Introduction

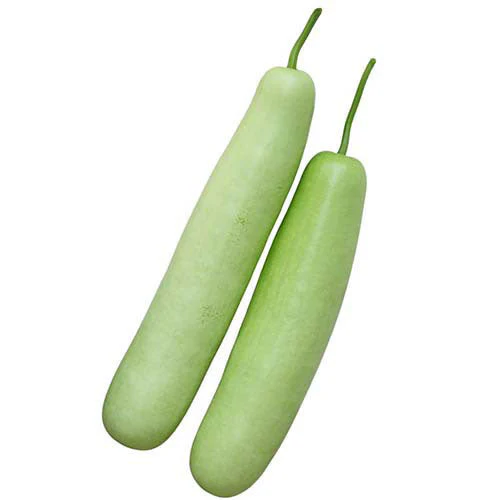

Dudhi Halwa is a traditional Indian sweet made from bottle gourd (also called lauki or dudhibhopla). It is known for its soft texture and delicious taste. However, making it fresh takes time and effort, which is not always possible in busy daily life.

To make this easier, I am working on a Dudhi Halwa Premix — a ready-to-cook version of the halwa. This premix can be quickly prepared at home by simply adding water and cooking for a few minutes. It is a convenient and healthy option for anyone who wants to enjoy homemade halwa without spending too much time.

What is Dudhi Halwa Premix ?

Dudhi Halwa Dry Premix is a mixture made from cooked and dried bottle gourd, sugar, ghee, and cardamom. Once prepared, it is packed in dry form. When needed, it can be cooked quickly to make fresh halwa. This type of premix helps in saving time while keeping the traditional taste.

What I want to achieve :

Through this premix project, I want to:

- Make a healthy sweet dish easy to prepare

- Use drying methods to increase shelf life

- Make a product that can be used at home, during travel, or by students

- Explore how this product can be used for small business or local production

- Keep the original taste and nutrition of dudhi halwa in a ready-to-use form

Why I chose Dudhi ?

- High water content makes it suitable for dehydration and shelf-stable premix.

- Mild taste blends well with milk, sugar, and ghee for halwa preparation.

- Contains fiber, calcium, iron, and is low in calories – adds nutritional value.

- Easily available, low-cost, and ideal for local processing and value addition.

Basic Ingredients –

- Grated bottle gourd (dudhi)

- Fresh milk

- Sugar

- Ghee

- Cardamom

- Dry fruits

Basic processing steps –

Here are some important steps I want to use while making the premix:

- Grating – shredding the raw dudhi into fine pieces

- Boiling Or Blanching – boiling the grated dudhi in water to soften it, reduce microbial activity

- Drying – removing moisture to make the mixture shelf-stable

- Mixing – adding sugar, ghee, and cardamom to the cooked mixture

- Packaging – sealing the premix in pouches for storage and use

Work Done On 27/06/25 to 29/06/25

Work on Trial 1 :-

I began the preparation of Dudhi Halwa Dry Premix with the following steps:

1. I selected fresh, good-quality dudhi and washed it properly.

2. The total weight of raw dudhi before peeling was 1.340 kg.

3. Then, I peeled the outer skin & grated the peeled dudhi using a hand grater.

4. After grating, I removed excess water and unwanted parts like seeds and soft pulp & the final weight of usable grated dudhi was 900 gm.

5. I boiled the 900 g grated dudhi by adding 900 ml of water in a pan on a gas flame.

- I used the same amount of water as the dudhi to make sure it cooks evenly and becomes soft, but not soggy.

- I cooked it for 32 minutes, which was the time needed for the dudhi to become soft and partially cooked.

6. To check whether the dudhi was cooked properly, I pressed and flaked a small amount with my fingers.

- This test was important to make sure the dudhi had reached the right softness before drying.

7. I then applied a thin layer of ghee on a steel tray to prevent the cooked dudhi from sticking (Because, we don’t have the butter paper available & spread the cooked dudhi evenly on the tray.

8. I placed the tray inside an electric dryer and set the temperature to 55°C.

- I let it dry for 3 hours to remove the moisture properly and prepare it for the next mixing stage.

9. After preparing and drying the cooked dudhi in the electric dryer at 55°C for 3 hours, I noticed that the dudhi had turned blackish or dark brown in color. This was not expected and affected the appearance of the final premix.

