There are different types of plastics are available and every type of plastic have some density. After the use of plastic, it came into a waste management facility or dumping grounds. Every plastic occupies some space, low-density plastics occupies more space because it is floppy. We have a scarcity of land because of the population that’s why huge mountains of waste plastics are formed on every dumping grounds. The extra cost will be added to transport waste plastics from the user to the treatment facility. It is not economical for running any waste treatment facility.

Need for Project:

- Densify waste plastics occupies more plastics.

- It helps to transport waste plastic from one place to another easily.

- It helps to the running of waste treatment facility economically.

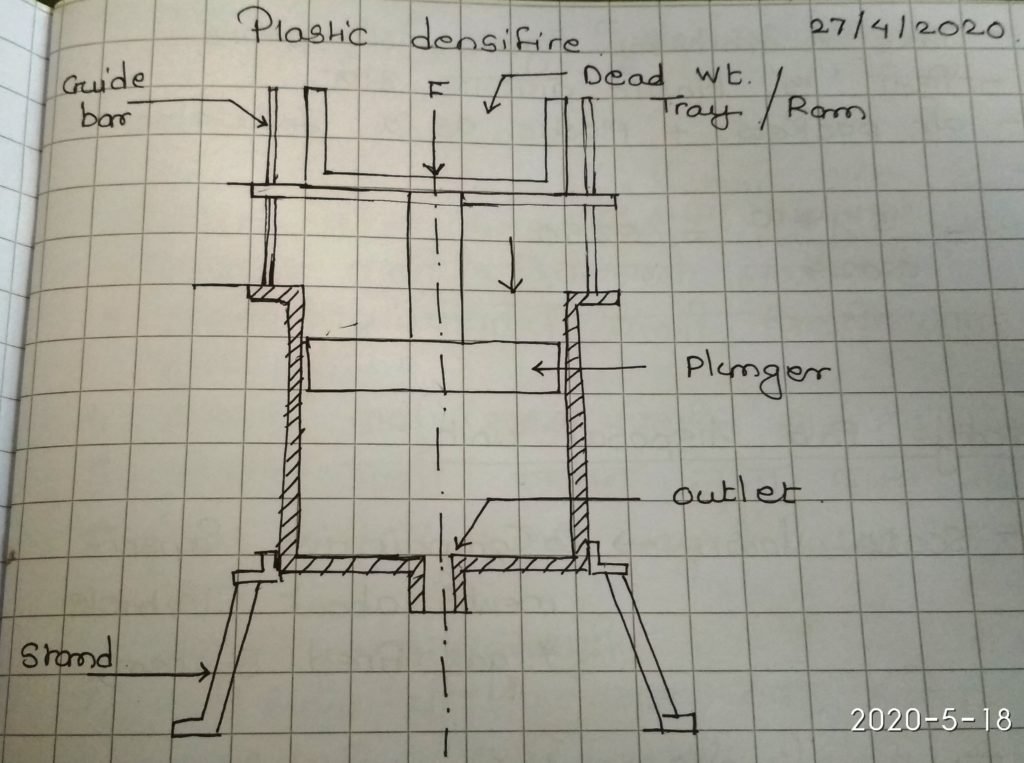

Concept rough sketch:

Proposed CAD Design:

Technical Specification:

| Parts | Descriptions |

| Densifier chamber | •Volume- 5.12 lit •Dimensions: O.D.= 182 mm I.D. = 179 mm Height = 220 mm |

| Shell | •Dimensions: O.D.= 265 mm I.D. = 262 mm Height = 263 mm |

| Heaters | 1150 Watt (3 Nos. ) |

| Ram | •Volume – 2 lit |

| Plunger | •Dimensions: Length = 200 mm Area = 0.024 m2 |

| Guide | • Dimensions: Length = 350 mm |

Meeting with Dr. J.B.Joshi and Mr. Anil Kelker:

For Plastic Densifier make a two cylinder arrangement and in outer cylinder use hot water as a heating source. Feed insert into inner cylinder and press it by using plunger. For solving a air pocket problem add some water inside feed i.e it cover that pockets and after evapouration they transfer heat.

- Make a Piston and cylinder arrangement for an experiment.

