DESIGN BRIEF: RETRO-COMPOST

To design a third generation Bio-compost system, an up-gradation to the existing setup, for the specific use in hotels and restaurants.

INTRODUCTION

What is compost?

Compost is an organic matter that has been decomposed and recycled as a fertiliser and soil amendment. Some composting textbooks narrowly define composting as being an aerobic form of decomposition, primarily by aerobic or facultative microbes.

Composting Process

Composting is nature’s way of recycling. Composting biodegradable organic waste i.e. food waste, manure, leaves, grass trimmings, paper, wood, feathers, crop residue etc., and turns it into a valuable organic fertiliser. Composting is a natural biological process, carried out under controlled aerobic conditions (requires oxygen). In this process, various microorganisms, including bacteria and fungi, break down organic matter into simpler substances. The effectiveness of the composting process is dependent upon the environmental conditions present within the composting system i.e. oxygen, temperature, moisture, material disturbance, organic matter and the size and activity of microbial populations.

Composting is relatively simple to manage and can be carried out on a wide range of scales in almost any indoor or outdoor environment and in almost any geographic location. It has the potential to manage most of the organic material in the waste stream including restaurant waste, leaves and yard wastes, farm waste, animal manure, animal carcases, paper products, sewage sludge, wood etc. and can be easily incorporated into any waste management plan.

The essential elements required by the composting microorganisms are carbon, nitrogen, oxygen and moisture. If any of these elements are lacking, or if they are not provided in the proper proportion, the microorganisms will not flourish and will not provide adequate heat. A composting process that operates at the optimum performance will convert organic matter into stable compost that is odour and pathogen free, and a poor breeding substrate for flies and other insects. In addition, it will significantly reduce the volume and weight of organic waste as the composting process converts much of the biodegradable component to gaseous carbon dioxide.

The composting process is carried out by three classes of microbes –

- Psychrophiles – low-temperature microbes

- Mesophiles -medium temperature microbes

- Thermophiles – high-temperature microbes

Generally, composting begins at mesophilic temperatures and progresses into the thermophilic range. In later stages, other organisms including Actinomycetes, Centipedes, Millipedes, Fungi, Sowbugs, Spiders and Earthworms assist in the process.

Factors in composting:

1.Temperature

Temperature is directly proportional to the biological activity of the composting system. As the metabolic rate of the microbes accelerates, the temperature within the system increases. Conversely, as the metabolic rate of the microbes decreases, the system temperature decreases. Maintaining a temperature of 130°F or more for 3 to 4 days favours the destruction of weed seeds, fly larvae and plant pathogens.

At a temperature of 155 degrees F, organic matter will decompose about twice as fast as at 130 degrees F. Temperatures above 155 degrees F may result in the destruction of certain microbe populations. In this case, the temperature may rapidly decline. The temperature will slowly rise again as the microbe population regenerates.

Moisture content, oxygen availability, and microbial activity all influence temperature. When the pile temperature is increasing, it is operating at optimum performance and should be left alone. As the temperature peaks, and begins to decrease, the pile should be turned to incorporate oxygen into the compost. Subsequently, the pile should respond to the turning and incorporation of oxygen, and temperature should again cycle upwards. The turning process should be continued until the pile fails to re-heat. This indicates that the compost material is biologically stable.

Composting microorganisms thrive in moist conditions. For optimum performance, moisture content within the composting environment should be maintained at 45 percent. Too much water can cause the compost pile to go anaerobic and emit obnoxious odours and too little will prevent the microorganisms from propagating.

2.Particle Size

The ideal particle size is around 2 to 3 inches. In some cases, such as in the composting of grass clippings, the raw material may be too dense to permit adequate air flow or may be too moist. A common solution to this problem is to add a bulking agent (straw, dry leaves, paper, and cardboard) to allow for proper air flow. Mixing materials of different sizes and textures also help aerate the compost pile.

3.Turning

During the composting process, oxygen is used up quickly by the microbes as they metabolise the organic matter. As the oxygen becomes depleted the composting process slows and temperatures decline. Aerating the compost by turning should ensure an adequate supply of oxygen to the microbes.

