PRESENT THEORIES AND PRACTICES:

Mass production of dry food is often accomplished through the use of convective

dryers. The products dried by these methods are often poor in color, flavor (taste and aroma), texture and rehydration qualities. Case hardening (the formation of hard outer shell) and shrinkage are also two major problems with conventional drying processes. In recent years, improvement of quality retention by dried products (rehydrability etc.), by altering process conditions and/or pre-treatments, has been a major research goal. Water molecules are polar, which means that they can rotate under the influence of an alternating electrical field. Foodstuffs usually contain 52 to 99 % water, and hence are very well suited for heating and drying with microwave energy. Now a day’s microwave drying is used mainly for drying post baking of biscuits. Microwave drying of fruits and vegetables is hardly carried out at an industrial scale Because of unavailability of standard operating procedure for different substrates.

Microwave ovens are widely used for research purposes. Understanding how the

microwave power is controlled will give the researchers insight into the experimental results obtained. Microwave is the machine, which is very helpful for the food sector. The modern age of life as well as the increasing number of working women requires simplified routines and standardization of foods with lesser preparation time and convenience in usage. The demands of the consumers are the real factor for the success or failure of any food items in the present scenario. The increasing consumer demands for food which offer more convenience in use and time savings in preparation of food, microwave is the novel tools to achieve this goal. Due to volumetric heating of food by the electromagnetic waves in the microwave, the cooking time drastically reduces. This makes a faster processing in domestic as well as in commercial.

PROBLEM STATEMENT:

Food preservation is the today’s need. Food can be preserved by various techniques and drying technology is one of them. All technologies have their own advantages and disadvantages but the most energy efficient and conventionally being adopted is drying technology. There is a lot of science behind how the things dry. In vigyan ashram, a lot of study has been done from last few years. This study has covered the almost all about drying technology.

Utilization of the microwaves in heating application is very much enormously evolving technology. So, it is also the important part of overall drying technology. Like the study that has been done on conventional drying, microwave drying also need to be studied and analyzed. Hence, I took this challenge to modify the given domestic microwave oven and make it a small lab scale apparatus to analyze the drying behavior of various substrates for various conditions.

CONCEPT/IDEA:

Idea is to make small lab-scale microwave drying apparatus which will have provision for the following

- Various Power levels

- Duty cycle control for controlled heating of various substrates.

- Controlled air flow through the cavity

- Load cell for continuous weighing

- Continuous data logging system(Drying curve)

Available small microwave oven is to convert into the apparatus with above provisions by using existing features and adding some extra as per requirement.

LITERATURE SURVEY:

What are microwaves and what are its properties ?How are they generated using magnetron in microwave oven?

Microwaves are electromagnetic radiations. The prefix micro in the name a not suggest that the wavelengths are in micrometer range but indicates that they are small (shorter wavelengths)compared to radio waves.

Wave spectrum:

Microwave wavelengths are ranging from 100cm to 0.1cm while frequencies from 300MHz to 300GHz.

How microwaves can be used for cooking food?

The Microwave Heating Principle:

Microwave heating is a multi physics phenomenon that involves electromagnetic waves and heat transfer; any material that is exposed to electromagnetic radiation will be heated up. The rapidly varying electric and magnetic fields lead to four sources of heating. A time-varying electric field will cause dipolar molecules, such as water, to oscillate back and forth.

In 1947, the microwave oven was accidentally made Percy Spencer, an engineer who was working at a radiation laboratory. One day, while Percy was working on an active radar set he noticed the candy bar he had in his pocket melted.

So, how did it happen?

Why microwaves of frequency 2.45GHz and wavelength 12.2cm are only used to cook food?

Main factor determining the rate of heating in a food is its water content however salt added to many foods may allow an additional heating mechanism.Hence it is possible to heat salty food more quickly than pure water.

Can microwaves get out of the oven?

Because it is a Faraday cage, little radiation is expected to escape.

How long will the microwaves remain in the chamber after the magnetron is turned off?

Nearly 45nano seconds and nobody can open the door that fast.

Do microwaves change the food chemically?

microwave photons have an energy in the order of 10 micro Ev which are very less to establish the ionization. to change the chemical properties of food photons need to have energy in the range of Ev.

