02/08/2022

1.Firstly dismantled the float switch with the help of cutting blade, sceve driver.

2.Checked out the continuity of the float switch with the help of multimeter.

3.It found faulty so we are going to a new float switch

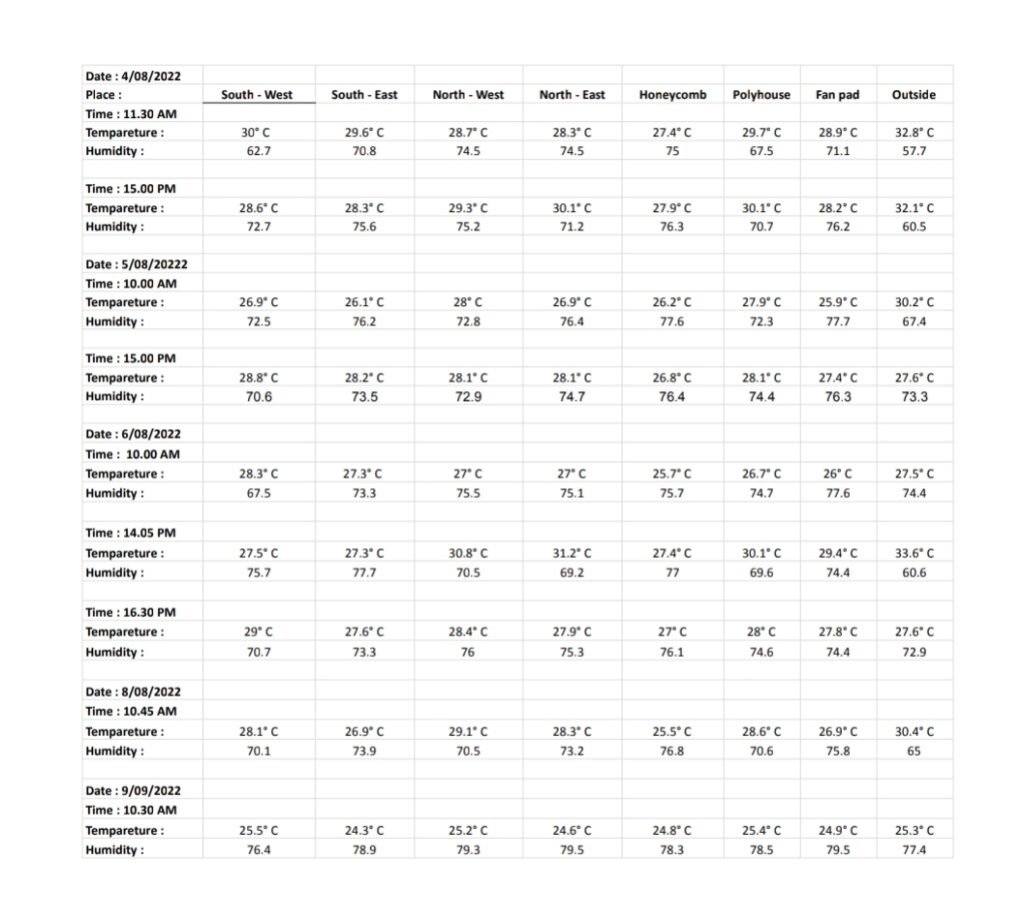

MEASURED TEMPERATURE OF POLYHOUSE

| PLACE | TIME (12:30 PM) | TIME (3:00 PM) |

| 1.SW Corner | 30 Degree | 24 Degree |

| 2.SE Corner | 33 Degree | 27 Degree |

| 3.NW Corner | 27 Degree | 23 Degree |

| 4.NE Corner | 28 Degree | 26 Degree |

| 5.Honeycome Structure | 22 Degree | 23 Degree |

| 6.Polyhouse outside | 29 Degree | 29 Degree |

| 7.Pan pad | 28 Degree | 27 Degree |

CUTTING OF PLATES IN WORKSHOP

- From 3:30 PM to 4:30 PM done cutting of plates in workshop.

03/08/2022

- Edited pending daily blogs.

- Helped in workshop for making shed-net for black bees.

- Cutting the shed-net according to size of the tray stand.

- And Tied the shed-net in such a manear in rectriangular type shape.

04/08/2022

- Completed remaining work of the shed-net.

- Attached zip line to it.

- Tied the shed-net to the tray stand.

- Done packing of culture in bags.

06/08/2022

- Firstly i attend the lecture on ownership.