4.Composting Period

The composting period is governed by a number of factors including, temperature, moisture, oxygen, particle size, the carbon-to-nitrogen ratio and the degree of turning involved. Generally, effective management of these factors will accelerate the composting process.

5.Carbon to Nitrogen Ratio

The microbes in compost use carbon for energy and nitrogen for protein synthesis. The proportion of these two elements required by the microbes averages about 30 parts carbon to 1 part nitrogen. Accordingly, the ideal ratio of Carbon to Nitrogen (C:N) is 30 to 1 (measured on a dry weight basis). This ratio governs the speed at which the microbes decompose organic waste.Most organic materials do not have this ratio and, to accelerate the composting process, it may be necessary to balance the numbers.

The C:N ratio of materials can be calculated by using table 1 below.

Example, if you have two bags of cow manure (C:N = 20:1) and one bag of corn stalks (C:N = 60:1) then combined you have a C:N ration of (20:1 + 20:1 + 60:1)/3 = (100:1)/3 = 33:1

Table 1 lists the Carbon/Nitrogen Ratios of Some Common Organic Materials

Table 1.

| Material | C:N Ratio |

| Vegetable wastes | 12-20:1 |

| Alfalfa hay | 13:1 |

| Cow manure | 20:1 |

| Apple pomace | 21:1 |

| Leaves | 40-80:1 |

| Corn stalks | 60:1 |

| Oat straw | 74:1 |

| Wheat straw | 80:1 |

| Paper | 150-200:1 |

| Sawdust | 100-500:1 |

| Grass clippings | 12-25:1 |

| Coffee grounds | 20:1 |

| Bark | 100-130:1 |

| Fruit wastes | 35:1 |

| Poultry manure (fresh) | 10:1 |

| Horse manure | 25:1 |

| Newspaper | 50-200:1 |

| Pine needles | 60-110:1 |

| Rotted manure | 20:1 |

The C:N ratios listed above are guidelines only.

STAGES IN COMPOSTING:

- First stage: The first stage of Composting is the aerobic decomposition of the organic waste under mesophilic bacteria, certain temperature and humidity. At Vigyan Ashram a batch of Enora culture is added at the starting of the composting process. This is a two bacteria and a fungi batch which achieves temperature up to 45C. Here in this stage most of the easy carbons are digested by the bacteria and it shows maximum growth. This stage is vital for odour prevention.

- Second stage: This is the stage which requires maximum time. Here all the pathogens and diseases causing germs are destroyed and the more complex carbons are digested by fungal growth. This stage usually requires 15-30 days. One thing to be noted is the prevention of growth of fly larva at this stage. This stage is responsible for providing nutrients to the compost.

- Third stage: This is curing stage where the nitrogen fixing is done. This can be done through vermin compost i.e. growth of earthworms. This is the final stage of composting and this can be directly used in the farms and cultivation.

EXISTING SETUP

Currently, the Ashram has two developed prototypes, one of which has been tested and the other is under iteration. The first prototype serves as the proof of concept for the next generation of “Bio drums”.

1st Generation Bio-Drum.