Cause of the Problem – Oxidation

The reason for the blackish color was oxidation, which started because I grated the dudhi before boiling it. Once dudhi is grated, it reacts very quickly with air due to the action of enzymes like polyphenol oxidase, leading to browning. Even though I boiled the dudhi after grating, the oxidation had already started and could not be reversed.

30/06/25 Discussion and Solution – After Feedback from Dixit Sir

After discussing this issue with Dixit Sir, I understood the correct process to avoid this problem. He explained that blanching (boiling in hot water) should be done before grating to prevent oxidation.

- Blanching first deactivates the enzymes responsible for browning.

- Cooling quickly after blanching helps stop heat-related changes.

- Grating after cooling keeps the dudhi color natural and fresh-looking.

Corrected Method for Next Trial

Based on this learning, in the next trial I will follow this improved method:

- Wash and peel the dudhi

- Blanch the peeled dudhi in boiling water for a short time

- Quickly cool it in cold water to stop the cooking

- Then grate the cooled dudhi and proceed with further steps

This change will help prevent blackening, improve product appearance, and maintain better quality in the final Dudhi Halwa Dry Premix.

Work done on 01/07/25 to 07/07/25

Work on Trial 2 :-

Step 1: Washing and Peeling

- Started with 1.016 kg of fresh dudhi.

- Washed and peeled properly to remove outer skin and dirt.

Step 2: Blanching in Cooker

- Peeled dudhi was blanched in a pressure cooker with 800–900 ml of water for 20 minutes.

- This helped in softening and deactivating browning enzymes.

- Weight after blanching: 936 g

Step 3: Grating and Water Removal

- The blanched dudhi was cooled and grated finely.

- After removing 350 ml of water and discarding 120 g of seed and fiber waste,

- The final weight of usable grated dudhi was 536 g

Step 4: First Drying (Before Milk Addition)

- Grated dudhi was spread on a ghee-coated tray to avoid sticking.

- It was dried in an electric dryer at 55°C for 3 hours.

- Weight after drying: 40 g

Step 5: Milk Addition and Second Drying

- Boiled 350 ml of milk for 5–6 minutes.

- The 40 g dried dudhi was soaked in hot milk.

- After absorption, the mixture was dried again at 62°C for 3 hours.

- Final weight after second drying: 75 g

A fresh dudhi weighing 1.016 kg was washed, peeled, blanched, grated, cooked, dried, soaked in milk, and re-dried to finally obtain a 75 g Dudhi Halwa Premix.

Observations :

- The texture and colour of the halwa looked good.

- The taste was nice and similar to homemade dudhi halwa.

- It was a little overcooked, which made it slightly dry and hard.

Work Done on 08/07/2025 to 10/07/2025

Work on Trial 3 :-

Step 1: Washing and Peeling

Started with 2.002 kg of fresh dudhi (bottle gourd).

The dudhi was thoroughly washed to remove soil and dirt, and then peeled to remove the outer skin.

Final weight after peeling: 1.758 kg

This cleaned and peeled dudhi was used for the next steps of processing.

Step 2: Blanching

The 1.758 kg of peeled dudhi was blanched to soften the texture and reduce enzymatic browning.

Blanching was done for 15 minutes.

Softness was checked manually by pressing a knife into the dudhi — the blanching was stopped when the dudhi became about 50% soft.

This partial softness ensured easier grating without losing structure.

Step 3: Grating

The blanched dudhi was grated manually.

After removing water and, the final grated dudhi weight was 1.226 kg.

Step 4: First Drying

The 1.226 kg grated dudhi was spread evenly on a tray lightly coated with ghee to prevent sticking.

It was then dried in an electric dryer at 55°C for 3 hours.

Final weight after first drying: 150 g

Step 5: Milk Addition and Second Drying

Boiled 600 ml of milk for 5–6 minutes.

Then, the 150 g of first dried dudhi & 4 gm of Elaichi was added into the hot milk and mixed thoroughly.

After complete absorption of milk, the mixture was spread on trays and dried again at 60°C for 3 hours.

Final Weight

After the second drying at 60°C for 3 hours, the final weight of the Dudhi Halwa Premix was 175 g.

Sensory Evaluation- Hedonic Test

After preparing the halwa from the final 175 g premix, a sensory evaluation test was conducted using the 9-point Hedonic Scale.

