taken.

In the first trial, 5kg of Maize was taken in which the seeds were socked for 24 hours and after socking, they were placed in the seed system and given 3-4 liters of water every 2 hours. But since the tray was made of iron sheet, after watering, it got rusted , so it got rusted on the maize and the maize got browned and spoiled.

Fig Name- Socking of seeds

Fig Name- Taking in tray

Trial Second

Fig Name – Second trial

Fig.Name – Result of Trial