- We measure the temperature and humidity of the polyhouse.

- We are thinking about how to place foggers in polyhouse system.

08/08/2022

- Firstly we measure the temperature and humidity of the polyhouse.

- We draw the layout of pipeline to transfer the water at filtration unit.

- After 2:30 we went for survey.

- In survey we are talking to farmer about they ise hand tool in there field or not.

09/08/2022

- There was a discussion session about energy cycle and nitrogen cycle.

10/08/2022

- Repaired the broken pipeline.

12/08/2022

- Installed a new float switch in the water tank of the polyhouse.

14/08/2022

- Tree plantation.

16/08/2022

- Supplied water from the farm pond to the filtration system of the polyhouse.

- Measured the incoming pressure of water at the inlet of the sand filter.

- It was about 0.5 kg/cm².

23/08/2022

- Measured water pressure of sand filter by stopping the flow of water.

- It was about 2.3 kg/cm².

- Purchased a saddle piece to attach a pressure gauge at the outlet of the disc filter.

- Survey.

24/08/2022

- Attached a saddle piece in the pipeline where we had to measured the pressure of water at the outlet of the screen filter.

- Rejoined the loosen T-joint.

- Measured water pressure at the inlet of sand filter and outlet of screen filter.

- It was about 2.8 kg/cm² &2 kg/cm² respectively.

25/08/2022

- Survey.

- PPT Presentation.

26/08/2022

- Survey.

27/08/2022

- PPT Presentation.

10/09/2022

- Discussion session – Theory of Relativity.

12/09/2022

- Information about mushroom farming.

13/09/2022

- Repairing honeycomb structure of the polyhouse.

14/09/2022

- Draw rough layout of fogging system for polyhouse.

15/09/2022

- Built a foundation structure for water tank.

- Helped in composter project.

16/09/22

- Built second layer of foundation of structure.

- Draw fogger system of the polyhouse.

- Helped in composter project.

17/09/2022

- Calculated pressure drop in lateral of fogging system.

- Attended PPT Presentation.

18/09/2022

- Holiday

19/09/2022

- Attended PPT Presentation.

20/09/2022

- Cleaned out polyhouse to place Water tank.

- Cleaned water tank.

- Placed water tank in polyhouse.

21/09/2022

- Reconstructed Azolla’s bed.

22/09/2022

- Made a list of questions for polyhouse survey.

