Objective:

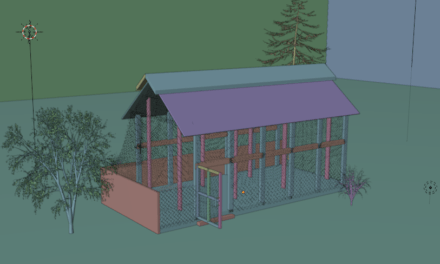

To design the solar powered Bubbling system for grey water treatment/ aquaponics system.

Problem Identification:

To maintain the oxygen level in hydroponics, aquaponics and grey water recycling system, aeration is required in water. So as to maintain the oxygen level, air pumps are used for aeration (bubbling). It requires about 5 to 12 hours of bubbling in water according to our application to maintain the oxygen level up to 2-5 PPM in water. [1]

In rural areas, load shedding is the factor due to which farmers unable to aerate water for 12 hours in a day, so to maintain this Solar DC bubbling system is the best solution for it.

If availability of electricity is not a barrier then cost required for bubbling in day is very large. If we take 2000 Liter pond of aquaponics, we need to spend 430 rupees for 43 KW electricity in 30 days. This cost of bubbling is very much higher and not economical. If the same system operates on DC air pump on solar system then the cost of electricity will also be saved.

Background:

Aeration brings water and air in close contact in order to remove dissolved gases (such as carbon dioxide) and oxidizes dissolved metals such as iron, hydrogen sulfide, and volatile organic chemicals (VOCs). Aeration is often the first major process at the treatment plant. During aeration, constituents are removed or modified before they can interfere with the treatment processes. Aeration brings water and air in close contact by exposing drops or thin sheets of water to the air or by introducing small bubbles of air (the smaller the bubble, the better) and letting them rise through the water. The bubbling process caused by the turbulence of aeration physically removes dissolved gases from solution and allows them to escape into the surrounding air. [2]

For Aquaponics:

In day time, algae present in the ponds produces oxygen in water, but it’s very low as compared to normal water as it is non-moving water. So to maintain the oxygen level up to 5ppm we need bubbling the water. In day time it not required on continue as algae already producing some oxygen, but in night time algae takes oxygen from water and release carbon dioxide in water so in absence of sunlight pond water requires continuous bubbling to maintain the oxygen level in water. [3]

The time between 2:00 am to 9:00 am pond water requires continuous bubbling as oxygen level is very low in this period of time.

Due to deficiency of oxygen in water, fishes present in the water dies. If we use the solar system then the effect on fish farming will not occur.

For grey Water treatment:

Any wastewater produced by domestic usage is known as greywater. Our daily life involves water usage in various causes like bathing, cleaning and washing. These already used waters are called greywater. However, sewage water cannot be considered as grey water as it contains larger organic components. This greywater can be preserved and used for multiple purposes that doesn’t involve drinking.

The content of biological oxygen demand (BOD) and chemical oxygen demand (COD) indicates the risk of oxygen depletion due to the degradation of organic matter during transport and storing and the risk of sulphide production, causing bad smell.

The parameters need to be maintained are BOD (Biological oxygen demand), COD (Chemical oxygen demand), DO (Dissolved oxygen), Turbidity, Oder, etc.

Type of users

- Farmers which are doing Aquaponics, hydroponics.

- Grey water treatment & black water treatment.