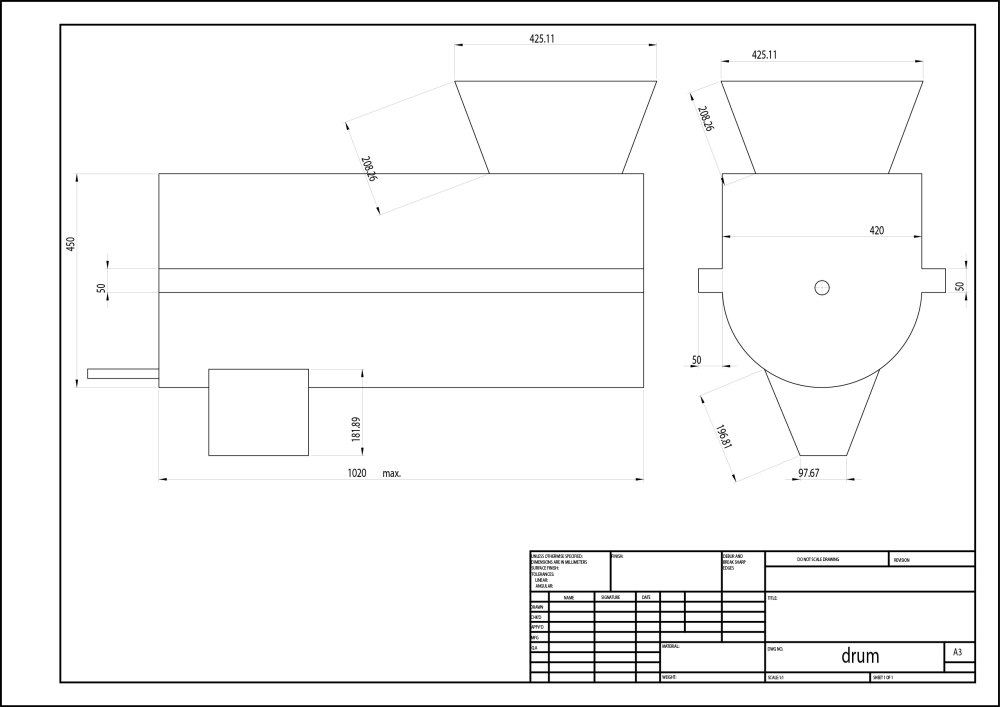

Fig.2. Rotating Drum (1st Generation).

In this setup, the drum is rotated about its horizontal axis using a timed motor. This is done to provide oxygen for the compost which will support aerobic reaction. The case study of this setup is summarised below:-

Waste per day – 3kg

Rotation of drum – Once in 2 hours

1st Stage completion – 5 days

2nd Stage completion – 15 days (minimum)

Problems Identified

- Waste spillage from holes and openings.

- Difficulty in handling.

- No insulation.

- Lacking in aesthetics.

- Emission of foul smell.

2nd Generation Bio-Drum.

This setup is a large 220 litres capacity drum rotating with a help of 1 HP motor. This whole setup is mounted on a large rigid frame. This is similar to the first generation prototype. The case study of this setup is summarised below:-

Waste per Day Capacity – 20kgs

Rotation – Manual

1st Stage completion – No data

2nd Stage completion – No data

Problems Identified

- Drum rotation violent.

- Too high power consumption.

- Low efficiency.

- Improper waste inlet.

USER SURVEY

A user survey was conducted consisting of consumers and end users from various aspects of life. The stakeholders were hotel owner, worker, the general public, kitchen staff and farmers. Through the survey, we could find the key aspects of solving waste problems.

The survey gave some insight into the problems of household waste and restaurant waste. The insights are noted below:

- Segregation of waste is must for this process, thus at restaurants, the current method of waste management is inadequate for this process.

- Rusting of Bio-Drum is a major problem because of moisture trapped inside.

- Some waste decomposes later than others like mango seeds etc.

- Flies are attracted to compost and this must be avoided at any cost.

- Out of the 10 people surveyed 6 complained of foul smells from the drum.

- The waste from the kitchen was identified as Onion peel (maximum), Cauliflower, Cabbage, Brinjal, Pumpkin, Chilli, Drumstick, Garlic, Lemon, Coriander leaves, Tomatoes etc.

So, from these insights, the user needs were prioritised and these are the guiding parameters for our design.

- Smell

- Handling

- Cleaning

- Design

- Efficient

- Insulation.

A visit to “Saswad Plant” was done to understand the existing method of solving community waste problems. Below are photos of the visit:

Fig. 2-tonne compost machine from Ecoman.

Fig. 1 tonne and ½ tonne compost machine.

Fig. Shredder and Compressor.

Fig. Pile of compost undergoing the second stage.

CONCEPT GENERATION

The following are the concepts generated keeping in mind the users need and expectations.