23/09/2022

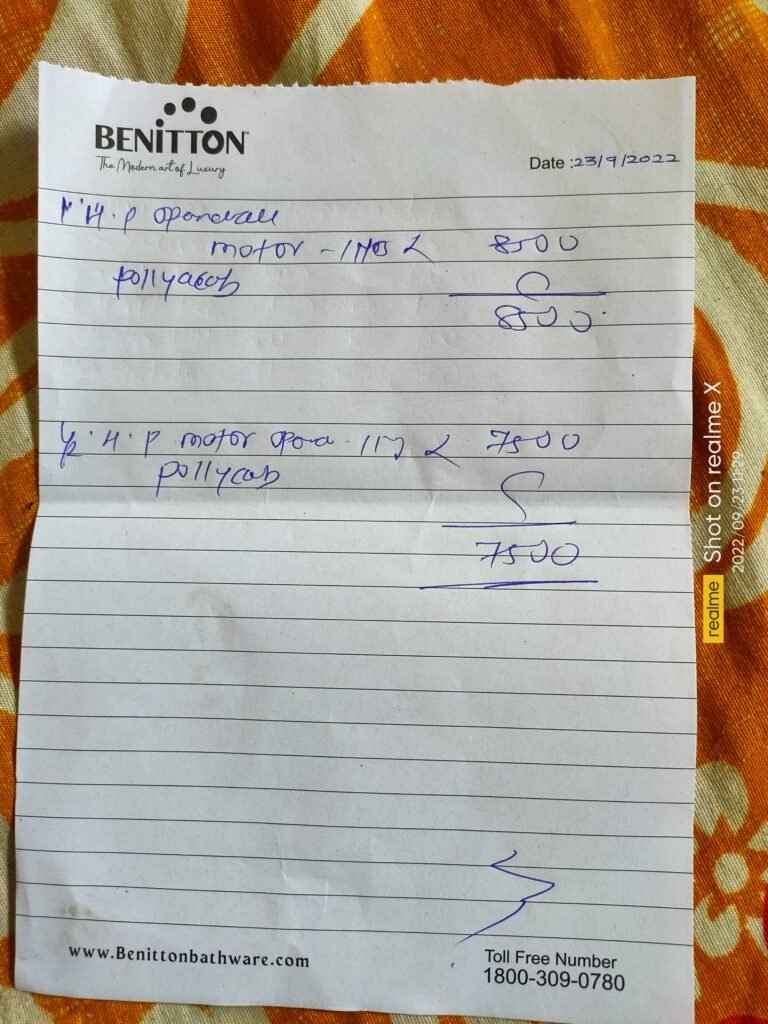

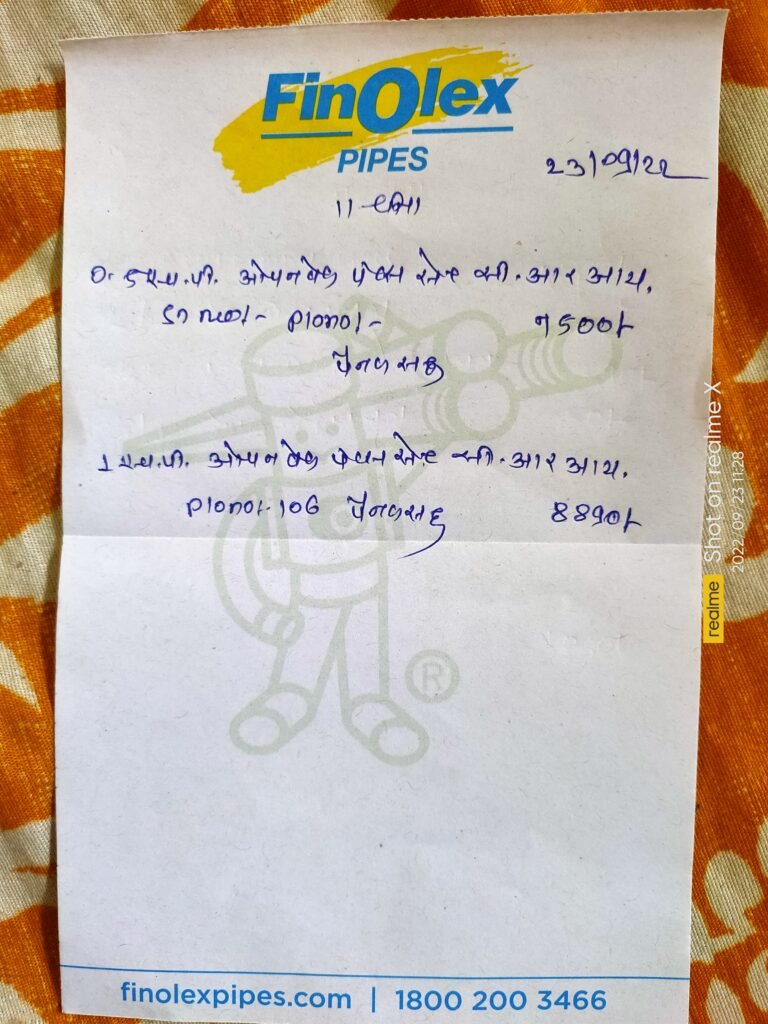

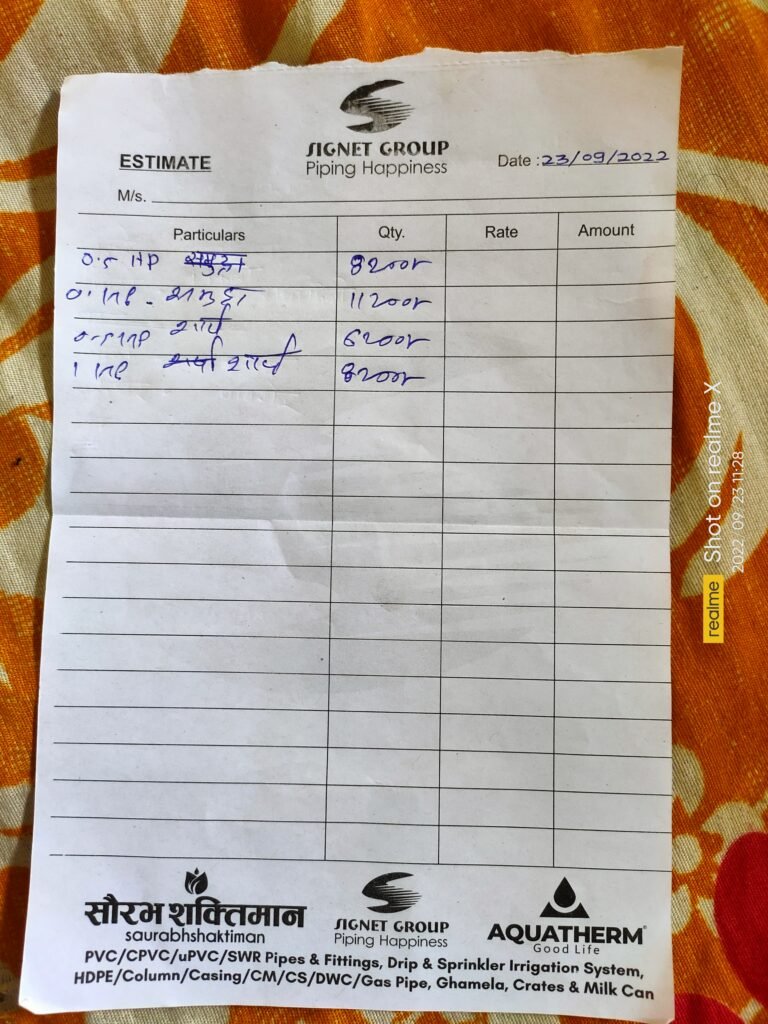

- Collected quotation of 1 hp motor from different plumbing shops.

24/09/2022

- Calculated pressure drop in 16mm lateral of the fogging system

For first lateral :

ΔP = f×L/D×ρ/2×V²

where,

ΔP – pressure drop in lateral,

f – friction factor,

L – length of lateral,

D – diameter of lateral,

ρ – fluid density,

V – velocity

∴ ΔP = 0.0357×(16.5/16×10-3)×1/2×(04.17)²

= 10.2436/0.032

= 0.3201 KPa

= 0.03264 kg/cm²

For second lateral :

ΔP = f×L/D×ρ/2×V²

∴ ΔP = 0.0357×(14/16×10-3)×1/2×(4.17)²

= 8.6915/0.032

= 0.2716 KPa

= 0.02769 kg/cm²

For third lateral :

ΔP = f×L/D×ρ/2×V²

∴ ΔP = 0.0357×(16.5/16×10-3)×1/2×(4.17)²

= 10.2436/0.032

= 0.3201 KPa

= 0.03264 kg/cm²

25/09/2022

- Holiday.

26/09/2022

- Calculated velocity of water inside 2.5 inch PVC pipe and 16 mm lateral.

Flow rate of water in 2.5 inch pipe –

Q = 9000 LPH = 0.000252 m3/s

Cross-sectional area of pipe –

d = 0.0635 m

r = 0.03175 m

A = πr²

= 3.14×(0.03175)²

= 0.003165 m

Velocity of water in pipe –

Q = AV

∴ V = Q/A

= 0.00252/0.003165

= 0.7962 m/s

Cross-sectional area of 16 mm lateral –

d = 0.016 m

r = 0.008 m

A = πr²

= 3.14×(0.008)²