- Aquarium users

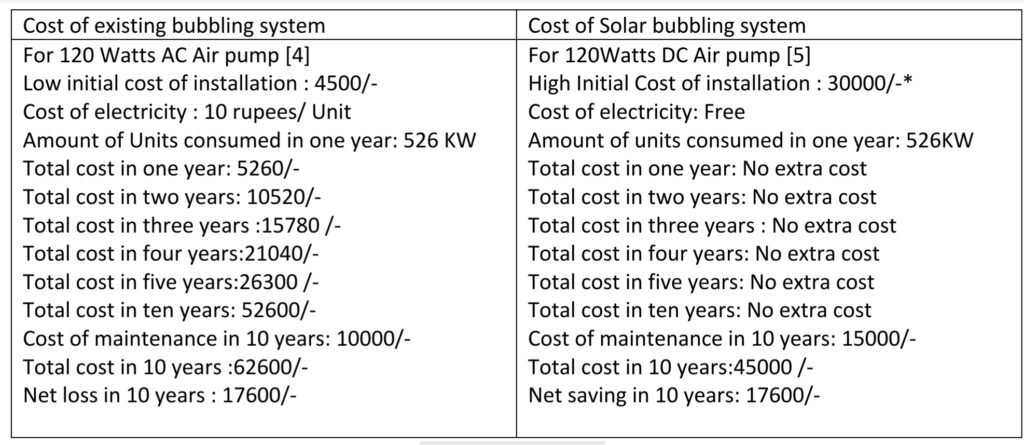

- The maintenance cost mention above for solar system is cost of replacement of batteries and its maintenance, distilled water costs and labor charges.

- The maintenance cost for AC air pump is changing of AC air pumps 2 times in 10 years or may be more as the warrantee is 2 years only.

Required motor: DC air pump/ Bubbler

Required specifications: Voltage: 12/24V

Frequency: 50Hz

Power: 35 Watts to 60 Watts

Pressure: 0.024 MPa to 0.03 Mpa

Output : 65 L/min to 100 L/min

Dia of mouth : 8mm to 10mm

The quotation received for DC air pump has specifications as follows:

Technical Specifications:

Voltage: 12VDC

Power :120 Watt

Pressure: 0.1 MPa

Discharge: 125 LPM

The above air pump has 125 LPM discharge

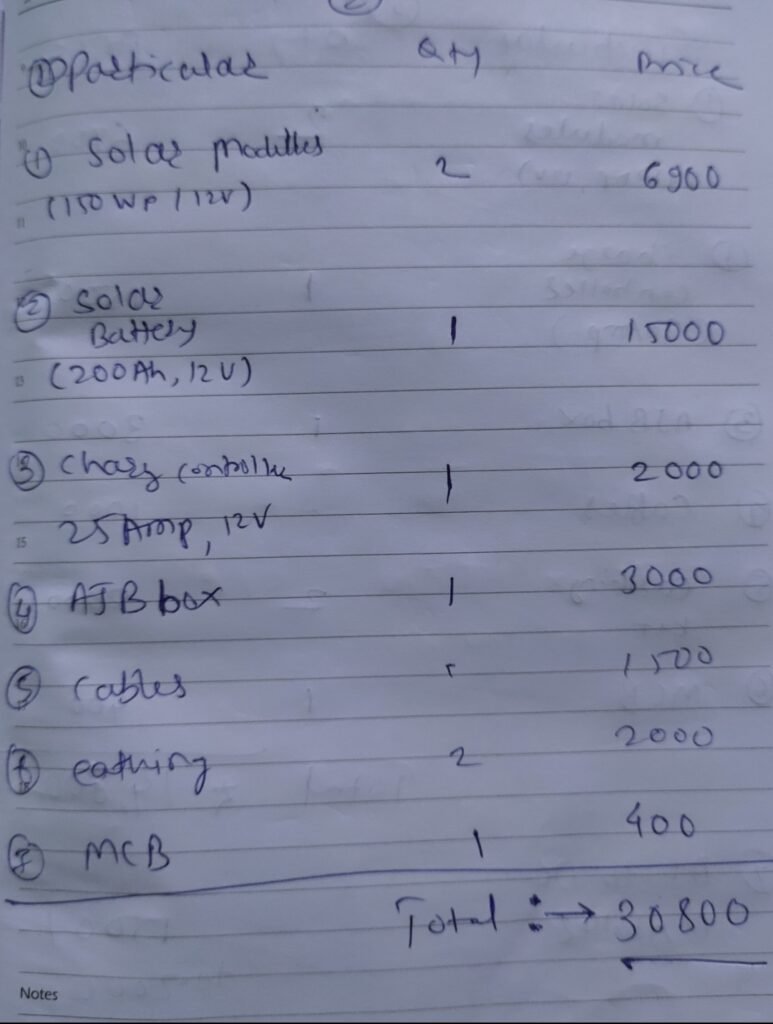

Solar System Design Calculations for DC air Pump :