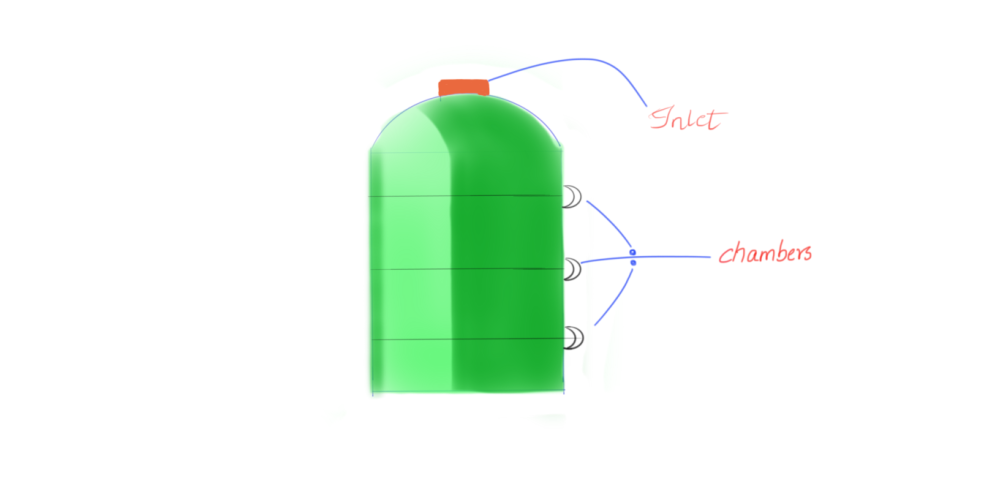

CONCEPT 1

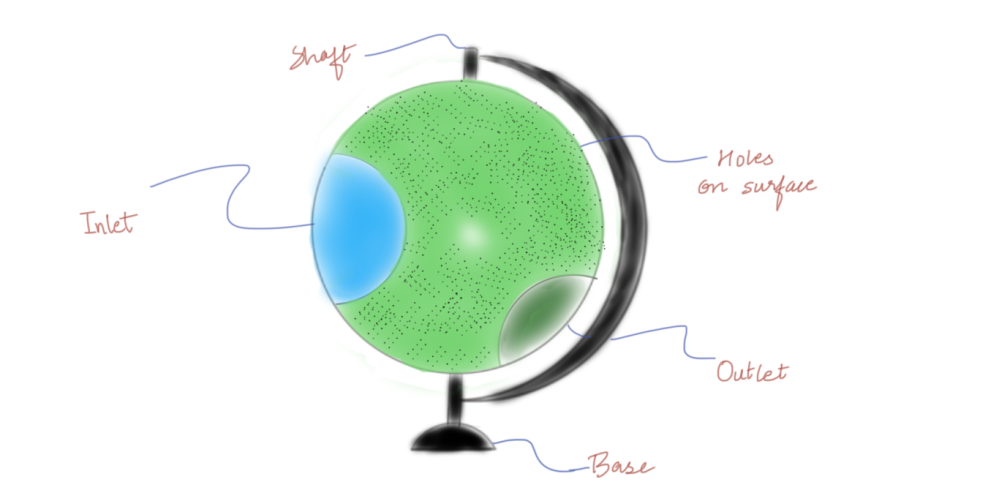

CONCEPT 2

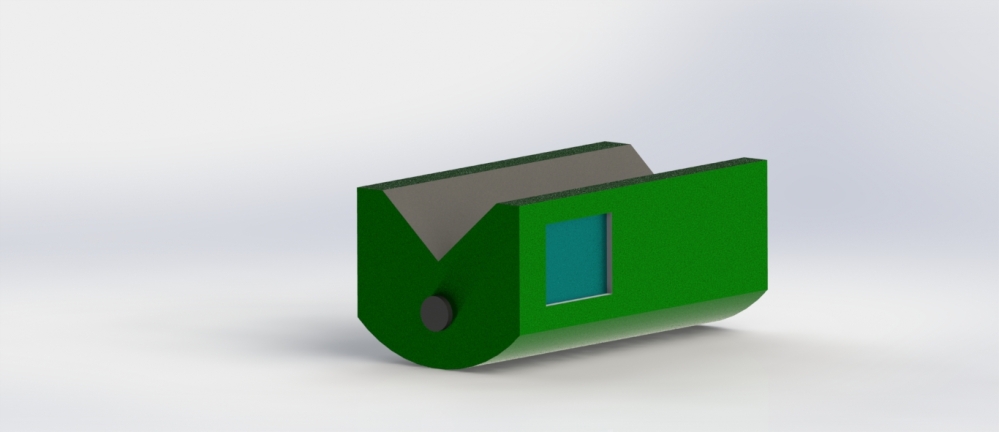