= 0.0002010 m²

Velocity of water in 16 mm lateral (3 laterals) –

Q = AV

∴ V = Q/A

= 0.00252/0.0002010

= 12.53 m²

Therefore, velocity in each lateral

V1 = V2 = V3 = V/3

= 12.53/3

= 4.17 m/s

27/09/2022

- There was a discussion session about design thinking.

28/09/2022

- Calculated flow rate (discharge) and velocity drop in 16 mm lateral of fogging system.

Discharge of one 4-way fogger –

30 LPH

Flow rate of water in 16 mm lateral –

Q = AV

= 0.0002010×4.17

= 0.0008382 m3/s

= 3006 LPH

Discharge at first fogger –

Q1 = Q – 30 LPH

= 3006 – 30

= 2976 LPH

= 0.0008267 m3/s

Discharge at second fogger –

Q2 = Q – 30 LPH

= 2976 – 30

= 2946 LPH

= 0.0008183 m3/s

Discharge at third fogger –

Q3 = Q – 30 LPH

= 2946 – 30

= 2916 LPH

= 0.0008100 m3/s

Discharge at fourth fogger –

Q4 = Q – 30 LPH

= 2916 – 30

= 2886 LPH

= 0.0008017 m3/s

Velocity drop in lateral when foggers are on –

V1 = A/Q1

= 0.0002010/0.0008267

= 0.243 m/s

V2 = A/Q2

= 0.0002010/0.0008183

= 0.246 m/s

V3 = A/Q3

= 0.0002010/0.0008100

= 0.248 m/s

V4 = A/Q4

= 0.0002010/0.0008017

= 0.251 m/s

Total velocity drop = V1 + V2 + V3 +V4

= 0.243 + 0.245 + 0.248 + 0.251

= 0.987 m/s

29/09/2022

- Brought the materials required for the installation of fogging system from plumbing shop.