Calculations for 7 hours of battery backup:

| Days of Autonomy | 3 Days |

| Load efficiency | 80% |

| Charging efficiency | 90% |

| Dust Factor | 95% |

| Max. Depth of discharge | 80% |

Panel wattage calculations

Maximum Daily load = (Total load in Wh)/(load efficiency× system voltage)

1.Maximum Daily load = (840)/(0.8×12)

= 87.5 Ah

2. Total current required=

(Max daily load)/ (eq. Sunshine hour× charging efficiency× dust factor) A

= 87.5 / ( 5 × 0.9× 0.95)= 20.46 Amp

3. Total panel wattage required=

= (Total current required× system voltage× (real panel voltage÷ input panel voltage)

= 20.46 × 12 × 18/12 = 368 W

Series module = ( system voltage) ÷ ( I/P panel voltage)= 12÷12 = 1

Parallel module:

= 368/(1/200)

= 1.84

Which tends to 2 panels of 200 W

Battery Capacity:

Battery capacity required=

( Days of autonomy × max daily load) ÷ DOD. ×discharing efficiency)

= (2 × 87.5)÷( 0.4 ×1) = 218 Ah

Charge controller

Current rating of CR should be above the maximum current from PV array and maximum load current that the CR should

handle.

Here in this case 20.46 is maximum current rating in system so we have to choose 25 A CR.