CONCEPT 3

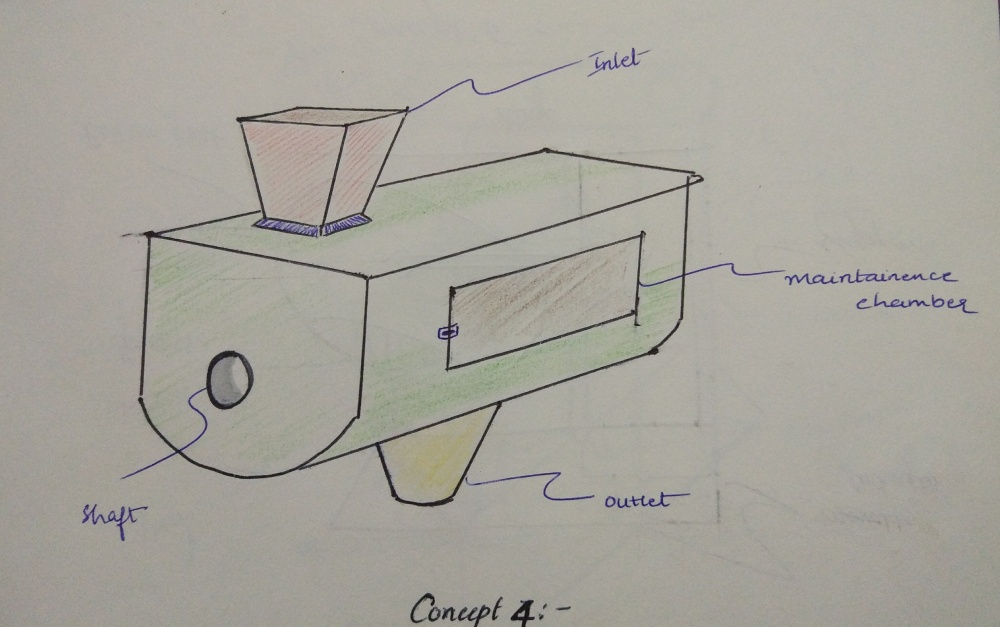

CONCEPT 4

CONCEPT 5

CONCEPT 6

CONCEPT 7

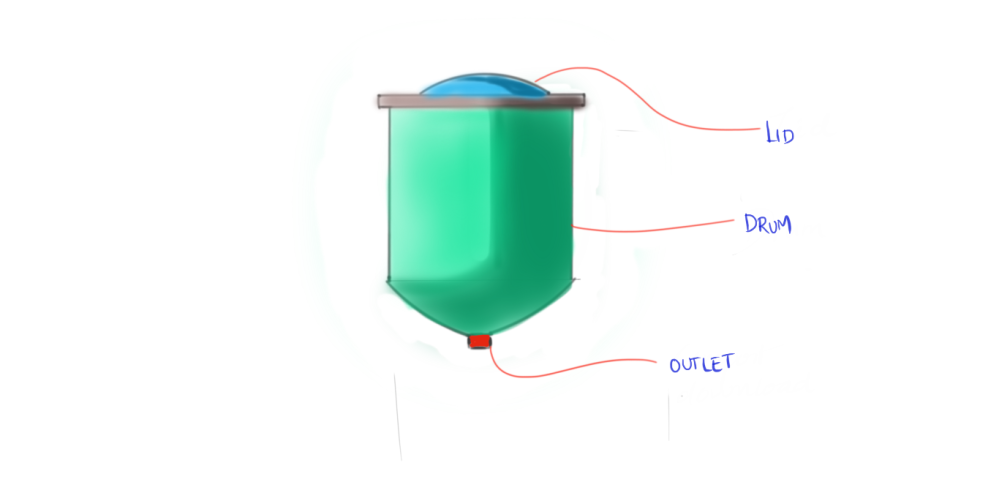

