Objective:

Understanding dome dryer

What is Dome dryer?

Dome dryer is an dome shape dryer which is used for drying purpose. Because of its dome shape the maximum surface area of dome is exposed to sun and drying process get faster. Dryer work on solar and also by using the exhaust fan drying process done and also because of it drying process get faster . Uniform distribution of air is done with the help of this fan.

Advatages:

- Efficient heating device

- It is easy to operate

- colour, taste and natural content of material maintainace

Disadvantage:

The efficiency of dryer depends on weather condition

Dome dryer trial on grapes(3/06/2019):

Ameya sir, sonali di, girija di and I did blanching on 15 kg grapes using dipping oil .After that we loaded batch of 15kg on dome dryer.

Weight of dome dryer tray are as follows:

| Number of tray | Weight of tray | Weight of tray | Weight of tray | Weight of tray | Weight of tary | Weight of tary |

| Tray 5 | 558 | 588 | 590 | 584 | 583 | 576 |

| Tray 4 | 526 | 522 | 524 | 526 | 522 | 522 |

| Tray 3 | 448 | 436 | 316 | 314 | 432 | 443 |

| Tray 2 | 298 | 298 | 302 | 296 | 300 | 297 |

| Tray 1 | 122 | 122 | 118 | 124 | 134 | 122 |

On each tray we loaded grapes of weight as follows:

| Number of trays | Weight of grapes on each tray |

| Tray no. 1 | 159.95g |

| Tray no. 2 | 375.45g |

| Tray no. 3 | 543.04g |

| Tray no. 4 | 662.77g |

| Tray no. 5 | 758.55g |

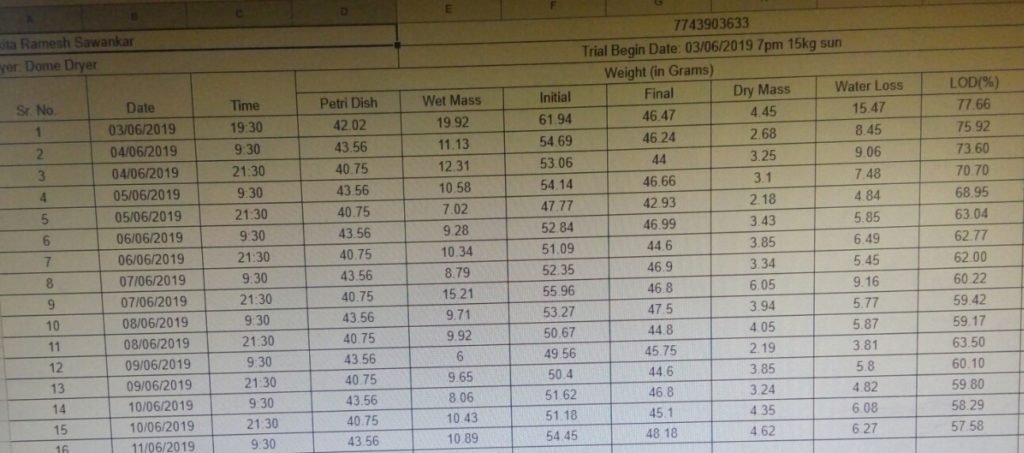

After that took initial LOD it was 77.4%. After every 12hr we took readings and details are as follows:

The readings are took but after 11 june, we stop taking reading because of rain . The last LOD we obtained is 57.58% . After that, the trial of grapes on Dome Dryer was stoped.

Visit to Nahavre:

Objective

1.Identifying problems related to dome dryer installed in Sahyadri school

2.Maintenance of dome dryer

I and Shubham Shembde Sir visited Sahyadri school on 8th June 2019 to Identify problems related to dome dryer installed there and to do maintenance of it. We identified problems they are facing and took their feedback about dome dryer working.

After visiting the school in the morning, we asked some questions and we understood some issues are as follows,

- Moisture content increases at night as humidity increases

- Rehydration happen due to fog

- Structural Integrity was poor

- Wires were bent during shifting plates.

After identifying issues, we asked them about what type of vegetable and fruits they dried in Dome dryer so, they dried 7 substrates,

- Chikoo 4. Banana 7. Cluster bean

- Okra 5. Tomato

- Mango 6. Onion

According to them, Chikoo took 8 days to dehydrate. They dried 6 kg Chikoo in dome dryer and they got 600 gm dehydrated Chikoo. Their other observation was the taste and color of dried Chikoo is not changes. The food value of dehydrated Chikoo remains the same. After drying Chikoo they send dried samples to sale.

Okra took 4 to 5 days to dry. Mango slices will dry in 8 days and because of sucrose, dehydrated mango slices didn’t get hard after drying. The banana will dry in 4 days and they dried 5kg banana slices and they got 500 gm dehydrated banana. One thing that is common in all these substrate dehydrations is the taste and color didn’t change that much.

Shubham Sir and I tasted samples and they were excellent in taste. Rajashri aunty works on dome dryer there and their feedback encouraged us to make more than enough for dome dryer, she said,

- Dome dryer is easy to operate.

- Substrate dries easily and in possible minimum time.

- Taste of dehydrated product is good.

- The functionality of the dryer is good.

Maintenance of dryer:

- We set the dome dryer properly.

- Some wires were not in proper position because of inappropriate handling Shubham sir and I made that proper.

- We did the insulation of the trays.

- There was a problem in handling trays and we resolved it. Shubham sir taught them how to operate a dome dryer properly one more time.

The requirement of customer:

1.They want a big shape dome dryer.

2.They want better build quality.

Visite to Nahavre:

Objective:

- For took customer feedback about Dome Dryer

- Identifing the problem they face while handling Dome Dryer

I visited Nahavre at 4pm. Mohite sir and Gitaram sir told me their opinion related to Dome Dryer. According to these, the Dome Dryer is very good for use because of its low cost and efficient working. They wanted to give these types of Dome Dryer to Farmer for there use. They dried many types of substrates like Okra, Onion, Pomegranate Arils, Curry leaves, etc

The above picture are of dried product.

The requirement of Customer:

- They want better build quality.

- They want 3 feet height of Dome Dryer stands above the ground level.

- According to them, they want some instrument which is fitted inside the Dome which helps it for maintaining a high temperature.

Issues related to Dome Dryer that they facing are as follows:

1.Moisture content increase at night as humidity increase.

Google Form:

I Make google form for collecting the data related to Dome dryer. For understnding the Financial Feasibility of Dome dryer we need to collect the data.I send these form to the persons which relates the Dome dryer .The main purpose of google form is to interact with customer and study on finacial feasibility of Dome Dryer. The link of google form are given below.