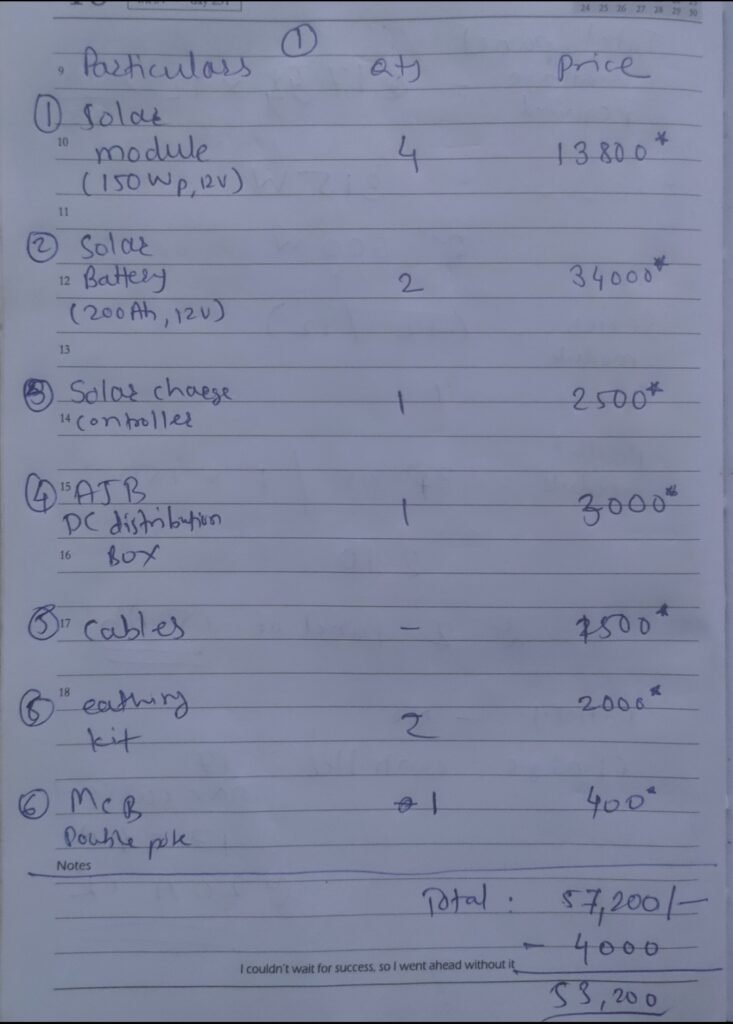

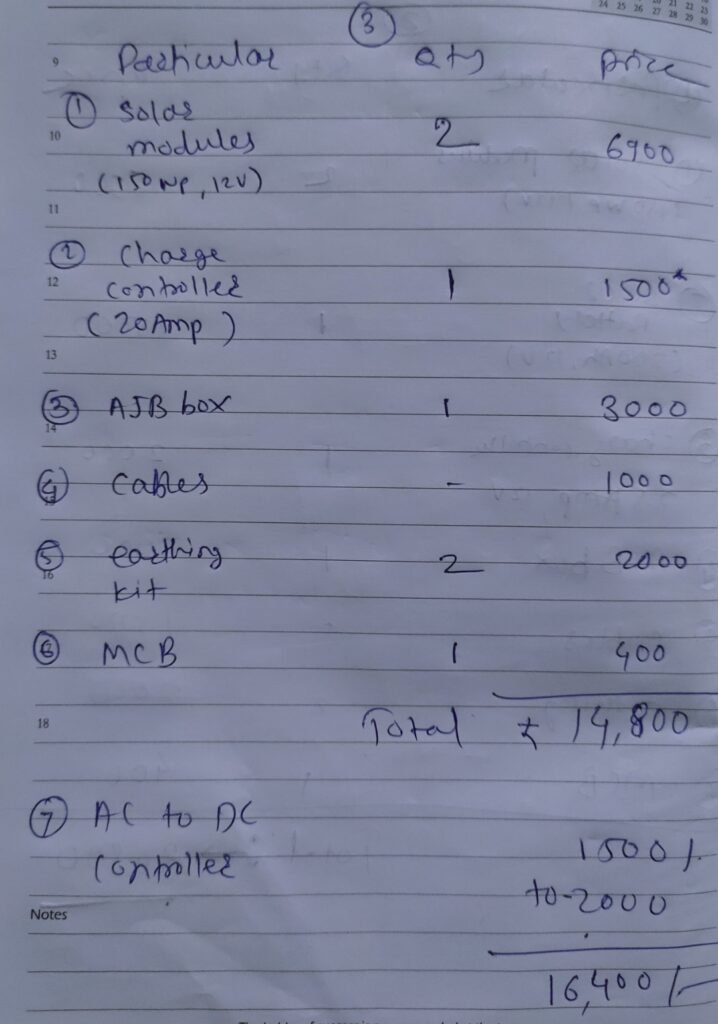

Design of solar system

The compareson study of solar system design is mentioned in the document below:

https://docs.google.com/presentation/d/1YYe–0GTydGmHomByMFoPuyj1DJursnCjq8Ye35ns20/edit

Final Bill of material:

| Item Name | Description | Quantity | Unit Cost | Total |

| DC Air Pump | 120 W, 125 L/min | 1 | 5200/- | 5200/- |

| Solar Panels | 165 W, 12V | 2 | 4290/- | 8580/- |

| Solar Charge Controller | 12 V, 20A PWM type | 1 | 900/- | 900/- |

| DC MCB | 2P-20A | 1 | 883/- | 883/- |

| DC cable | 4 Sq. mm ( Black & Red) | 8 meter | 33.50/- | 268/- |

| DC cable | 6 Sq. mm (Black & Red) | 8 meter | 46.20/- | 369/- |

| Battery | 12 V, 26 Ah | 1 | 2300/- | 2300/- |

| Flexible pipe | To cover the wires from open atmosphere | 20 foot | 3/- | 60/- |

| C clamps | Used to clamp the flexible pipe on wall | 10 | 5/- | 50/- |

| MCB holder box | Used to mount MCB | 1 | 20/- | 20/- |

| Hose pipe | 10 mm ID | 50 foot | 4.5/- | 225/- |

| Drip T | 16 mm dia | 7 | 5/- | 35/- |

| Hose clamps | ½ inch | 6 | 10/- | 60/- |

| Insulation Tape | Black | 1 | 10/- | 10/- |

| Total | 18960/- |

This solar system design given by SELCO team was costing abount 54000/- rupees. Our system gives 9* hours of continuous bubbling oparation. it costed arount 18960/- rupees. Our system design is 35% less costly than SELCO design.