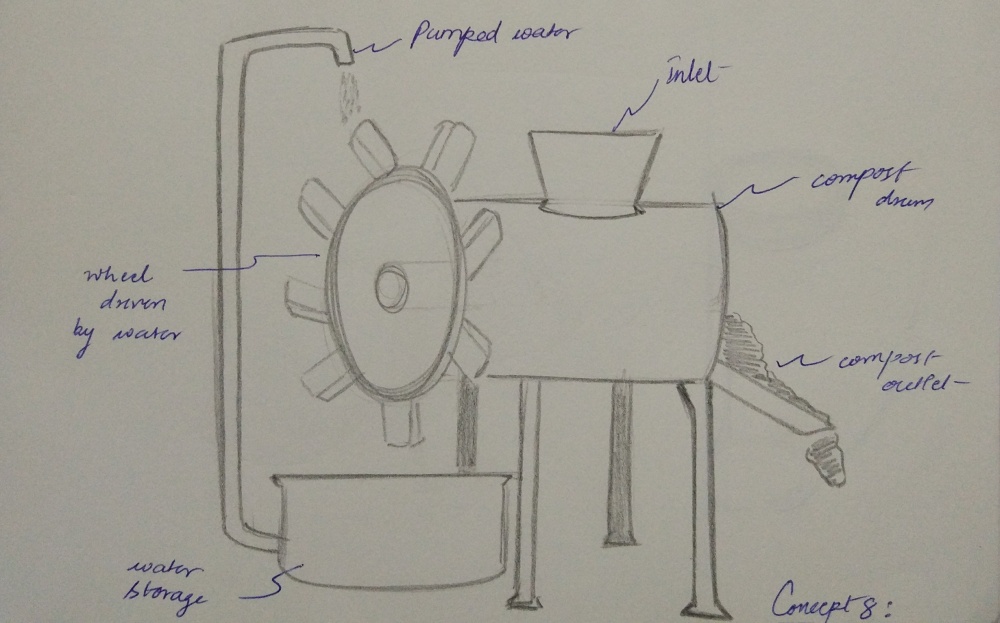

FINAL CONCEPT

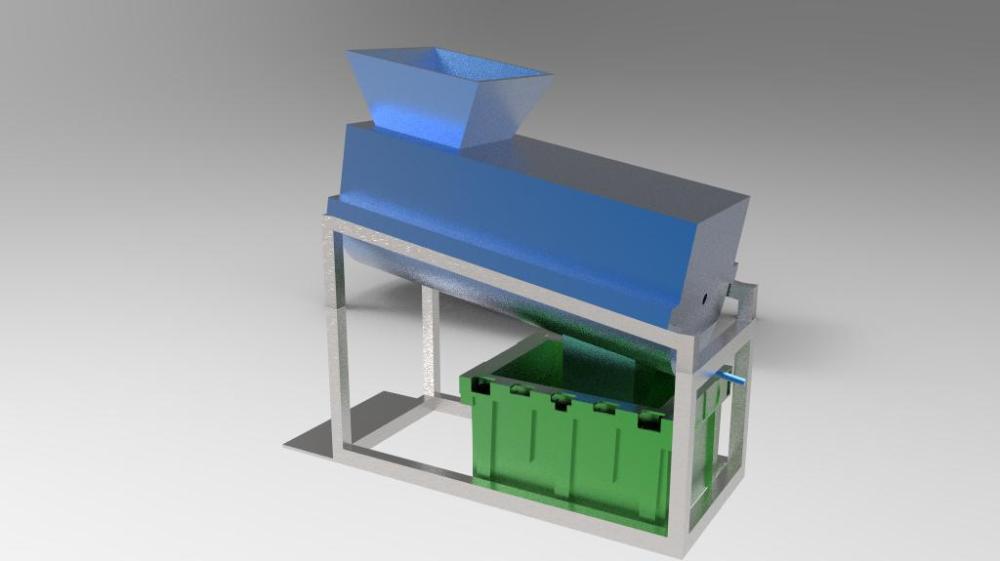

CAD MODEL

CAD DRAWINGS