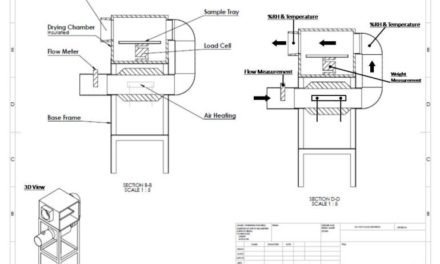

PROTOTYPE:

STEPS/ACTIVITIES:

After literature survey, concepts are quite clear and now prototyping can be done.

1] Reverse engineering of the given microwave oven:

For this, i first went through the oven manual but except operating procedure and safety norms i found nothing. So, I decided to go for it myself by dismentalling of oven and traced its circuit diagram.

2] Power control:

EXISTING MAGNETRON POWER SUPPLY TECHNOLOGIES:

A] VARIABLE TRANSFORMER:

*High resolution power control

*Require motorized control

*Slow time response and also bulky

*Mechanical wear and tear

B]TRIAC CONTROL:

*Supply voltage to be switched on each half cycle at specified delay

*Switching is synchronized by means of zero crossing detection

*Fast response from the controller

*Chopped sine wave introduces higher order harmonics which standard microwave circuitry is not designed to cope with.

*High transformer losses hence rated capacity of the transformer must be reduced.

C] SATURABLE REACTOR CONTROL:

*Mostly used in domestic ovens

*nonlinear reactor placed in series with HV capacitor, designed to be series-resonant at freq. about 15% higher than 50Hz.

*Decreases as voltage increases

*Increasing resonant freq. results in increased impedance at 50 Hz

*Fixed power setting and is not a feedback control method.

D] VARIABLE MAGNETIC FIELD CONTROL

*Decrease in magnetic field will increase power input.

*Electromagnet with a variable source

*More attractive for high power industrial use(as not affect PF, current W/F or efficiency).

*Directly coupled electromagnet to magnetron or separate electromagnet that opposes the magnetic field of magnetrons fixed magnets.

*Separate controllable power source with high current delivering capacity is required.

E] INVERTER POWER SUPPLY:

*Fast switching capabilities of IGBT to work at high frequencies.

*Power supply reduces in physical size and weight.

Understanding that the basic phenomenon to control the power of magnetron is to control the voltage applied across anode to control the no. of electrons captured by anode to pass through the cavity(i.e. controlling the electrostatic field). Simply it’s like a variac supplying the bulb load where the intensity of light varies with a change in voltage applied.

So, i decided to go with variac to control the power of magnetron.

Experiments

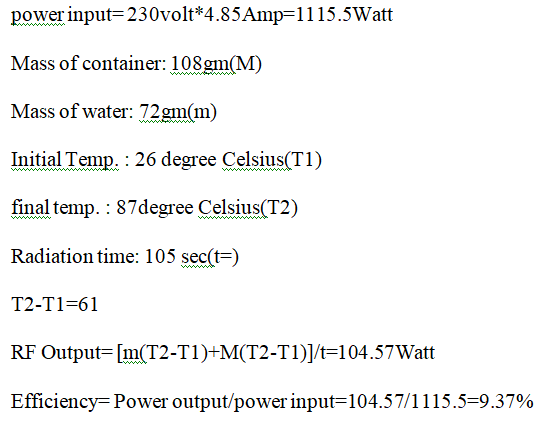

0] Experiment on method for finding the RF output of magnetron:

AIM: Before going to apply the power control system for the given oven, it is required to understand that how it is to be analyzed.So, I experimented with beaker filled with pure water.

*Arrangement has to done such that all power will be absorbed by the water to check the power control scheme. Power detecting diodes are to be used which requires continuously circulating water through oven cavity(very difficult to implement, so dropped this idea for this time and will think about it later).

1] Checking the voltage and current behavior of variac:

Aim: To understand the current(can be vary for different loads) behavior of Variac.

Variac: 0-230v, 15A

230v, 200W electric bulb is supplied with variac. current drawn by the bulb and the intensity of bulb for various voltage inputs is observed.

conclusion:

As the voltage applied to the bulb decreases the intensity of bulb decreases and also the current drawn by bulb also decreases(Observation for which i was not sure).

So, i decided to use variac for power control

2] Existing power setting in the given oven:

AIM: To understand the power setting type and values provide for given microwave oven.