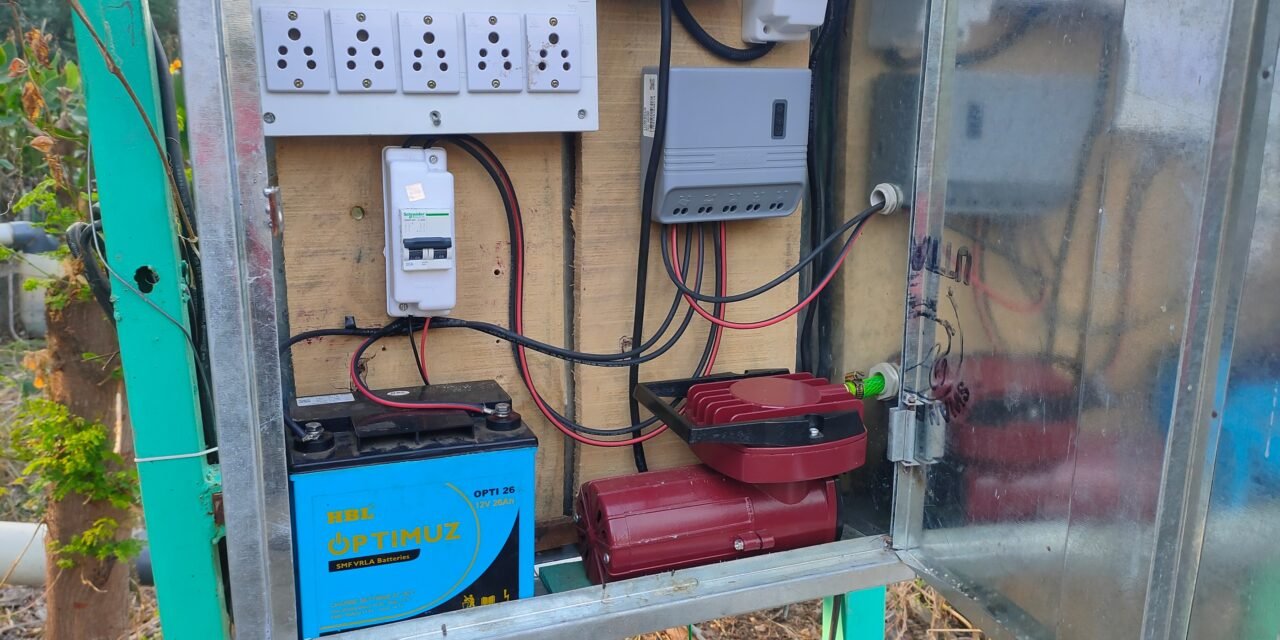

Installation of System:

Payback period and Return on investment:

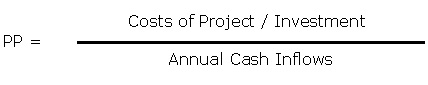

Payback period:

Payback period = 18960/ 5260 = 3.6 years

Return on investment:

ROI = (5260/18960) * 100 = 27.74%

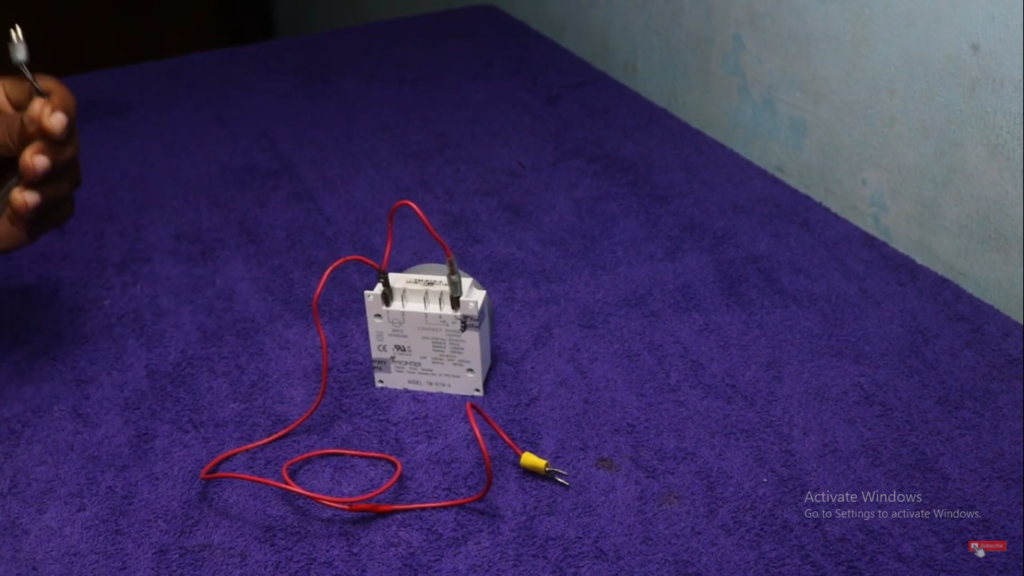

Bubbler:

This Porous tube has infinite small opening on its periphery so its blows air in water with high pressure.