- Made same connection of pipeline to supply water from the filtration system to the water tank.

30/09/2022

- Cut the 20 mm lateral into designed length of the lateral.

02/10/2022

- Holiday

03/10/2022

- Cut the 20mm lateral into designed length.

- Collected some required material from scrap.

04/10/2022

- Marked out the points on 20mm lateral where we are going to attach fogger.

- Drilled 20mm holes in mainline for the lateral.

06/10/2022

- Drilled holes in 20mm lateral for/to attach fogger.

07/10/2022

- Tied metal wire in the polyhouse to give support to the lateral.

08/10/2022

- Attached lateral to the main line.

- Attached the fogger to the lateral.

09/10/2022

- Holiday

10/10/2022

- Digged soil for the pipeline .

11/10/2022

- Tied metal wire in one half the polyhouse to give support to the lateral.

12/10/2022

- Tied metal wire in other half of the polyhouse.

13/10/2022

- Connected mainline to the water pump.

14/10/2022

- Made electricity connection of motor to operate foggers.

- Placed humidity and temperature senor inside BSF net.

17/10/2022 – 21/10/2022

Measured temperature of the polyhouse.

Attended weekly review.

Replaced the humidity and temperature sensor of BSF net.

Covered electricity board of polyhouse with plastic sheet.

22/10/2022 – 27/10/2022

- Holiday

28/10/2022 – 29/10/2022

Measured temperature of the polyhouse.

Sprayed water on honeycomb pads.

Calculated the discharge of the outlet of mainline of the fogging system.

Made a excel sheet of readings that we collected in last two weeks.

30/10/2022

- Holiday

31/10/2022

- Attended technical review.

1/11/2022

- We noticed a leakage in the water tank of the fogging system. So we fixed that leakage by using M-seal clay.

2/11/2022 – 4/11/2022

Measured temperature and humidity of polyhouse and BSF net.

Harvested Marigold flowers from polyhouse sold it in market.

5/11/2022

Discussed about the systems which we have to install in BSF net for maintaining humidity and temperature.

Wick hydroponic system

This system consist of a reservoir i.e. any bucket or container that can hold enough water.

Several long strips of suitable wicking material, string or rope.

Some common household choices for a wick are :

- Nylon rope

- Wool rope / strip

- Braided PU yarn

- Propylene strips

- Mop head strings

- Strips from old clothes or blankets.

100 % cotton strip is very good for absorption and evaporation of water.

100% rayon doesn’t absorb water easily, but when it does absorb water, it holds on to it for a longer time.

50% polyester – 50% nylon , this blend of fabrics is very effective at absorbing water, but very ineffective at expelling it. Therefore, it holds on to its liquid contents for a long time.

100% polyester is neither good nor bad at retaining water.

Advantages :

- Cheap and easy setup.

- Minimal maintenance required.

6/11/2022

- Holiday

7/11/2022

8/11/2022

- Discussed about the corrections that we have to make into the sensor of BSF net with PJ.

9/11/2022

- Removed the sensor from BSF net to install new programme and to check whether both the sensor showing same temperature at same time or not.

13/11/2022

- Holiday

14/11/2022

- Today we noticed that some foggers were not working due to clogging dust inside it.

- So, we cleaned it properly.

15/11/2022

- Placed humidity and temp. sensor in BSF net with new programme and corrections.

16/11/2022

- Repaired broken pipeline of farm pond.

17/11/2022

- Replaced the cloth of wet bulb sensor of BSF net with cotton cloth.

18/11/2022

19/11/2022

- Refilled Azolla’s bed with water and added new Azolla in bed.

20/11/2022

- Holiday

21/11/2022

22/11/2022

- Helped in workshop for making new shed net for black soldier flies.

23/11/2022

Brought a new screen filter from market to attach it in pipeline of the fogging system.

Done some preparations for the tour which will be held on 24th November 2022.

24/11/2022

- Done project guidance for the tour.