Most of the microwave ovens are generally provided with the time sliced/ average power control systems using mechanical relays. Given microwave oven has settings as follows

| Power Setting | On Time | Off Time |

| P-1 | 4 | 18 |

| P-2 | 6 | 16 |

| P-3 | 8 | 14 |

| P-4 | 10 | 12 |

| P-5 | 12 | 10 |

| P-6 | 14 | 8 |

| P-7 | 16 | 6 |

| P-8 | 18 | 4 |

| P-9 | 20 | 2 |

| P-H1 | Always | 0 |

TABLE-1

cooking rate or heating rate depends on the water content(which in turn decides the dielectric constant of food) in the substrate. Green and blue color plot indicates 2.45Ghz and any other frequency microwaves respectively.

so, the food is cooked in the microwave oven by frequently monitoring and checking that is by guessing.

The same control system is provided for the operating industrial microwave dryer at Nhawre, Pune. in this type of control, high power induces the uncontrollable exothermic reactions hence not suitable for drying application.

Cost Analysis Of Installed Microwave Dryer At Nawhare(click here))

3] Designed new power control system for given oven using variac:

AIM:

To check the power levels achieved by new power control system and RF heating outputs for different settings.

Result/Conclusion:

| Power Setting | Anode Voltage(V) | Anode current(A) | Power input(W) | Moding time(sec.) |

| 1 | 214 | 6.00 | 1284 | 0 |

| 2 | 206 | 5.51 | 1135 | 1 |

| 3 | 195 | 5.10 | 994.5 | 3 |

| 4 | 185 | 5.35 | 989.75 | 4 |

| 5 | 175 | 5.45 | 953.75 | 5 |

| 6 | 163 | 5.70 | 929.10 | 6 |

| 7 | 155 | 5.35 | 829.25 | 8 |

| 8 | 150 & below | ——— | ———- | infinity |

TABLE-2

| Voltage(volt) | Current(Amp) | Power(Watt) | InitialWt.(gm) | FinalWt.(gm) | InitialTemp. | FinalTemp. | Wt. loss(gm) |

| 210 | 5.15 | 1081.5 | 50.230 | 47.300 | 26.5 | 82 | 2.93 |

| 200 | 4.95 | 990 | 50.260 | 48.50 | 27 | 71 | 1.76 |

| 190 | 4.50 | 855 | 50.100 | 49.30 | 27 | 70 | 0.80 |

| With Exhaust fan on | |||||||

| 210 | 5.30 | 1113 | 50.250 | 48.800 | 26 | 76 | 1.45 |

| With Exhaust Fan Off | |||||||

| 210 | 5.35 | 1123.5 | 50.245 | 48.900 | 25 | 74 | 1.35 |

[Experiment with water]

With the above experiment, I ensured that my power control system is working well(i.e. for lower power levels, water evaporated is less than that for higher powers. )

Power variation is achieved in between 1284(max) to 829(min) which is not as desired. Below 829W can be achieved by installing new transformer to supply the cathode. Because, at some point cathode don’t get enough supply to heat up and emit the electrons which is called infinite moding in magnetron.

4] Installed exhaust fan for air flow through cavity:

AIM: To optimize the air flow through the oven cavity as existing air flow is not sufficient.

Attempt 1:

Fan rating: 220-240v ,0.14/0.12A ,50/60Hz

With this arrangement also, air flow was not acceptable.

Attempt 2:

I tried to install other fan inside cavity for extra high air flow but it burned out(smoke started to come out of oven and all my friends ran away from the lab). This experiment helped me to upload my first video on you tube. Remember, keep the pure metals(causes sparking) and highly dielectric materials(causes rapid heating and burning) away from microwave oven.

Attempt 3:

I found blower in the microbiology lab. I started thinking on where it can be implemented on the oven cavity and how.

JUGAAD 1: Removed turn-table motor of oven and decided to use that hole to blow the air into cavity. After watching the existing arrangement of that hole,I realized that it was not feasible to implement blower at that place.For this, i went through following prototypes.

JUGAAD 2: I started observing the oven more carefully to find the place to implement blower arrangement on oven. Fortunately, oven has one exhaust mesh(where i already installed one exhaust fan) and another mesh as light source & cooling air source into cavity. I decided to install my blower there only but it was quite risky(because, it means to remove 100% electronic part of the oven and find another idea to relocate it). Although with lot of efforts(not expressible), this idea worked well.