- Take some trials on single composition plastic.

Fabrication:

Experimental Setup:

Trial- I:

- PET Bottles:

| PET Bottles | |||

| Weight of Bottles (g) | Volume occupied (cm3) | Density (g/ cm3) | |

| Before Experiment | 132 | 2147.76 (2.1476 lit) | 0.0146 |

| After Experiment | 132 | 452.16 (0.452 lit) | 0.2919 |

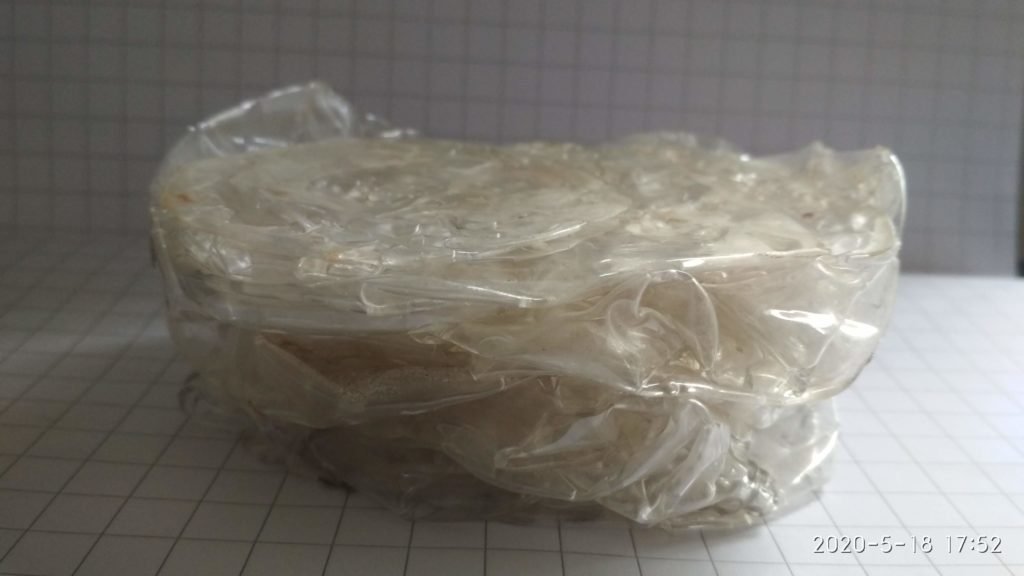

2. LDPE (Syringe wrap):

| LDPE | |||

| Weight of Bottles (g) | Volume occupied (cm3) | Density (g/ cm3) | |

| Before Experiment | 607 | ||

| After Experiment | 607 |

Meeting with Dr. J.B.Joshi and Mr. Anil Kelker:

For the next experiment, we should try PET bottles directly put into hot water and press them by using a plunger (200 lit drum). In which we can use latent heat of the water and if the inner temperature goes down then apply heat externally it may more economical than passing the steam directly to feed.

- To take a trial on different single composition plastics.

- To calculate the energy requirement of the process.

- To write down the economic model.

Fabrication:

Experimental Trial II:

- PET Bottles:

For a trial, I took 104 g PET bottles. Add a 100 oC water in a vessel and kept up to 15 minutes, simultaneously gradually compression occurs.

| PET Bottles | |||

| Weight of Bottles (g) | Volume occupied (cm3) | Density (g/ cm3) | |

| Before Experiment | 104 | 2147.76 | 0.0480 |

| After Experiment | 104 | 379.94 | 0.2737 |

2. LDPE (Syringe wrap):

| LDPE | |||

| Weight of Bottles (g) | Volume occupied (cm3) | Density (g/ cm3) | |

| Before Experiment | 50 | ||

| After Experiment | 50 |

Experimental Trial III:

- PET Bottles:

| PET Bottles | |||

| Weight of Bottles (g) | Volume occupied (cm3) | Density (g/ cm3) | |

| One PET Bottle | 20 | 2147.76 | 0.0093 |

| Without Temperature(Cold drawn) Experiment | 20 | 785 | 0.0254 |

| With 100 0C Temperature Experiment | 20 | 314 | 0.0637 |