Objective: – To design chopper for composter.

Tools & Material: – Power cutter, GI pipe, iron sheet, welding machine, paint and grinder.

Constructional classification:-

1.length of chopper=130cm

2.wt.of chopper=5kg

3.diameter of chopper=25mm

4.blade lenght=length*width=20cm*11cm

5.blade thickness=0.2mm

6.stroke length=30cm

Design of chopper:-

Compost chopper

Construction:-

1.A hallow pipe diameter 25mm & length of chopper is 130 cm taken,cut as per diamension.

2.Blade of chopper iron sheet o.2 mm thick,cut as diamension 20cm*11cm using cutter grinder.

3.Blade was sharp with the help of blade grinder.

4.The groove of 5 cm were made on pipe as well as blade for fixing the blade into the pipe.

5.After the blade fitted into each other & pipe groove.

6.Then blade and pipe welded with welding machine.

7.Then chopper was painted.

Parts of chopper:-

Chopper assembly

- Flywheel

- Crank

- Connecting rod

- Chopper

- Motor

2. Vessel

3. Supporting system

All the above parts were designed as per dimensions given in table below.

| Sr. no. | Parts | Specifications |

| 1. | Flywheel | Diameter = 30cm |

| 2. | Crank | Length = 15 cm Rpm=20 Width=38.1mm |

| 3. | Connecting rod | Length = 23.84 cm |

| 4. | Motor | Rpm=60 |

| 5. | Vessel | Volume = 0.0266 m3 i.e. 26 lit |

| 6. | Supporting system |

Material selection:-

Motor selection:-

As the main purpose of development of chopper is to reduce the man power. Power requirement of chopper was 47.12 Watts and calculated torque was 22.50 Nm.

Connecting rod:-

Length of connecting rod was calculated as 23.84 cm. Therefore mild steel plate of width 38.1 mm and thickness 5 mm was selected. joining these bearing 6301 (inner dia = 12 mm, Outer dia. = 37 mm) was selected.

Now,i replaced connecting rod to half cam.

Problem defination:-

Connecting rod does not get affected as waste does not get chopped and then it can not be used as a fertilizer. So half the cam is going to be used.

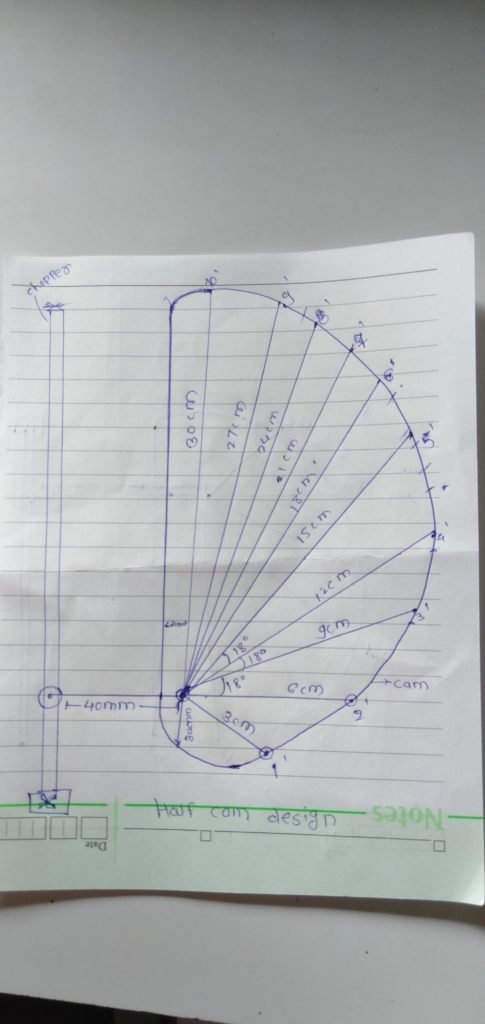

Cam design :-

Cam profile

Mechanism of cam:-

Rough diagram of half cam:-

changes in chopper:-

1.firstly connecting rod replace by half cam.

2.Then supporting system & bearing system change by another place.

a)firstly two metel plate cut as per diamension.

b) four drill I made on metal plate with the help of drilling machine.

3. Then supporting system welded with a welding machine,Also bearing system welded with welding machine.

4.Motor and crank is a chain drive that has to be reduced, because the changing of the bearing system has changed, so the chain link will be reduced.

![Progress Report for [August] – Web Development and Testing Updates](https://vadic.vigyanashram.blog/wp-content/uploads/2024/09/image-3-440x264.png)