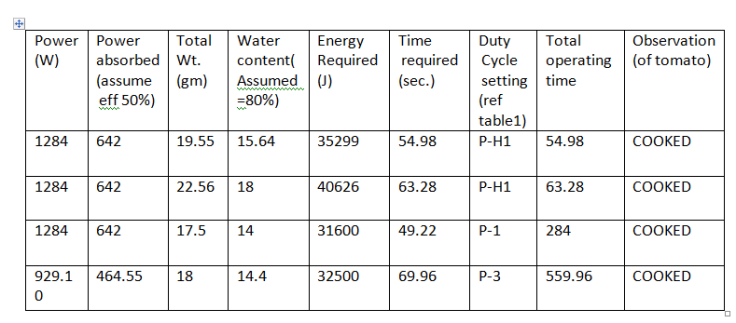

5] testing of tomato sample with achieved power levels and duty cycles:

AIM:

To prove that any substrate with higher water content can’t be dried with microwaves. Predrying is required.Although possible(with very low power magnetron(say 100W)), It is not efficient. loosely bounded moisture can be easily evaporated by simply passing air over it(convection dryer, desiccant drying etc. )

Description for table-3:

*For power settings refer table-2.

*power absorbed by substrate=power input- RF losses (assumed efficiency=50%)

*moisture/water content in tomato is 80%. hence water content= 0.8* total Wt.

*Heat energy required to evaporate 1 gm of water=540 cal= 540*4.18=2257J

time required = energy required/power absorbed by substrate

Eg. For 15.64gm, energy required= 15.64*2257J=35299J

since, power absorbed=642W or J/Sec hence time required=35299/642=54.98sec

As shown in above table, though trying of different options to dry the tomato I found that even for small time exposure of microwaves there induces uncontrolled exothermic reactions and cooks the tomato.

Conclusion:

- Power range obtained by variac control is not desirable.

- Fruits with high water content can’t be dried with microwaves even with very low duty cycle(behavior at very low RF outputs has to be observed).

6] Installation of new power control system for given oven using triac voltage regulator:

I imported the triac based voltage regulator(Generic Imported High-Power 2000W SCR Voltage Regulator Dimmer Speed Temperature Controller) from amazon.

Initially, i did the testing of component by continuity check, Potentiometer resistance check and others. I conducted this experiment for confirming the actual operation and to adjust the minimum voltage setting.

Then, i tried it on magnetron and results got are as follows,

| Voltage(Volt) | Current(Amp) | Power(Watt) |

| 205 | 5.6 | 1148 |

| 190 | 5.4 | 1026 |

| 171 | 5.5 | 940.5 |

| 150 | 5.6 | 840 |

| Below 150v | ————- | —————- |

Unlike the variac control, the current nearly remain constant. Below 150v, magnetron cathode doesn’t heat up similarly as in variac control. So, a separate transformer is required. Also, one hissing noise is observed in this case which was not present in the variac control scheme.

7] Efficient method of measuring RF output of magnetron:

8] Installation of separate power transformer to supply the cathode of magnetron:

I installed a new power transformer to supply the cathode of magnetron separately. But, may be connections went wrong and following failures got happen

- control panel switches started to gone off one by one.

- cooling fan went off

- 20A rated fuse blown

After a long way struggle, i found the reasons and corrected this failures. Now all things are working properly.

Separate transformer rating: 230v/9v(0-1A) {Major mistake}

Current drawn by cathode is in the range of 5-10A and i used a transformer whose secondary winding current rating is 1A. Transformer got to heat up very bad(Supplied load current of nearly 4A). So, the transformer with proper rating need to be installed.

Solution:

Considering the above failure, i started to search for the options to supply the cathode with constant source. Cathode of the magnetron can be supplied with the AC as well as DC. So there was two options as 1] High secondary current transformer 2] Switch mode power supply. After designing the required specifications , i ordered one transformer from TRUTECH, pune(Primary voltage 0- 230v, secondary voltage 0-6 v @20A ). I tried two connections and both got quite unexpected results[Failed].

9] speed regulator for Exhaust fan

[STILL GOING ON]

OTHER REFERENCES:

physics of microwave oven(click here)

A novel low cost magnetron power control for microwave(click here))

Power control circuit for magnetron(click here))

Power control of a domestic microwave oven(click here))

Measuring the voltage and current of a microwave oven magnetron(click here))

MICROWAVE DRYING TECHNOLOGY(click here))

4-Investigation-of-Microwave-Power(click here))

Drying and dehydration(click here))

High_Power_Variable_Attenuators(click here))

Maguire-Europe-Drying(click here))

microwave oven working(click here))

microwave oven parts and functions(click here))

How To Check the Output Power (wattage) of a Microwave Oven(click here))