- Making of Shoes stand :-

1)Number of Shoes :- 16 Shoes

2) Dimensions of Shoes :-

| Sr.No | Dimensions Shoes(cm) | Weight of Shoes(gm) |

| 1. | Length= 25 cm | Slipper Chapal=200 to 300 gm |

| 2. | Height=15 cm | Sandal=400 to 500 gm |

| 3. | Width=20 cm | Shoes=500 to 700 gm |

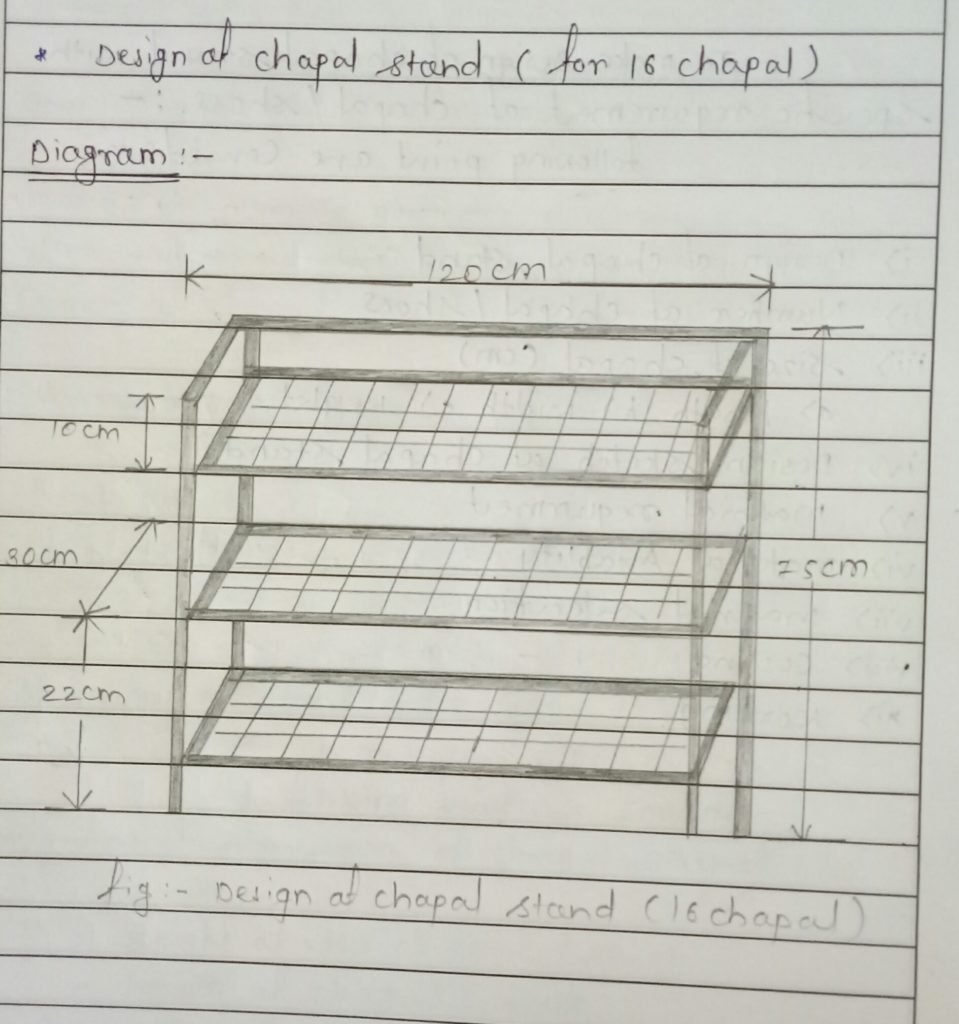

4)Design sketch of shoes stand :-

5) Material requirement :-For making of shoes stand following type of material required 1. 16 mm MS bar = 720 cm 2.L angle bar =1384 cm 3.narrow metal sheet =160 cm

6) Material availability :- The availability of material was checked in Scrap.

7)Material selection :- The selection of material according to strength, strain and elasticity of the material.

8)Costing of shoes stand :-

- Density of the mild steel bar= 7.85 gm/cc

- volume = Area x Length

- Weight= Density x Volume

- Total cost = Weight x Cost of mild steel material

9)Working on shoes stand :- Following type of operation were performed

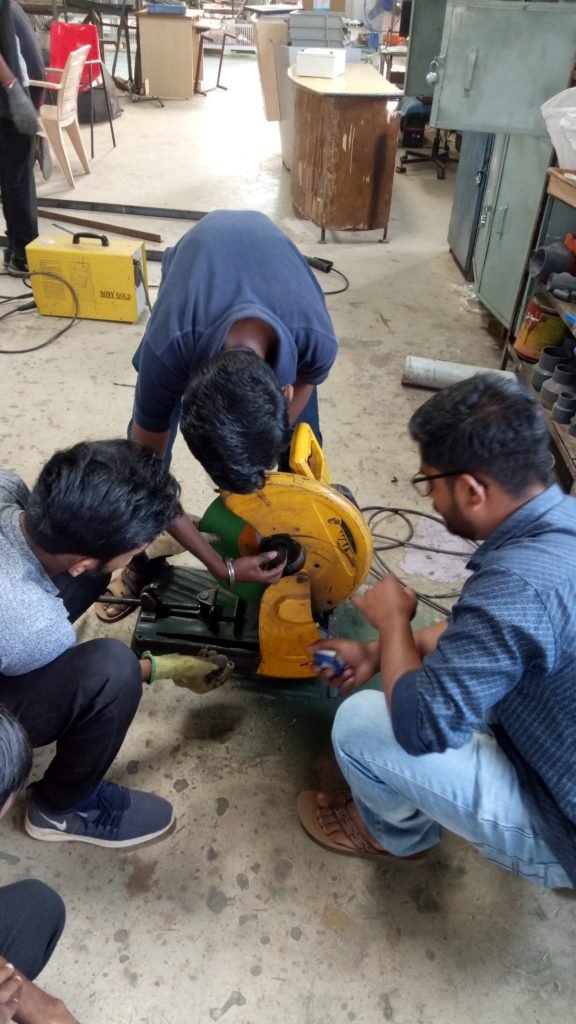

1. Cutting of material :- Metal cutting is a processes when in material is brought to specified geometry by removing excess material using various kind of tooling to leave a finished part that meet specification.

2.Welding :- Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals when cool result in a binding of the metals. Arc welders can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes.

3.Grinding of bar :- Grinding is a way of refining the raw metal of bar stock. Companies may grind bar stock for a variety of reasons to aid manufacturing firms or construction agencies. The grinding process uses a variety of different cutting mechanisms to remove any unnecessary components from the stock.

4.Painting :- The protective paint systems usually consist of primer, undercoat and finish coats may contain inhibitive pigments to interfere with the corrosion process.