Pressure loss due to length of hose pipe:

dp= (7.57×q^1.85×L×10^4)/d^5× p

dp = pressure drop ( kg/cm2)

q= Air volume flow at atmospheric conditions (m3/min)

L= Length of pipe (m)

d= inside diameter of pipe

P= Initial pressure (kg/cm2)

q= 0.125 m3/min

P= 1.0197 kg/ cm2

L= 12 m

d= 10mm

dp = ( 7.75× 0.125^1.85 × 12× 10^4)/ 10^5×1.0197

dp = 0.19 kg/cm2

Therefore 0.018MPa pressure will be drop.

The pressure drop is around 10% which is negligible as per our application.

Document on Solar water bubbling system

https://docs.google.com/document/d/1QaropVfDT0NMH98ASxE65Unrv7KrjYur-16voLjfehM/edit?usp=drivesdk

Installation of 2nd solar bubbling system for grey water treatment plant for girls hostel. This is the replication of the same system as of earlier installed system. In this system I have designed and fabricated the solar panels mounting structure, all the wiring part and plumbing part is covered. The replication of the system is for testing the performance of our newly developed technology. The data analysis of both system will give us the opportunity to replicate this as a product in the market. In the Analysis of system we are observing the performance of PMDC aerator, battery, solar panels, charge controller etc.

The report document is attached below for the project.

https://docs.google.com/document/d/18oTk9nhMMF7na6cWfr0DoledYVmEtofFC23AZB39ffE/edit?usp=drivesdk

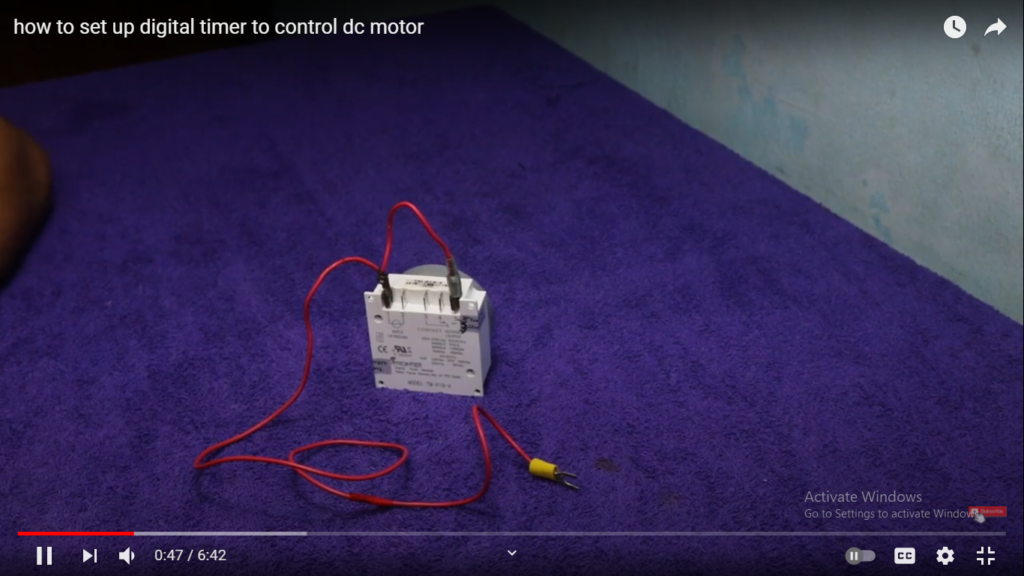

Conclusion notes on DC air bubblers:

DC air bubbler has permenant magnets and brushes, which are in continuous contact with friction, due to this high amount of friction it gets fail.

So to operate a DC blower you need to run it on timer.

To operate the system on AC bubbler we can use solar inverter: