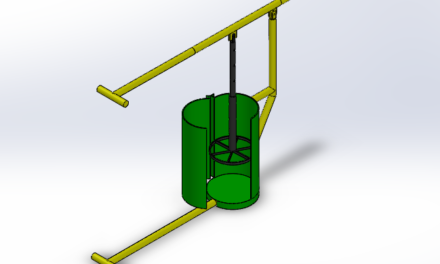

First, we measured the total length of the guide required to pull the cement bag is 420 mm. we design the roller guide to guide the arm and lever mechanism. guide design the consideration in the following factor. total stroke divided in the 3 part.

- Total stoke length of the pulling arm.

- The uplift distance of the arm when the initial position of the arm.

- Travel through on cement bag

- Step down movement to lock the cement bag at the end position of the arm.

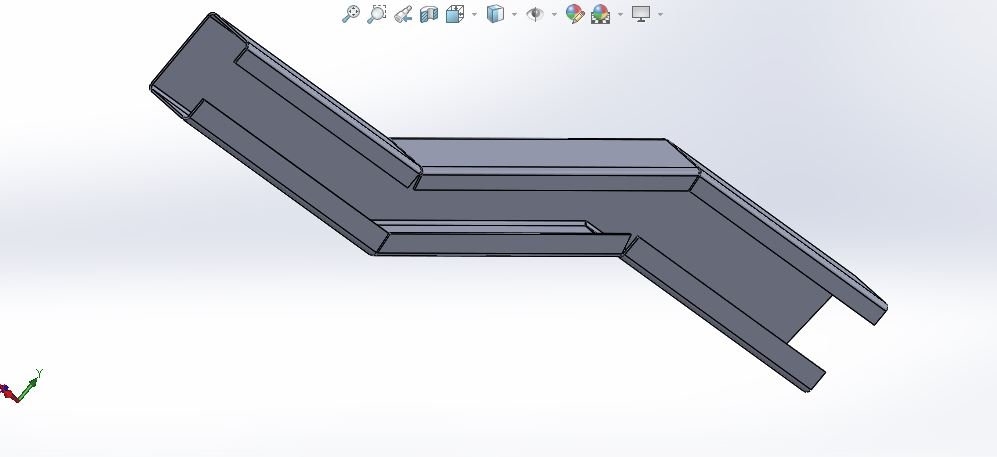

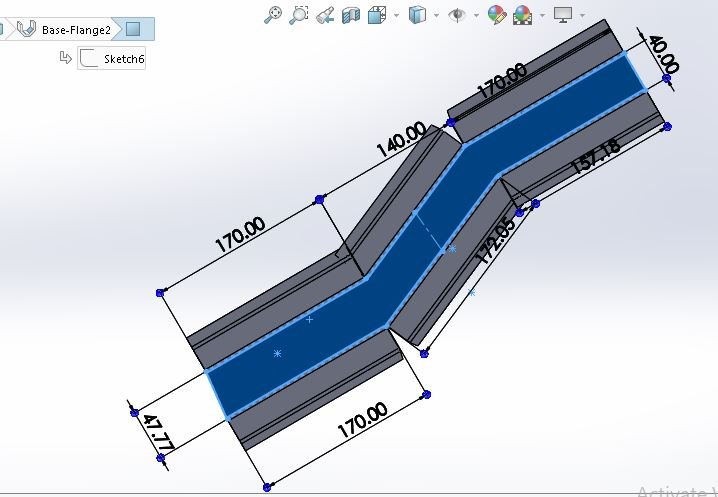

Roller guide fabricated in the sheet metal . the daimention of guide is Desided bas on the the size of bearing. Its design on SOLIDWORK sheet metal as per design requierments.

Guide divide by basic 3 part. its design and then it converts to the co-ordinate form. fast cam software used to convert the design file to DXF format. MS material sheet 0.8 mm select to cut on the plasma machine.

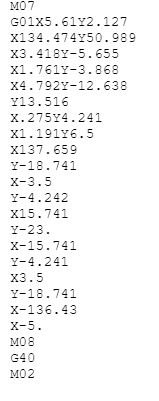

NC CODE FOR PLASMA SHEET METAL CUTTING

G92X0.Y0.

G21

G91

G00

X277.971Y82.324

G41

M07

G01

X.586Y-5.972

X.429Y-4.373

X6.644Y-17.524

X-137.336Y-52.074

X-3.418Y5.655

X-1.761Y3.869

X-4.792Y12.637 Y-13.515 X-.275Y-4.242

X-1.19Y-6.5

X-137.66 Y18.742

X3.5 Y4.241

X-15.741 Y23. X15.741 Y4.241

X-3.5 Y18.741

X139.492 Y-18.741

X1.149Y-4.241

X1.308Y-4.826 M08

G40

G00

X-11.129Y25.681

G41

M07

G01

X5.61Y2.127

X134.474Y50.989

X3.418Y-5.655

X1.761Y-3.868

X4.792Y-12.638

Y13.516

X.275Y4.241

X1.191Y6.5

X137.659 Y-18.741

X-3.5 Y-4.242

X15.741 Y-23.

X-15.741 Y-4.241

X3.5 Y-18.741

X-136.43 X-5.

M08

G40

M02

RESULT AND OBSERVATION :

- Plasma cutting sheet metal does not bend properly. we do not include the all parameter for the as per requirement on the sheet bending.

- we did not include the extra dimension addition at the time of design therefore in at the time of the point of actual bending time it reduces the actual size of the guide.

- And its lot much difficulty in the bending operation.

- After fabrication of the guide, the dimension will not match with the designed so the guide was not used in the pulling mechanism.