Participants were asked to evaluate the halwa based on the following parameters:

- Appearance

- Texture

- Taste

- Aroma

- Overall Acceptability

Each category was rated from 1 (Dislike Extremely) to 9 (Like Extremely).

The feedback was collected from the Ranjit Sir, Dixit Sir, Reshma Madam & Akshay Tambe sir & it will be used to further improve the formulation in the next trial.

Observation from Sensory Evaluation

From the hedonic test results, it was observed that while the taste and aroma were acceptable, the texture still felt slightly dry.

This indicates that the product may be less-dried or the recipe needs adjustment in terms of milk absorption or drying time.

Work Done On 12/07/2025 To 16/07/2025

Work On Trial 4 :-

Step 1: Washing and Peeling

Started with 2.006 kg of fresh dudhi.

The dudhi was properly washed and peeled to remove outer skin and any dirt.

Final weight after peeling: 1.868 kg

This cleaned dudhi was used for further processing.

Step 2: Blanching

The 1.868 kg of peeled dudhi was blanched to slightly soften the texture while minimizing water absorption.

Blanching was done for 8 minutes, just until the dudhi became 30–40% soft.

This controlled blanching was important to avoid excess moisture in the grated dudhi, which can affect drying and texture.

Step 3: Grating

The blanched dudhi was grated using a slicer machine, which provided uniform grating and proved to be more efficient compared to manual grating, reducing manpower and time.

After grating, water was removed manually, and seed or fibrous parts were discarded.

Final weight after grating and water removal: 1.344 kg

Step 4: First Drying

The 1.344 kg grated dudhi was spread on trays lightly coated with ghee to prevent sticking.

It was dried in an electric dryer at 55°C for 4 hours.

Final weight after first drying: Approx. 140 g

Loss on Drying (LOD):

Initial grated weight = 1344 g

Final dried weight = 140 g

LOD = (1344 − 140) / 1344 × 100 = 89.58%

Step 5: Milk Addition and Second Drying

600 ml of milk was boiled for 5–6 minutes and then mixed with 2g of elaichi thoroughly with the 140 g of first dried dudhi.

After full absorption of milk into the dudhi mixture, it was spread evenly on tray for drying.

Second drying was carried out at 60°C for 4 hours in the electric dryer.

Final Weight

After the second drying at 60°C for 4 hours, the final weight of the Dudhi Halwa Premix was 200 g.

I also done the Moisture Analysis of this Premix by checking LOD test :-

- Initial Sample Weight: 15 grams

- Final Weight After Drying: 13.41 grams

- Calculated LOD:

The prepared Dudhi Halwa Premix showed a Loss on Drying of 10.6%

Observation:-

- During the cooking trials, it was observed that the Dudhi Halwa Premix did not rehydrate effectively when mixed with hot water.

- Taste and flavour were good.

- Colour after preparation was also appealing and natural.

Fixing the Rehydration Problem in Dudhi Halwa Premix

In my earlier trials, I noticed that when I cooked the premix, the dudhi stayed a bit dry even after adding the right amount of water.

I looked for ways to solve this and found that adding citric acid during blanching could help. Citric acid is safe to use in food and can:

- Keep the green color fresh

- Stop the dudhi from turning brown

- Make the dudhi soak up water better when cooking later

So, I decided to try it in my next batch.

Work Done on next Trial :

Step 1: Washing and Peeling

- Raw lauki weight: 596 g

- After peeling weight: 686 g

Step 2: Grating

- After grating: 580 g

Step 3: Blanching

- Added 1 g citric acid to 1 litre water

- Blanched the grated dudhi for 10 minutes

Step 4: First Drying

- Temperature: 45 °C

- Duration: 4 hours

- Purpose: Reduce moisture while preventing over-drying or browning

Step 5: Milk & Ingredient Addition

- Milk: 100 ml

- Cardamom: 2 g

- Ghee: 8 g

- Purpose: To enhance flavor, aroma, and richness of the premix before the second drying stage.

Step 6: Second Drying

- Temperature: 45 °C

- Duration: 4 hours

- Final Weight of the premix: 31 gm

Observation

I took the recipe trial on this premix with water to premix ratio 1:4 and cooked for 7 minutes with adding sugar the result of better rehydration with 85% cooked that somehow some premix is not well rehydrated. I will take one next trial with some changes in blanching process timing and citric acid addition percentage.

Work Done on next trial by increasing citric acid content & blanching time

Step 1: Washing and Peeling

Raw dudhi weighing 1.2 kg was washed and peeled properly to remove the outer skin.

- Weight after peeling: 1.1 kg

Step 2: Grating

The peeled dudhi was grated directly for further processing.

Step 3: Blanching

The grated dudhi was blanched in 2.5 g citric acid solution prepared with water in 1:1 ratio with dudhi.

- Blanching time: 20 minutes

- Condition after blanching: Dudhi softened enough to be pinched by hand, colour turned slightly yellowish.

Step 4: First Drying

The blanched grated dudhi was spread on trays and dried.

- Drying conditions: 45 °C for 4 hours

- Intermediate dried weight: ~40 g

Step 5: Milk & Ingredient Addition

To the first dried dudhi, the following were added:

- Milk: 350 ml

- Cardamom: 4 g

This mixture was blended well before the second drying step.

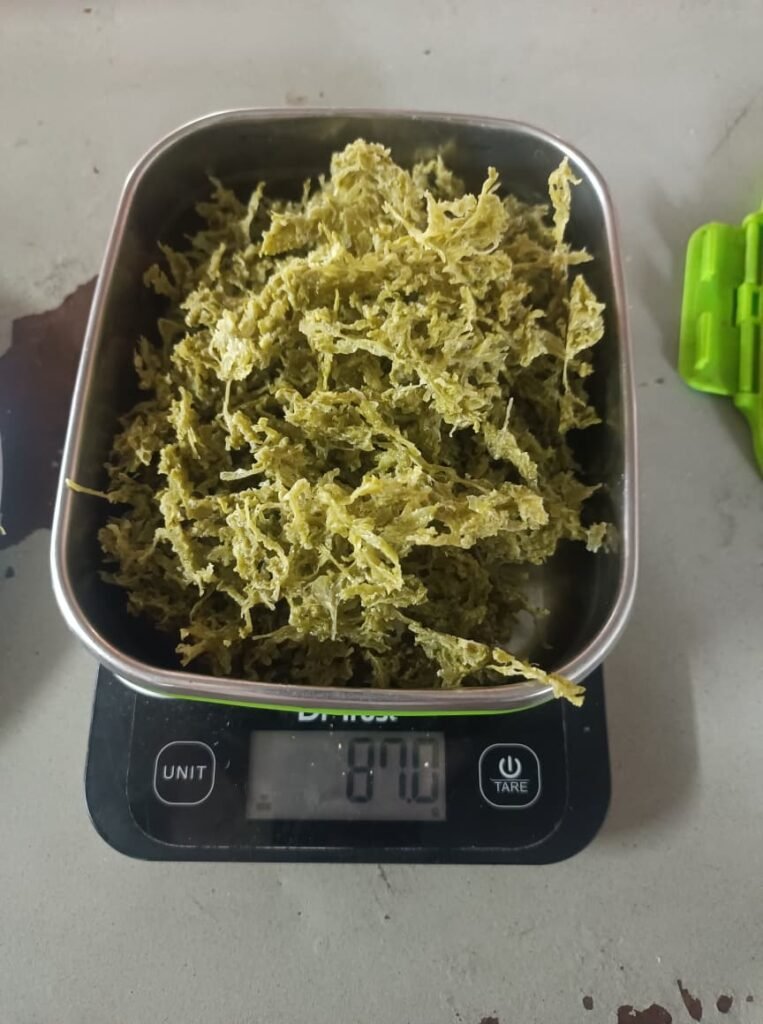

Step 6: Second Drying

The mixture was dried in an electric dryer.

- Drying conditions: 45 °C for 4 hours

- Final premix weight: 87 g

Observation

- The rehydration was still not fully effective, even with increased blanching time and higher citric acid level.

- The final halwa texture was slightly dry and lacked full uniformity.

- Taste was acceptable but improvement is required in rehydration and mouthfeel.

Conclusion

The Dudhi Halwa Premix project was carried out through multiple trials with different processing conditions such as blanching time, citric acid addition, drying temperature. The trials showed that the texture, taste, and flavour of the product were close to homemade dudhi halwa, but the rehydration remained a consistent problem. Even after optimizing blanching with citric acid and adjusting drying parameters, the premix did not fully rehydrate during cooking, resulting in a slightly dry and uneven texture.

Based on these outcomes & discussions, the project is being put on hold until a suitable solution for rehydration is developed. The learnings from this work can be used for future improvements.